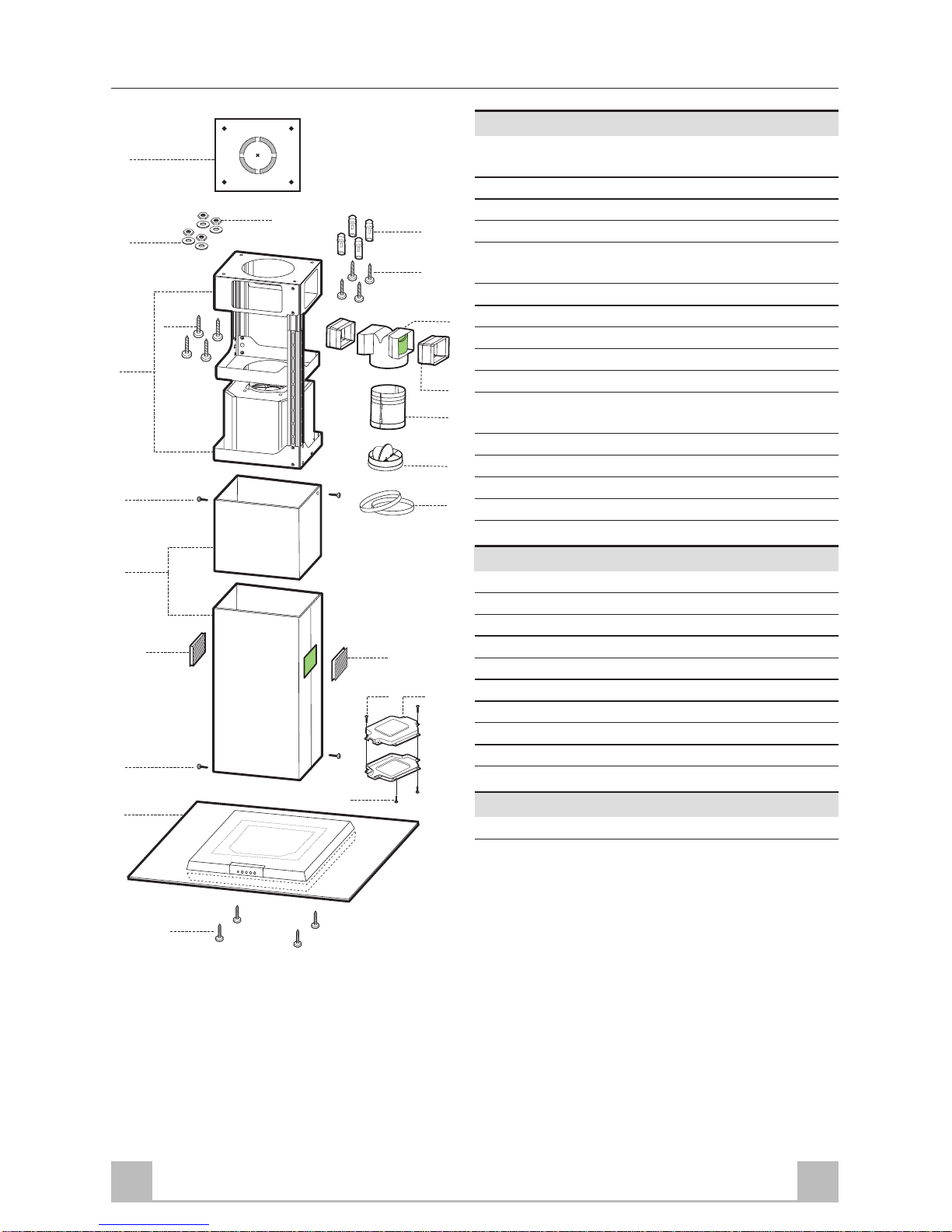

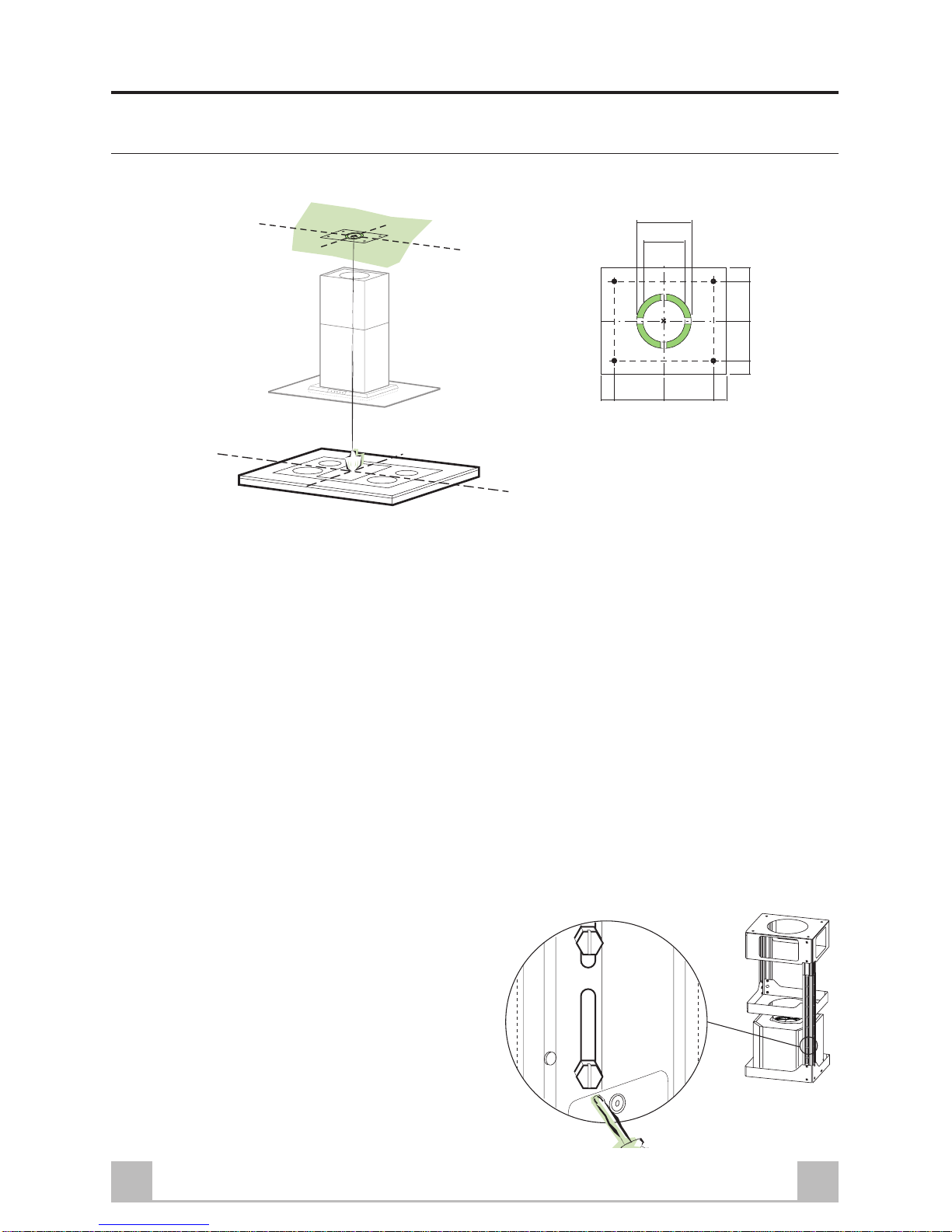

Flue assembly - Mounting the hood body

• Position the upper chimney section and fix the

upper part to the frame using the 2 screws 12c

(2,9 x 6,5) provided.

• Similarly, position the lower chimney section

and fix the lower part to the frame using the 2

screws 12c (2,9 x 6,5) provided.

Recirculation version

• Makesure that the outlet of the extension pieces

14.1 is horizontally and vertically aligned with

the chimney outlets.

• Ifthis is not the case, remove the lower chimney

section and adjust the position by either

reversing the connection extension pieces 14.1

or by cutting the hood body extension 14 along

one of the thinner section channels denoting the

pre-fixed lengths, then reassemble as described

previously.

• Fit the directional grids 8a-8b in their housings

making sure that the directional symbols are

towards the top. Also make sure that they are

correctly inserted in the connection extension

pieces 14.1.

