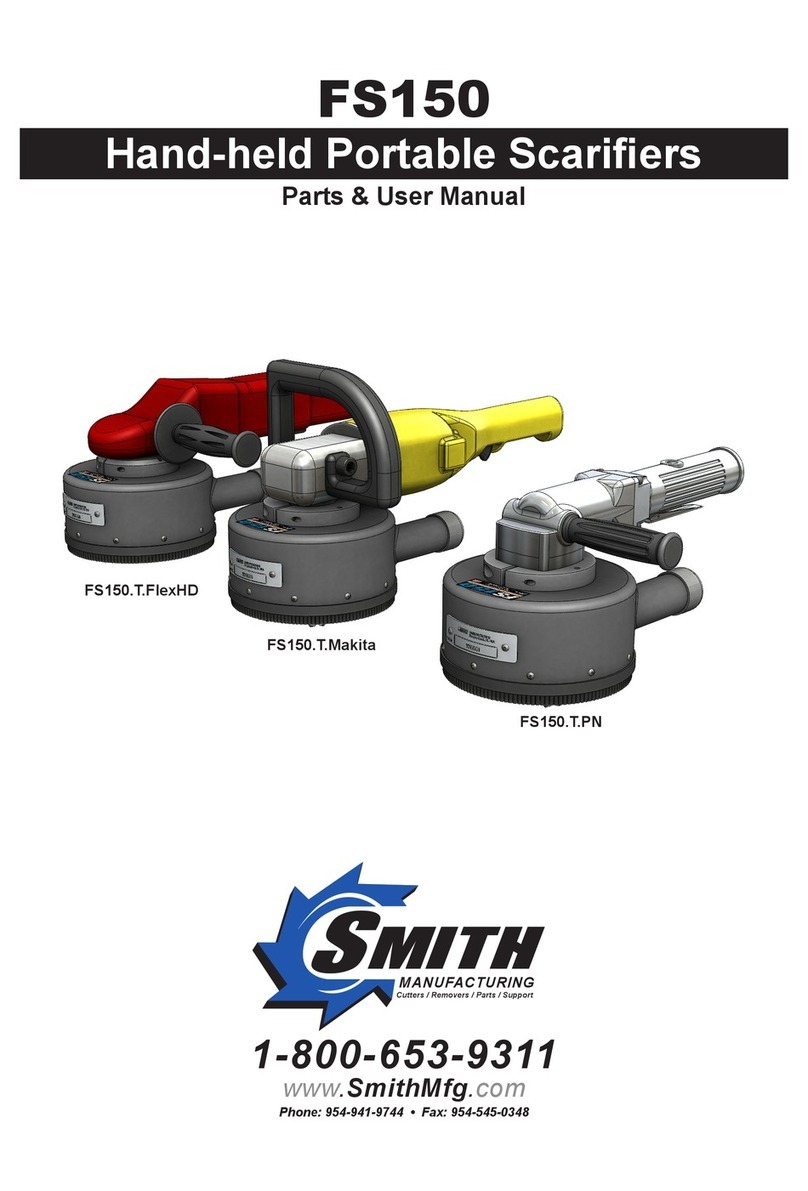

Smith SPS8 Gas User manual

SPS8 Gas

Multi-Use Surface Preparator

User Manual

(954) 941-9744

www.SMITHMFG.com

MANUFACTURING

Cutters / Removers / Parts / Support

1-800-653-9311

www.SmithMfg.com

3KRQH)D[

1p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

INTRODUCTION

2

Congratulations on purchasing

the SPS8™ Surface Preparator from

SMITH Mfg. Company.

Your machine will:

&OHDQVXUIDFHVLPSDFWHGE\JUHDVHRLO

SODVWLFVWDUVUHVLQVWLOHDGKHVLYHVLFHDQG

more

3ODQHRUPLOODVSKDOWDQGFRQFUHWHVXUIDFHV

5HPRYHKLJKVSRWVLQFXUEVDQGJXWWHUV

(OLPLQDWHWULSKD]DUGVRQFRQFUHWHVLGHZDONV

0LOODUHDVIRUUXPEOHVWULSV

&OHDQRXWFUDFNVDQGMRLQWV

&UHDWHDQWLVOLSSDWWHUQVLQZDONZD\VDQGEDUQV

3UHSDUHVXUIDFHVIRUQHZFRDWLQJDSSOLFDWLRQV

3HUPDQHQWO\UHPRYHDOOURDGDQGVXUIDFH

FRDWLQJVWRLQFOXGH

HSR[\XUHWKDQHWKHUPRSODVWLFSDLQW

JOXHEDFNHGWDSHVDQGPRUH

*URRYHLQOD\DVSKDOWIRUVWULSLQJ

BEFORE START-UP,

READ THIS..

