8

Powerlight 612 version1.03

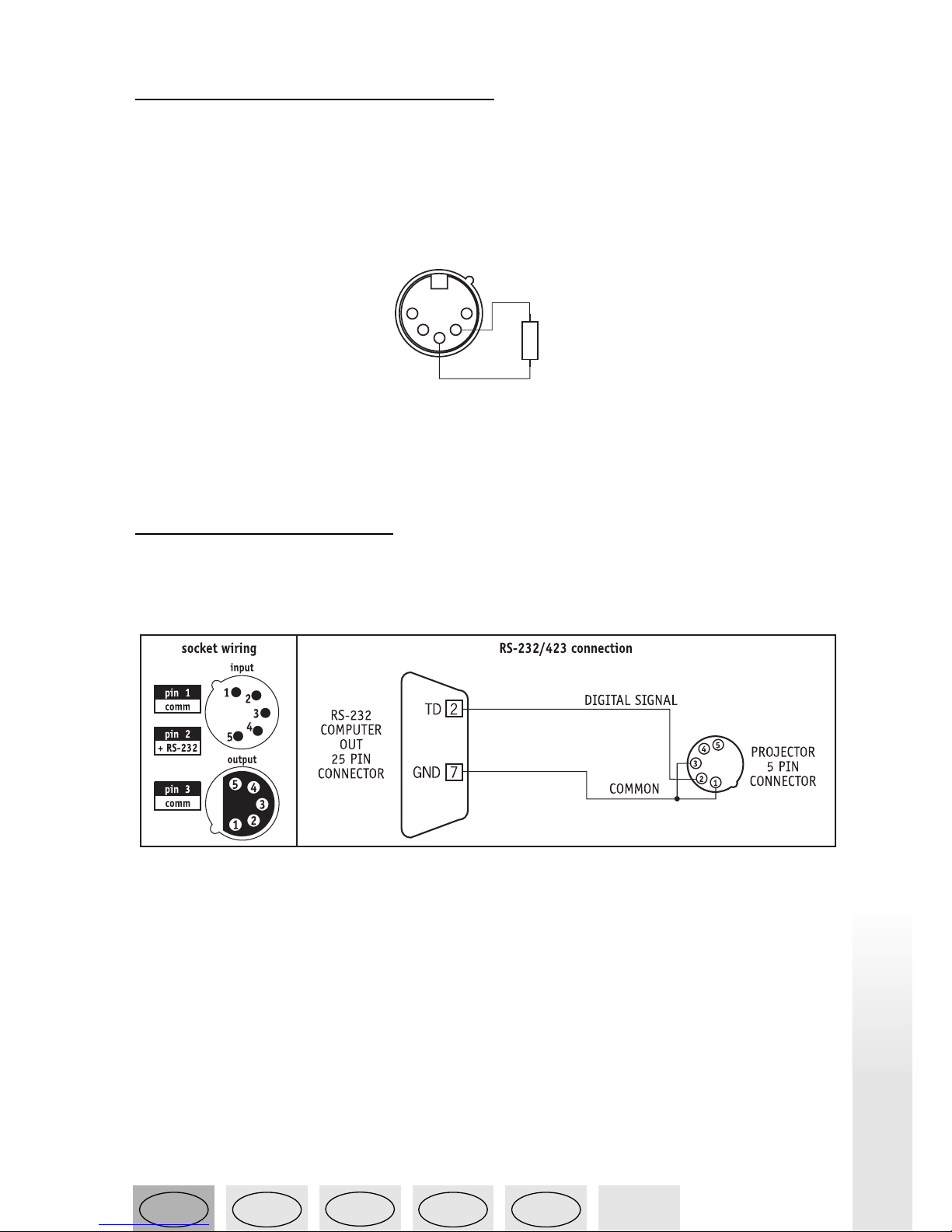

1.3.3 DMX signal cable construction

Power Light P612 has a DMX 512 input that uses standard XLR 5-pin connectors.

