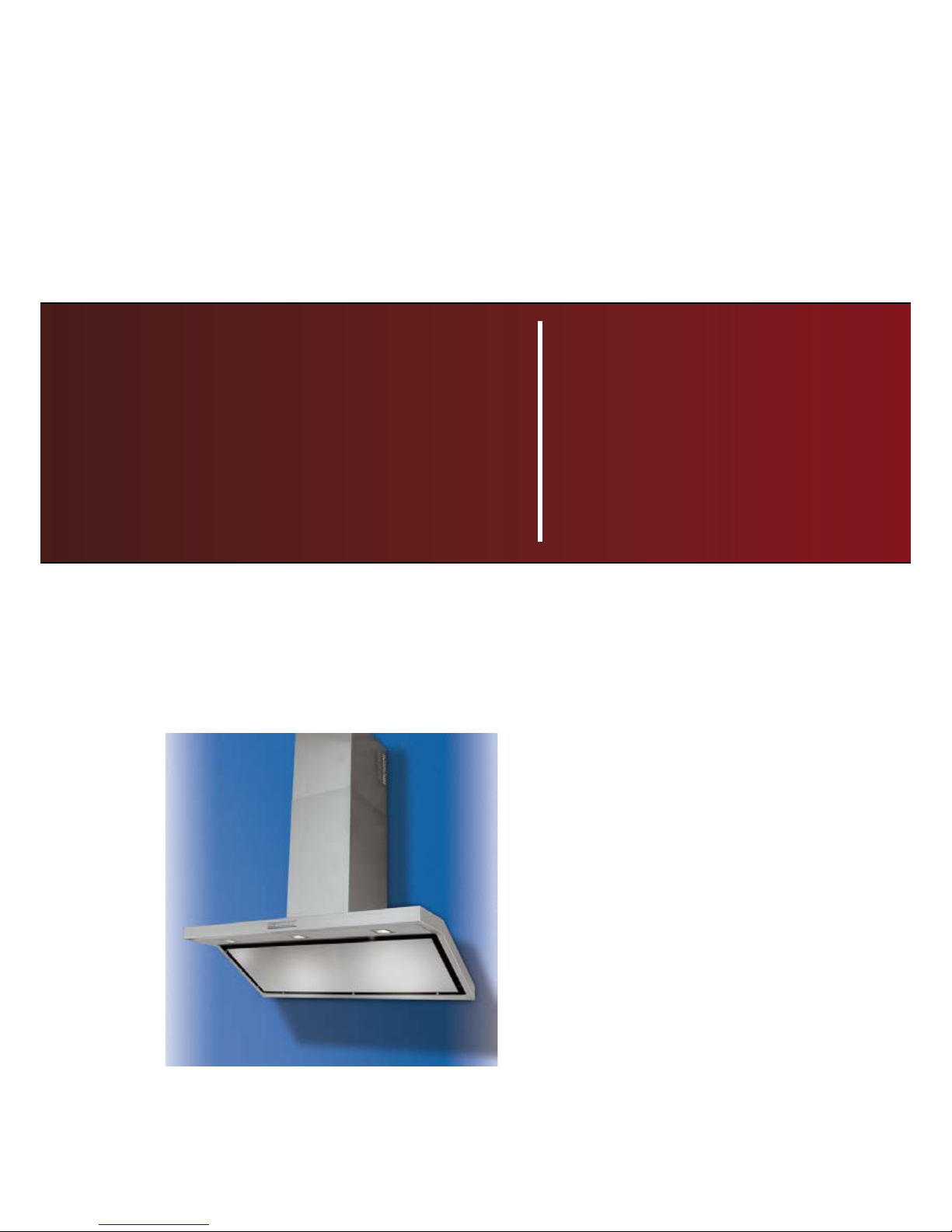

Fixing to the wall: for fixing to the wall refer to the instructions for the ducting version (see points 1, 2, 3), then continue

with the instructions below.