3OHDVHUHDGDOORSHUDWLQJLQVWUXFWLRQVLQFOXGLQJ

WKHSURYLGHGHQJLQHPDQXDODQGEHFRPSOHWHO\

IDPLOLDUZLWK\RXUHTXLSPHQWEHIRUHRSHUDWLQJ

:KHQLQGRXEWSOHDVHFRQWDFW60,7+

0DQXIDFWXULQJ&XVWRPHU6HUYLFHIRURSHUDWLRQDO

GHWDLOV7KLV2ZQHU¶V0DQXDOZLOOJXLGH\RX

WKURXJKWKHUHPRYDOSURFHVVIURPVWDUWWR¿QLVK

DQGVKRZ\RXKRZWRFDUHIRU\RXUPDFKLQH

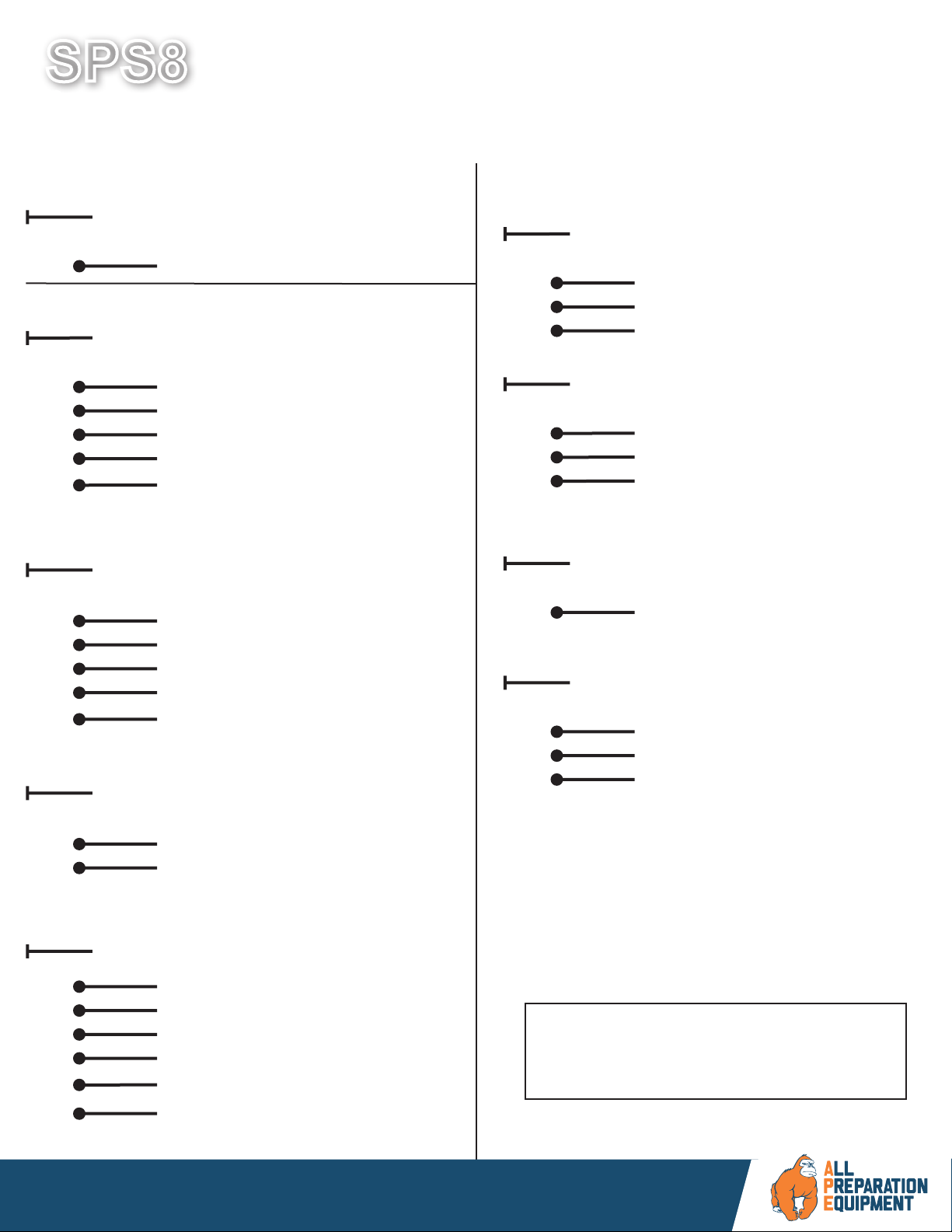

3DJH &RQWHQWV

2,QGH[,QWURGXFWLRQ

36DIHW\*XLGHOLQHV

4<RXU6366XUIDFH3UHSDUDWRU

50DFKLQH6WDUW8S

66XEVWUDWH5HPRYDO

76WRUDJH2UGHULQJDQG:DUUDQW\&ODLPV

7URXEOHVKRRWLQJ

90DLQWHQDQFH&KHFN/LVW

10 'UXP5HSODFHPHQW

11-13 %HOW5HSODFHPHQWDQG$OLJQPHQW

14-15 %HDULQJ5HSODFHPHQW

16-21 2SWLRQDO(TXLSPHQW

22-23 0DLQWHQDQFH/RJ

24 /LPLWHG(TXLSPHQW:DUUDQW\

25 :DUUDQW\$FWLYDWLRQ

INDEX

2p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

3

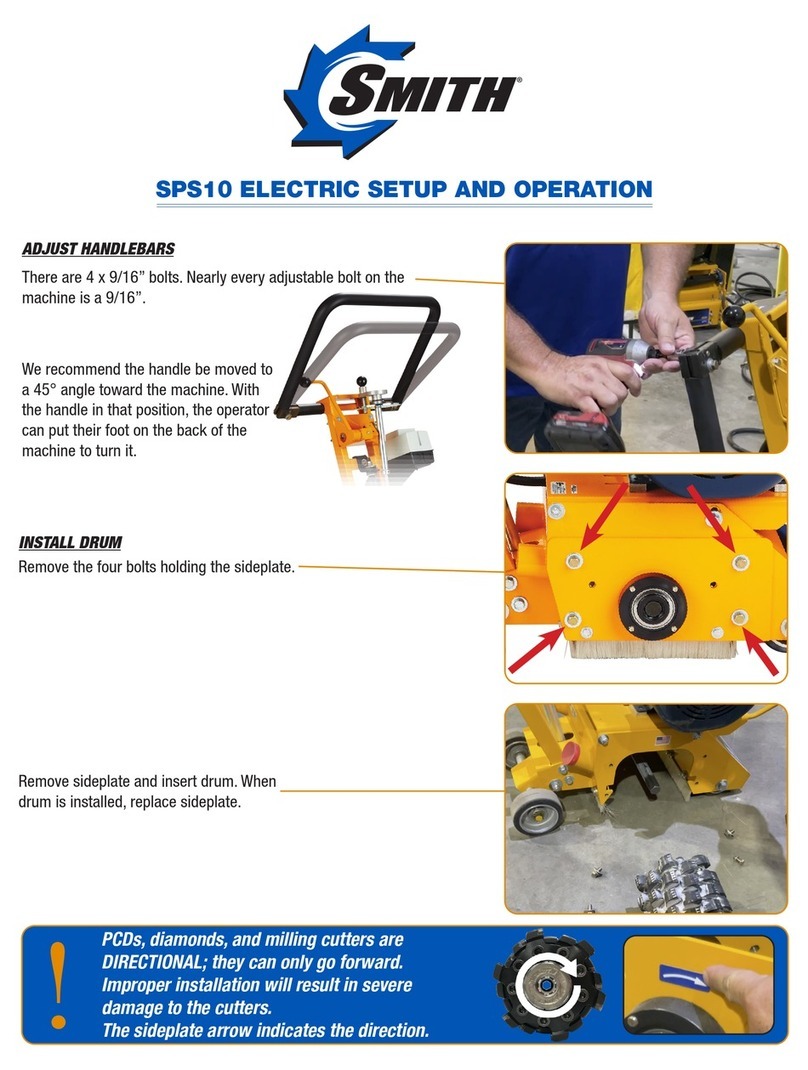

UNCRATING EQUIPMENT

:KHQ\RXXQFUDWH\RXUHTXLSPHQWPDNHFHUWDLQ

WKDWWKHPDFKLQHKDVQRWEHHQGDPDJHGDQG

WKDWDOOIDVWHQHUVDQGJXDUGVDUHSURSHUO\

WLJKWHQHG

<RXUPDFKLQHPD\QRWKDYHEHHQVKLSSHG

DVVHPEOHGZLWKFXWWHUVDQGRWKHUDFFHVVRULHV

$VVHPEO\PD\EHUHTXLUHG

REMEMBER:2QO\DXWKRUL]HGH[SHULHQFHGDQG

SURSHUO\WUDLQHGSHUVRQQHOVKRXOGRSHUDWHWKLV

HTXLSPHQW2SHUDWLQJSHUVRQQHOVKRXOG

SUDFWLFHVDIHW\DWDOOWLPHVDQGZHDUSURWHFWLYH

JHDUJORYHVJRJJOHVVDIHW\YHVWVHDUSOXJV

VWHHOWRHVKRHVHWF

$OZD\VZHDUSURWHFWLYHHTXLSPHQWLQFOXGLQJ

HDUSURWHFWLRQDQGJRJJOHV

1HYHUZHDUEDJJ\RUORRVH¿WWLQJFORWKLQJWKDW

FDQEHFDXJKWRQFRQWUROVRUPRYLQJSDUWV

7KHVXUIDFHSUHSDUDWRUFDQHPLWÀ\LQJ

SDUWLFOHVDQGGHEULVGXULQJRSHUDWLRQ1HYHU

RSHUDWHWKHPDFKLQHQHDUE\VWDQGHUVDQLPDOV

RUFKLOGUHQ

&KHFNÀXLGOHYHOVDQGJHWDFTXDLQWHGZLWK

WKHFRQWUROVHQJLQHNLOOVZLWFKDQGRWKHUVDIHW\

FRQWUROV

'RQRWRSHUDWHWKHPDFKLQHLQDQH[SORVLYH

DWPRVSKHUHQHDUFRPEXVWLEOHPDWHULDOVRU

ZKHQJDVIXPHVPD\QRWEHSURSHUO\GLVSHUVHG

5HSDLUDQ\IXHOOHDNVLPPHGLDWHO\DQGUHPRYH

DFFXPXODWHGGXVWIUHTXHQWO\IURPWKHDLU¿OWHU

V\VWHP

1HYHUOHDYHWKHPDFKLQHXQDWWHQGHGZKHQ

UXQQLQJDQG\RXPXVWKROGRQWRWKHKDQGOHZLWK

WZRKDQGVZKHQWKHFXWWHUGUXPLVHQJDJHG

$YRLGFRQWDFWZLWKWKHPXIÀHUZKHQWKHHQJLQH

LVKRWDVLWPD\FDXVHVHYHUHEXUQV

:KHQXVLQJDYDFXXPV\VWHPDYRLGKRVH

FRQWDFWZLWKWKHPXIÀHU

(QVXUHWKDWDOOJXDUGVDUHLQSODFHEHIRUHWKH

PDFKLQHLVRSHUDWHGVLQFHURWDWLQJDQGPRYLQJ

SDUWVZLOOFDXVHLQMXU\XSRQFRQWDFW

0DNHVXUHWKDWWKHHQJLQHLVVKXWGRZQDQG

WKHVSDUNSOXJLVGLVFRQQHFWHG

EHIRUHVHUYLFLQJ

Incorrect use of the surface preparator can

result in property damage, personal injury,

or death. Be sure to read and follow all

directions and precautions as outlined in

this manual.

