Contents

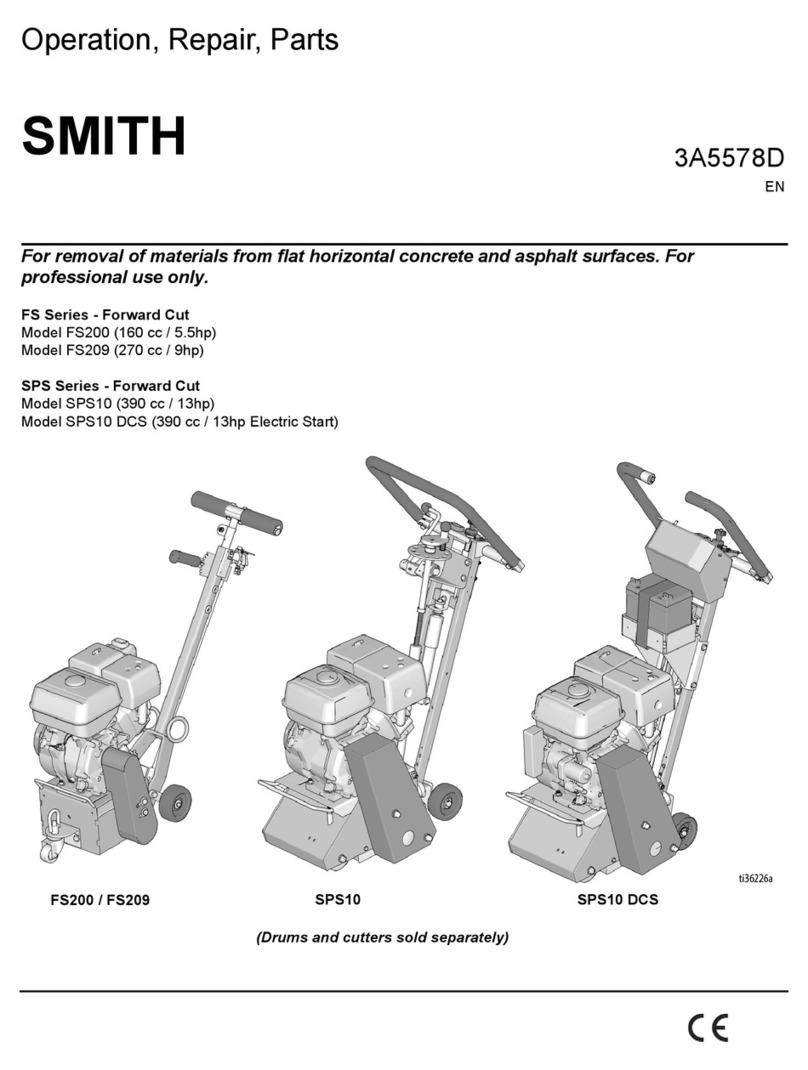

23A7832A

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gasoline/Propane Engine Warnings . . . . . . . . . . . . . . . 5