Fixing the telescopic flues: - Adjust the width of the support bracket (D) of the telescopic flue by means of the screws

(E) as shown in Fig. 8. - Then, by means of the screw anchors and screws (F) provided, fix the bracket to the ceiling in

such a way that it is positioned along the axis with your hood. - Mount the flange on the hood in correspondence to the

air outlet point (Fig. 19). - Take the air baffle and fit a flexible pipe to it (125 mm diameter) locking it with a metal hose

clamp (pipe and clamps are not provided). Fit the air baffle to the upper flue (Fig. 20) with 4 screws.

- Connect the flexible pipe to the flange on the air vent (Fig. 21). - Plug in the hood. - Insert the extension flues setting

them on the hood; extend the upper flue to the ceiling and secure with the 2 screws H (Fig. 11).

OPERATION

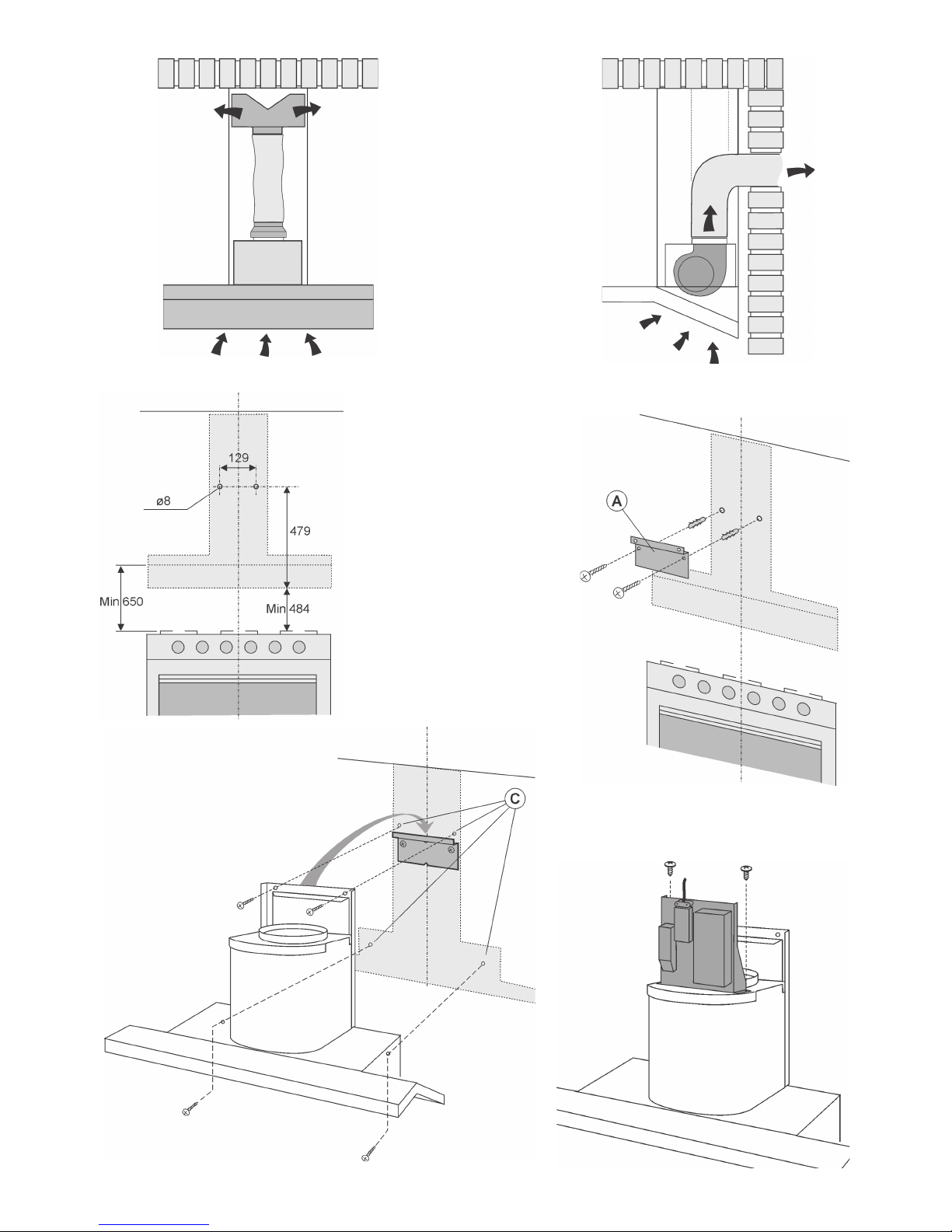

Depending on the model, the unit is equipped with the following controls:

Controls shown in Fig. 22/23:

Key L: light switch. Key A : B = Motor ON/OFF switch - Speed I

Key 2: B = Motor ON/OFF switch - Speed I

Key 3: B = Motor ON/OFF switch - Speed I

Key 4: B = Motor ON/OFF switch - Speed I

Filter alarm: after about 30 hours of operation, with the motor off, the speed keys (keys 1, 2, 3 and 4) flash for 30

seconds to indicate the anti-grease filters need cleaning. After cleaning the anti-grease filters (and/or replacing the

charcoal filters), restart the hour counter (RESET) by pressing key C during filter alarm display.

Timer 5'; the timer can be started (switch-off delayed by 5 minutes) by pressing one of the speed keys for 2 seconds