SAFETY GUIDELINES

3p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

YOUR SPS8TM SURFACE PREPARATOR

3OHDVHWDNHWLPHWRIDPLOLDUL]H\RXUVHOIZLWKWKH636¶V

FRQWUROVDVZHOODVVRPHRIWKHIHDWXUHVRI\RXUQHZPDFKLQH

5HDGWKHHQJLQHPDQXDOEHIRUHSUHSDULQJWKHHQJLQHIRUVWDUWLQJ

2SWLRQDO(QJLQH0HWHU Throttle

&RUGHG³(QJLQH.LOO´%XWWRQ

)LQH$GMXVWPHQW+DQG:KHHO

&DP/HYHU

2LO'LSVWLFN

(QJLQH6KXW2II

*DV7DQN

5HPRYDEOH6LGH3ODWH

&KRNH

)XHO6XSSO\/HYHU

4

4p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

MACHINE START-UP

Do not start machine while drum is in

contact with the ground. Doing so can

cause the operator to lose control of the

machine, resulting in property damage

and/or personal injury.

NOTE: 'RQRWDWWHPSWWRUDLVHRUORZHUWKHFDP

OHYHUE\IRUFH,ILWGRHVQRWPRYHHIIRUWOHVVO\

UDLVHRUORZHUWKHKDQGZKHHOXQWLOWKHFDPOHYHU

FDQEHDGMXVWHG2SHQWKHIXHOFRFNRQWKH

FDUEXUHWRUDQGWKHQSODFHWKHWKURWWOHOHYHUDWWKH

³)DVW,GOH´SRVLWLRQ6WDUWWKHHQJLQHRSHQFKRNH

VOLJKWO\WRSUHYHQWÀRRGLQJ0RYHWKURWWOHFRQWURO

WRRSHQRUUXQSRVLWLRQZKHQHQJLQHLVZDUPHG

XS,QFUHDVHWKURWWOHWRPD[LPXPRSHUDWLQJ

SRVLWLRQDSSUR[530DQGFORVHFKRNH

%HIRUHVXEVWUDWHUHPRYDOWHVWUXQWKHGUXP

ZLWKFXWWHUVQRWWRXFKLQJWKHVXUIDFH,IWKHUHLV

H[FHVVLYHYLEUDWLRQ\RXQHHGWRUHEDODQFHWKH

FXWWHUVHWXSFKHFNEHDULQJFRQGLWLRQDQGRU

PDNHVXUHWKDWWKHGULYHVKDIWLVVHFXUHG

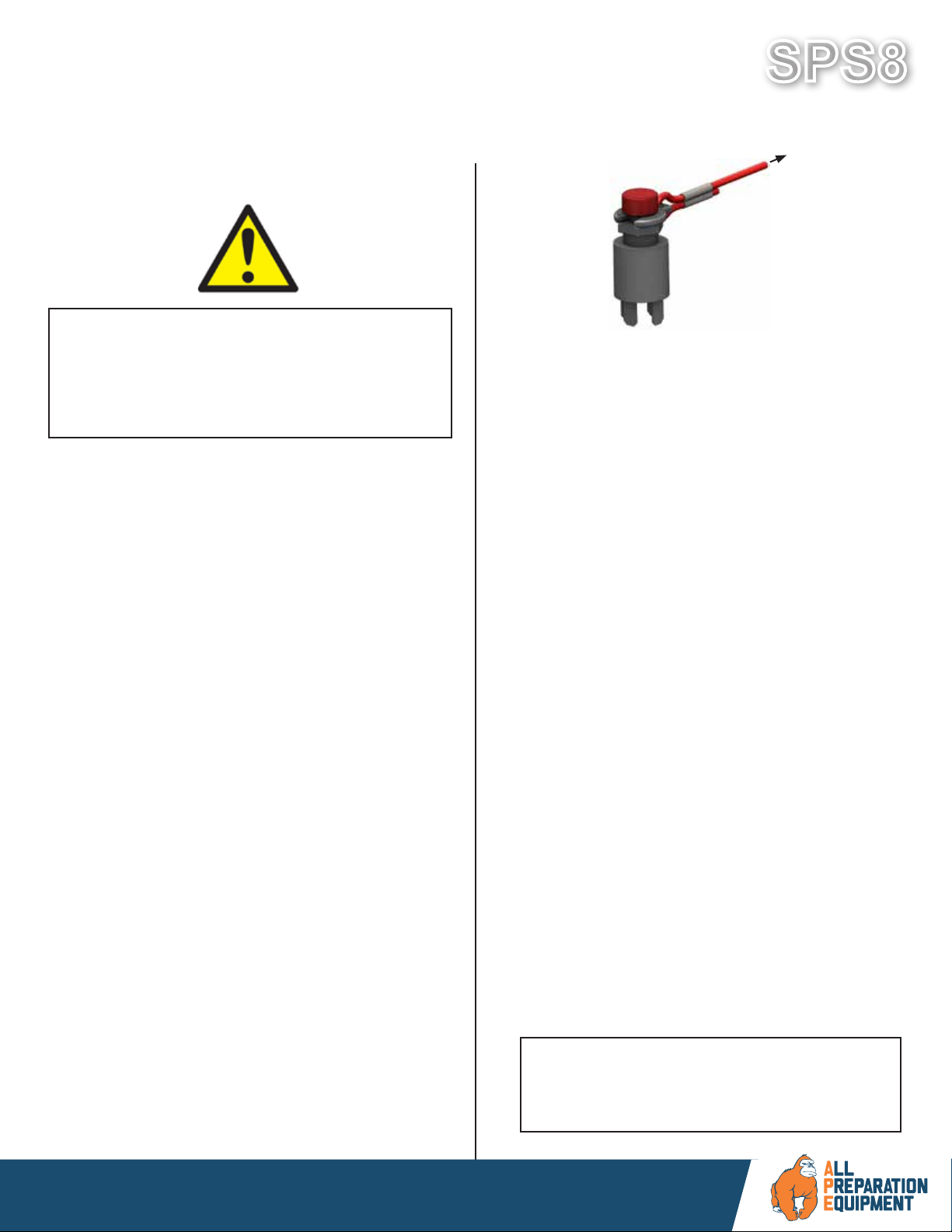

Corded “Engine Kill” Button (not available

on electric motor): ,QWKHHYHQWRID

PDOIXQFWLRQRUDQDFFLGHQWVXFKDVWKH

PDFKLQHRSHUDWRUIDOOLQJRUORVLQJIRRWLQJWKH

636LVHTXLSSHGZLWKDFRUGHG³(QJLQH.LOO´

%XWWRQ$WWDFKWKHHQGRIWKHFRUGWRWKH

RSHUDWRU¶VEHOWRUZULVWDQGVQDSWKHFOLSLQWR

SODFHRQWKHVWRSVZLWFKE\UDLVLQJWKHWRSRI

WKH(QJLQH.LOO%XWWRQDQGLQVHUWLQJWKHFOLSLQWR

WKHJDS,IWKHRSHUDWRUEHFRPHVGLVWDQFHGWRR

IDUIURPWKHPDFKLQHWKHFRUGZLOOGHWDFKIURP

WKHVWRSVZLWFKDQGWKHPDFKLQHZLOOVWRS

running.

$WWDFKWR

RSHUDWRU

*NOTE: the Engine will not start without the

Corded Engine Kill’s clip securely in place.

CAUTION: The machine will still move with

the engine off.

