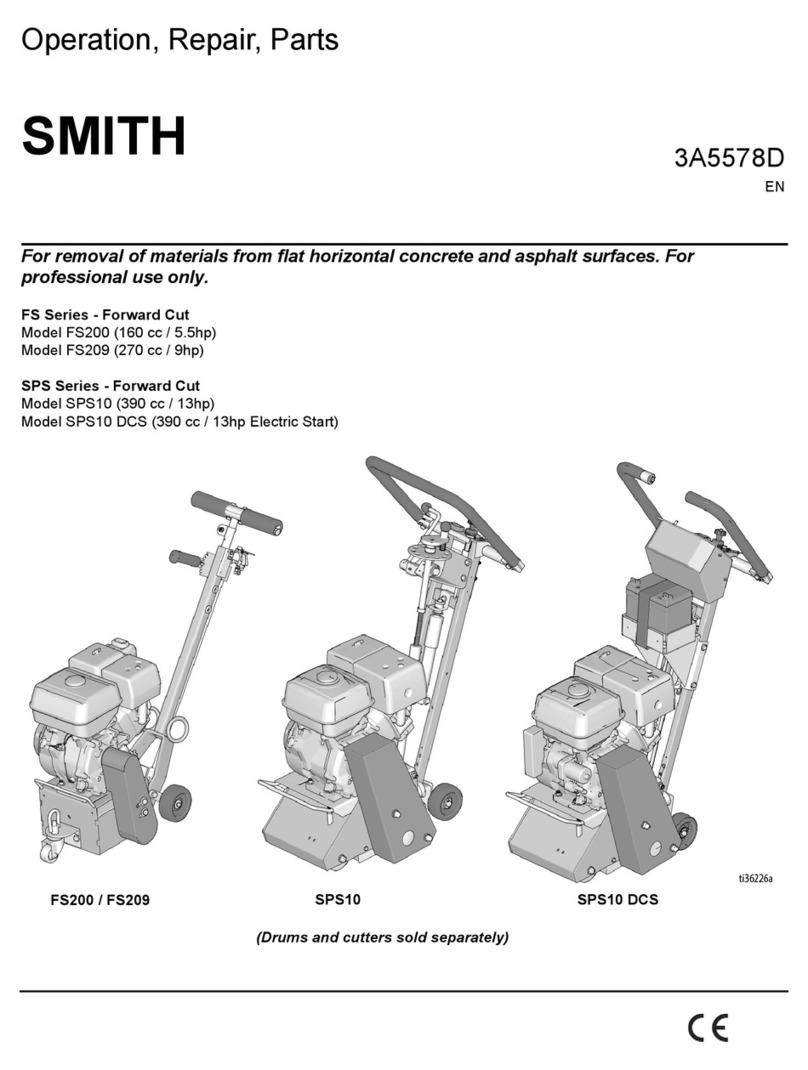

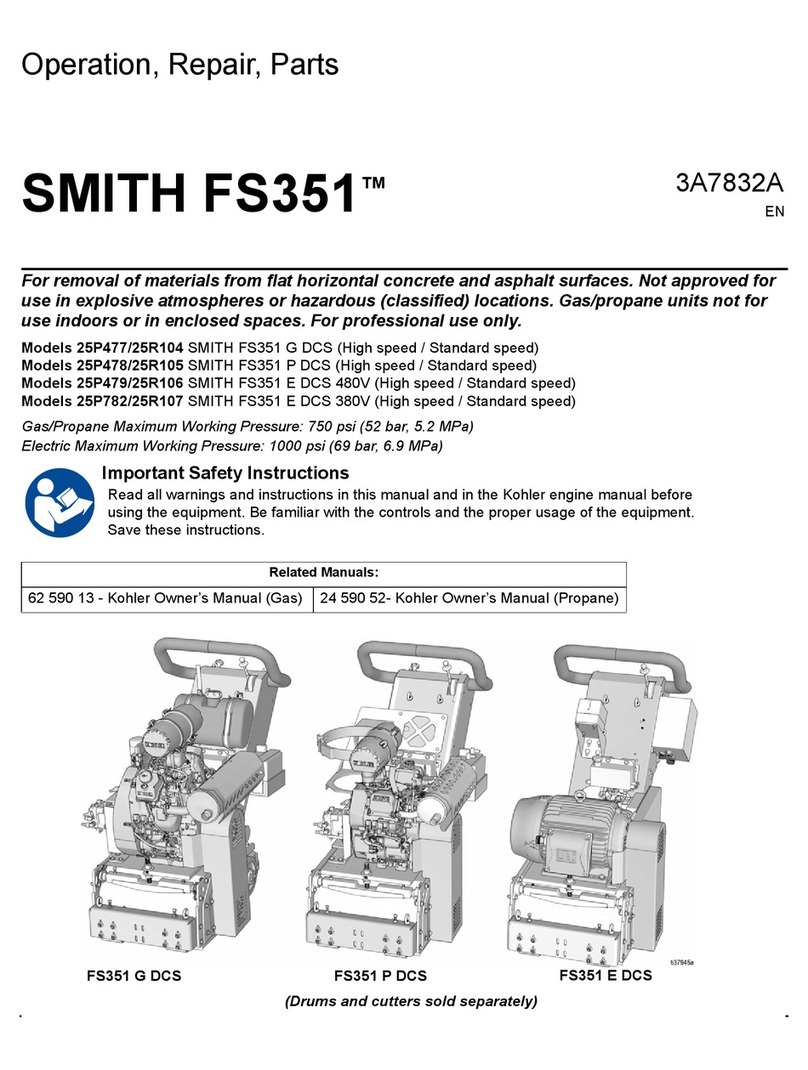

Smith FS050 User manual

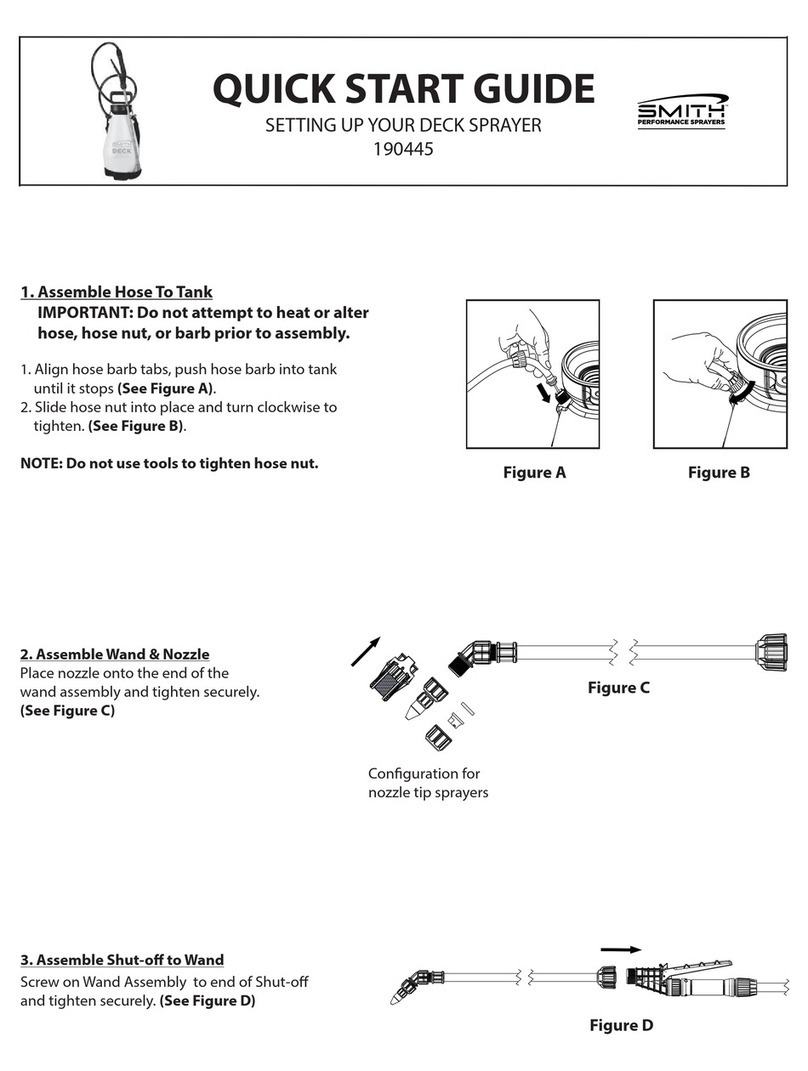

FS050

Hand-held portable scariers

Parts & User Manual

(954) 941-9744

www.SMITHMFG.com

MANUFACTURING

Cutters / Removers / Parts / Support

1-800-653-9311

www.SmithMfg.com

Phone: 954-941-9744 • Fax: 954-545-0348

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

2

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

INTRODUCTION

Congratulations on purchasing the

FS050™from SMITH Mfg. Company.

