EN 3

3

RECOMMENDATIONS AND SUGGESTIONS

The Instructions for Use apply to several versions of this appliance. Accordingly, you may find

descriptionsofindividualfeaturesthatdonotapplytoyourspecificappliance.

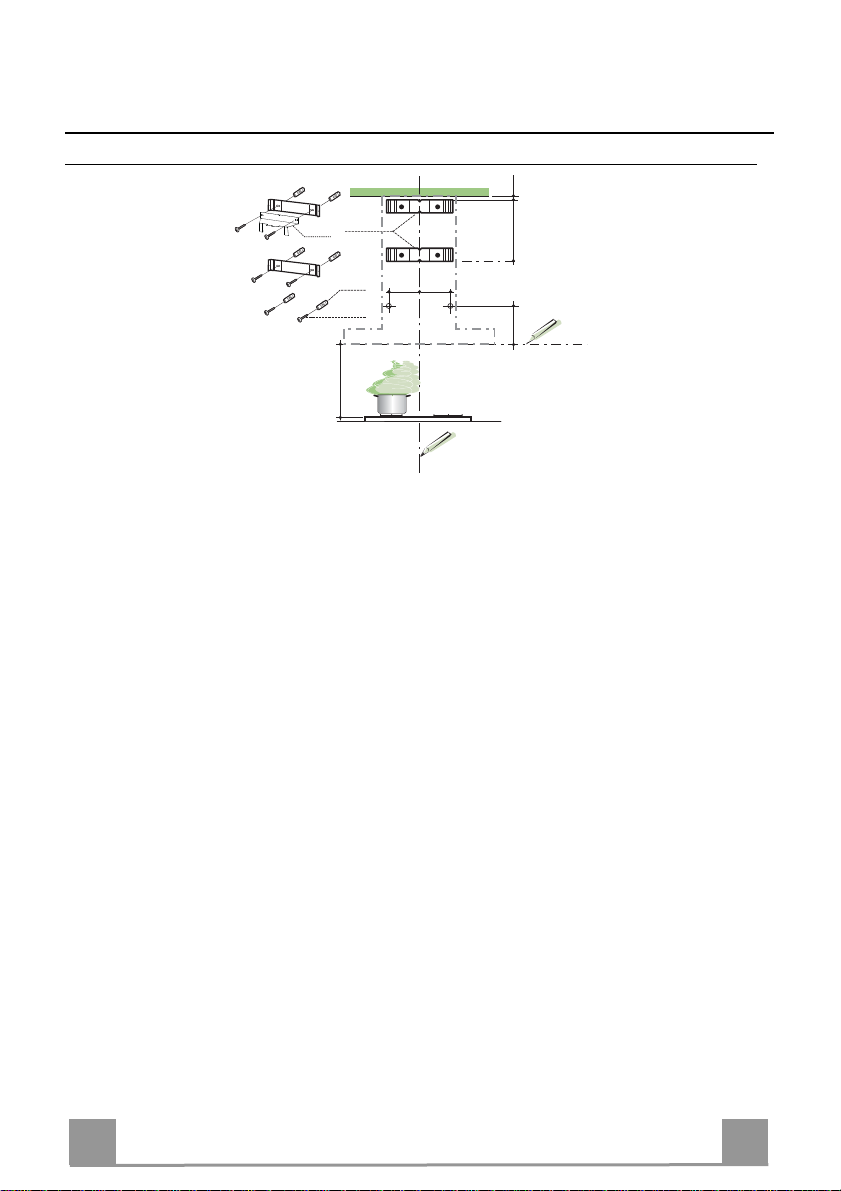

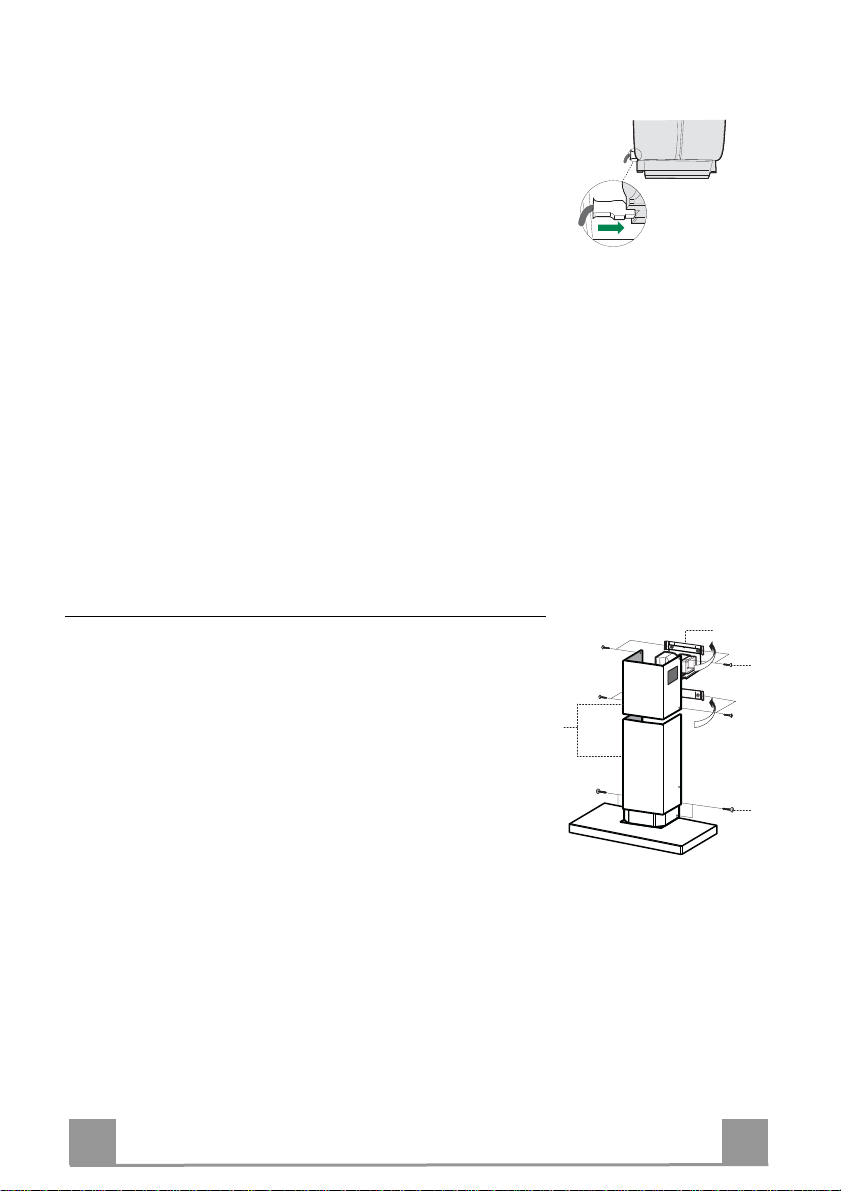

INSTALLATION

• The manufacturer will not be held liable for any damages resulting from incorrect or improper

installation.