IF THE ENGINE DOES NOT

START

&KHFN(QJLQHIRUSURSHUJDVDQGRLOOHYHOV

UHIHUWR(QJLQHPDQXDO

&KHFNVSDUNSOXJ0DNHVXUHWKHVRFNHW

DUHDVDUHFOHDQDQGFOHDURIGHEULVDQGWKDW

WKHSURSHUJDSLVVHW5HSODFHLIQHHGHG

&KHFN%URZQ(OHFWULFDOFOLSKDQJLQJRQWKH

IURQWRIWKHHQJLQHDQGHQVXUHWKDWWKH

HOHFWULFDOZLUHVDUHPDNLQJFRQWDFWZLWKLQWKH

FOLS

7XUQWKH2Q2IIVZLWFKRQWKHIURQWRIWKH

(QJLQHWR³2Q´

&KHFN&RUGHG(QJLQH.LOO%XWWRQ¶V

&RQQHFWLRQV

D0DNHVXUHWKH&RUGHG6DIHW\6WRS³&´

&RQQHFWRULVFOLSSHGSURSHUO\

E7U\VZLWFKLQJWKHFRQQHFWLRQWRWKHRSS

RVLWHSRVW)URPOHWWHU³&´WROHWWHU³0´IRU

H[DPSOH

(QJLQHPD\KDYHWLOWHGEDFNZDUGV,IVR

DOORZRLOWRGUDLQDIWHUUHPRYLQJVSDUNSOXJDQG

SXOOLQJVWDUWHUFRUGVHYHUDOWLPHV

*Engine repair and engine warranty

issues are handled directly

by your local engine service center.

5

5p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SUBSTRATE REMOVAL

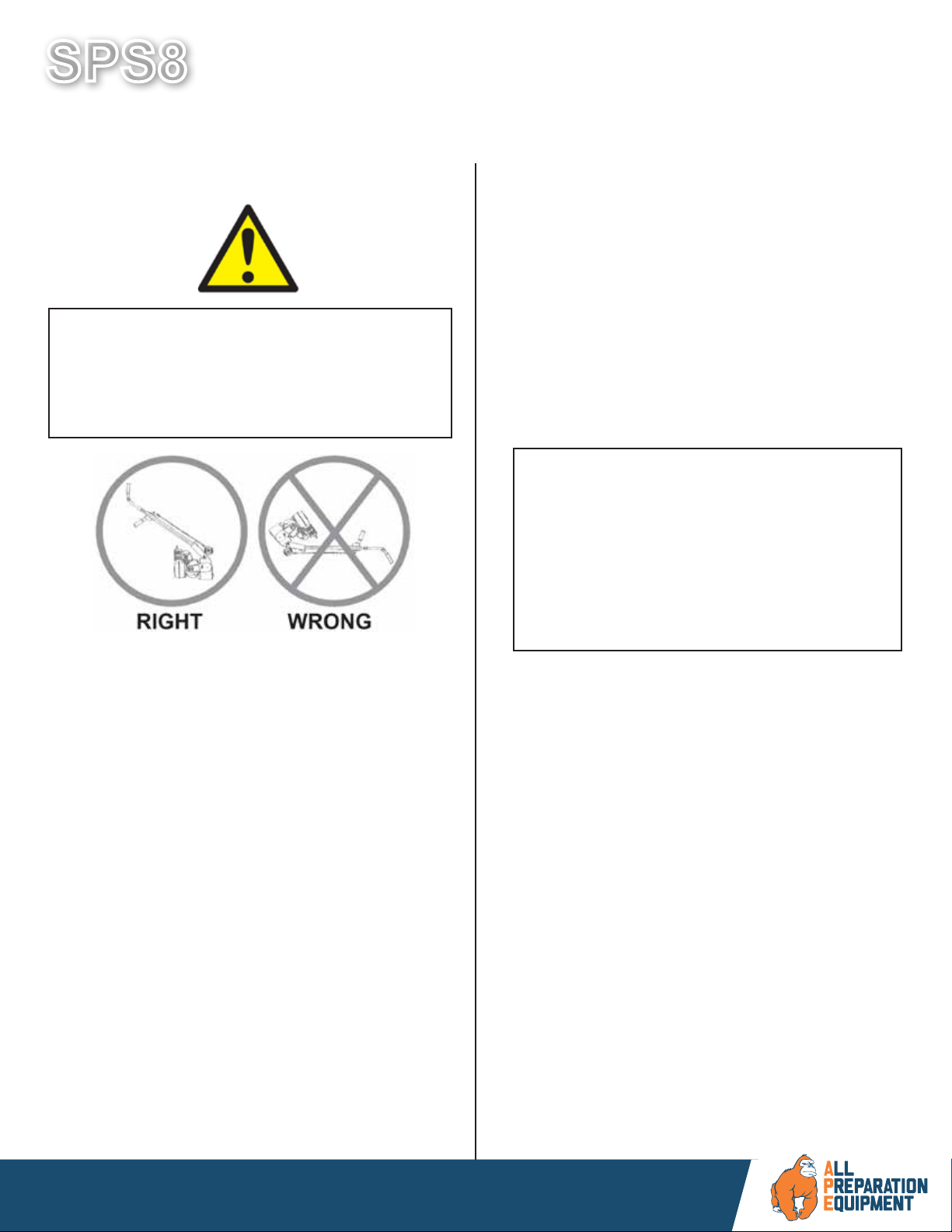

Warning: Should you desire to tilt the

machine, always tilt forward. Tilting the

PDFKLQHEDFNZDUGVDWDQ\WLPHZLOOÀRRG

the spark plug with oil and may cause

damage to your engine!

$GMXVWWKHKHLJKWRIWKHFXWWHUGUXPZLWK

WKH+DQG:KHHODQG&DP/HYHU7XUQWKH

KDQGZKHHOWRUDLVHWKHFXWWHUGUXPRIIRIWKH

VXEVWUDWH/RZHURUUDLVHWKHFDPOHYHUWR

HQJDJHRUGLVHQJDJHWKHGUXPDIWHUVHWWLQJ

WKHSURSHUFXWWHUGHSWK

6HWWKHGHSWKRIFXWWRDOORZWKHFXWWHUVWRJR

WKURXJKRQO\WKHPDWHULDOVWREHUHPRYHG

0DNHFHUWDLQWKDWWKHGUXPLVSRVLWLRQHGWR

ZKHUHRQO\WKHFXWWHUVVWULNHWKHVXUIDFH

DQGWKDWWKHGUXPDVVHPEO\QHYHUFRPHV

LQWRFRQWDFWZLWKWKHVXEVWUDWHThe cutter

tips alone should strike the surface´

WR´PD[LPXPGHSWKSHUUHPRYDOSDVVRQ

QHZFXWWHUV

7KHGUXPZLOOQRWZLWKVWDQGVXEVWUDWH

contact. Contacting the removal surface

too deeply will cause premature wear to

cutters, shafts, drum and other

components!