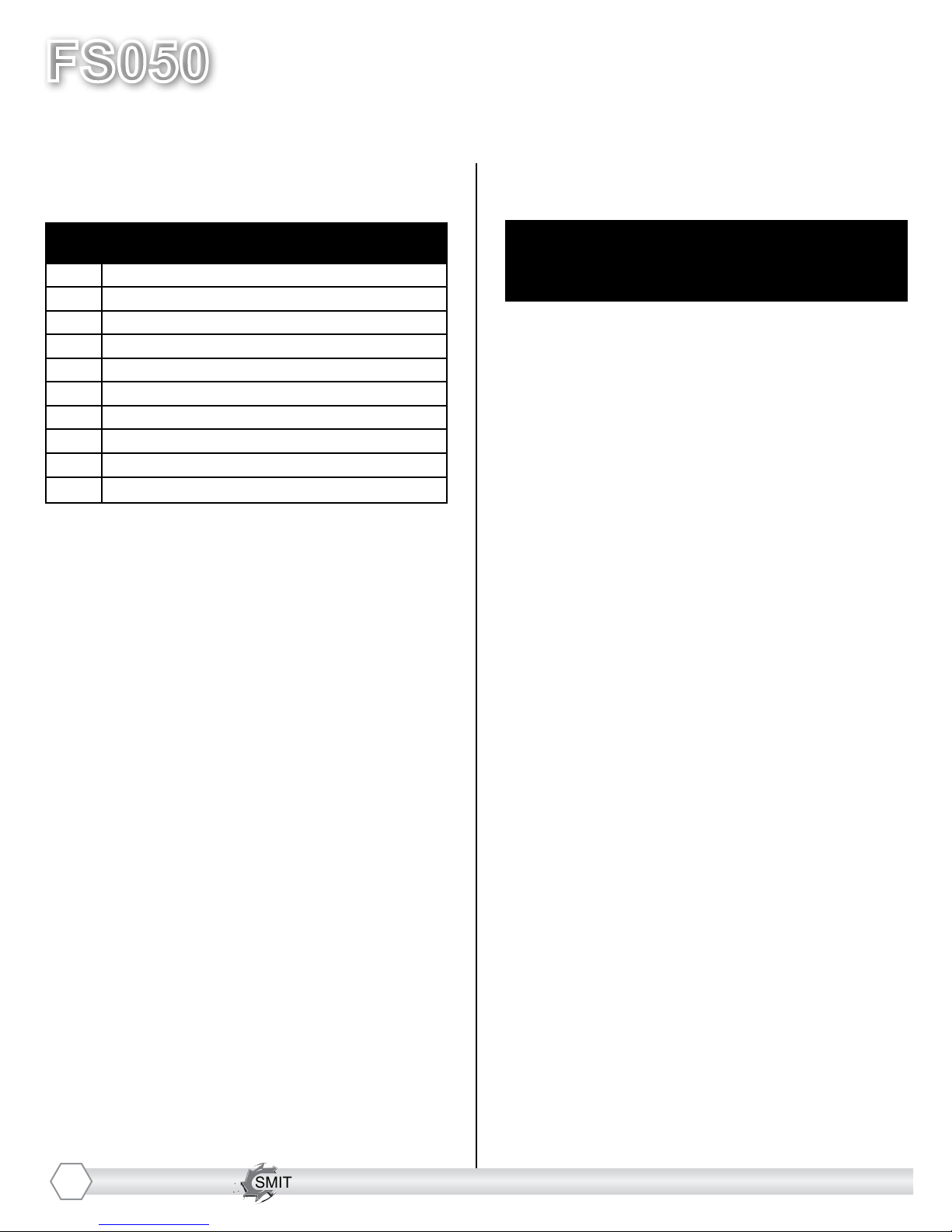

Page Contents

2 Index / Introduction

3 Required Safety Equipment / Safety Guidelines

4Your FS050 Hand held scarier

5 Using the FS050 properly

6 Maintenance checklist

7-8 Drum and cutter options

9-10 Maintenance Log

11 Limited Equipment Warranty

12 Warranty Activation

INDEX

The SMITH brand FS050 is a fast, rugged and

lightweight portable hand-held scarier designed

for high performance edging or removing in hard

to reach locations by hand or in the upright caddy

that removes faster than conventional diamond

discs.

Best for touch-ups, edging, removing in hard

to reach areas, walls, ceilings, under tables.

Add FS050.C caddy for upright removal. Used

by Concrete Resurfacing Contractors, Striping

Contractors, DIYers

Exclusive features of this machine:

• It’s versatile, offering a variety of cutters with a

4 or 6 shaft cutter set-up with extra set of shaft

holes.

• It’s lightweight

• It’s reversible, with an adjustable housing and

handle to power through high spots, low spots

and in very tight areas.

You will obtain years of satisfying service when your

machine is properly used and maintained. Please

read completely this guide and parts list manual

to assure your REMOVAL SUCCESS. If you have

any questions about the operation of your machine

or would like to order replacement parts, please

contact your SMITH Dealer directly, or call SMITH

at 1-800-653-9311 or (954) 941-9744 for the name

of your local dealer.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 13/2016

FS050

3

REQUIRED SAFETY

EQUIPMENT

When using this tool the following

safety equipment MUST be worn!

DO NOT USE THE MACHINE

WITHOUT SAFETY EQUIPMENT

SAFETY GLASSES

SAFETY GLOVES

SAFETY MASK

SAFETY GUIDELINES

-PNEUMATIC-

• Read all instructions before using the tool.

All operators must be fully trained in its use

and aware of these safety rules.

• DO NOT exceed the maximum working

pressure of 100 psi

• Use ONLY compressed air at the

recommended conditions

• If the tool appears to malfunction, remove

from use immediately and arrange for

service and repair

• If the tool is used with a balancer or other

supporting device ensure that it is xed

securely

• Always keep hands away from the working

attachment tted to the tool

• The tool IS NOT electrically insulated.

