Smipack FP6000CS User manual

Use and maintenance manual FP6000CS - FP8000CS

3

USE AND MAINTENANCE MANUAL

Automatic L-Sealer

FP6000CS - FP8000CS

MANUAL CODE:

CREATION DATE:

RELEASE:

RELEASE DATE:

DM210300

28.09.2007

1.0

12.11.2008

4

FOREWORD

In thanking you for the preference given us, SMIPACK S.p.A. is glad to welcome you to its wide

circle of Clients and hopes that the use of this machine completely satisfies you.

This manual can be used for model FP6000CS and FP8000CS was prepared with the aim

to allow you to operate on the various components, explain the various operations for

maintenance and operation.

Where not expressly indicated by the ,instructions refer to all the above mentioned

models..

In order to guarantee a satisfactory level of efficiency, life and performance of the machine, we

urge you to scrupulously observe the instructions contained in this manual.

SMIPACK S.p.A. is absolutely not responsible for any direct or not direct consequence due to

proper or not proper use of this issuing or of the system software and has got right to make

technical modification on his system and on his manual without advising the users.

SMIPACK S.p.A. - Viale Vittorio Veneto, 4 - 24016 San Pellegrino T. (BG) - Italy - Tel.

+39.0345.40400 - Fax +39.0345.40409

PLEASE READ THIS MANUAL CAREFULLY BEFORE INSTALLING THE

MACHINE.

THIS MANUAL IS AN INTEGRAL PART OF THE PRODUCT AND MUST

ALWAYS TAKE WITH THE SAME UP TO ITS DISMANTLING.

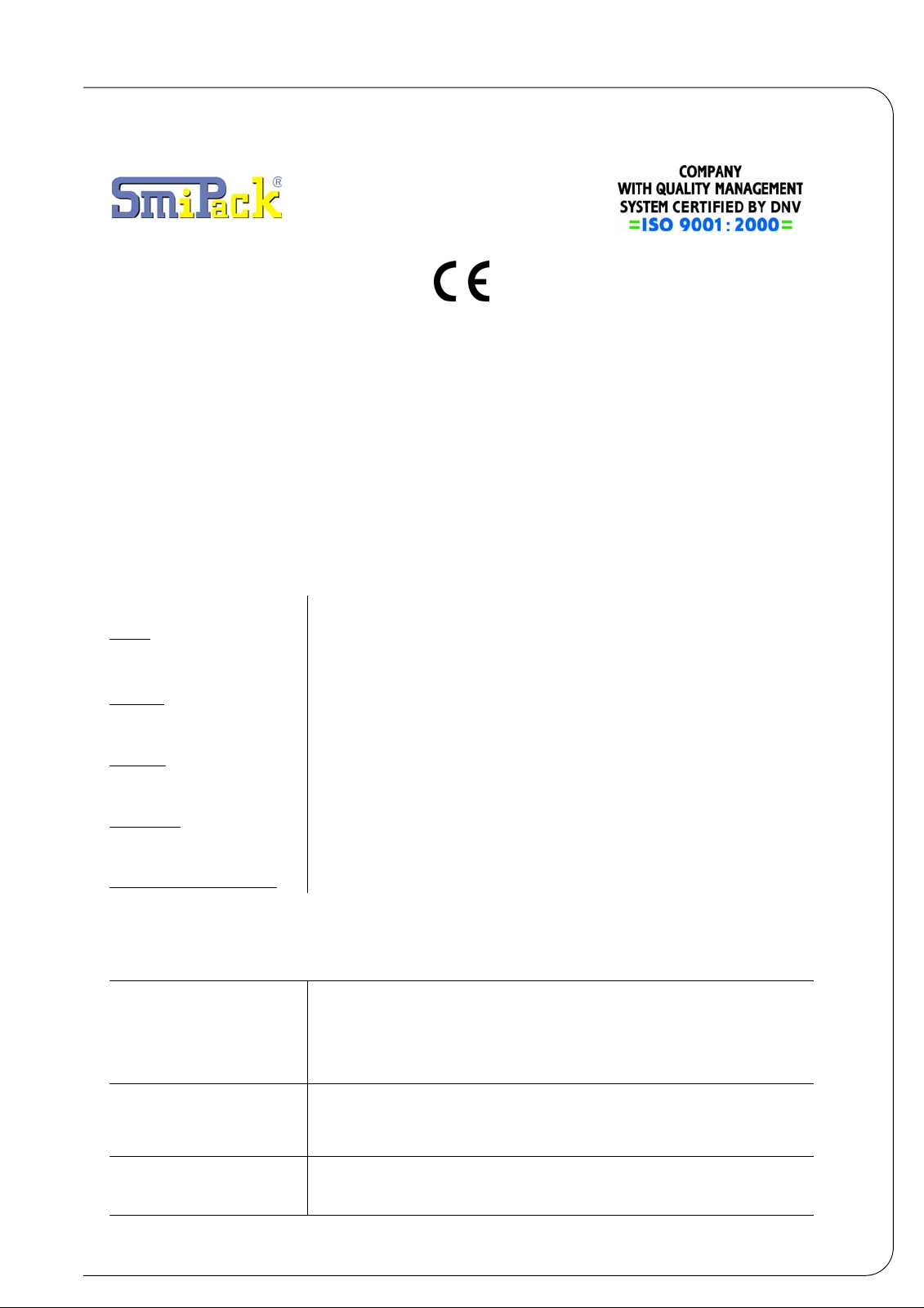

Dichiarazione di conformità CE

EC Declaration of conformity

Il fabbricante SMIPACK S.p.A., con insediamentiproduttivi in Via Tasso, 75 S.Pellegrino Terme

(BG) Italia e uffici amministrativi in Via Piazzalunga, 30 San Giovanni Bianco (BG) Italia.

The company SMIPACK S.p.A., with production site in San Pellegrino Terme (BG) - Italy, Via

Tasso, 75 and head-quarters in San Giovanni Bianco (BG) - Italy, Via Piazzalunga 30

dichiara che la macchina

declares that the machine

è conforme alle direttive comunitarie

complies with EC Directives

tipo: confezionatrice angolare automatica

type: automatic L-Sealer

serie: FP6000CS - FP8000CS

series:

modello:

model:

matricola n.:

serial nr.

anno di costruzione: 2008

year of construction:

98/37/CE

Concernente il riavvicinamento delle legislazioni degli Stati

membri relative alle macchine

On the approximation of the laws of the Member States relating to

machinery

89/336/CEE

92/31/CEE

Compatibilità elettromagnetica

Electromagnetic compatibility

73/23/CEE Bassa tensione

Low voltage

e alle norme armonizzate di buona pratica costruttiva, tra cui:

and with Harmonized Standards:

Il sottoscrittore per l'azienda

The company undersigner

EN 422

Macchine per gomma e materie plastiche - Sicurezza - Macchine per

soffiaggio per la produzione di corpi cavi - Requisiti per la

progettazione e costruzione.