7RRPXFKGRZQZDUGSUHVVXUHRQO\KDV

QHJDWLYHUHVXOWV7U\WRUHPRYHPDWHULDOVLQ

VHYHUDOSDVVHVUDWKHUWKDQRQHGHHSSDVV

6HYHUDOWHVWVZLOOVKRZWKHEHVWPRVW

DSSURSULDWHFXWWHULPSDFW8VHDIRUZDUG

EDFNZDUGDQGRUFLUFXODUSDWWHUQWRDFKLHYH

\RXUGHVLUHG¿QLVK

NOTE: 2QO\XVHDIRUZDUGPRWLRQZKHQWKH

&0RU&0FDUELGHPLOOLQJFXWWHUV

DUHXVHG

TIP: 3RVLWLRQLQJWKHPDFKLQHRYHUWKH

VXUIDFHLQPDQ\GLUHFWLRQVDVZHOODV

GLDOLQJWKHKDQGZKHHOXSRUGRZQFDQKHOS

FUHDWHGHVLUDEOHVXUIDFHSDWWHUQV

$IWHUVHYHUDOKRXUVRISUDFWLFHWKHRSHUDWRU

ZLOOEHFRPHFRPIRUWDEOHDQGVKRXOGEHDEOH

WRUHPRYHPDWHULDOVIDVWHUZLWKHQKDQFHG

UHVXOWV

:KHQWKHMRELVFRPSOHWHGRUWKHRSHUDWRU

ZDQWVWRFHDVHZRUNVWRSWKHHQJLQHE\¿UVW

OLIWLQJWKHGUXPDERYHWKHVXEVWUDWHXVLQJWKH

KDQGZKHHODQGRUWKHFDPOHYHU6WRSWKH

PDFKLQHRQO\DWWKHHQJLQH7KHQFORVHWKH

IXHOFRFNWRVKXWRIIWKHIXHOVXSSO\

7KHGUXPDVVHPEO\PXVWEHUHPRYHGGDLO\

DQGLQVSHFWHGIRUGUXPZHDUKROH

HORQJDWLRQDQGSRVVLEOHZHOGVHSDUDWLRQ

5HSODFHWKHFXWWHUVKDIWVDQGGUXPEXVKLQJV

HYHU\KRXUVRUSULRUWRDQ\GUXPZHDU,I

WKHGUXP¶VFHQWHUKROHVDUHHORQJDWHGRUGHU

DQRWKHU60,7+FXWWHUGUXP

6

6p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

STORAGE

6KXWRIIIXHOYDOYHDQGUHPRYHDOOIXHORU

DGGIXHOVWDELOL]HU6WDUWHQJLQHDQGUXQXQWLO

LWVWDOOV5HPRYHVSDUNSOXJDQGSRXUWZR

RXQFHVRIPRWRURLOLQWRF\OLQGHUDQGVORZO\

FUDQNWKHHQJLQHE\KDQGWRGLVWULEXWHRLOWR

SUHYHQWUXVWGXULQJVWRUDJH5HSODFHVSDUN

SOXJDQGVWRUHPDFKLQHXSULJKWLQDFRROGU\

DQGZHOOYHQWLODWHGDUHD

ORDERING

To ensure product safety and reliability,

and to maintain your warranty, always use

genuine replacement cutters and parts

from SMITH when making repairs to the

equipment.

:KHQRUGHULQJSOHDVHVSHFLI\WKHPRGHODQG

VHULDOQXPEHURIWKHPDFKLQH,QDGGLWLRQJLYH

DSDUWQXPEHUGHVFULSWLRQDQGTXDQWLW\DV

OLVWHGRQ\RXUSDUWVOLVW

,I\RXKDYHDQ\TXHVWLRQVDERXWWKHRSHUDWLRQ

RI\RXUPDFKLQHRUZRXOGOLNHWRRUGHU

UHSODFHPHQWSDUWVFRQWDFW\RXU60,7+

0DQXIDFWXULQJUHSUHVHQWDWLYHGLUHFWO\

&RQWDFW

for information.

9LVLWRXUZHEVLWHDW

www.smithmfg.com

WARRANTY CLAIMS

7KHPDQXIDFWXUHUUHVHUYHVWKHULJKWWR

FKDQJHRULPSURYHWKHPDFKLQHGHVLJQZLWK-

RXWDVVXPLQJDQ\REOLJDWLRQWRXSGDWHDQ\

SURGXFWVSUHYLRXVO\PDQXIDFWXUHGEHIRUH

WKLVPDQXDO,WLVWKHFXVWRPHU¶VUHVSRQVLELO-

LW\WRFRPSOHWHWKHZDUUDQW\FDUGDQGPDLOLW

WRWKHVHOOHUZLWKLQGD\VIURPGDWHRISXU-

FKDVH,IDIDLOXUHRFFXUVGXULQJWKHZDUUDQW\

SHULRGWKHFXVWRPHUPXVWFRQWDFWWKHVHOOHU

WRGHWHUPLQHWKHDSSURSULDWHDFWLRQ

Any and all transportation charges are to

be borne by the purchaser.

7

7p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

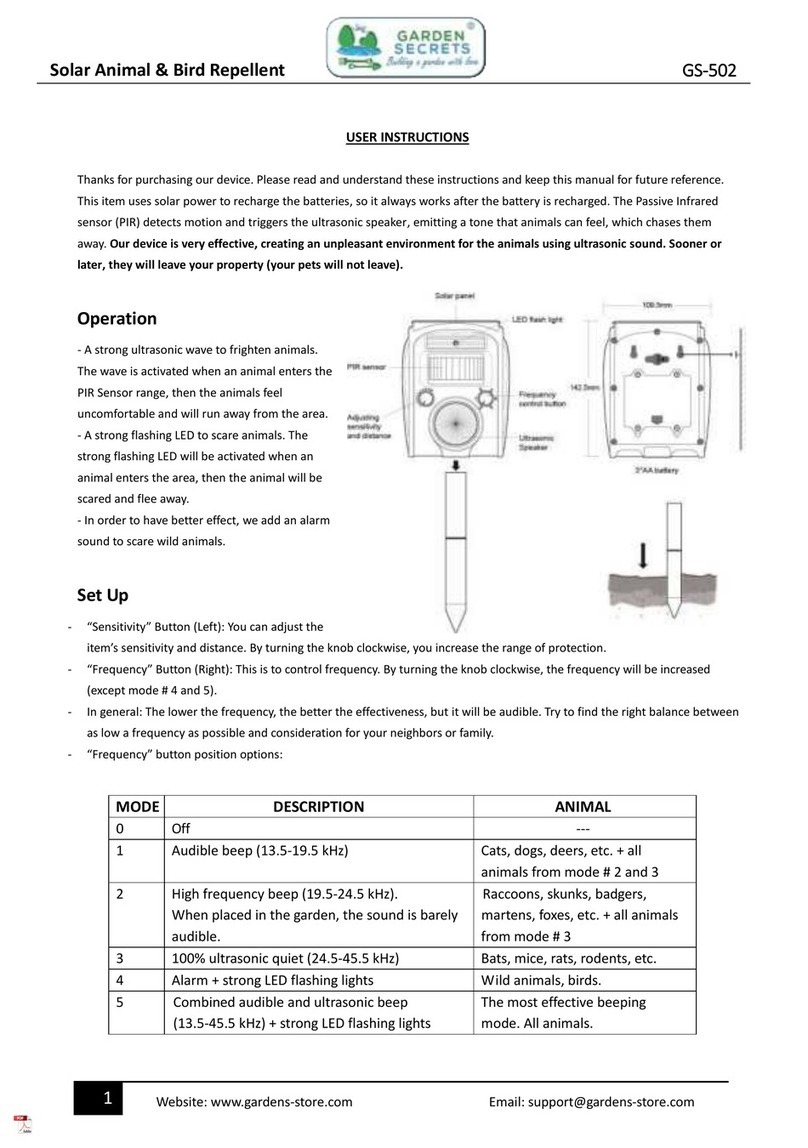

TROUBLESHOOTING

PROBLEM

Possible Reason(s)/Solution(s)

CUTTERS WEARING

UNEVENLY/PREMATURELY

Drum is too low

Incorrect set-up

Material Build-up

Cutters too tightly loaded

Wrong cutters for

application

CUTTERS SHAFT BREAKAGE

UNEVENLY/PREMATURELY

Drum is too low

End plates or bushings worn

Shafts worn

Wrong cutter set-up

Over 40 hours service-life

DRUM WEARING

PREMATURELY OR CRACKING

Drum hitting ground

Shafts and bushings not replaced

within 40 hours

EXCESS VIBRATION

Bearing worn

Hex bushing worn

Drive shaft worn

Improper cutter set-up

Drum contacting ground

Wheels worn out

MACHINE JUMPS

ERRATICALLY

Drum hitting ground

RPM is too low

Surface is severely uneven

DRIVE BELT WEARING

PREMATURELY

Pulley is misaligned

Wrong belt

Drum is contacting

the surface

CAM LEVER WILL NOT

RAISE/LOWER

Raise or lower hand-wheel

HAND-WHEEL WON’T

TURN

Clean & grease threads

Linkage may be bent

Hand-wheel may be

out of position

*Engine repair and engine warranty

issues are handled directly

by your local engine service center.