NEVER use tool if there is any chance of it

coming into contact with live electricity

• When using the tool always adopt a rm

footing and/or position and grip the tool

rmly to be able to counteract any forces

that may be generated while using the tool

• Use only the correct spare parts. Do not

improvise or make temporary parts

• Do not lock, tape, wire etc the ON/OFF

valve in the run position. The trigger/lever

must always be free to return to the off

position when it is released

• Always shut off the air supply to the tool

and depress the trigger/lever to exhaust air

from the feed hose before tting, adjusting

or removing the working attachment

• Check hose and ttings regularly for wear,

replace if necessary

• Always use a suitable vacuum cleaner or

dust extraction unit

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

4

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

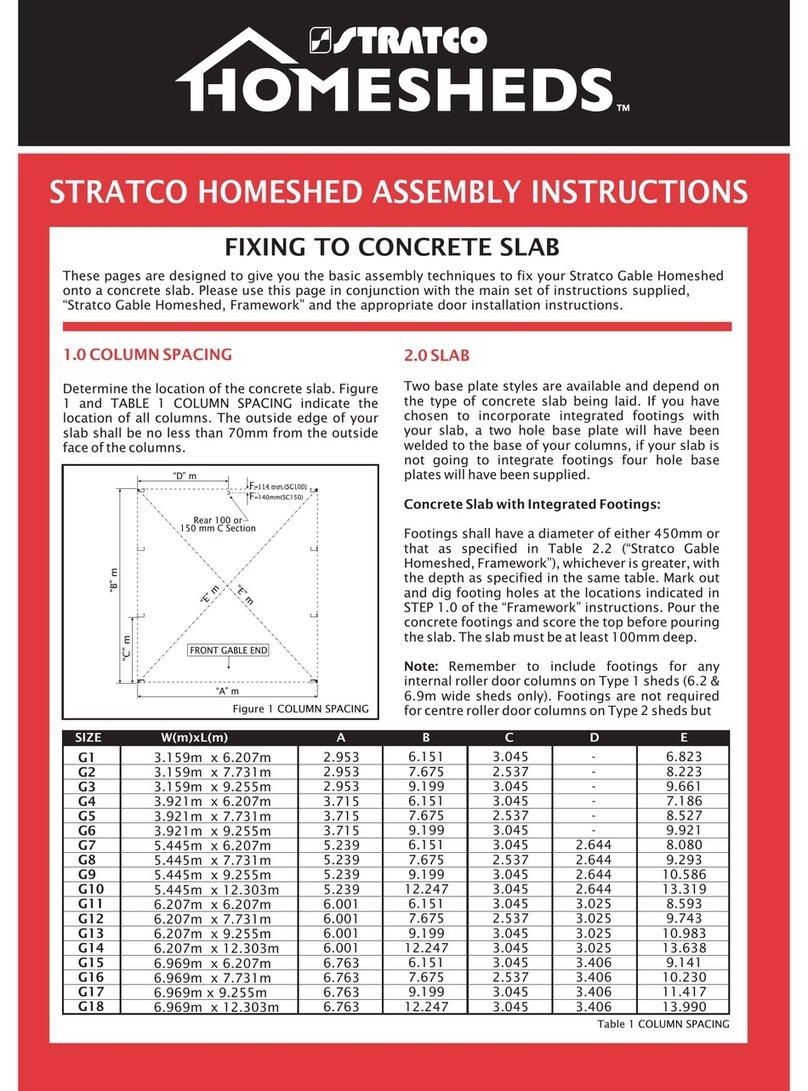

YOUR FS050TM HAND HELD SCARIFIER

Please take time to familiarize yourself with the FS050™’s controls, as well as some

of the features of your new machine.

1

2

3

4

5

6

7

Item: P/N Qty Description

1 FS050.P 1 Pneumatic Grinder

2 FS050.008.2 1 Replaceable Foam Grip for Handle

3 FS050.003.ASM.P 1 FS050 pneumatic housing assembly

4 FS150.006 1 Pneumatic Adapter

5 FS050.015 1 Vacuum Port Cap

6 FS050.001.L5A 2 Drum Offset Spacers

7 Varies 1 See FS050 Drum and cutter assemblies on pg. 7 -8

8 FHSCS.M5-0.8x35mm 4 M5x0.8x35mm Flat Head Screw

8

NOTE: Item 3 includes item numbers 2, 4,5,6, and 8

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 13/2016

FS050

5

RECOMMENDATIONS

• Recommended working pressure:

6.3 bar / 90 psi

• Maximum working pressure:

7.0 bar / 100 psi

• Recommended hose bore:

10 mm / 3/8”

• Recommended hose length:

10 m / 30 ft.

USING THE FS050

AIR SUPPLY:

Use clean lubricated air supply that will give

a measured air pressure at the tool of 6.3

bar / 90 psi when the tool is running with the

trigger/lever depressed.

Use the recommended hose size and length.

Do not connect the tool to the air line system

without incorporating an easy to reach an

operate air shut off valve.

The air supply should be lubricated. It is

strongly recommended that an air lter,

regulator, lubricator (FRL) is used as this

will supply clean, lubricated air at the correct

pressure for the tool.

Details of such equipment can be obtained

from your supplier/dealer. If such equipment

is not used, the tool should be lubricated

by shutting off the air supply to the tool and

depressurizing the line by pressing the trigger

on the tool.

Disconnect the air line and pour into intake

bushing a teaspoon (5 mL) of a suitable

pneumatic motor lubricating oil preferably

incorporating a rust inhibitor.

Reconnect the tool to an air supply and

run slowly for a few seconds to allow air to

circulate the oil.

If tool is used frequently lubricate on a daily

basis and also if tool starts to lose power.

WORK STATIONS:

The tool should only be used as a hand

operated tool. It is recommended that the tool

is used when standing on a solid oor. It can

be used in other positions but before any such

use the operator must be in a secure position

having a rm grip and footing and be aware

of safety rules to be obeyed when using the

grinder.

•

•

•

•

•

•

•

•

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

6

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE CHECK LIST

Before beginning servicing on any

FS050 unit, DISCONNECT FROM

AIR SUPPLY SOURCE

• Check all fasteners and re-tighten, since the

machine will vibrate the fasteners loose if they

are not secured. Use locktite.

• Clean drum housing regularly to prevent

material build up.

• Inspect drum, and shafts for damage and

replace as needed.

• Regularly lubricate grinder with a suitable

pneumatic motor lubricating oil. Preferably

one that incorporates a rust inhibitor.

• Check hose and ttings regularly for wear or

leaks, replace if necessary.

SAFETY GUIDELINES

-ELECTRIC-

• Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels

and other accessories running over rated speed

can y apart and cause injury.

• Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring or its own cord.

Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the

operator.

• NEVER use tool with wood cutting blades or

other saw blades. Such blades when used on

a polisher frequently kick and cause loss of

control leading to personal injury.

• Hold the tool rmly and keeps hands away from

rotating parts.

• Make sure the drum is not contacting the work

piece before the switch is turned on.

• When working near metal surfaces, watch out

for ying sparks. Hold the tool so that sparks y

away from you and other persons or ammable

materials.

• Do not leave the tool running. Operate the tool

only when hand-held.

• Do not touch the work piece immediately after

operation; it may be extremely hot and could

burn your skin.

• Check that the work piece is properly supported.

• Pay attention that the wheel continues to rotate

after the tool is switched off. Check hose and

ttings regularly for wear, replace if necessary

• This tool has not been waterproofed, so do not

use water on the work piece surface.

• Ventilate your work area adequately and use a

suitable vacuum attached to the housing.

• Use of this tool to sand/grind some products,

paints and wood could expose user to dust

containing hazardous substances. Use

appropriate respiratory protection.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 13/2016