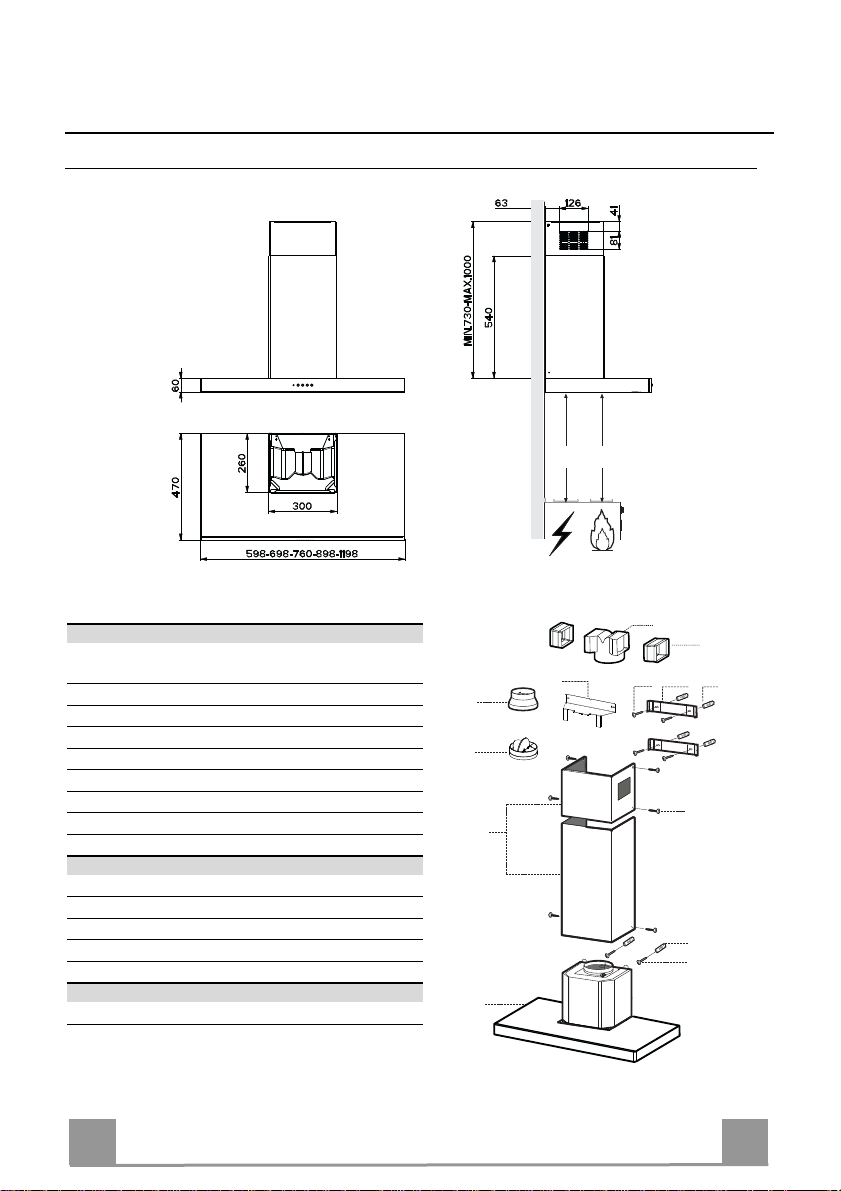

• The minimum safety distance between the cooker top and the extractor hood is 650 mm (some

models can be installed at a lower height, please refer to the paragraphs on working dimensions

andinstallation).

• Checkthatthemains voltage corresponds to that indicatedonthe ratingplate fixed to the insideof

thehood.

• ForClassIappliances,checkthatthedomesticpowersupplyguaranteesadequateearthing.

Connecttheextractortotheexhaust flue througha pipe of minimumdiameter120mm.Theroute

ofthefluemustbeasshortaspossible.

• Donotconnecttheextractorhoodtoexhaustductscarryingcombustionfumes(boilers,fireplaces,

etc.).

• Iftheextractorisusedinconjunctionwithnon-electricalappliances(e.g.gasburningappliances),a

sufficient degree of aeration must be guaranteed in the room in order to prevent the backflow of

exhaust gas. Thekitchen musthave anopening communicating directlywith theopen air inorder

to guarantee the entry of clean air. When the cooker hood is used in conjunction with appliances

supplied with energy other than electric, the negative pressure in the room must not exceed 0,04

mbartopreventfumesbeingdrawnbackintotheroombythecookerhood.

• In the event of damage to the power cable, it must be replaced by the manufacturer or by the

technicalservicedepartment,inorderto preventanyrisks.

• Iftheinstructionsforinstallationforthegashobspecifyagreaterdistance specifiedabove,thishas

tobetakenintoaccount.Regulationsconcerningthedischargeofairhavetobefulfilled.

“WARNING:Failuretoinstallthescrewsorfixing devicein accordancewiththeseinstructionsmay

resultinelectricalhazards.”