Electric Motor Warnings . . . . . . . . . . . . . . . . . . . . . . . . 6

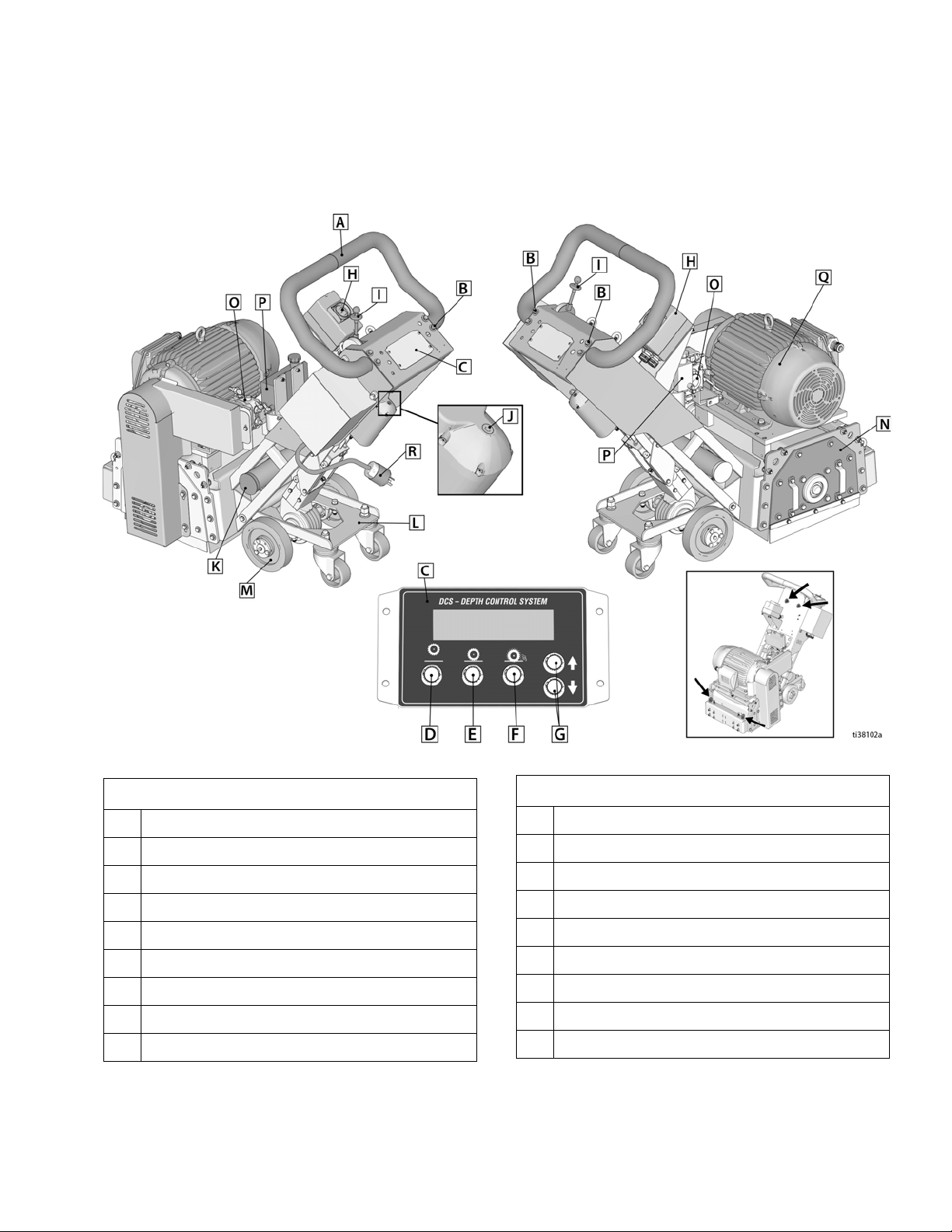

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . 7

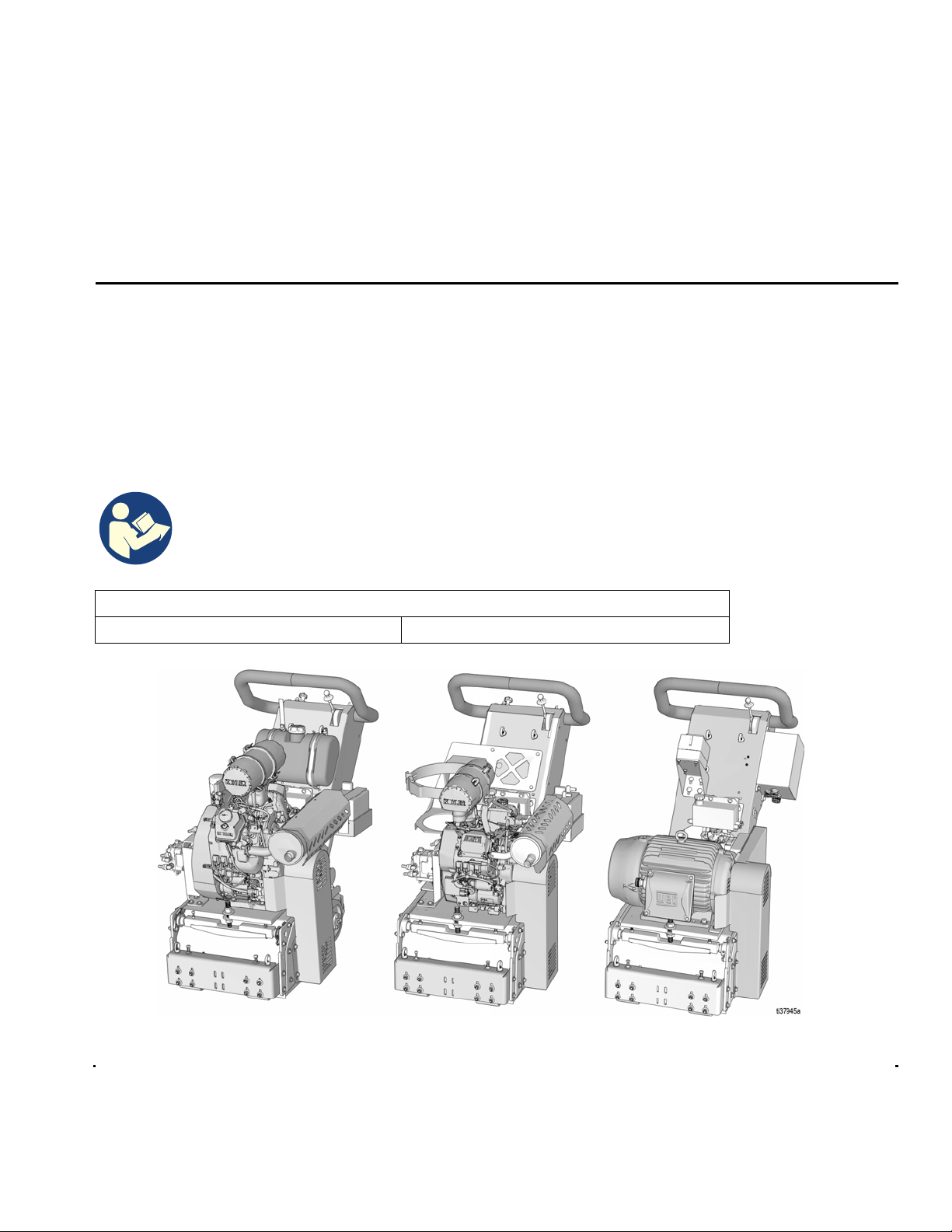

FS351 G DCS (Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

FS351 P DCS (Propane) . . . . . . . . . . . . . . . . . . . . . . . 8

FS351 E DCS (Electric) . . . . . . . . . . . . . . . . . . . . . . . . 9

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Propane Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lifting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