FS050

7

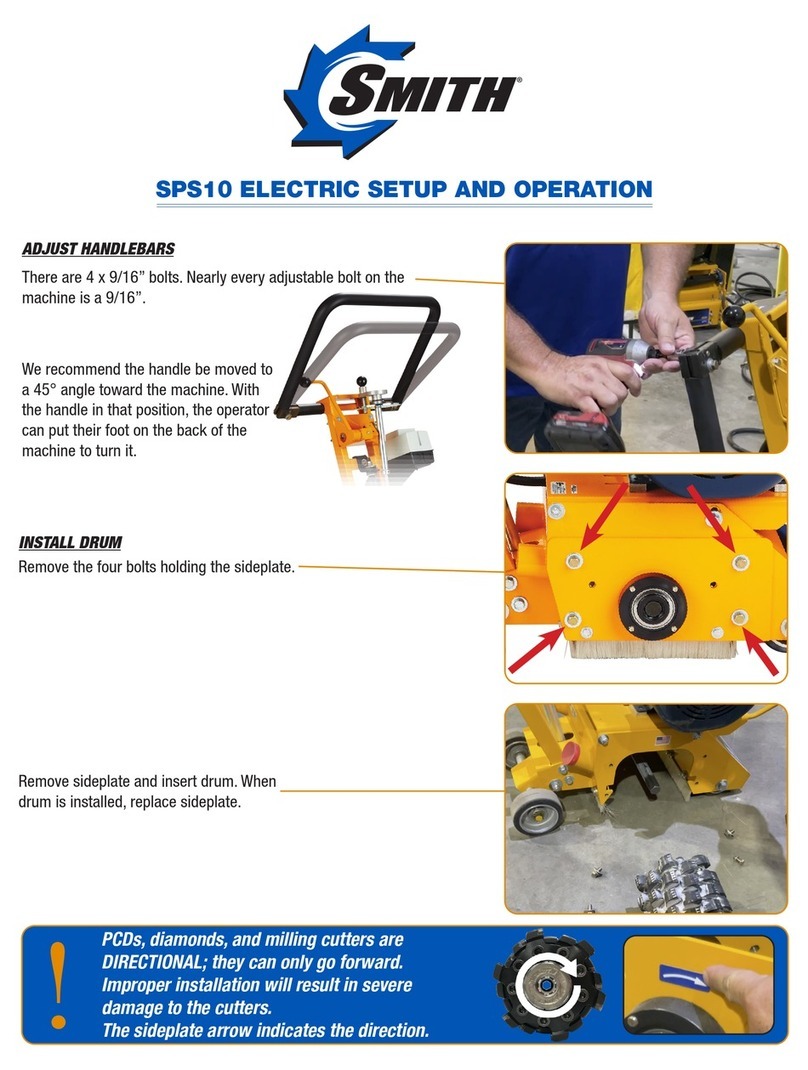

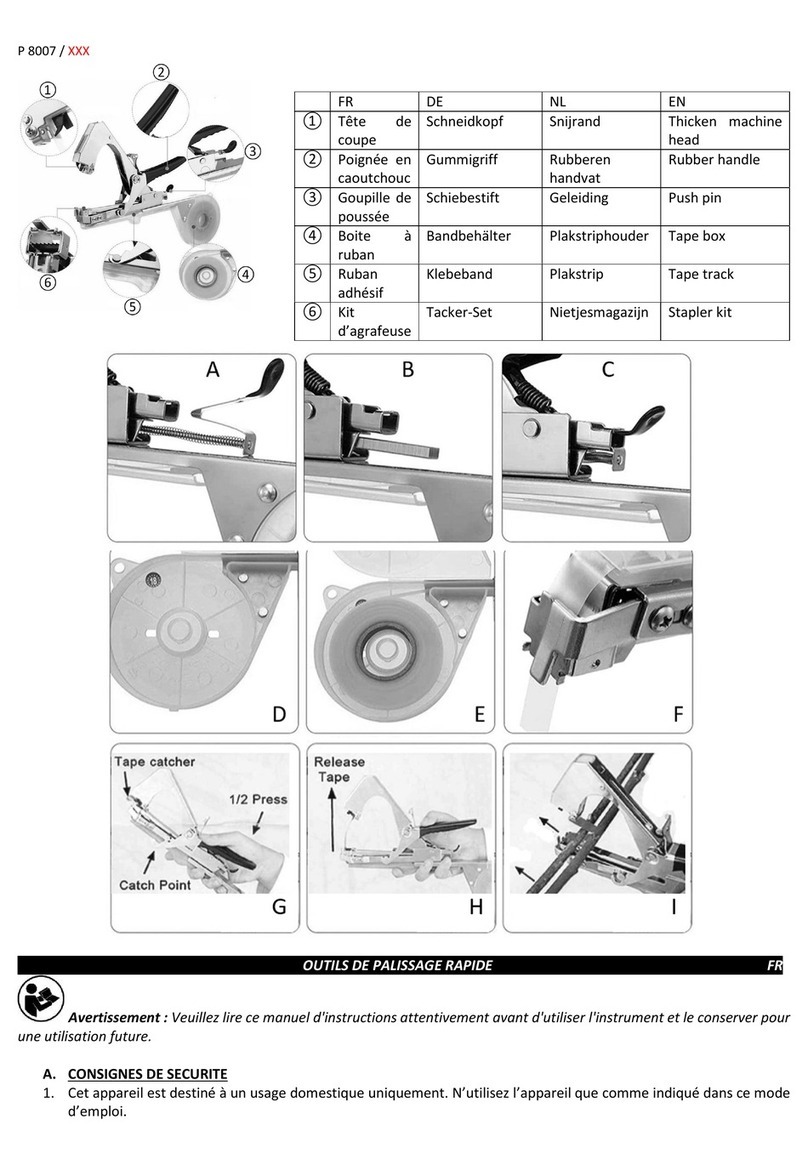

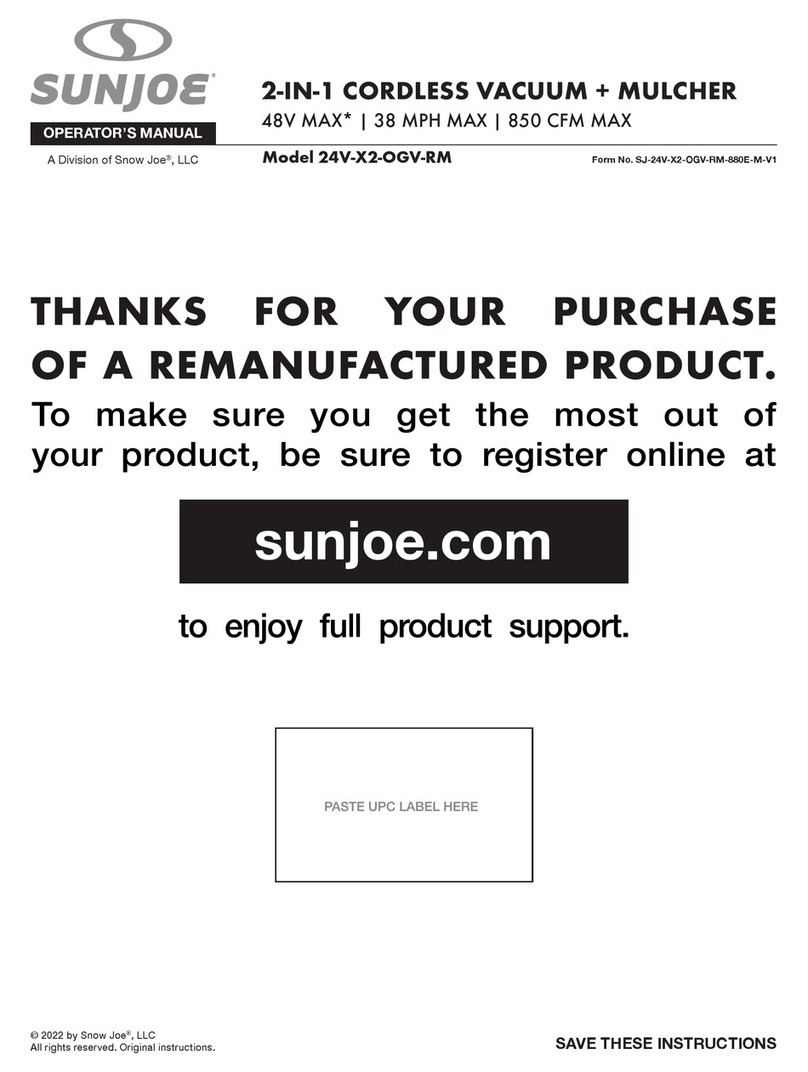

YOUR FS050TM HAND HELD SCARIFIER

Please take time to familiarize yourself with the FS050™’s controls, as well as some

of the features of your new machine.

NOTE: Item 3 includes item numbers 2, 4,5,6, and 8

Item: P/N Qty Description

1 FS050.ME

FS050.FXHD

FS050.FXHD220

1 Electric Grinder: Makita

Electric Grinder: Flex

Electric Grinder: Flex 220V

2 FS050.008.2A 1 Replaceable Foam Grip for Handle

3 FS050.003.ASM 1 FS050 Housing Assembly

4 FS050.005

FS050.005.FX

FS050.006

1 Adapter: Makita

Adapter: Flex

Adapter: Dewalt

5 FS050.015 1 Vacuum Port Cap

6 FS050.005.2FX 1 Spacers

7 Varies 1 See FS050 Drum and Cutter

Assemblies (see pg. 9 - 10)

8FHSCS.M6-1.0x16mm 8 M6x1.0x16mm Flat Head Screw

1

A

B

C

D

2

3

8

54

6

7

Special Note: For Flex 220 (220V Model), special

care must be taken when installing the Drum (item

number 7). One side is tapped for M14-2.0, and one

is tapped for 5/8-11. The drum should be attached

to the machine carefully, feeling for the threads to

engage correctly. The 14mm shaft on the 220V Flex

will t into the 5/8” end of the drum, but can strip

the threads or lock the drum in place if improperly

attached.