Safety of rubber and plastics machines - Blow moulding machines intend-

ed for the production of hollow articles - Requirements for design and con-

struction

EN ISO 12100-1

Sicurezza del macchinario. Concetti fondamentali, principi generali

di progettazione. Terminologia di base.

Safety of machinery. Basic concepts, general principles for desig Basic

terminology.

EN ISO 12100-2

Sicurezza del macchinario. Concetti fondamentali, principi generali

di progettazione. Specifiche e principi tecnici.

Safety of machinery. Basic concepts, general principles for design. Tech-

nical principles and specifications.

EN 294

Sicurezza del macchinario. Distanze di sicurezza per impedire il

raggiungimento di zone pericolose con gli arti superiori.

Safety of machinery. Safety distances to prevent danger zones from being

reached by the upper limbs.

EN 349

Sicurezza del macchinario. Spazi minimi per evitare lo

schiacciamento del corpo.

Safety of machinery. Minimum gaps to avoid crushing of parts of the hu-

man body.

EN 60204-1

Sicurezza del macchinario. Equipaggiamento elettrico delle

macchine. Parte 1: regole generali.

Safety of machinery. Electrical Equipment of Machines. Part 1: General

rules.

EN 60439-1 Apparecchiature assiemate di protezione e manovra per bassa

tensione (quadri B. T.)

Low voltage switchgear and controlgear assemblies (Low voltage panels)

Nome: Giuseppe

Name:

Cognome: Nava

Surname:

Funzione Legale Rappresentante

Charge: Legal Representative

San Pellegrino Terme, ..........................................................

Data\date Firma\signature

COPY

Use and maintenance manual FP6000CS - FP8000CS

7

EC Declaration of conformity ..........................................................................................................................................5

1. REGULATIONS AND GENERAL INSTRUCTIONS ....................................9

1.1. HOW TO CONSULT AND USE THIS MANUAL .................................................................................................9

1.2. WARRANTY CONDITIONS ................................................................................................................................9

1.3. LEGAL REFERENCES .......................................................................................................................................9

1.4. REMARKS ON GENERAL SAFETY .................................................................................................................10

1.5. LEGEND ...........................................................................................................................................................11

2. MACHINE INSTALLATION ........................................................................13

2.1. DESCRIPTION OF THE MACHINE ...............................................................................................................13

2.2. SAFETY SYSTEM ........................................................................................................................................13

2.3. CONTROL SYSTEMS .......................................................................................................................14

2.4. WEIGHT AND DIMENSIONS OF THE PACKED MACHINE ...........................................................................16

2.5. WEIGHT AND DIMENSIONS OF THE MACHINE .........................................................................................16

2.6. TRANSPORT AND UNPACKING .....................................................................................................................17

2.7. POSITIONING AND LEVELLING .....................................................................................................................17

2.8. FP6000CS AND FP8000CS L-SEALER AND T450 TUNNEL POSITIONING .................................................18

2.9. ASSEMBLING THE ACCUMULATION PHOTOELECTRIC CELLS (OPTIONAL) ...........................................18

2.10. DEMOLITION AND DISPOSAL ........................................................................................................................18

2.11. ELECTRICAL CONNECTIONS ........................................................................................................................18

2.12. TECHNICAL DATA FOR THE ELECTRIC CONNECTION ..............................................................................19

2.13. CONDITIONS OF USE .....................................................................................................................................19

3. INFORMATION ON THE MACHINE ..........................................................21

3.1. OPERATING FEATURES OF THE MACHINE .................................................................................................21

3.2. MACHINE IDENTIFICATION ............................................................................................................................21

3.3. TECHNICAL SPECIFICATIONS OF THE PRODUCT ...........................................................................21

3.4. DATA FOR THE PNEUMATIC INSTALLATION ...............................................................................................22

3.5. DETERMINING THE REEL'S EXACT WIDTH .................................................................................................22

3.6. FILM REEL’S MAX. SIZE LIMITS ...................................................................................................................22

4. PREPARATION TO THE USE OF THE MACHINE ...................................23

4.1. ADJUSTING THE BELT TO THE PRODUCT'S WIDTH ...................................................................................23

4.2. ADJUSTING THE PACKAGE HEIGHT ............................................................................................................23

4.3. POSITIONING OF THE FILM REEL .................................................................................................................24

4.4. ADJUSTING THE FILM WINDING ROLLER'S HEIGHT .................................................................................25

4.5. ARRANGING THE FILM COURSE ..................................................................................................................25

4.6. ADJUSTING THE MICROPERFORATORS .....................................................................................................26

4.7. ADJUSTING THE FILM SEPARATING RODS ................................................................................................26

4.8. FILM POSITIONING ........................................................................................................................................26

4.9. FIRST FILM SEALING ......................................................................................................................................27

4.10. SCRAP FILM GUIDE DEVICE .......................................................................................................................27

4.11. SCRAP FILM WINDER .................................................................................................................................28

4.12. REGULATION FOR THE PACKAGING OF LOW PACKS ...............................................................................29

5. ELECTRONIC BOARD ..............................................................................31

5.1. ELECTRONIC BOARD KEYS DESCRIPTION .......................................................................................31

5.2. STARTING UP THE MACHINE .....................................................................................................................32

5.3. MANUAL OPERATION MODE .........................................................................................................................33

5.4. AUTOMATIC OPERATING MODE ...................................................................................................................34

5.5. FORMAT PARAMETERS .................................................................................................................................35

5.6. OPERATOR MENU ..........................................................................................................................................42

5.7. DATA DISPLAY ................................................................................................................................................43

5.8. SYSTEM SETUP ..............................................................................................................................................46

5.9. UTILITY .............................................................................................................................................................47

5.10. SYSTEM PARAMETERS ..................................................................................................................................49

5.11. PARTICULAR COMBINATION OF THE KEYS ................................................................................................51

5.12. EMERGENCY PUSH-BUTTON ........................................................................................................................51

5.13. MACHINE STATES ...........................................................................................................................................52

6. MACHINE USE ...........................................................................................55

6.1. INTENTED USE ................................................................................................................................................55

6.2. OPERATING PRINCIPLES ...............................................................................................................................55

SUMMARY

8

6.3. SETUP ..............................................................................................................................................................55

6.4. CHECKING FOR GOOD OPERATING CONDITIONS .....................................................................................56