Before fixing the hood body to the frame:

• Remove the grease filters from the hood body.

• Remove any activated charcoal filters.

• From below, use the 4 screws 12f (M6 x 10)

provided to fix the hood body to the frame.

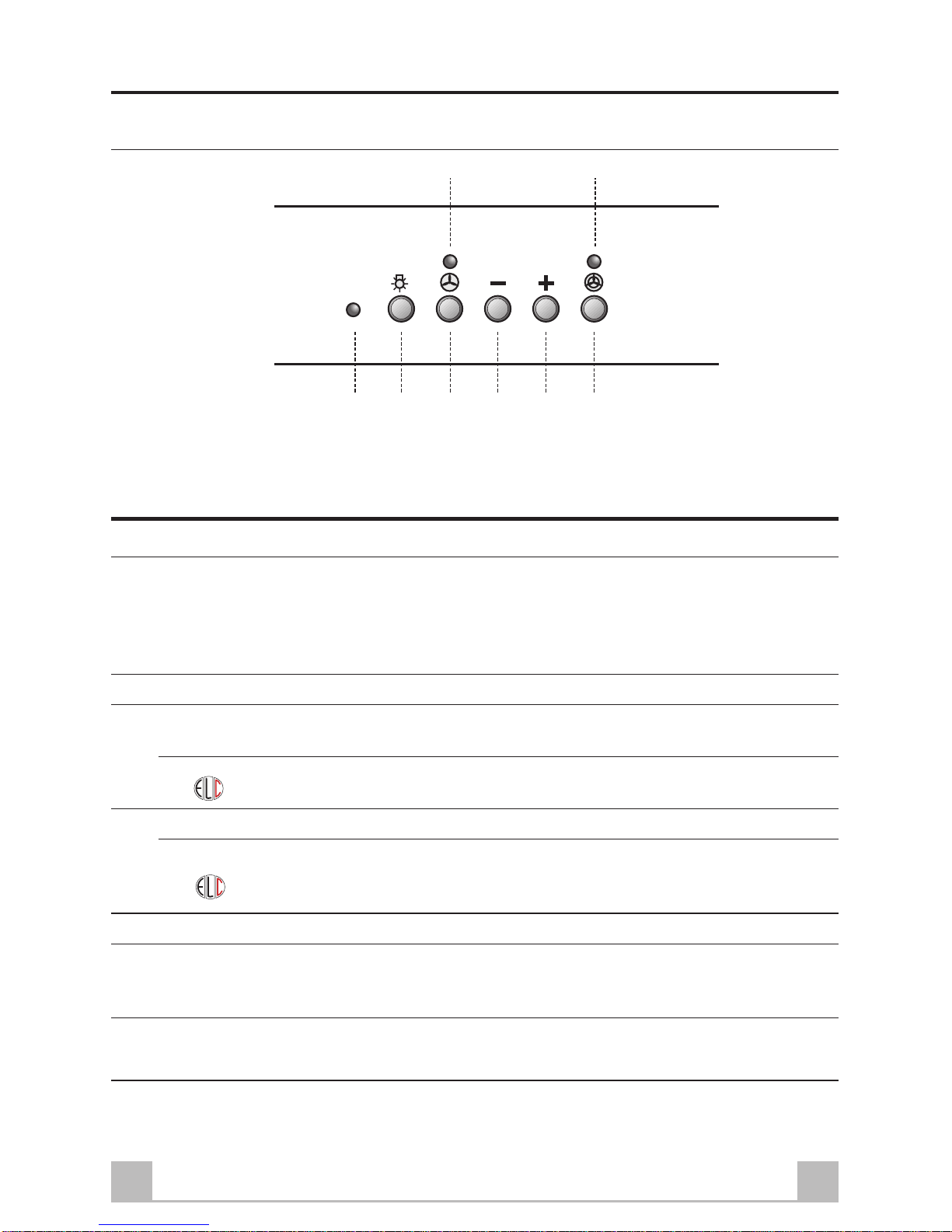

ELECTRICAL CONNECTION

• Connect the hood to the mains through a two-

pole switch having a contact gap of at least 3

mm.