There are four controls on the handheld machines

A: Button near head - Locks drive shaft for attaching/detaching drum

B: Trigger button - Turns machine on when held

C: Small button by trigger - Lock trigger into “on” position

D: Dial near trigger - Controls rpm speed of machine (1-slowest; 6-fastest)

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

8

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

RECOMMENDATIONS

• ELECTRICAL SAFETY: Grounded tools

must be plugged into an outlet properly

installed and grounded in accordance with

all codes and ordinances. Never remove the

grounding prong or modify the plug in any

way. Do not use any adaptor plugs. Check

with a qualied electrician if you are in doubt

as to whether the outlet is

properly grounded. If the tools should

electrically malfunction or break down,

grounding provides a low resistance path to

carry electricity away from the user.

• Avoid body contact with grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded.

• Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges

or moving parts. Replace damaged cords

immediately. Damaged cords increase the

risk of electric shock.

• When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and

reduce the risk of electric shock.

USING THE FS050

• PERSONAL SAFETY: Stay alert, watch what

you are doing and use common sense when

operating a power tool. Do not use tool while

tired or under the inuence of drugs, alcohol,

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

• Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

• Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your

nger on the switch or plugging in tools that

have the switch on invites accidents.

• Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

• Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used

for appropriate conditions. Ordinary eye or sun

glasses are NOT eye protection.

• WORK STATIONS: Keep your work area

clean and well lit. Cluttered benches and dark

areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or

fumes.

• Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 13/2016

FS050

9

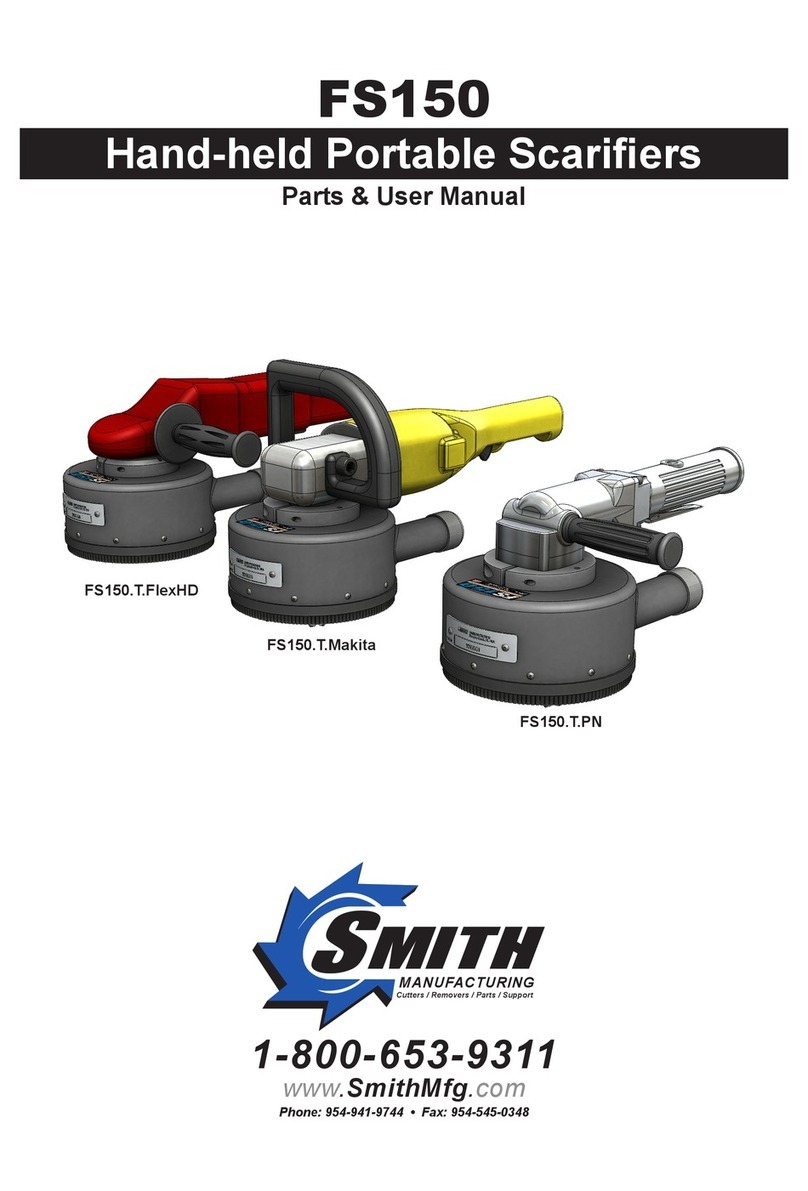

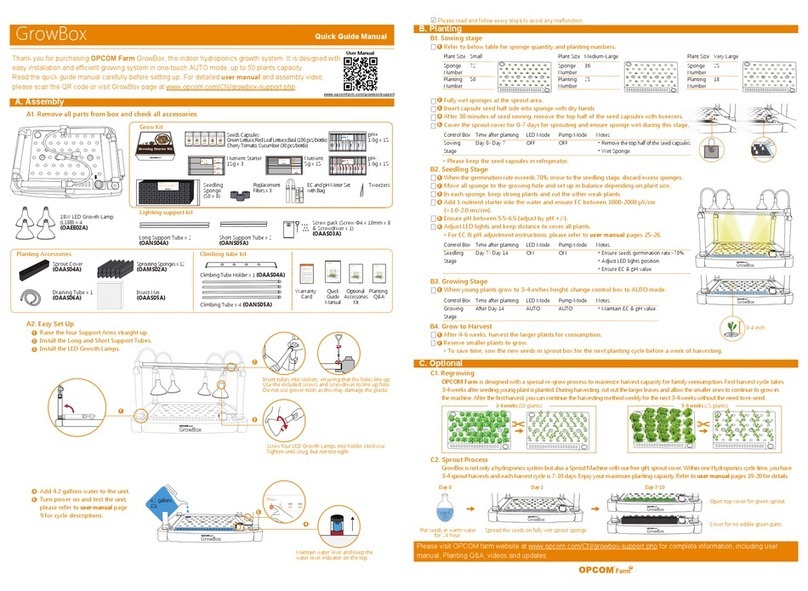

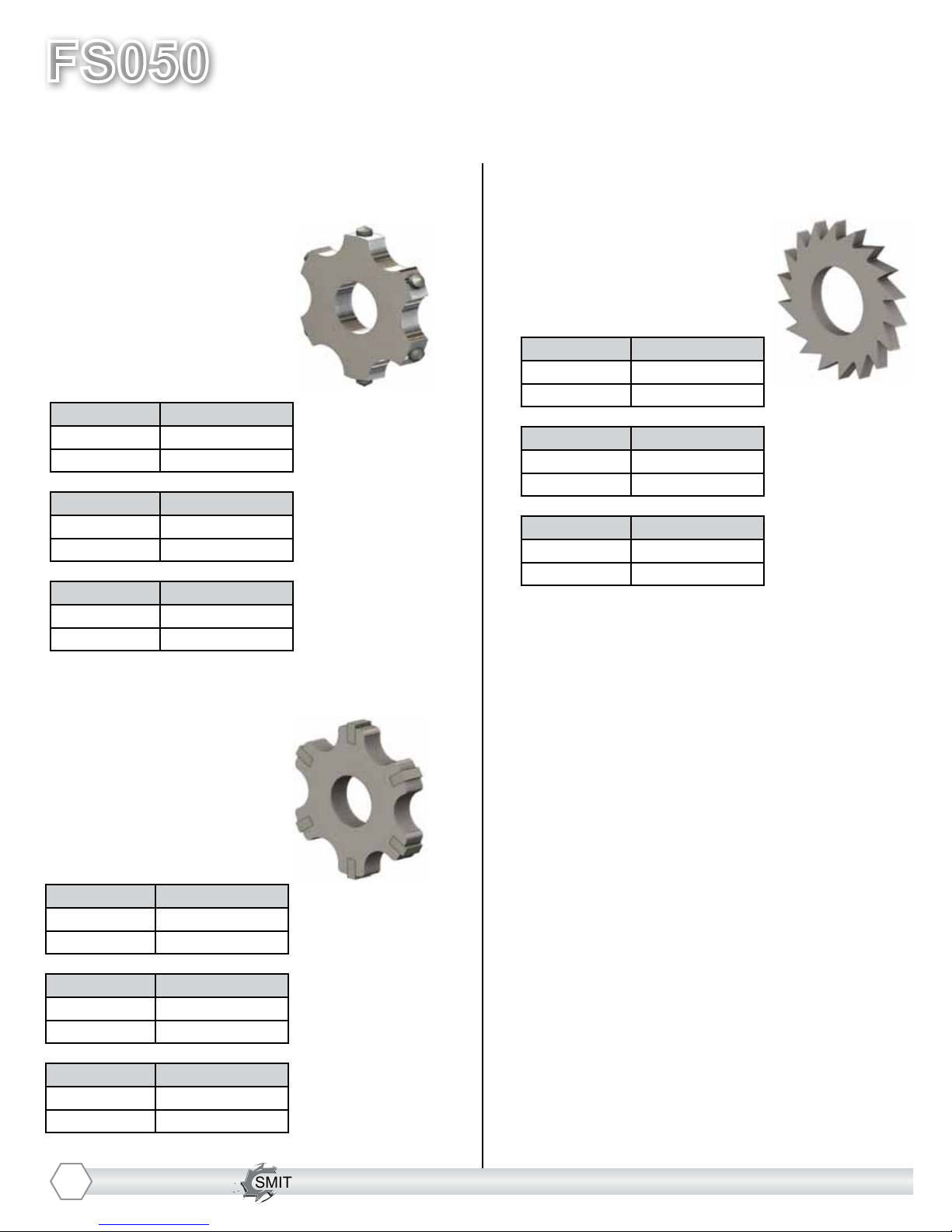

DRUM OPTIONS

A variety of cutters with a 4 or 6 shaft set

up is available for the FS050 to suit all your

removal needs.

FINE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0409.2F 5502.4.0409.2F

Rebuild kit: FS050.6.0409.2F.RK FS050.4.0409.2F.RK

SCRAPE-IT

CF0409 - 10 Pointed

Angled Edge Star, 100%

sintered ultra-premium life,

tungsten carbide cutter

Available in:

MEDIUM FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0409.2M 5502.4.0409.2M

Rebuild kit: FS050.6.0409.2M.RK FS050.4.0409.2M.RK

COARSE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0409.2C 5502.4.0409.2C

Rebuild kit: FS050.6.0409.2C.RK FS050.4.0409.2C.RK

FINE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0410.2F 5502.4.0410.2F

Rebuild kit: FS050.6.0410.2F.RK FS050.4.0410.2F.RK

MEDIUM FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0410.2M 5502.4.0410.2M

Rebuild kit: FS050.6.0410.2M.RK FS050.4.0410.2M.RK

COARSE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0410.2C 5502.4.0410.2C

Rebuild kit: FS050.6.0410.2C.RK FS050.4.0410.2C.RK

CF0410 - 15 Pointed

Straight Edge Star, 100%

sintered ultra-premium life,

tungsten carbide cutter

Available in:

FINE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0411.2F 5502.4.0411.2F

Rebuild kit: FS050.6.0411.2F.RK FS050.4.0411.2F.RK

SCRAPE-IT

CF0411 - 15 Pointed

Straight Edge Star, 100%

sintered ultra-premium life,

tungsten carbide cutter

Available in:

MEDIUM FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0411.2M 5502.4.0411.2M

Rebuild kit: FS050.6.0411.2M.RK FS050.4.0411.2M.RK

COARSE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.0411.2C 5502.4.0411.2C

Rebuild kit: FS050.6.0411.2C.RK FS050.4.0411.2C.RK

FINE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.1519.2F 5502.4.1519.2F

Rebuild kit: FS050.6.1519.2F.RK FS050.4.1519.2F.RK

CF1519 - 8 spike extended

tip ultra-premium life,

tungsten carbide cutters

Available in:

MEDIUM FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.1519.2M 5502.4.1519.2M

Rebuild kit: FS050.6.1519.2M.RK FS050.4.1519.2M.RK

COARSE FINISH 6 SHAFTED 4 SHAFTED

Drum assembly: 5502.6.1519.2C 5502.4.1519.2C

Rebuild kit: FS050.6.1519.2C.RK FS050.4.1519.2C.RK

FLAIL-IT

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

10

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

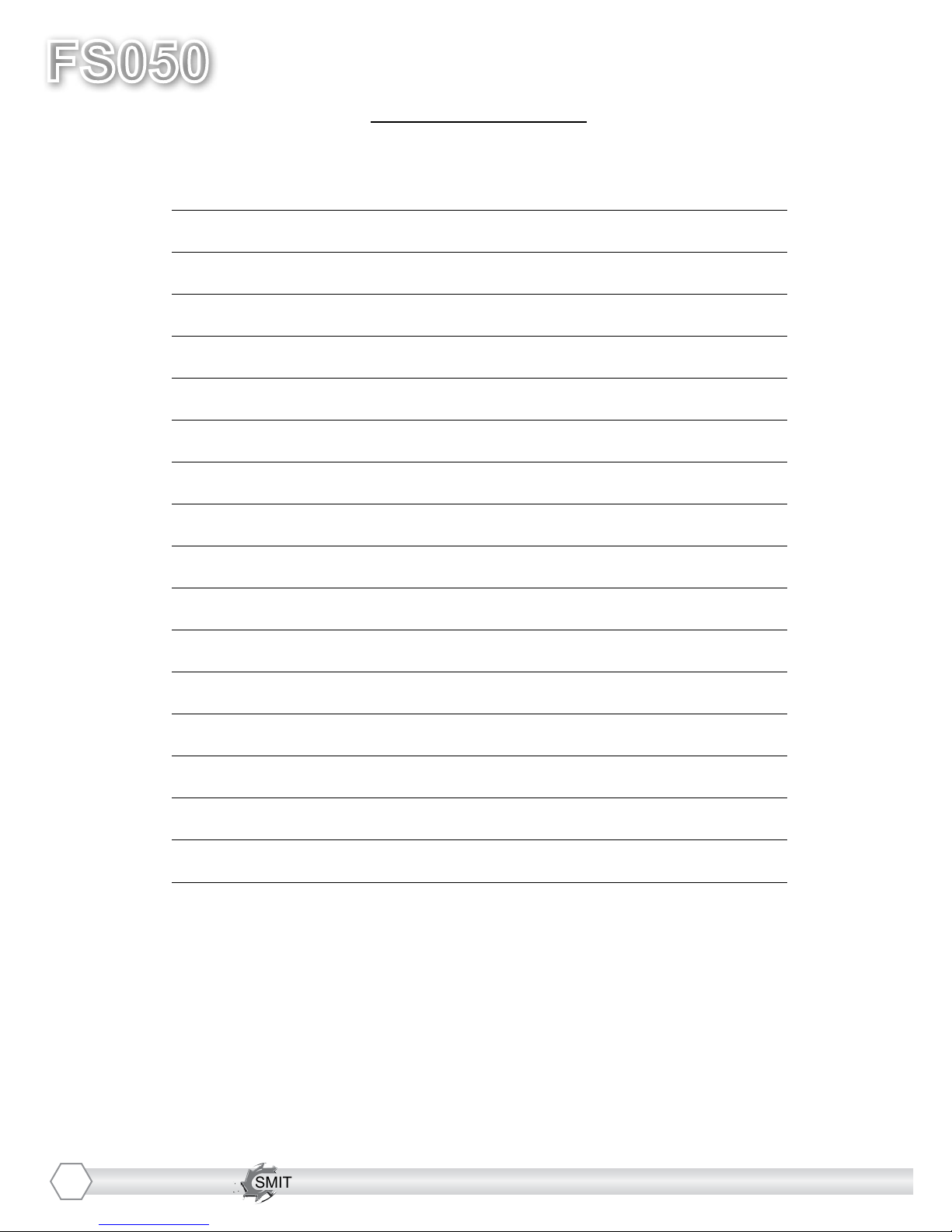

DRUM OPTIONS

CONTINUED

FINE FINISH 4 SHAFTED

Drum assembly: 5502.4.2516.2F

Rebuild kit: FS050.4.2516.2F.RK

FLAIL-IT

CF2516 - 6 spike ultra-

premium life, tungsten

carbide cutters

Available in:

MEDIUM FINISH 4 SHAFTED

Drum assembly: 5502.4.2516.2M

Rebuild kit: FS050.4.2516.2M.RK

COARSE FINISH 4 SHAFTED

Drum assembly: 5502.4.2516.2C

Rebuild kit: FS050.4.2516.2C.RK

FINE FINISH 4 SHAFTED

Drum assembly: 5502.4.2526.2F

Rebuild kit: FS050.4.2526.2F.RK

MEDIUM FINISH 4 SHAFTED

Drum assembly: 5502.4.2526.2M

Rebuild kit: FS050.4.2526.2M.RK

COARSE FINISH 4 SHAFTED

Drum assembly: 5502.4.2526.2C

Rebuild kit: FS050.4.2526.2C.RK

CF2526 - 6 tooth ultra

premium grade “full-width”

tungsten carbide cutter

Available in:

FINE FINISH 4 SHAFTED

Drum assembly: 5502.4.0011.2F

Rebuild kit: FS050.4.0011.2F.RK

FINISH-IT

HS0011 - Hardened Steel

SAW - tooth style

Ultra-Premium Grade Cutter

Available in:

MEDIUM FINISH 4 SHAFTED

Drum assembly: 5502.4.0011.2M

Rebuild kit: FS050.4.0011.2M.RK

COARSE FINISH 4 SHAFTED

Drum assembly: 5502.4.0011.2C

Rebuild kit: FS050.4.0011.2C.RK

STRIP-IT

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 13/2016

FS050

11

MAINTENANCE LOG

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

12

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE LOG

WARRANTY CLAIMS

The manufacturer reserves the right to change or improve the machine design without assuming any

obligation to update any products previously manufactured before this manual. It is the customer’s

responsibility to complete the warranty card and mail it to the seller within 10 days from the date

of purchase. If a failure occurs during the warranty period, the customer must contact the seller

to determine the appropriate action. Any and all transportation charges are to be borne by the

purchaser.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 13/2016

FS050

13

Limited Equipment Warranty

All statements, technical information and recommendations contained in SMITH’s literature are based on tests believed to be reliable, but the accuracy

or completeness thereof is not guaranteed and the following is made in lieu of all warranties, expressed or implied. SMITH warrants all equipment or part

referenced in this document which is manufactured by SMITH and bearing its name to be free from defects in material and workmanship on the date of

sale to the original purchaser under normal use and maintenance as herein provided. This warranty does not apply to components manufactured by others

such as, but not limited to, bearings and engines; such components that may or may not have their own warranties.

With the exception of any special, extended, or limited warranty published by SMITH, SMITH will, for a period of three months (90 days) from the

date of sale or up to ve hundred (500) hours of use by buyer, whichever shall occur rst; repair or replace any part of the equipment determined by

SMITH to be defective. This warranty applies only when the equipment or part is installed, operated and maintained in accordance with SMITH’s written

recommendations.

SMITH’s sole obligation for any breach of warranty or breach of contract for defects, deliberate or accidental omissions, shall be limited to repairing,

replacing or allowing credit for, at SMITH’s option, any part which, under normal and proper use and maintenance, proves defective in material or

workmanship within warranty period, provided, however, that notice of any such defect or omission and satisfactory proof thereof is promptly given by

buyer to SMITH, and thereafter, such defective part is returned to SMITH with transportation charges prepaid, and SMITH’s examination proves such part

to have been defective. This warranty does not obligate SMITH to bear any transportation charges or personnel time in connection with the replacement

or repair of defective parts. This warranty does not obligate SMITH to bear any expense for travel time or of personnel in connection with any service calls.

SMITH will not, in any event, be liable to the user for any consequential damages arising out of this sale for the loss of use, lost prots or revenue, interest,

lost goodwill or work stoppage. SMITH shall not be liable for any injury, loss or damage, direct or consequential, arising out of the use or the inability to use

the product or for environmental claims. It being understood that SMITH has no means of controlling the products nal use; therefore, it shall be buyer’s

responsibility to determine suitability of product for intended use and buyer assumes all risks and liabilities whatsoever, in connection therewith. In no event

shall SMITH be liable for consequential or special damages. Used products are sold on an “as is” basis, and there is no implied warranty of merchantability

or of tness for a particular purpose, unless made in writing by an ofcer at SMITH’s ofce.

This warranty does not cover, and SMITH shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation,

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-SMITH component parts.

Nor shall SMITH be liable for malfunction, damage or wear caused by the incompatibility of SMITH equipment with structures, accessories, equipment

or materials not supplied by SMITH, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment

or materials not supplied by SMITH. This warranty does not apply in respect to damages to any product or accessory or attachment thereof caused by

overloading or other misuse, neglect or accident, nor does this warranty apply to any product or accessory or attachment thereof, which has been repaired

or altered in any way which, in the sole judgment of SMITH, affects the performance, stability or general purpose for which it was manufactured. In the

manufacture of buyer’s equipment, parts may be omitted or equivalent functioning equipment and components may be substituted for the original specied

equipment upon the sole judgment and discretion of SMITH.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized SMITH Reseller for verication of the

claimed defect. If the claimed defect is veried, SMITH will repair or replace free of charge any defective parts and return of merchandise back to the

customer freight collect. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable

charge, which charges may include the costs of parts, labor and transportation.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

SMITH’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy (including,

but not limited to, incidental or consequential damages for lost prots, lost sales, injury to person or property, or any other incidental or consequential loss)

shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

SMITH MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY SMITH.

These items sold, but not manufactured by SMITH (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer.

SMITH will provide purchaser with reasonable assistance in making any claim for breach of these warranties. In no event will SMITH be liable for indirect,

incidental, special or consequential damages resulting from SMITH supplying equipment hereunder, or the furnishing, performance, or use of any products

or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of SMITH, or otherwise.

ADDITIONAL WARRANTY COVERAGE - SMITH does provide extended warranty and wear warranty for products.

Corrections - typographical or clerical errors contained herein are subject to correction by SMITH.

Assignment - buyer shall not assign or transfer this warranty without SMITH’s written consent.

Entire agreement and applicable law - the rights and obligations of SMITH and buyer shall be governed by the laws of the state of Florida, U.S.A. In force

on date hereof. The provisions hereof are intended by buyer and SMITH as a nal expression of their agreement, and are intended also, as a complete

and exclusive statement of all terms apply cable to buyer’s order. No waiver, modication, or addition to any of the terms hereof shall be binding on SMITH,

unless made in writing by an ofcer at SMITH’s ofce as stated herein. In the event of conict between buyer’s purchase order and the terms hereof, the

latter shall control. If any provisions herein are to any extent invalid or unenforceable, the remainder of the warranty shall not be effected thereby and shall

be valid and enforceable to the fullest extent permitted by law.

Legal action - buyer shall be responsible for all costs of collection of outstanding indebtedness, including but not limited to attorney’s fees and court costs

to seller. Buyer shall reimburse seller for any and all litigation expenses seller incurs as a result of an unsuccessful buyer claim. The jurisdiction and venue

of the court for any litigation, state or federal, brought by the buyer and/or seller shall be located in venue determined by seller.

Fair labor standards - seller’s products are produced in the United States and in conformity with all applicable provisions of the fair labor standards act of

1938 as amended and any regulations and orders of the United States Department of Labor issued thereunder.