)RUDQ\RWKHUSUREOHPVRUTXHVWLRQV

SOHDVHFRQWDFW\RXUORFDOUHSUHVHQWDWLYH

or

60,7+0IJWRGD\DW

or

8p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

MAINTENANCE CHECK LIST

Note: 0DNHVXUHWKHLJQLWLRQLVLQWKHOFF

SRVLWLRQDQGWKHVSDUNSOXJLVGLVFRQQHFWHG

EHIRUHVHUYLFLQJ

0DLQWDLQ SURSHU HQJLQH RLO DQG FUDQNFDVH

OHYHOV

&KDQJHHYHU\KRXUV

VHH+RQGDPDQXDO

&OHDQ VSDUN SOXJV UHJXODUO\ DQG VHW WKH

SURSHUJDS

:DVKWKHDLUFOHDQHUHOHPHQWLQDQRQ

RLOEDVHGVROYHQWWKHQVTXHH]HRXWUHVLGXH

$OORZ¿OWHUWRGU\EHIRUHUHLQVWDOOLQJLQFOHDQHU

.HHSDFRDWLQJRIJUHDVHRQWKHGULYHVKDIW

DQGWKUHDGVIRUHDV\LQVWDOODWLRQRUUHPRYDO

DQGIRUORQJHUKH[EXVKLQJOLIH

*UHDVH WKH WLOW OHYHU ORZHU OLQNDJH &OHDQ

GLUWRIIRI¿WWLQJVEHIRUHJUHDVLQJ

&KHFNDOOIDVWHQHUVDQGUHWLJKWHQVLQFHWKH

PDFKLQHZLOOYLEUDWHWKHIDVWHQHUVORRVHLIWKH\

DUHQRWVHFXUHG8VHORFNWLJKW

7KLVLQFOXGHV

$%RWKVHWVFUHZV31DOLJQHGRQ

KH[VKDIW31DUHWRUTXHGWLJKW

% $OO WKUHH KH[ %ROWV 31 RQ

GUXPUHWDLQLQJSODWH310XVWEH

DOLJQHGDQGWLJKW

&KHFN WKH 'ULYH EHOW IRU ZHDU DQG DGMXVW

WLJKWHQRUUHSODFHDVUHTXLUHG

&KHFNWKDWWKHSXOOH\VDUHDOLJQHGSURSHUO\

WRHQVXUHWKH'ULYHEHOWLVUXQQLQJWUXH

&KHFNZKHHOIRUZHDUDQGWKDWWKH\DUH

URWDWLQJ SURSHUO\ UHSODFH LI ZRUQ &OHDQ

ZKHHOVRIPDWHULDOEXLOGXS

7KHLQVLGHKRXVLQJPXVWEHFOHDQDQG

UHPRYHDQ\EXLOGXSIURPLQVLGHWKHFDJHVR

FXWWHUVDQGGUXPURWDWHIUHHO\

,QVSHFW DQG FKDQJH GUXP EXVKLQJV DQG

VKDIWVHYHU\KRXUVRUZKHQZRUQ

9

9p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

DRUM REPLACEMENT

Normal use will require periodic drum in-

spection and may necessitate drum replace-

ment.

Time of replacement will vary according to

usage and load factors.

Replacement is easy and requires a few hand

tools.

1. 3/4” socket or wrench

2. 1” open-end wrench

3. 1” socket or second 1” wrench

4. Rubber mallet

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

$ *TIP: SMITH recommends owning an extra

drum loaded with cutters for rapid job-sight

replacements, and to ensure that the 6 cut-

ter shafts and 12 drum bushings are replaced

every 40 hours, or prior to bushing wear, to

increase the life of the drum.

10

1. Tip the machine over towards the FRONT

as shown below. Remove the belt guard

using the 3/4” socket or wrench (A) and

place the 1” wrench over the hex shaft to

prevent it from rotating (B).

%

2. With the shaft rotation locked, remove

the 2 hex nuts locking it in place using a 1”

socket or a second wrench.

***NOTE: Hex nuts are LEFT HANDED

THREAD meaning they loosen in the

clockwise direction ***

2QFH WKH KH[ QXWV DUH RII ¿UVW VXSSRUW

the drum and then remove the shaft by slid-

ing it out towards the sideplate side of the

machine. (use precaution as it is HEAVY)

10 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

BELT REPLACEMENT

Normal wear may necessitate belt

tensioning or replacement.

Time of replacement will vary according to

usage and belt load factors.

Replacement is easy and requires a few

hand tools.

1. Two 9/16” wrenches

2. 3/4” wrench

3. 3/8” open-end wrench

4. Carpenters square or a straightedge

5. WD40

6. Spark plug wrench

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Make sure the removable side cover is

installed. This ensures the drive ends are in

the proper position for servicing.

2. Disconnect the spark plug.

3. Clean the machine exterior so you can

locate all the appropriate parts.

4. Using a 3/4” wrench, remove the two

acorn nuts attaching the belt cover to the

side of the machine. Remove the cover and

set it aside.

5. Lubricate the motor plate (belt

tensioning) jackscrew with WD40 on the

front left of the machine.

6. Use a 9/16” wrench to loosen the jack-

screw jam nut.

7. Using the 3/8” open-end wrench, begin to

screw the motor plate jackscrew back into

the long hex nut below it. Continue to screw

it in until resistance is felt.

11

11 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

BELT REPLACEMENT

(CONTINUED)

8. Loosen (do not remove) the four bolts (2

per side) that secure the motor mount plate

to the main machine frame.

9. Loosen the four bolts attaching the

PRWRUWRWKHPRWRUSODWH$IWHUVXI¿FLHQWO\

loosening all four, slide the motor back all

the way to the rear. This will loosen the belt

VXI¿FLHQWO\WRUHPRYHLW

10. Either cut or roll off the belt from the

pulleys. If you roll it off, move it over one

groove at a time on the upper and lower

pulleys to completely remove it

11. Roll the new belt on one groove at a

time (two or single multi-groove belt) on

both the top and bottom pulleys.

12. Using the straight edge, lay it across the

lower pulley outer face and against the

upper pulley. They must be directly over

top of each other to ensure optimum belt

life. If adjustment is required, align before

tensioning the belt.

13. After installation, use the 3/8” open-end

wrench to screw out the belt tensioning

jackscrew under the motor plate to tension

the belts to your desired tension. Do not

over-tension the belt.

14. After the correct tension is reached,

tighten the front motor plate securing screw

on the belt side with the 9/16” box end

wrench.

15. Now from the front of the machine

observe the motor plate to machine

alignment. Tightening the belts with the

jackscrew tends to cause the right side of

the motor plate to lift higher than the left

side. By pushing down on the right front

side you can level the plate and then

tighten the front right screw to secure in a

level position.

12

12 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

BELT REPLACEMENT

(CONTINUED)

18. Replace the belt cover using the 3/4“

box wrench.

19. Replace the spark plug and the spark

plug wire.

16. Now tighten the rear securing bolts with

the two 9/16” wrenches.

17. Tighten the motor plate jackscrew re-

taining nut with a 9/16” wrench to prevent it

from turning.

BELT ALIGNMENT

If the unit has premature belt wear, breakage

or pulley problems, the issue may be

incorrect alignment or excessive belt

tensioning. All pulleys must be aligned

directly above each other to ensure belt

integrity. This includes possible timing belts

used on newer models. Incorrect alignment

wears the sides of the belts excessively and

will cause slippage.

1. Use a long straight edge (carpenters

square) to check alignment during belt

tensioning or belt replacement time.

2. By laying the straight edge against the

outer face of the lower pulley, the square will

extend up and rest against the outer face of

the upper (engine pulley). If not, move the

motor pulley in or out to obtain alignment.