(key 1, 2, 3 or 4) when the motor is running; the selected speed key starts flashing.

Controls shown in Fig. 24/25:

Button A = turns the lights on/off.

Button B = turns the TIMER on/off: press once to turn the timer on, therefore, after 5 minutes, the motor cuts out (at the

same time the selected speed blinks on the display); the timer remains on if the motor speed is changed.

Display C = - indicates the selected motor speed (from 1 to 4); - indicates Timer On when the number blinks; - indicates

Filter Alarm when the central segments is on or blinking.

Button D = makes the motor work (at the last speed selected); pushing the button again, the speeds of the motor are

sequentially selected from 1 to 4; keeping this button pressed for about 2 seconds shuts down the motor.

Button R = resets the grease filters or charcoal filters; when the filter alarm appears (i.e. when the central segment on

the display goes on), the grease filters must be cleaned (30 hours of operation); when the central segment starts blinking,

the grease filters must be cleaned and the charcoal filters replaced (120 hours of operation). Obviously, if the hood is

not a filtering model and does not have a charcoal filter , clean the grease filters both when the central segment goes

on and when it starts blinking. The filter alarm can be seen when the motor is off and for about 30 seconds. To reset the

hour counter, keep the button pressed for 2 seconds while the alarm can be seen.

Controls shown in Fig. 26:

Button A: light switch.

Button B: first speed motor ON/OFF switch.

Button C: second speed switch.

Button D: third speed switch.