• Connect the control connector Cmd.

• Connect the lights connector Lux.

• Place the connector in the junction box 24 and

close it using the 2 screws 12e (2,9 x 9,5)

provided.

• Fix the junction box to the hood body using the

2 screws 12c (2,9 x 6,5) provided.

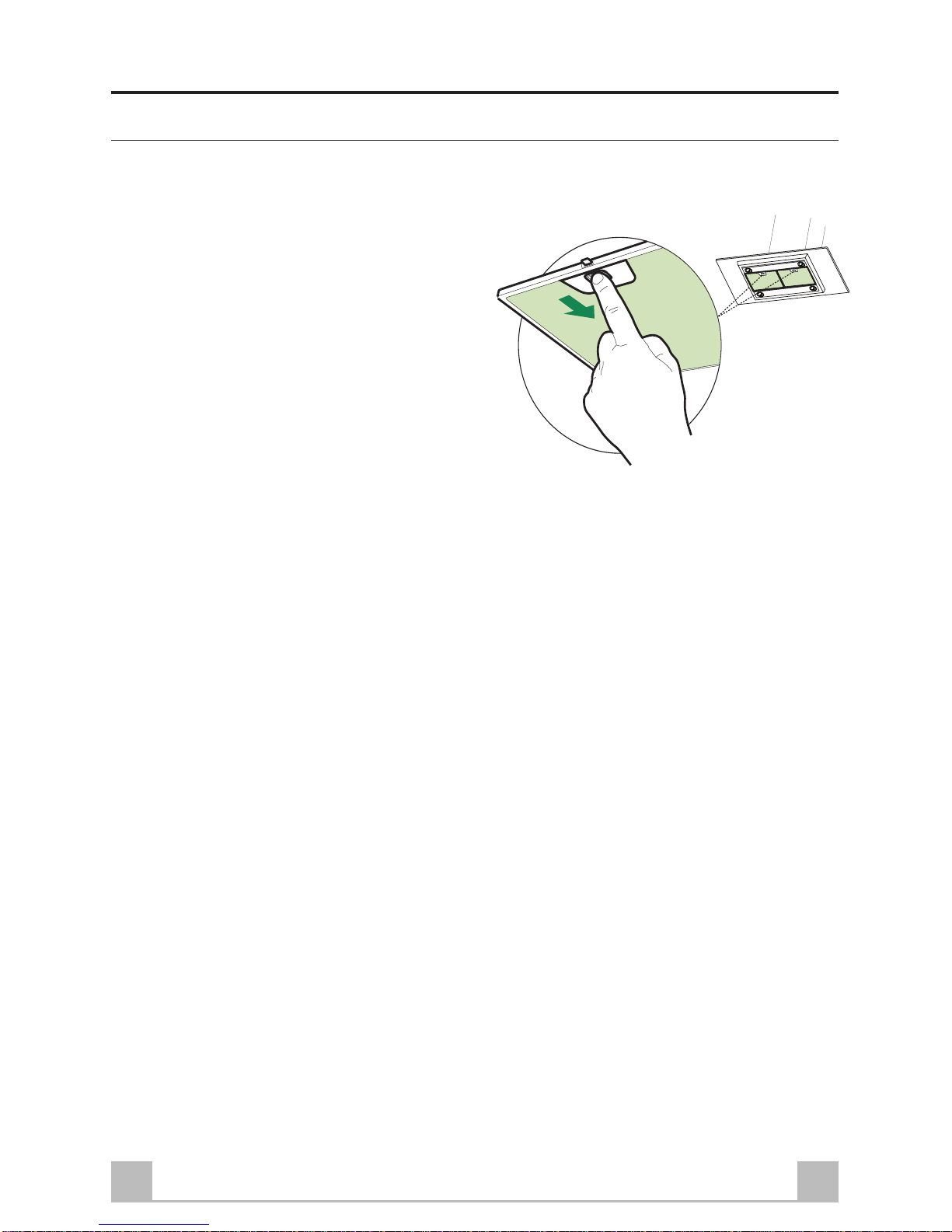

• For the recirculation version, fit the activated

carbon odour filter.

• Replace the grease filters.