6.5. DANGEROUS AREAS ......................................................................................................................................56

6.6. FORMAT CHANGE INSTRUCTIONS ...............................................................................................................56

7. MAINTENANCE AND REPAIRS ................................................................57

7.1. TYPE OF CHECKING FREQUENCY AND MAINTENANCE OPERATIONS ..........................57

7.2. REPLACING THE SEALING BLADE ................................................................................................................59

7.3. REPLACING THE BRAKE SHOES ..................................................................................................................60

7.4. ADJUSTMENT OF THE SEALING ROD PLANARITY ..................................................................................60

7.5. ADJUSTING THE SEALING BAR’S SENSORS ...............................................................................................61

7.6. CORRECT BELTS TENSIONING .....................................................................................................................61

7.7. LIST OF SPARE PARTS ..................................................................................................................................61

1. UNIT MY440003 - MY440005 .......................................................................................................................62

2. UNIT MH440029 ...........................................................................................................................................63

3. UNIT MH440024 ...........................................................................................................................................64

4. UNIT MH440030 ...........................................................................................................................................65

5. UNIT MY320011 - MY320009 .......................................................................................................................66

6. UNIT MH320010 - MH320022 ......................................................................................................................67

7. UNIT MH320014 - MH320021 ......................................................................................................................68

8. UNIT MY340043 - MY340067 .......................................................................................................................69

9. UNIT MY340063 (FP6000CS) ......................................................................................................................70

10. UNIT MY340049 (FP8000CS) ....................................................................................................................71

11. UNIT MH340068 (FP6000CS) ....................................................................................................................72

12. UNIT MH340041 (FP8000CS) ....................................................................................................................73

12a UNIT MH340042 (FP8000CS) ...................................................................................................................73

13. UNIT MY370029 - MY370025 .....................................................................................................................74

14. UNIT MH370012 - MH370008 ....................................................................................................................75

15. UNIT MY380011 - MY380008 .....................................................................................................................76

16. UNIT MH380043 - MH380042 ....................................................................................................................77

17. UNIT MH380009 - MH380034 ....................................................................................................................78

18. UNIT MH200007 .........................................................................................................................................79

19. UNIT MH430005 .........................................................................................................................................80

20. UNIT MH310008 - MH310002 ....................................................................................................................81

21. UNIT MH340000 (FP6000CS) ....................................................................................................................82

UNIT. UNIT MH340075 (FP8000CS OPTIONAL) ...........................................................................................82

22. UNIT MH400006 FP6000CS - FP8000CS ..................................................................................................83

23. UNIT TIMING UNIT - FIXED BELT .............................................................................................................84

24. UNIT TIMING UNIT - MOBILE BELT .........................................................................................................85

25. UNIT MH400016 - MH400045 ....................................................................................................................86

26. UNIT MH350009 .........................................................................................................................................87

7.8. OPTIONAL ......................................................................................................................................................102

7.9. WEAR AND TEAR MECHANICAL PARTS ...................................................................................................102

8. ANOMALIES AND FAILURES – HOW TO REMEDY ..............................103

8.1. PROBLEMS AND SOLUTIONS ......................................................................................................................103

8.2. ERROR DISPLAY ...........................................................................................................................................105

INDEX ...............................................................................................................111

Use and maintenance manual FP6000CS - FP8000CS

9

1.1 HOW TO CONSULT AND USE THIS MANUAL

Keeping of this manual

• This manual costitutes integral part of the machine andthus must be kept for as long as the

machine is in the user’s possession or, if that be the case, handed over to any other user

or subsequent owner.

• Use this manual in a way that will not damage all or part of its contents.

• Do not remove, tear or rewrite parts of this manual for any reason.

• Ensure that any amendment to this manual sent to you is incorporated in the manual itself.

Consultation of the manual

The consultation of this manual is made easy be the insertion,in the first pages, of a summary,

which allows those consulting it to immediately locate the topic required and, in the last pages,

of an analytical index. The chapters are ordered following such a structure to facilitate the

research of the required information.

Method of updating the manual in case of modifications to the machine

The descriptions and drawings contained in the present manual are intended as non refutative.

SMIPACK S.p.A. reserves the right at any moment to apport modifications to its machines

(while keeping their essential characteristics), for the purpose of improving their functionality

and commercial and aestethic value, with no obligation to update manuals and previous

production except in exceptional cases.

Any updating or integration of the manual are to be considered as integral parts of the manual.

We would like to thank you in advance for all the suggestions that you may want to forward to

us in order to bring about further improvements to the machine.

SMIPACK S.p.A. - Viale Vittorio Veneto, 4 - 24016 San Pellegrino T. (BG) - Italy - Tel.

+39.0345.40400 - Fax +39.0345.40409

1.2 WARRANTY CONDITIONS

The machine is sent to the Client ready to be installed, and having passed, at our factory, all

expected tests and trials, in compliance with the current regulations. Within the guarantee

period SMIPACK S.p.A. undertakes to remove any eventual flaws and defects, onthe condition

that the machine has been correctly used, and that the indications found in its manuals have

been respected. The warranty has a validity of 365 days from the date of purchase and covers

all the materials and manufacturing defects found by the builder. The warranty is valid only for

the original buyer and subject to the condition that the warranty certificate is duly filled in all its

sections and posted within 20 days from the date of purchase. The warranty is no longer valid

if the machine has been damaged through accident, misuse, breakdowns due to atmospheric

agents, maintenance operations or modifications carried out by unauthorised personnel or not

belonging to the servicing department of SMIPACK S.p.A. Consumption materials, parts

subject to normal wear and tear, transport from the user to the servicing centre or vice-versa

as well as labour are excluded from the warranty and therefore are to be paid by the Buyer.

1.3 LEGAL REFERENCES

The machine "Automatic L-Sealer" complies to the Legislative Provisions of the law that

regulates the following Directives:

European Directives on machinery and/or assemblies

• 98/37/CE - On the approximation of the laws of the Member States relating to machinery.

• 73/23/EEC and 93/68/EEC - Low voltage directive.

• 89/336/EEC and 92/31/EEC - Electromagnetic compatibility.

Technical standards applied on machinery and assemblies

CHAPTER 1 - REGULATIONS AND GENERAL INSTRUCTIONS

Chapter 1 - Regulations and general instructions

10

• EN 422 - Safety of rubber and plastics machines - Blow moulding machines intended for

the production of hollow articles - Requirements for design and construction.

• EN ISO 12100-1 - Safety of machinery - basic concepts, general principles for design:

terminology and methods.