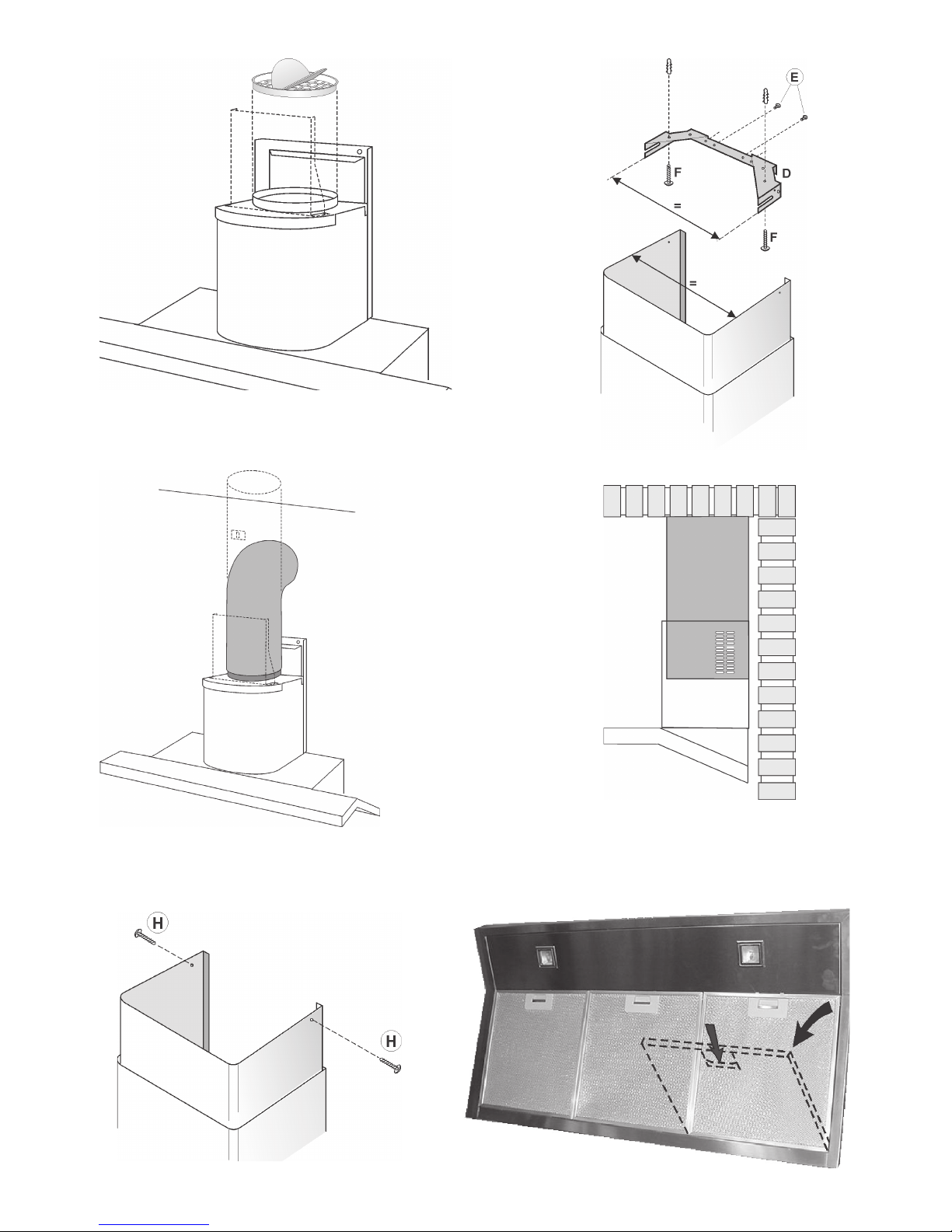

Grease filters: pay special attention to the grease filters, that must be cleaned at regular intervals.

Wash the grease filter/s with neutral detergent.

Filter cleaning frequency:

If the model purchased by you has the controls represented in Fig. 22 and 23 : the grease filters must be cleaned

about every 30 hours of operation (when, with the motor off, the 4 speed keys flash). Once the clean filters have been

remounted, keep one of the 4 keys pressed for 2 seconds (during flashing) to start the hour count again.

If the model purchased by you has the controls represented in Fig. 24 and 25 : the grease filters must be cleaned

about every 30 hours of operation (when, with the motor off, the centre segment comes on or flashes on the display

screen). Once the clean filters have been fitted back on, keep the key R (Reset) pressed for 2 seconds to start the

count again.

If the model purchased by you has the controls represented in Fig. 26: the grease filter/s require particular care and

must periodically be cleaned in relation to use 2 .