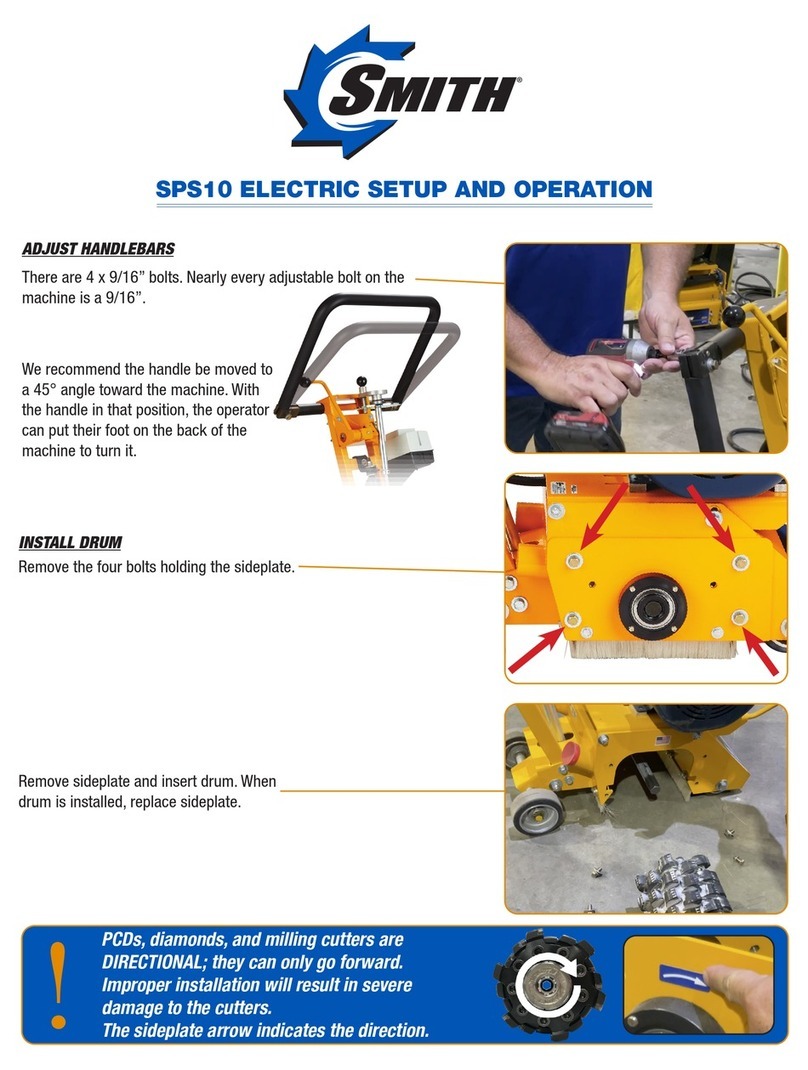

Handlebar Adjustment . . . . . . . . . . . . . . . . . . . . . . . . 11

Engine Kill Button (Gas/Propane) . . . . . . . . . . . . . . . .11