• EN ISO 12100-2 - Safety of machinery - basic concepts, general principles for design:

technical principles and specifications.

• EN 294 - Safety of machinery - Safety distances to prevent danger zones from being

reached by the upper limbs.

• EN 60204-1 - Electrical Equipment of Machines.

• EN 418 - Emergency stop.

• EN 349 - Safety of machinery - Minimum gaps toavoid crushing of parts of thehuman body.

• EN 1050 - Safety of machinery - Risk assessment.

• EN 811 - Safety of machinery - Safety distances to prevent danger zones from being

reached by the lower limbs.

• EN 894 -1 - Safety of machinery - Ergonomic requirements for the design of displays and

control actuators - part 1: human interaction with displays and control actuators.

• EN 894-2 - Safety of machinery - Ergonomic requirements for the design of displays and

control actuators - part 2: displays.

• EN 894-3 - Safety of machinery - Ergonomic requirements for the design of displays and

control actuators - part 3: control actuators.

• EN 953 - Safety of machinery - General requirements for the design and construction of

fixed and movable guards.

• EN 50099-1 - Safety of machinery - Signalling and marking principles - part 1: visual,

audible and tactile signals.

1.4 REMARKS ON GENERAL SAFETY

The operator, before starting to work withthis machine, must have acquired enough knowledge

on the location, function of the controls, characteristics of the machine, and must have read

this manual in all its entirety..

The employer must see to it that its personnel is informed on the following topics relative to the

safe usage of the machine:

• Accidents risks.

• Devices meant for the safety of the operator.

• General accidents prevention rules as provided by international directives and by the laws

of the country of destination of the machines.

It is necessary to comply to the following general precautions:

• Do not install the machine in areas posing a risk of explosion or fire.

• Do not temper with, remove or modify the safety devices; in such cases SMIPACK S.p.A.

declines any responsibility on the safety of its machines.

• Do not modify parts of the machine to install other devices without prior authorization by

SMIPACK S.p.A.; in case of unauthorized modifications the former will not be held

responsible for any possible consequences.

• Do not operate the machine in automatic mode with the fixed or mobile protections

removed.

• Do not open the fuse blocks with the mains on.

• Do not intervene on switches, valves and sensors without authorization.

• Do not intervene on the moving parts even without the aid of objects or tools.

• Do not manually oil or grease any moving part.

Use and maintenance manual FP6000CS - FP8000CS

11

• Before carrying out any work on the electrical installation, ensure that the voltage has been

disconnected.

• After an adjustment or security operation, restore the state of the machine with active

protections.

ATTENTION!

The operator, the maintenance and cleaning personnel must scrupulously adhere to both the

regulations for the prevention of accidents and the safety regulations of the Country of

destination of the machine and the plant, besides the instructions, warnings and general rules

concerning the safety included in this manual.

During maintenance or repair work on the machine, the latter has to be shut down, and the special

signals (MACHINE OFF FOR MAINTENANCE, DO NOT START,etc...) have to be used. Make sure

that the switches are not re-inserted by unauthorized personne

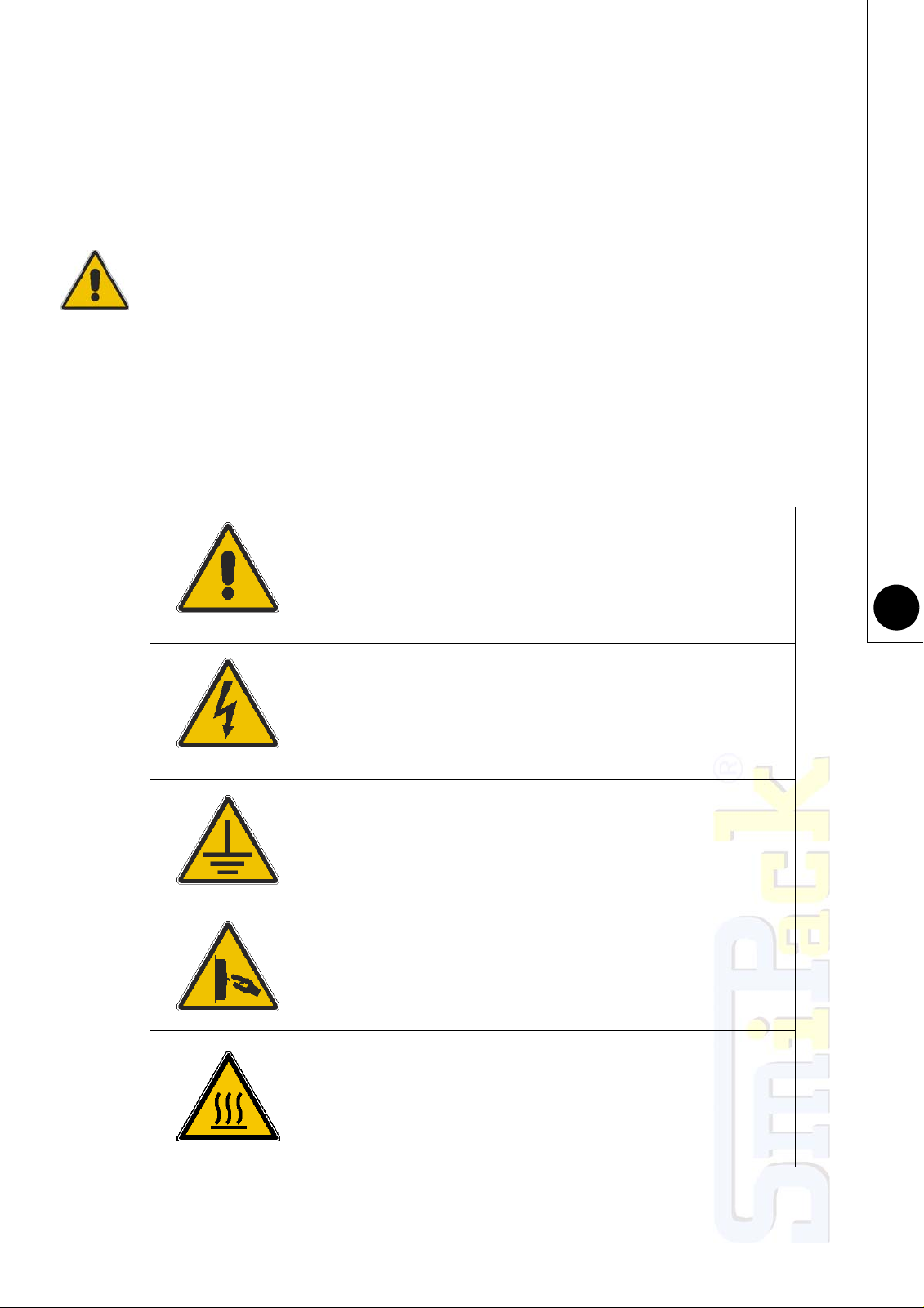

1.5 LEGEND

All instructions and notes contained in this manual are graphically represented in the following

way:

ATTENTION: READ CAREFULLY BEFORE OPERATING.