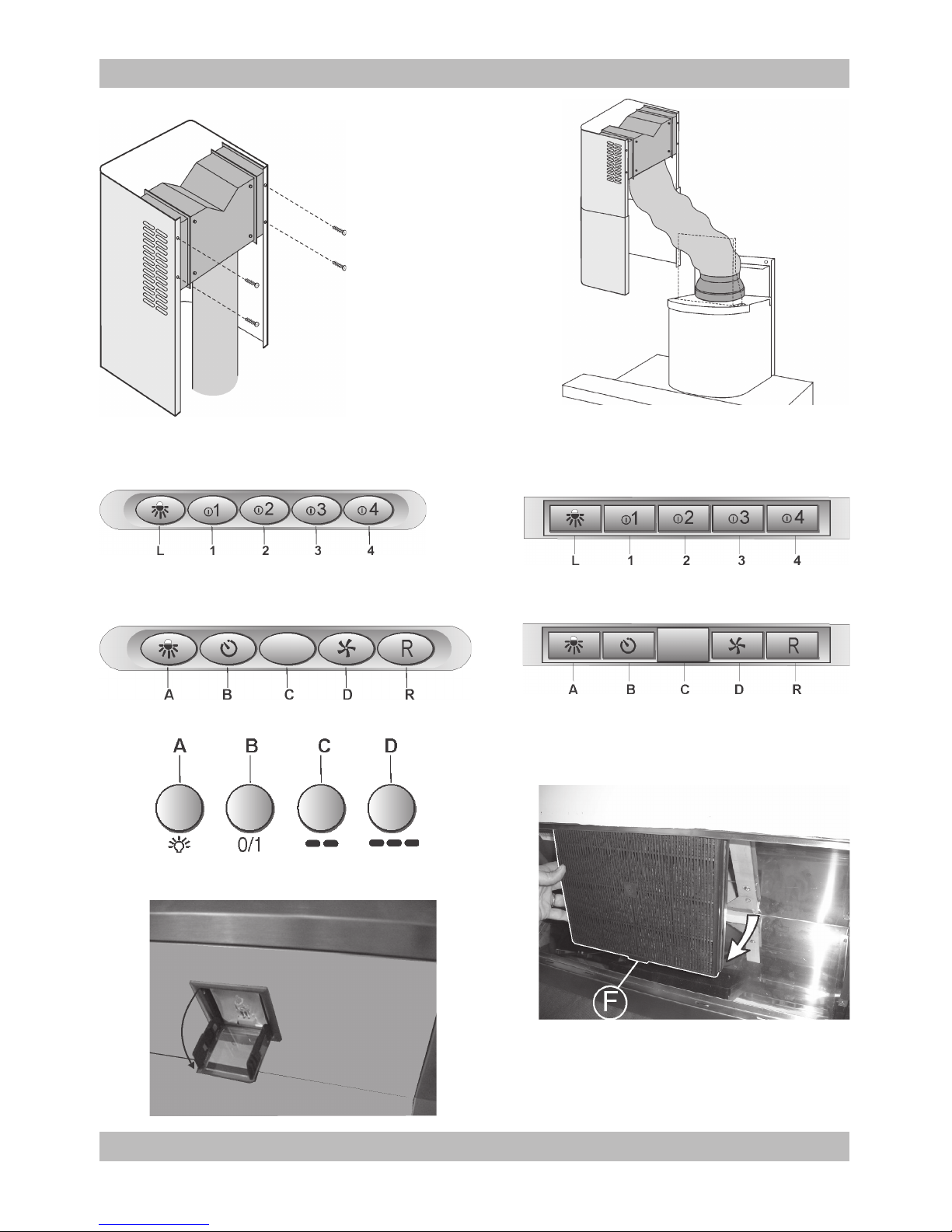

Removing the grease filter/s : refer to Fig.12, Fig.13 or Fig.14 depending on the model purchased.

Fig. 12: Remove the grease filters by pushing the catch towards the rear of the hood and turning the filters outwards.

Fig. 13: grip the knob and push it towards the opposite side of the filter and turn the filter outwards (Fig. turn the filter

outwards.

Fig. 14: Turn the glass panel by gripping it from the front part of the hood. Remove the grease filters by pushing the

catch towards the rear of the hood and turning the filters outwards.

Charcoal filters: If the hood is used in the filtering version, the charcoal filter will periodically have to be

replaced in relation to use.