Drum Installation/Replacement . . . . . . . . . . . . . . . . . . 12

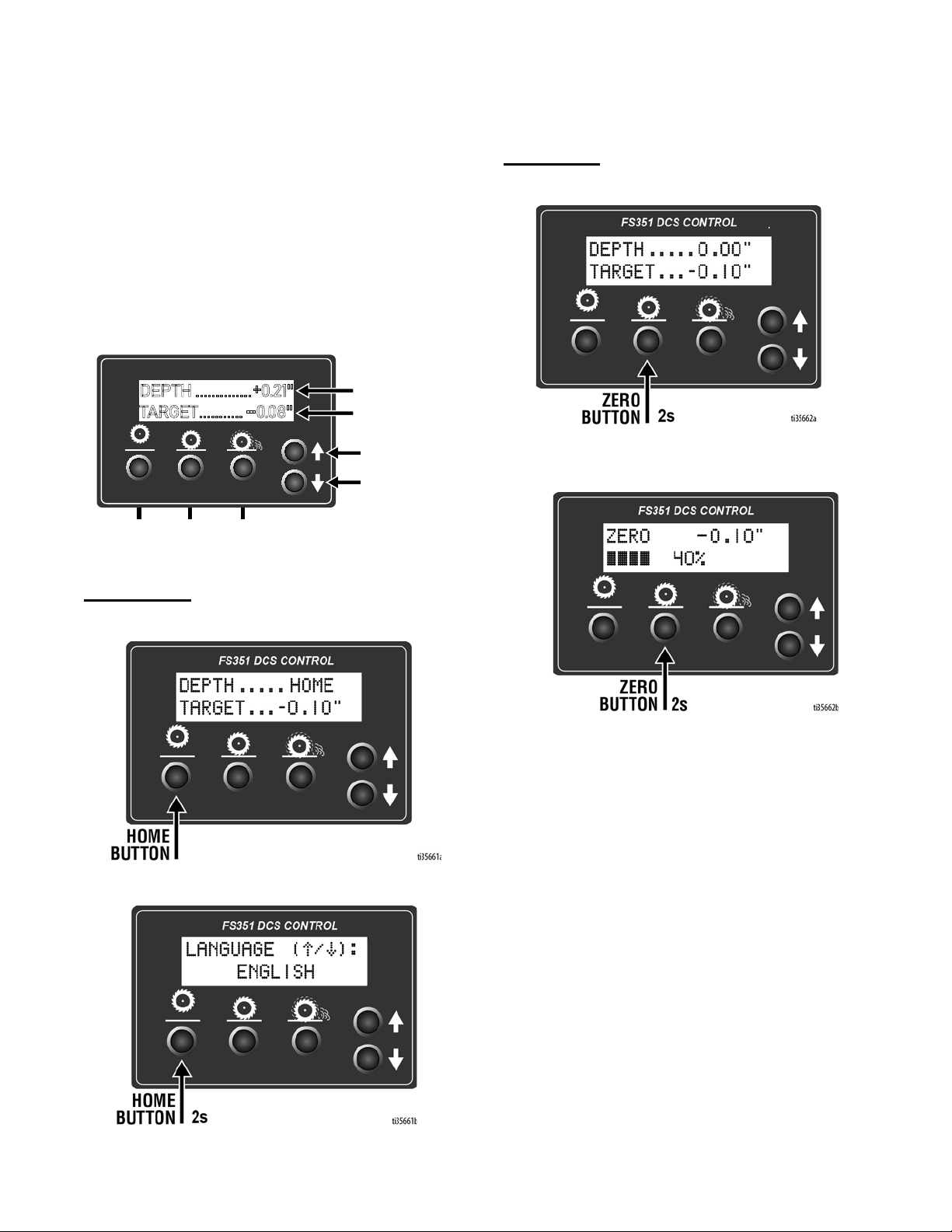

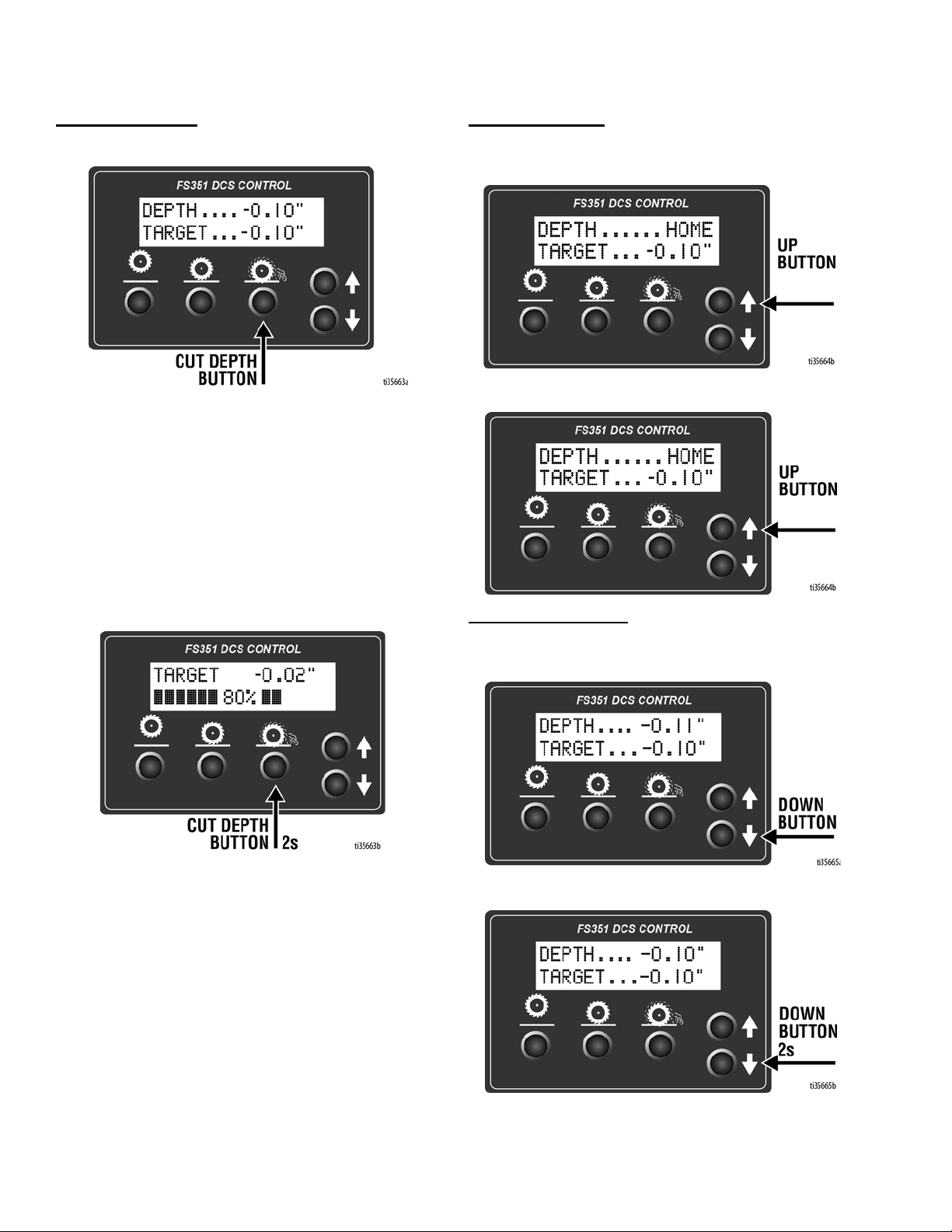