DANGER OF ELECTROCUTION: HIGH VOLTAGE ZONE.

DANGER OF ELECTROCUTION: EARTHING IS

COMPULSORY.

DANGER OF ELECTROCUTION: EARTHING IS

COMPULSORY.

DANGER OF BURNING DUE TO HIGH TEMPERATURE

SURFACES.

Chapter 1 - Regulations and general instructions

12

WARNING! DON’T TOUCH.

DANGER OF TRAPPING BETWEEN MECHANICAL

MEMBERS.

DANGER OF SHEARING.

DANGER OF INJURY

WARNING! BEFORE OPERATING, CHECK THAT THE

MACHINE TYPE IS THE ONE THAT HAS BEEN BOUGHT.

Use and maintenance manual FP6000CS - FP8000CS

13

2.1 DESCRIPTION OF THE MACHINE

2.2 SAFETY SYSTEM

CHAPTER 2 - MACHINE INSTALLATION

Fig. 2.1.1

GLOSSARY

1Infeed conveyor belt

2Reel-holder

3Electronic card

4Upper square

5Lower square

6Product guide

7Connecting belt

8Sealing unit

9Film drive unit

10 Scrap winder

11 Belt turnbuckles

12 Electric panel

13 Lifting group

POS. DESCRIPTION

1Plexiglas and sheet movable

protections.

2Fixed protections made of

plexiglas and sheet that

require special equipment to

be removed.

3Safety sensors mounted on

the sealing bar.

4Safety limit switches placed

on the machine frame and

intended to stop the machine

if the movable protections

open unexpectedly.

5Emergency push-button.

Fig. 2.2.1

Chapter 2 - Machine installation

14

2.3 CONTROL SYSTEMS

Pos. Code Description Function

1KZ010166 Flextron-Master

It enables you to set up the machine for the functions it is

expected to perform.

2KZ010160 Flextron-Bell

3KZ010159 Flextron-Power

Base

4KZ010153 Flextron-I/O

5EP010198

EP010200 Emergency push-

button It stops the machine in case of an emergency

6EP010139 Main switch It can turn the machine on and off

7EP300021 Lighting column

The GREEN light signals that the machine is on START.

The RED light signals that the machine is on ALARM. The

BLUE light signals that the machine is on STOP. The

INTERMITTENT GREEN light signals that the machine is

on PAUSE. The INTERMITTENT BLUE light signals that

the sealing bar is heating up

8EF100084 Vertical detection

photoelectric cell It detects and monitors very low packages

9EF100084 Horizontal detection

photoelectric ce It detects and monitors very narrow packages

10 EF100086 Film unwinding

sensor It activates the reel-holder motor when the film is being

dragged.

11 EF100022 Movable belt

detecting sensor

(Only for FP6000CS)

It detects the movable belt group position and prevents the

sealing when the group hinders the sealing bar. If the

sensor is disconnected and the parameter "movable belt" is

activated, the machine will not work.

12 EF100022 The sensor to

activates the

sealing bar safety It detects the presence of an object during the sealing bar's

downstroke

13 EF110006 Position transducer

It allows the card to know the sealing bar position, by

detecting the position of the sealing bar cylinder rod. This

allows the machine to calculate the sealing time, to

deactivate the sealing bar safety sensor during the sealing,

etc…

14 EF100150 Photocell of full

scrap reel Once the scrap reel has reached its full capacity, the

photocell sends the signal to the board. The display will

then show the warning "REEL-SCRAP-FULL"

15 EF010049 High/low package

micro-switch It checks the position of the height adjusting system and

stops

it as soon as the maximum or minimum height is reached.

16 EP010191

EP010199 Upstroke/

downstroke push-

button contacts

It adjusts the machine according to the package, by

modifying the height of the squares, of the dragging roller

and of the sealing bar.

17 EP010193

EP010199 Film pressing

cylinder selector It separates the 2 wheels of the film dragging device, when

the film is positioned.

18 EF100022 Sealing bar position

sensor It determines the opening position of the sealing bar.

19 EF100022 Reel-holder roller

sensor It allows to verify the position of the reel-holder roller. If the

roller is open during the machine operation, the error

“REEL-MOTOR-OPEN“ will be displayed on the board.