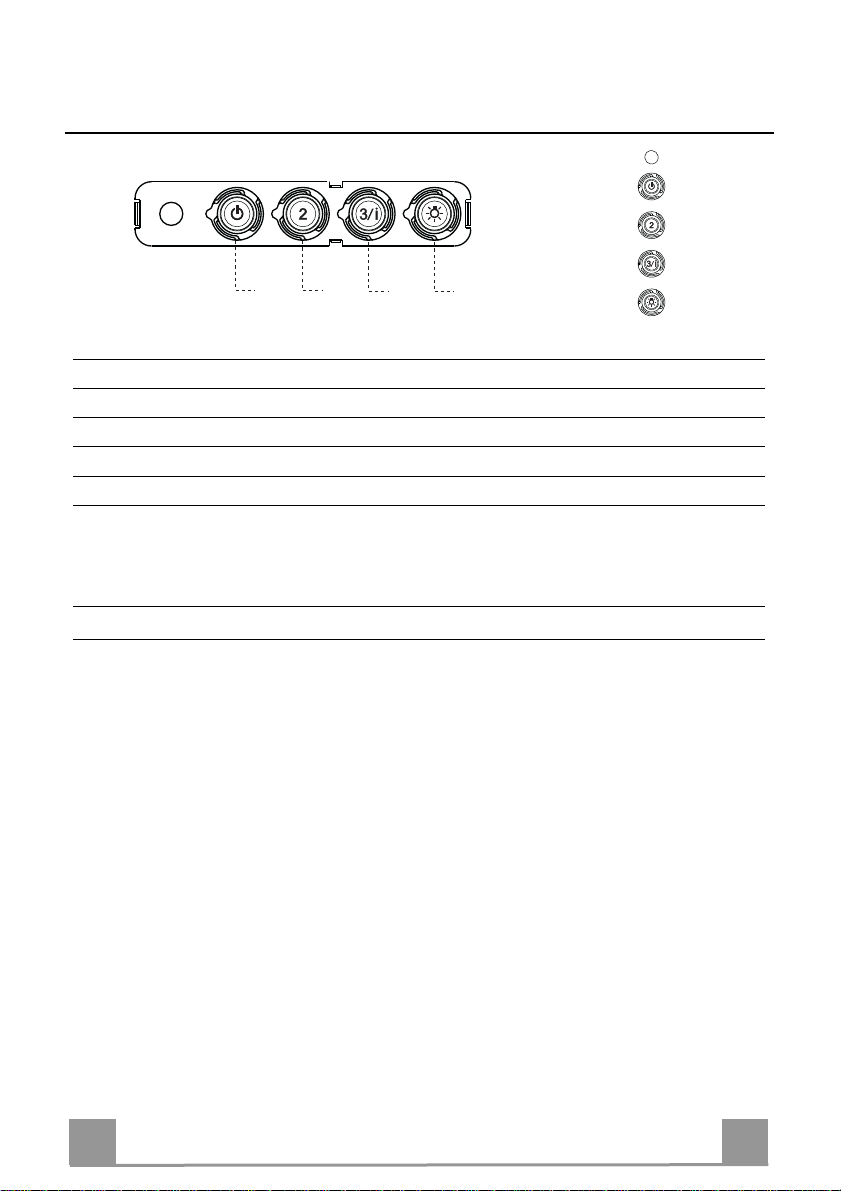

USE

• Theextractorhoodhasbeendesignedexclusivelyfordomesticusetoeliminatekitchensmells.

• Neverusethehoodforpurposesotherthanforwhichithasbeen designed.

• Neverleavehighnakedflamesunderthehoodwhenitisinoperation.

• Adjust the flame intensity to direct it onto the bottom of the pan only, making sure that it does not

engulfthesides.

• Deepfatfryersmustbecontinuouslymonitoredduringuse:overheatedoilcanburstintoflames.

• Donotflambèundertherangehood;riskoffire

• This appliance is not intended for use by persons (including children) with reduced physical, sen-

soryormentalcapabilities, or lackofexperienceand knowledge,unless they havebeengiven su-

pervisionorinstructionconcerninguseofthe appliancebyapersonresponsiblefortheirsafety.

• Childrenshouldbesupervisedtoensurethatthey donotplaywiththeappliance.

• “WARNING:Accessiblepartsmaybecomehotwhenusedwithcookingappliances.”.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance

work.

• Cleanand/orreplacetheFilters afterthespecifiedtimeperiod(Firehazard).

• Cleanthehoodusingadampclothandaneutralliquiddetergent.

Thesymbol on the product or on its packaging indicates that this product may notbe treated as household waste. Instead it

shallbehandedovertotheapplicablecollectionpointfortherecyclingofelectricaland electronicequipment.Byensuring this product

is disposed of correctly, you will helpprevent potentialnegative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more detailed information about recycling of this product,

pleasecontactyourlocalcityoffice,yourhouseholdwastedisposalserviceortheshop whereyoupurchasedtheproduct.