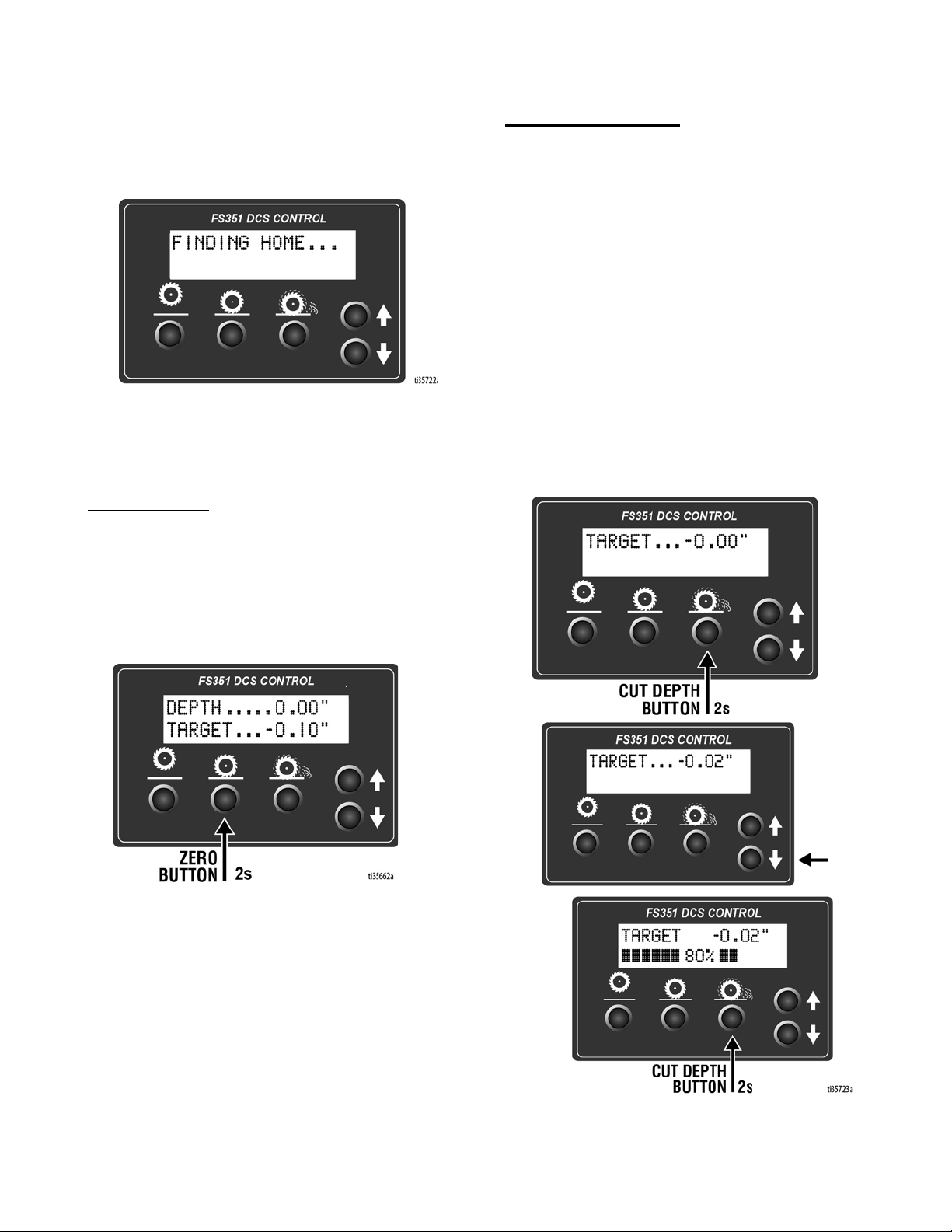

DCS Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Machine Start Up (Gas & Propane) . . . . . . . . . . . . . . 17