Use and maintenance manual FP6000CS - FP8000CS

15

Fig. 2.3.1

Fig. 2.3.3

Fig. 2.3.2

ELECTRICAL

CABINET

Chapter 2 - Machine installation

16

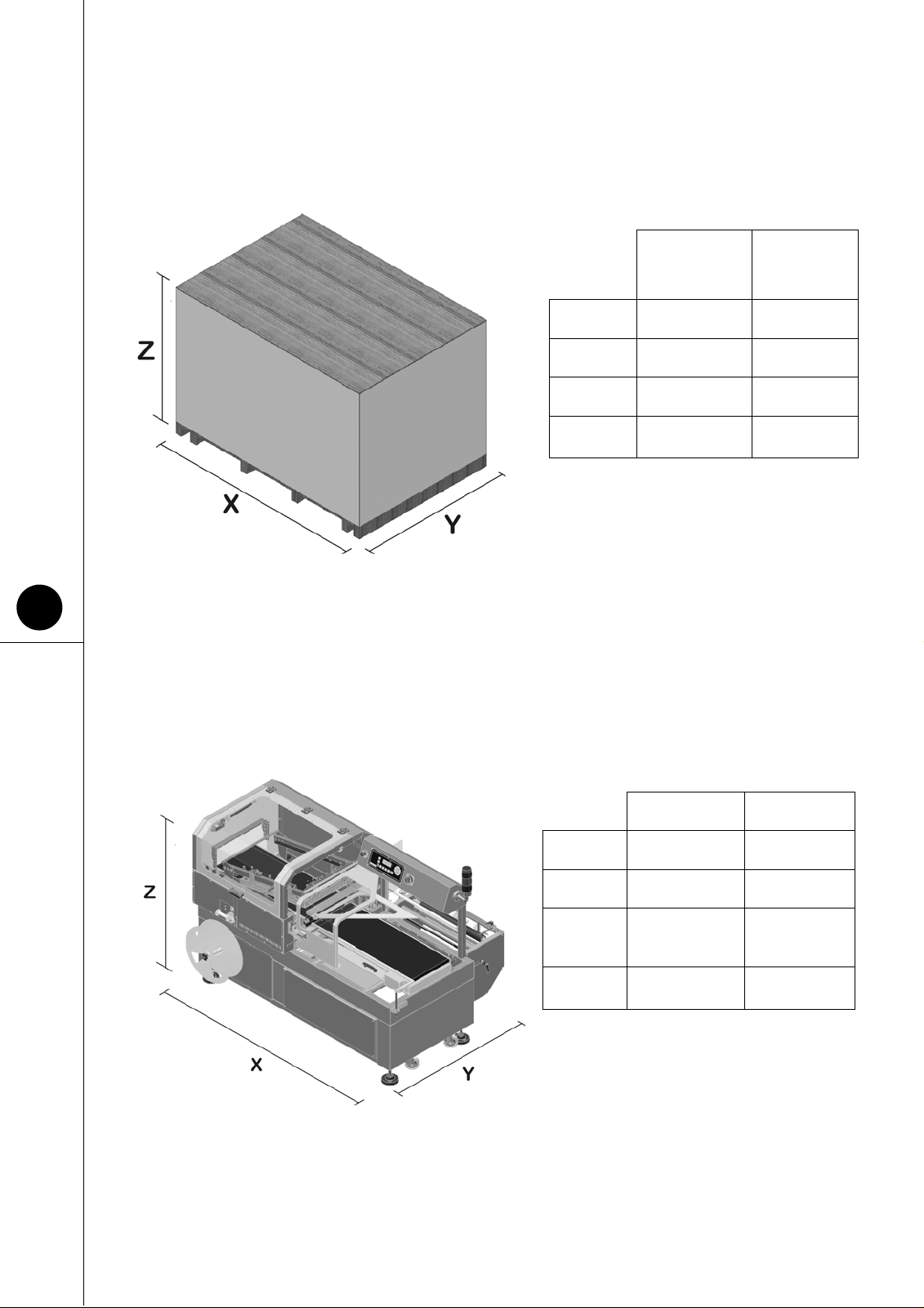

2.4 WEIGHT AND DIMENSIONS OF THE PACKED MACHINE

2.5 WEIGHT AND DIMENSIONS OF THE MACHINE

Fig. 2.4.1

FP6000CS

cardboard case

packaging

FP8000CS

case

packaging

X2200 mm 2650 mm

Y1520 mm 1740 mm

Z1550 mm 1760 mm

WEIGHT Kg660 Kg 810

Fig. 2.5.1

FP6000CS FP8000CS

X2090 mm 2537 mm

Y1433 mm 1633 mm

Z1565-1675

mm 1666-1776

mm

WEIGHT Kg 550 Kg 720

Use and maintenance manual FP6000CS - FP8000CS

17

2.6 TRANSPORT AND UNPACKING

ATTENTION!

Before handling make sure that the hoisting equipment are suitable to lift the load that

has to be handled.

In the case of long storing, place the machine in a sheltered environment with a

temperature between -15°C and +55°C degree of humidity, variable between 30% and

90% without condensation.

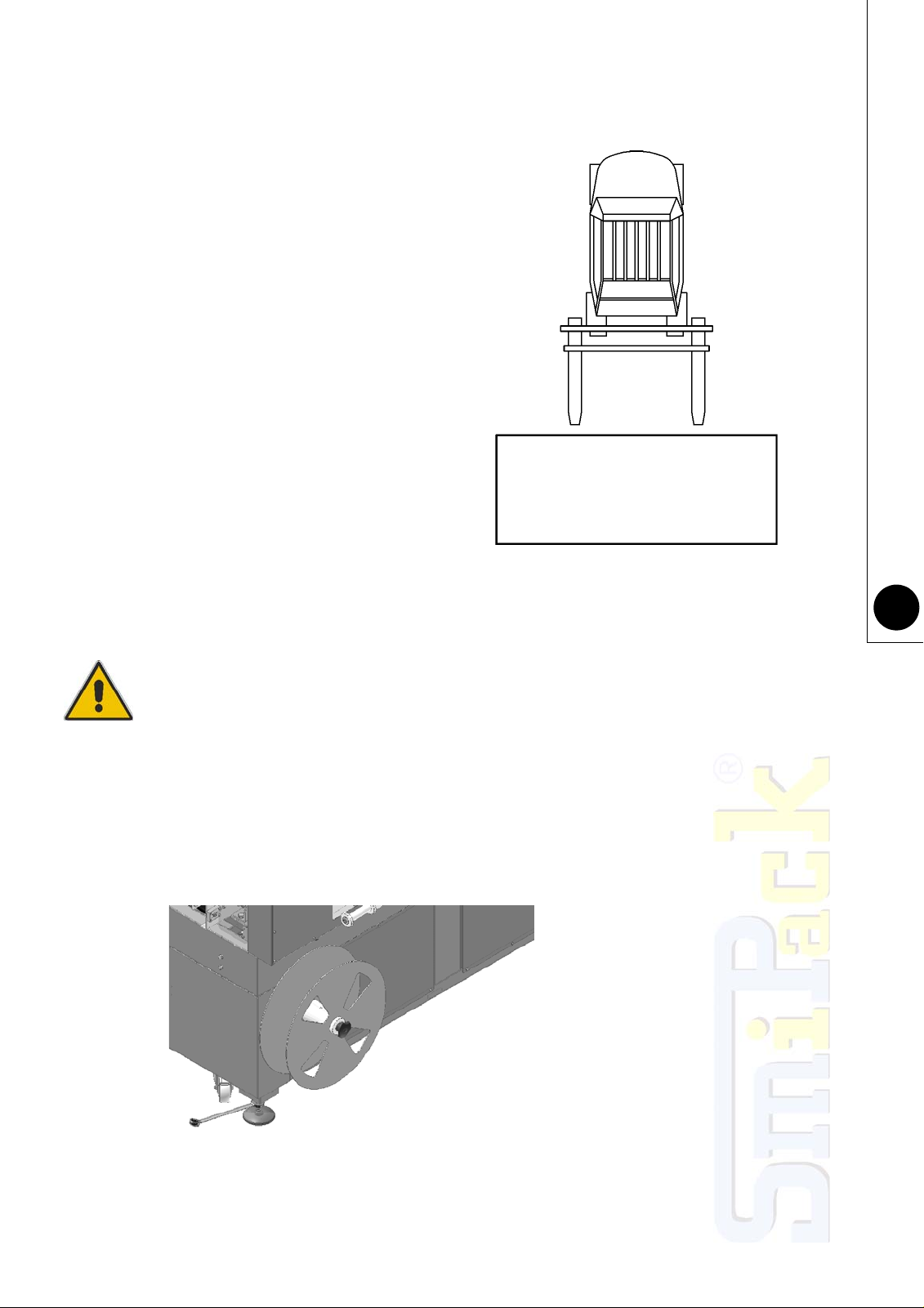

2.7 POSITIONING AND LEVELLING

SMIPACK S.p.A. in function of the means of

transport and of the type of products to be

shipped utilizes packagings adequate to

guarantee the integrity and preservation during

transportation. It is recommended to handle

with great care the machine during transport

and positioning. The forwarder is responsible

for every damage that may occur during

transport. Unpack the unit making sure not to

damage any exposed parts.