When connecting, screened cable in compliance with E A RS-485 specifications and with the

following characteristics must be used:

- 2 conductors plus screen

- 120 Ohm impedance

- low capacity

- maximum transmission rate 250Kbaud.

Connecting the cable:

see diagram, taking care to ensure that the screen is connected to Pin 1

Attention: the cable screen (braid) must NEVER be connected to the s stem's

ground, as this would cause fault unit or controller operation.

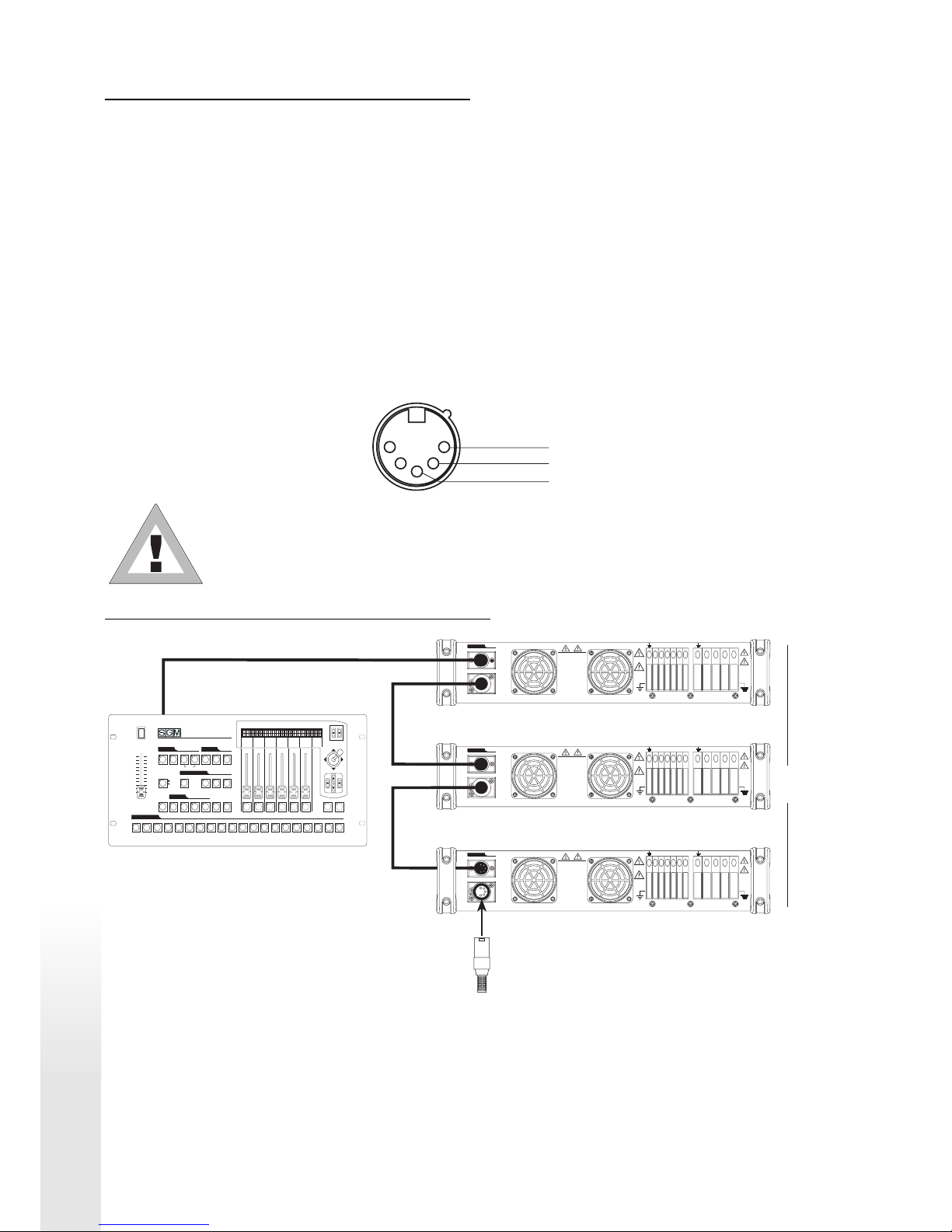

1.3.4 Example of DMX line connection

To avoid the risk of fault operation, follow the following indications:

Maximum cable length: 500m

Maximum N° of units connected: 32

Cable run: Avoid running the cable alongside power lines.