Machine Start Up (Electric) . . . . . . . . . . . . . . . . . . . . . 17

When operating... . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Hydrostatic Drive Operation . . . . . . . . . . . . . . . . . . . . 18

DCS Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Drive Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . 21

Hydraulic Belt Replacement (Electric Models only) . . 22

Bearing Housing Replacement . . . . . . . . . . . . . . . . . . 23

Drive Pulley Replacement . . . . . . . . . . . . . . . . . . . . . . 24

Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Gas/Propane Models only . . . . . . . . . . . . . . . . . . . . . . 25

All Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Purge Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Front Wheel Adjustment . . . . . . . . . . . . . . . . . . . . . . . 26

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rechargeable Battery Disposal . . . . . . . . . . . . . . . . .27

End of Product Life . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DCS Control Translations . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DCS Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DCS Actuator Rod Does Not Move . . . . . . . . . . . . . . . 33

Parts - Main Housing Assembly (All Models) . . . . . . . . 34

Parts List - Main Housing Assembly (All Models) . . . . 35

Parts - Front Wheel / Wheel Carrier Assemblies (All Models)

36

Parts List - Front Wheel / Wheel Carrier Assemblies (All

Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Parts - Guidebar / Vacuum Assemblies (All Models) . . 38

Parts List - Guidebar / Vacuum Hose Assemblies (All

Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Parts - Hydraulic Motor / Rear Assembly (All Models) . 40

Parts List - Hydraulic Motor / Rear Assembly (All Models)

41

Parts - Support System / Hydraulic Tank (All Models) . 42

Parts List - Support System / Hydraulic Tank (All Models)

43

Parts - Motor / Hydraulic Assemblies (Gas) . . . . . . . . . 44

Parts List - Motor / Hydraulic Assemblies (Gas) . . . . . 45

Parts - Hydraulic Fittings / Fuel Tank Assemblies (Gas) 46

Parts List - Hydraulic Fittings / Fuel Tank Assemblies (Gas)

47

Parts - Pulley Assemblies (Gas) . . . . . . . . . . . . . . . . . . . 48

Parts List - Pulley Assemblies (Gas) . . . . . . . . . . . . . .49

Parts - Dashboard / Battery Assemblies (Gas) . . . . . . . 50

Parts List - Dashboard / Battery Assemblies (Gas) . . 51

Parts - Motor / Hydraulic Assemblies (Propane) . . . . . . 52

Parts List - Motor / Hydraulic Assemblies (Propane) . 53

Parts - Propane Tank / Dashboard Assemblies (Propane)

54

Parts List - Propane Tank / Dashboard Assemblies

(Propane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Parts - Pulley Assemblies (Propane) . . . . . . . . . . . . . . . 56

Parts List - Pulley Assemblies (Propane) . . . . . . . . . . 57

Parts - Battery Assembly (Propane) . . . . . . . . . . . . . . . . 58

Parts List - Battery Assembly (Propane) . . . . . . . . . . . 59

Parts - Electrical Components (Electric) . . . . . . . . . . . .60

Parts List - Electrical Components (Electric) . . . . . . . 61

Parts - Hydraulic Motor Assemblies (Electric) . . . . . . . 62

Parts List - Hydraulic Motor Assemblies (Electric) . . . 63

Parts - Hydraulic Assembly (Electric) . . . . . . . . . . . . . . 64

Parts List - Hydraulic Tank Assembly (Electric) . . . . . 65

Parts - Pulley Assemblies (Electric - 480V & 380V) . . . 66

Parts List - Pulley Assemblies (Electric 480V & 380V) 67

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Gas Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Propane Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Electric Models (480V) . . . . . . . . . . . . . . . . . . . . . . . . 70

Electric Models (380V) . . . . . . . . . . . . . . . . . . . . . . . . 71

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

SMITH Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . 74

SMITH Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74