The lifting of the machine module must be

carried out by means of hoisting systems

operating from below; due to the packaging

modalities, it is not possible to use hoisting

systems operating from above.

Lift the machinefrom the longer side andadjust

the forks of the forklift at themaximum distance

from each other.

Fig. 2.7.1

Make sure that the floor, in the

installation area, does not

present irregularities that may

prevent the normal and correct

positioning of the machine. Place

a spirit level on the belt's upper

side and then level the machine

using the adjustable support feet

then lock them by tightening the

locknuts

Fig. 2.6.1

Chapter 2 - Machine installation

18

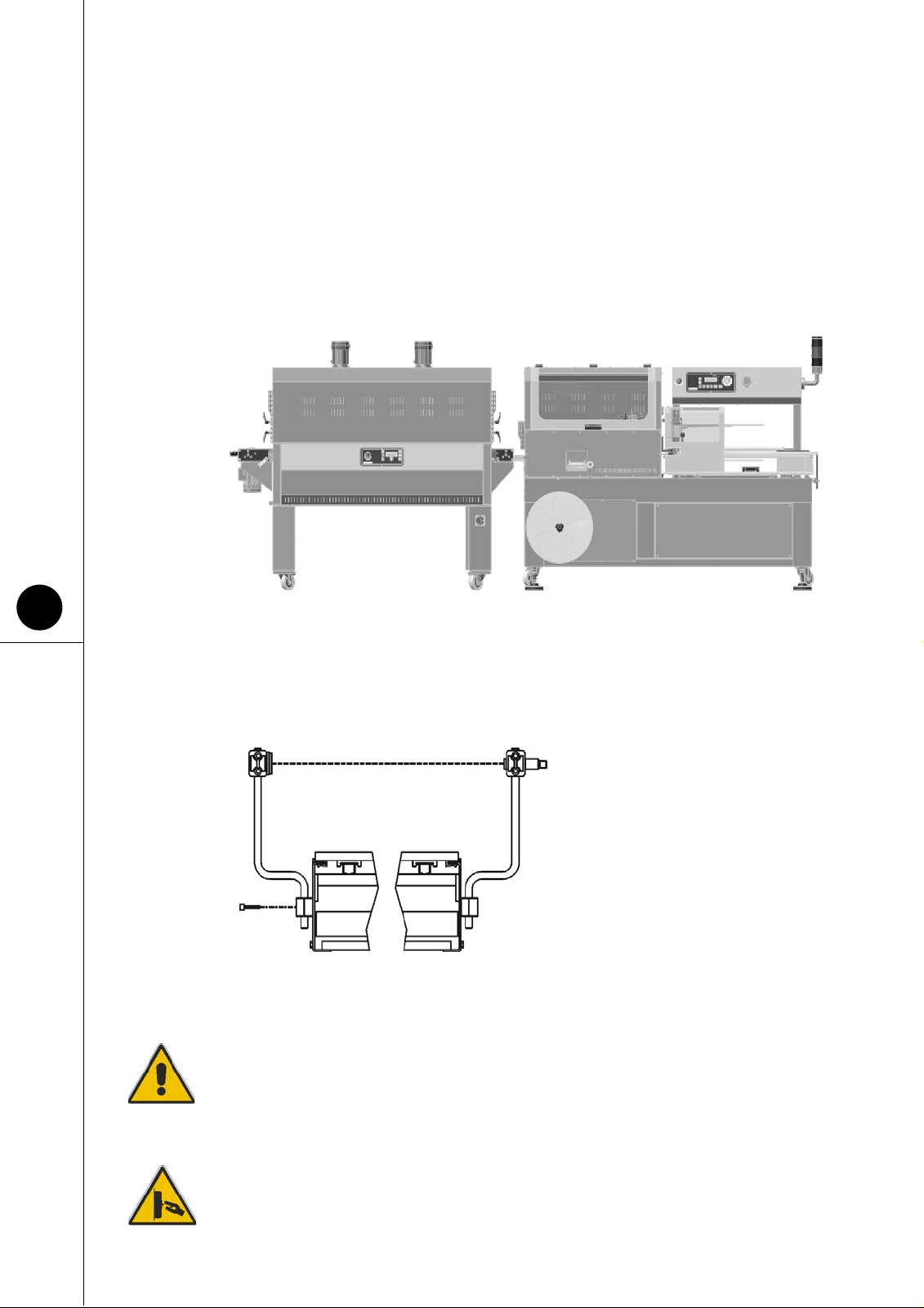

2.8 FP6000CS AND FP8000CS L-SEALER AND T450 TUNNEL

POSITIONING

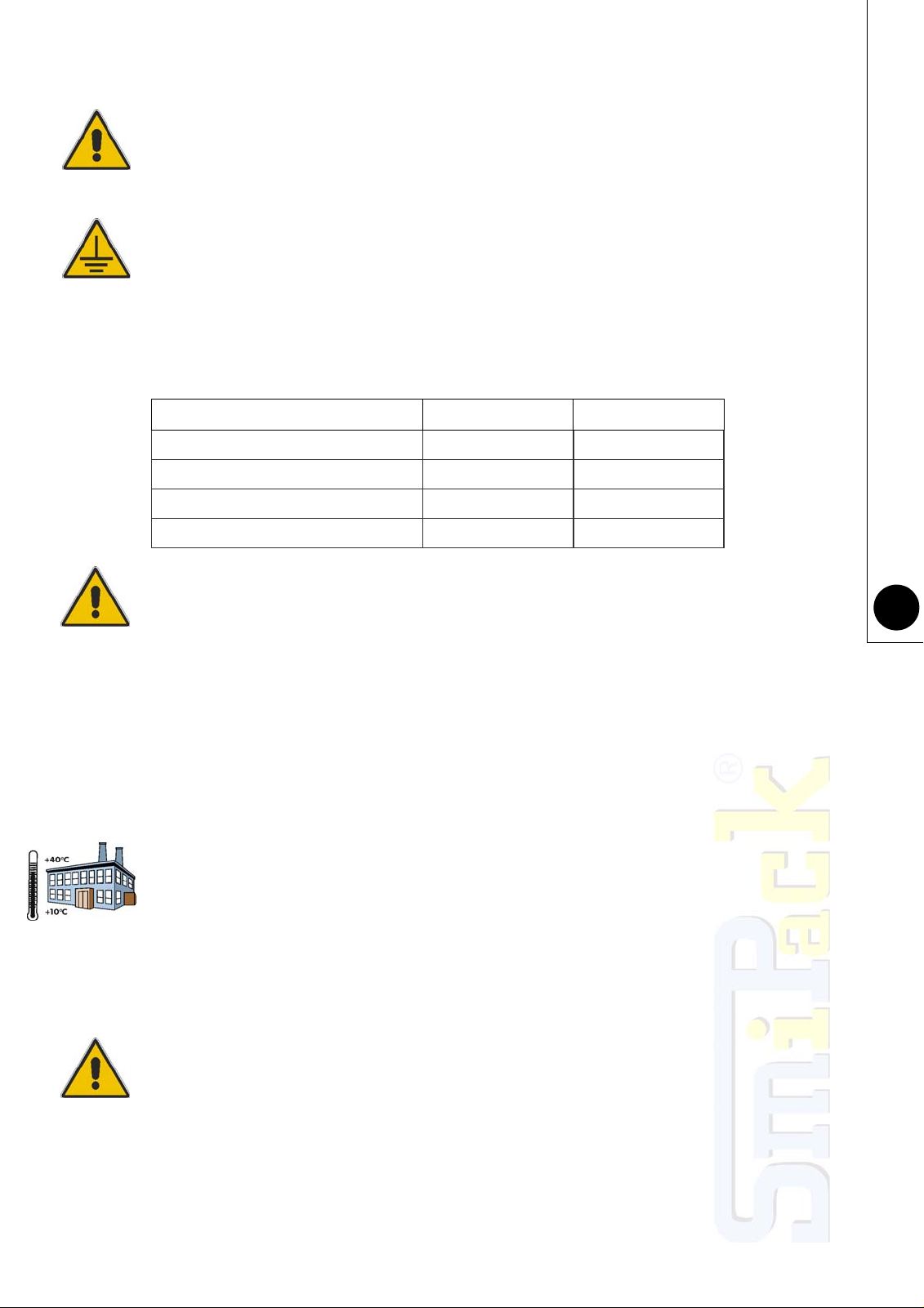

2.9 ASSEMBLING THE ACCUMULATION PHOTOELECTRIC CELLS

(OPTIONAL)

2.10 DEMOLITION AND DISPOSAL

ATTENTION!

The machine does not contain dangerous components or substances that require

particular removal procedures. Regarding the elimination of the various materials, it is

necessary to follow the regulations of the Country in which the tunnel will be

dismantled.

2.11 ELECTRICAL CONNECTIONS

All operations for the connection to the mains must be carried out with no voltage

applied to the machine.

Once the machine has been levelled, place the machine's connecting belt as close as possible

to the tunnel's.

Make sure that the tunnel's belt is kept approximately 1 mm higher than the sealer's, so as to

prevent the falling over of packages at the tunnel inlet zone. Adjust the height by acting on the

adjustable support feet. Position the tunnel in such a way as to have the wrapped package

perfectly centred on the tunnel's belt

Fig. 2.8.1

Fig. 2.9.1

Two groups of photoelectric cells are

supplied along with the machine. One

group is to be placed two meters ahead of

the machine inlet and is intended to detect

any possible end of flux. The other group

is to be placed two meters after the tunnel

and is meant to detect any possible

product accumulation. After placing a level

on the upper part of the frame, level the

machine using the adjustable support feet

then lock them by tightening the locknuts.

Use and maintenance manual FP6000CS - FP8000CS

19

ATTENTION!

In the case which someone wants access to the electrical system, remember to turn off

the power supply and wait at least 5 minutes before operating.

Earthening is compulsory!