Termination: 120 ohm resistor across Pins 2 and 3 of the last unit.

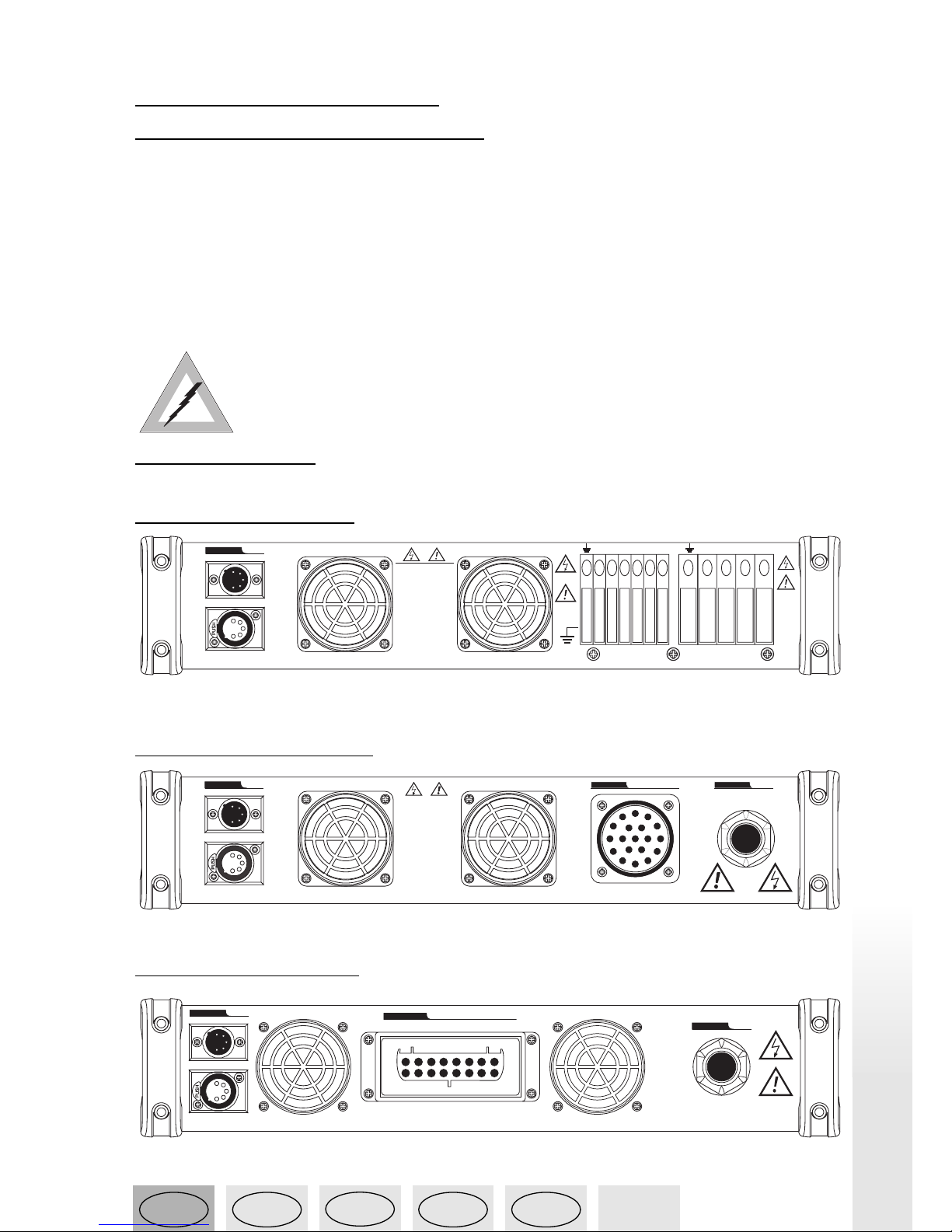

load phase out

inductive or resistive

dmx

inputoutput

see top cover for pin out

Dis onne t from main sour e

before opening.