All written and visual data contained in this document reects the most current product information available at the time of this publication. SMITH reserves

the right to make changes at any time without notice.

TO ORDER, contact your SMITH distributor or call 1-800-653-9311 to identify the nearest distributor.

SMITH Manufacturing Co, Inc.

1610 South Dixie Highway

Pompano Beach, FL 33060

www.smithmfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

FS050

VERSION 13/2016

14

Check this box to receive special pricing

on your recommended wear parts kit

Organization __________________________________

Name ___________________________________________ JobTitle _______________________________

Phone___________________________________ Email ________________________________________

Address _______________________________________________________________________________

City __________________________________________________________________________________

State __________________________Zip __________________________

SMITH Product _________________________________________________________________________

Machine Serial # __________________________________________________________________________

Date of Purchase (MM / DD / YYYY) _________________________________________________________

Purchased from ___________________________________________________________________________

Signature: ___________________________________

Thank you for purchasing a SMITH. Please complete this form upon receipt of your equipment and prior to use on

the job. A pre-operation inspection is required to activate your warranty. All sections must be completed. Should you

have any questions, please add them to the comments section below. Fax the completed form to (954) 545-0348.

Pre-OPeratiOn insPectiOn (Please check all)

1. No parts or components on the machine appear damaged or lost in shipment. Yes No

2. All bolts and fasteners are in place and tightly secured. Yes No

3. Grease points have been identied for future maintenance requirements and appear lubricated.

Yes No

4. Wheels are operational. Yes No

5. Motor has been started and in good working condition. Yes No

6. All Decals appear in place and securely attached. Yes No

7. Equipment runs and tested to assure all components are operating correctly. Yes No

8. Do you have a Wear Parts Kit with an Extra Cutter set in stock? Yes No

9. Did you join Remove Faster News for tech updates, experience sharing and special offers? Yes No

Comments (add any additional or from above answers below)

____________________________________________________________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________________

1610 South Dixie Highway - Pompano Beach, FL 33060 • Ph: 954-941-9744 • Fax: 954-545-0348 • Email: [email protected] • www.SMITHMFG.com

Pre-OPeratiOn insPectiOn - Warranty activatiOn

PrOduct registratiOn

nOte: All power equipment is warranted directly from the motor/engine manufacturers direct and not from SMITH Manufacturing.

Prior to starting your equipment, please nd the name of your engine/motor repair center for warranty and service:

• Honda: http://engines.honda.com/dealer-locator/

• Subaru: http://robinamerica.com/dealerusacan.aspx

• Leeson: http://www.leeson.com/leeson/servicecenter.do?invoke=viewServiceCenterLocator

• US Motors: http://www.usmotors.com/Contact-Information.aspx

• Kohler: http://www.kohlerengines.com/contact/contact.htm

iMPOrtant: Gas Engine owners: Never tip engine forward which will lock the recoil pull cord until the fuel and oil returns back into

their respective fuel chambers and the carburetor is free before it can be started.

Electric motor owners: To avoid problems, power cord must be connected to the correct current and amperage power rating for the motor.

FS050 Handheld Scarier

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing

1610 South Dixie Highway

Pompano Beach, FL 33060

Toll Free: 800.653.9311

Phone: 954.941.9744

Fax: 954.545.0348

E-mail: [email protected]

www.SmithMfg.com

(954) 941-9744

www.SMITHMFG.com

MANUFACTURING

Cutters / Removers / Parts / Support

Other manuals for FS050

1

Table of contents

Other Smith Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Fimco

Fimco LG-2500-304 owner's manual

TSL Horti Tech

TSL Horti Tech ROI-E900 Series user manual

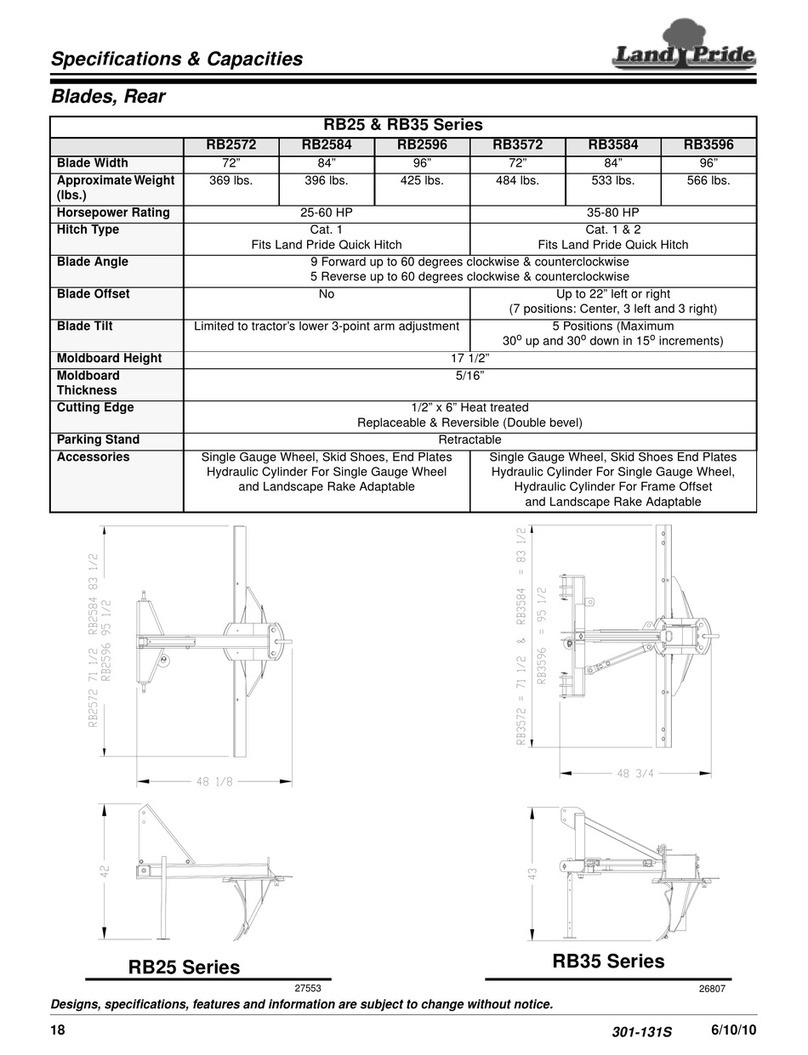

Land Pride

Land Pride QuickHitch RB35 Series Specifications

EGO

EGO PH1400-FC Operator's manual

Premier designs

Premier designs Wing Garden Lighthouse Assembly instructions

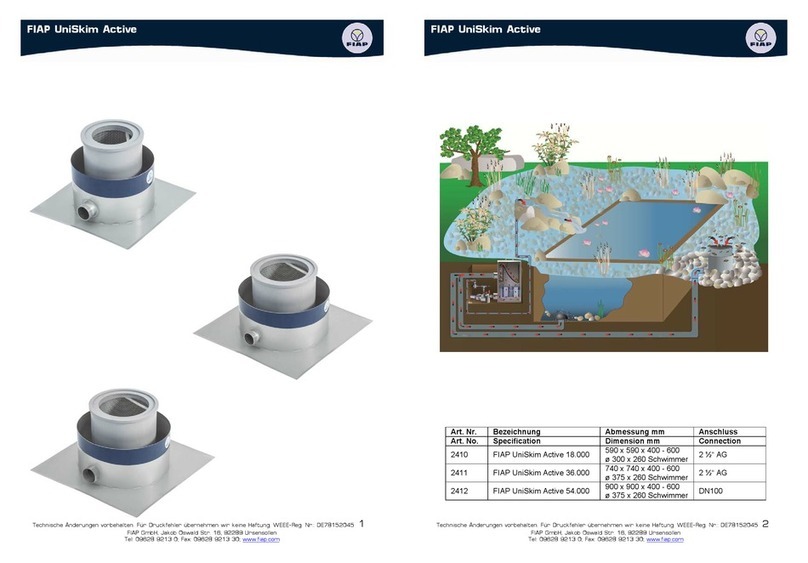

Fiap

Fiap UniSkim Active Series operating manual