The machine's connection to the mains must be carried out in thorough compliance

with the regulations of the user's country.

Make sure that the frequency and voltage of the machine's power supply (as indicated

on the nameplate to be found on the rear of the machine) correspond to the mains'.

2.12 TECHNICAL DATA FOR THE ELECTRIC CONNECTION

ATTENTION!

The machine's supply line must be equipped with a thermal magnetic circuit breaker

capable of withstanding the rated values stated in table 2.12.1

2.13 CONDITIONS OF USE

Make sure that there is enough space for easy application and maintenance.

THE MACHINE NEEDS AN INSTALLATION IN A CLOSED AND WELL AIRED

SURROUNDING, WHERE THERE ARE NOT ANY EXPLOSION OR FIRE DANGEROUS.

THE MINIMUM LIGHTING MUST BE 300 LUX.

Make sure that there is enough space for easy application and maintenance. Position the

machine in the planned space with no humidity, flammable materials, gas, and explosives and

making sure that it is level on the floor.

We suggest operating temperatures varying from +10°C to +40°C with a relative humidity from

30% to 80% with no condensation.

The airborne noise is lower than 70 dB.

FP6000CS and FP8000CS L-Sealer's IP class rating = IP54

ATTENTION!

The pressure and the plate acoustical power of the machine can change depending on

the material of containers to be packaged. Therefore, the user must perform an

assessment on the noise exposure of his personnel in accordance with the types of

packages worked, so as to equip his operators with suitable personal protection

equipment.

Tab. 2.12.1

FP6000CS FP8000CS

RATED VOLTAGE 230 V 230 V

RATED FREQUENCY 50 Hz 50 Hz

RATED POWER 3250 W 3850 W

RATED CURRENT 13,5 A 16 A

White page

This manual suits for next models

1

Table of contents

Other Smipack Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SpinTouch

SpinTouch RapidScreen Wall Mount Assembly instructions

Grundfos

Grundfos UPE 2000 FZ Series Installation and operating instructions

ICC

ICC RONER R PLUS Operating and maintenance manual

RenewAire

RenewAire BR Series quick start guide

Reflex

Reflex Refix DD Series Instructions for use

SCHUNK

SCHUNK PGH 30 Repair instructions

MB

MB 700 Series Operation manual

Bühler technologies

Bühler technologies GAS 222.11 Ex2 Installation & operation instructions

Siemens

Siemens SINUMERIK Equipment manual

WAMGROUP

WAMGROUP EXTRAC RBB Installation operation & maintenance

General Measure

General Measure Checkweigher user manual

STEPCRAFT

STEPCRAFT D Series manual