Do not obstru t air vents.

Non aprire prima di avere

s ollegato lappare hio.

Non ostruire le ventole.

Vor dem öffnen,

den strom Auss halten.

Du müßt die Flügelrad

ni ht verstpften.

Antes de abrir la tapa,

des one tar la maquina.

Non obstruir los rotores.

Avant d'ouvrir, s'assurer que

l'appareil il n'est pas sous tension.

Ne pas obstruir les rotors.

Please see on the top cover for serial number, part number and customer informations. see top cover for pin out & informations

123456 N R S T earth

main in

logic main is R phase + N

load outputs

inductive or resistive

dmx

inputoutput

see top cover for pin out

Dis onne t from main sour e

before opening.

Do not obstru t air vents.

Non aprire prima di avere

s ollegato lappare hio.

Non ostruire le ventole.

Please see on the top cover for serial number, part number and customer informations. see top cover for pin out & informations

RSTN

main input

logic main is T phase + N

21 3 456

load phase out

inductive or resistive

dmx

inputoutput

see top cover for pin out

Dis onne t from main sour e

before opening.

Do not obstru t air vents.

Non aprire prima di avere

s ollegato lappare hio.

Non ostruire le ventole.

Vor dem öffnen,

den strom Auss halten.

Du müßt die Flügelrad

ni ht verstpften.

Antes de abrir la tapa,

des one tar la maquina.

Non obstruir los rotores.

Avant d'ouvrir, s'assurer que

l'appareil il n'est pas sous tension.

Ne pas obstruir les rotors.

Please see on the top cover for serial number, part number and customer informations. see top cover for pin out & informations

123456 N R S T earth

main in

logic main is R phase + N

load outputs

inductive or resistive

dmx

inputoutput

see top cover for pin out

Di s onne t from main sour e

before opening.

Do not obstru t air vents.

Non aprire prima di avere

s ollegato lappare hio.

Non ostruire le ventole.

Please see on the top cover for serial number, part number and customer informations. see top cover for pin out & informations

RSTN

main input

logic main is T phase + N

213456

load phase out

inductive or resistive

dmx

inputoutput

see top cover for pin out

Dis onne t from main sour e

before opening.

Do not obstru t air vents.

Non aprire prima di avere

s ollegato lappare hio.

Non ostruire le ventole.

Vor dem öffnen,

den strom Auss halten.

Du müßt die Flügelrad

ni ht verstpften.

Antes de abrir la tapa,

des one tar la maquina.

Non obstruir los rotores.

Avant d'ouvrir, s'assurer que

l'appareil il n'est pas sous tension.

Ne pas obstruir les rotors.

Please see on the top cover for serial number, part number and customer informations. see top cover for pin out & informations

123456 N R S T earth

main in

logic main is R phase + N

load outputs

inductive or resistive

dmx

inputoutput

see top cover for pin out

Di s onne t from main sour e

before opening.

Do not obstru t air vents.

Non aprire prima di avere

s ollegato lappare hio.

Non ostruire le ventole.

Please see on the top cover for serial number, part number and customer informations. see top cover for pin out & informations

RSTN

main input

logic main is T phase + N

213456

DMX controller

DMX line

DMX Termination

(Last unit)

Max

32

Pilot

1 or 21 2 or 22 3 or 23 4 or 24 5 or 25 6 or 26 7 or 27 8 or 28 9 or 29 10 or 30 11 or 31 12 or 32 13 or 33 14 or 34 15 or 35 16 or 36 17 or 37 18 or 38 19 or 39 20 or 40

program chase psycho preset unit step

page store edit levels times

copy enter play extra lamp reset

smpte

rec

on/off

universal dmx controller

0

10

20

30

40

50

60

70

80

90

100%

2000