3. If replacing pulleys (top or bottom) be sure

to place the pulley on the same plane as the

original one to ensure alignment.

13

13 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

BEARING REPLACEMENT

Before reading ahead go back and follow

the instructions on how to remove the belt

from the machine. Bearing replacement is

easy and requires a few additional hand

tools.

1. 7/16” socket or wrench

2. 1/2” socket or wrench

3. 1” open-end wrench

4. 1” socket or second 1” wrench

4. C-clip removal pliers

5. 5/32” Hex Key

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Once the belt is removed from the ma-

chine, tip the machine over towards the

FRONT and place the 1” wrench over the

hex shaft to prevent it from rotating.

2. With the shaft rotation locked, remove

the 2 hex nuts locking it in place using a 1”

socket or a second wrench.

***NOTE: Hex nuts are LEFT HANDED

THREAD meaning they loosen in the clock-

wise direction ***

Once the hex nuts are off, you can remove

the shaft by sliding it out towards the side-

plate side of the machine.

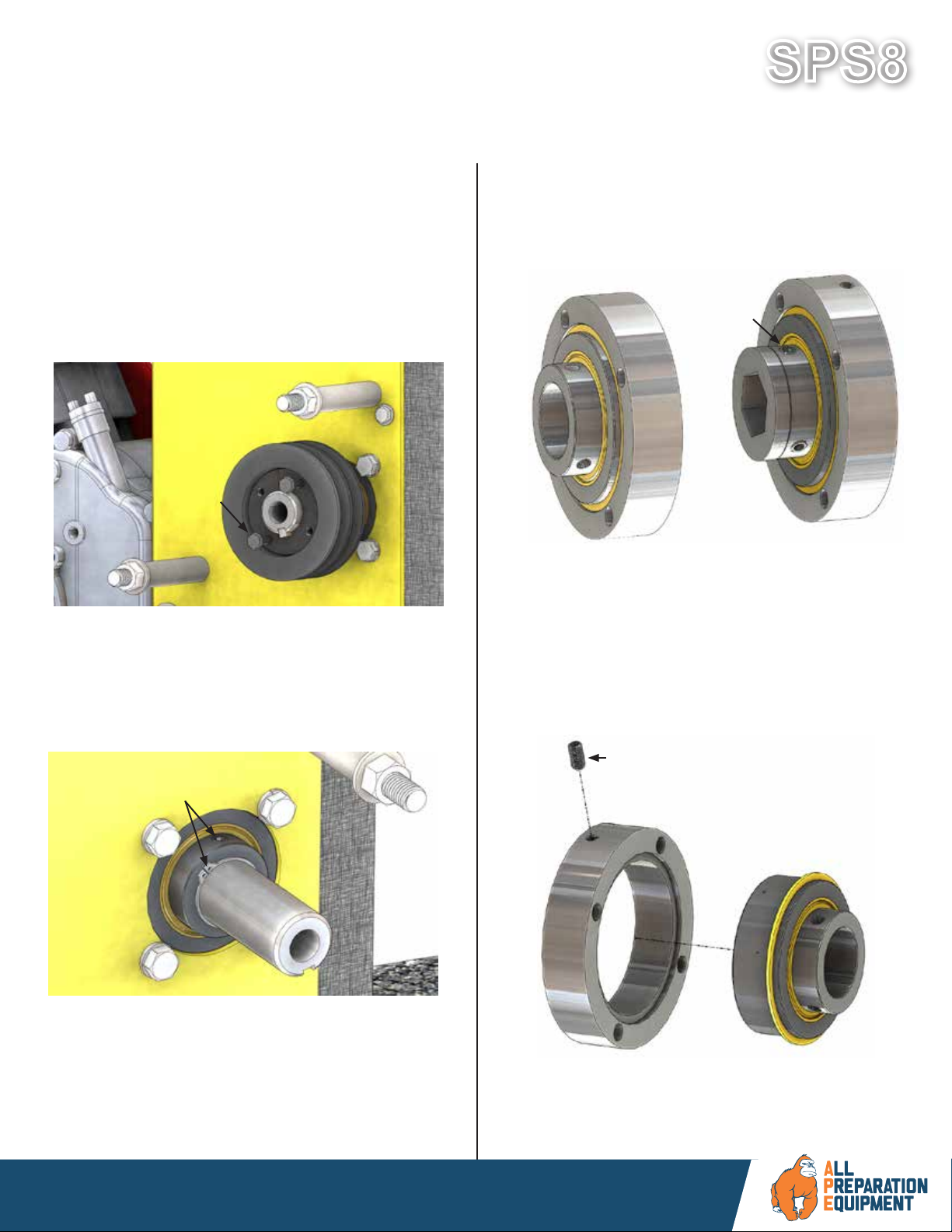

3A. Remove the 2 screws in the pulley bush-

ing using the 7/16” socket and insert them

by hand into the 2 threaded holes as shown

¿JXUH%

$

14

14 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

BEARING REPLACEMENT

(CONTINUED)

6. At this point remove the hex bushings

from the side plate side bearing assembly

by removing the set screws using the 5/32”

hex key.

%(/76,'(

7. With the hex bushings out, the both the

bearings and housings are the same. To

remove the bearing from the housing use

the 1/8” hex key to remove the set screw on

the housing and then tap out the bearing us-

ing a mallet.

8. Reverse the process and apply thread

ORFNLQJÀXLGORFWLWHWRWKHVHWVFUHZV

3B. Once both screws are in, begin to turn

them using a socket and do so EVENLY

in order to allow the bushing to back out

smoothly. Once the bushing is out, remove

the pulley and key.

%

4. At this point the shaft driver must be

removed by using the C-clip removal pliers

for the retaining ring and a 5/32” hex key for

the 2 set screws.

5. Remove the bearing assemblies on both

sides on the machine using the 9/16” socket

15

15 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

OPTIONAL EQUIPMENT

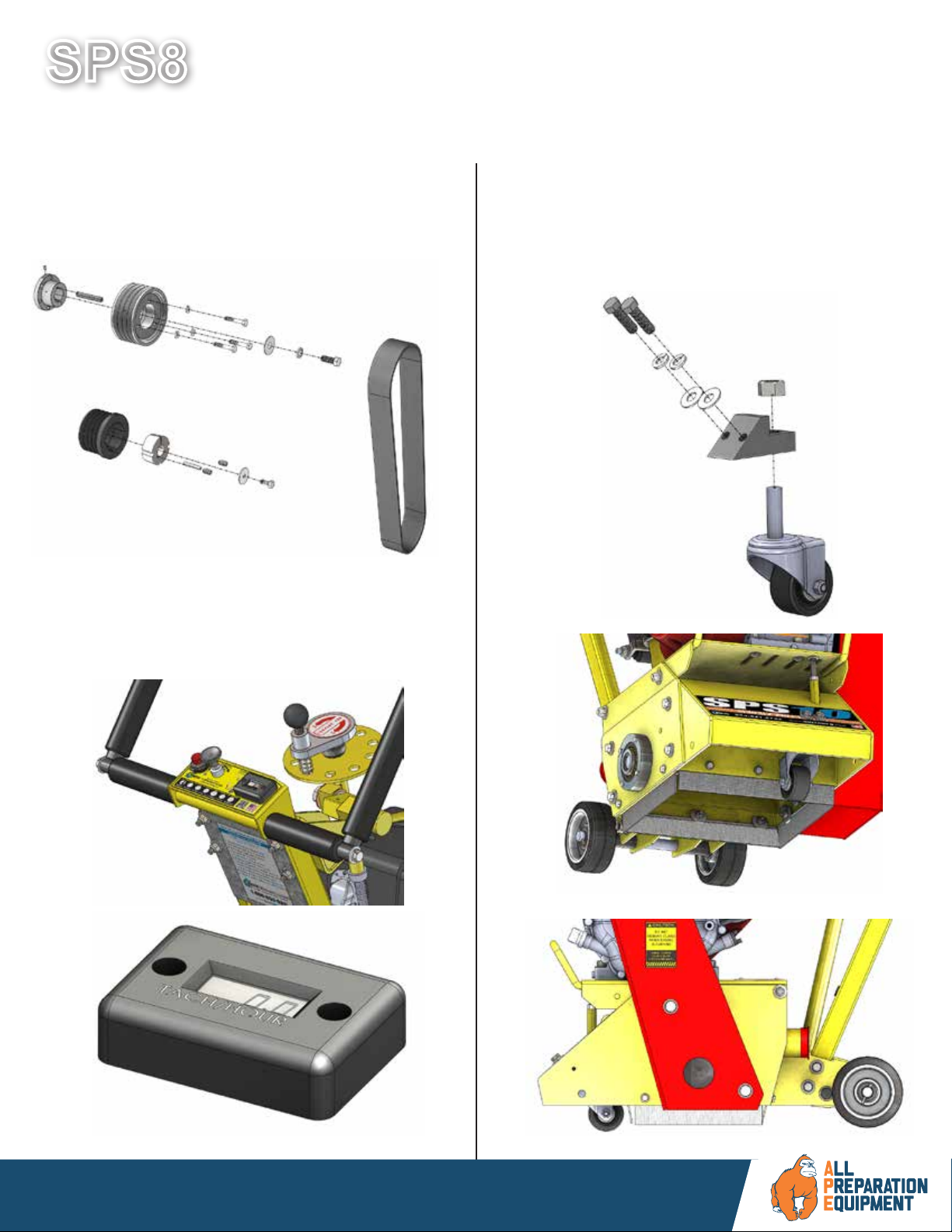

t HIGH SPEED KIT

7KHKLJKVSHHGNLWLVXVHGZLWKWKH'LDPRQG

6KDYHLW'UXP$VVHPEO\21/<

t TACH/HOUR METER

0DLQWHQDQFHPHWHUIRUVHUYLFHDQGXVH

control

t SWIVEL WHEEL

7KH VZLYHO ZKHHO DOORZV \RX WR PRYH WKH

PDFKLQH QRW RQO\ IRUZDUG DQG EDFNZDUG LQ

DVWUDLJKWOLQHEXWDOVRIURPside to side to

eliminate grooves!

SHOWN ON SPS10, SPS8 COMPATIBLE

16

16 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

OPTIONAL EQUIPMENT

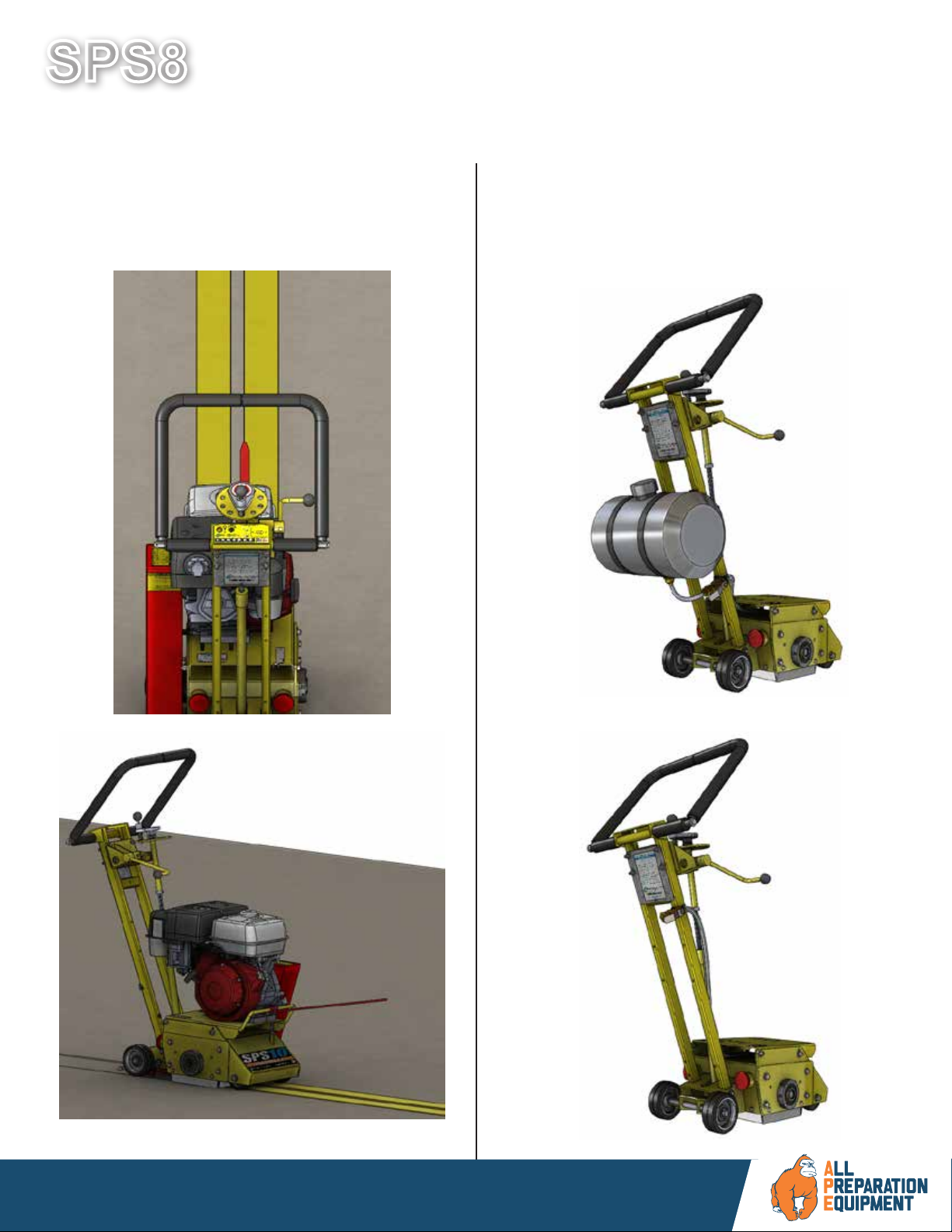

t SPS CRADLE

&DP5HOHDVH$GMXVWPHQW'DPSHQHU/LIH

([WHQGHU VKRFN DVVHPEO\ SUHYHQWV KDUG

GUXPGURSV

t CENTER STAND BRAKE KIT

7KH &HQWHU 6WDQG %UDNH .LW DOORZV IRU VDIH

³SDUNLQJ´RIWKH636RQLQFOLQHGVXUIDFHV

SHOWN ON SPS10, SPS8 COMPATIBLE

17

17 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

OPTIONAL EQUIPMENT

t POINTER/DIRECTIONAL

SIGHT GUIDE SYSTEM

$OORZVRSHUDWRUWRPDNHVWUDLJKWSDVVHV

HDVLHU

t WATER CONTROLS

8VHGWRH[WHQGOLIHRQ'LDPRQGGUXP

DSSOLFDWLRQVDQGIRUGXVWFRQWURORQDOORWKHUV

$YDLODEOHZLWKRUZLWKRXWJDOORQWDQN

SHOWN ON SPS10, SPS8 COMPATIBLE

18 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 10/2016

SPS8

Gas

OPTIONAL EQUIPMENT

t BALL MOUNT HITCH

$OORZVDWWDFKPHQWWRRWKHUFRPSRQHQWV

t EDGER DRUM ASSEMBLY

$YDLODEOHIRU'LDPRQGEODGHVDQGFXWWHU

DSSOLFDWLRQV

SHOWN ON SPS10, SPS8 COMPATIBLE

19

19 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS8

VERSION 10/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

OPTIONAL EQUIPMENT

t UP-CUT CART

,QFUHDVHVUHPRYDOVSHHGXSWR;IDVWHUWKDQ

SXVKLQJ

t SR-25 DRIVER

+\GURVWDWLF 5LGHRQ JDV SRZHUHG 'ULYHU IRU

TXLFNDQGHDV\DWWDFKPHQW%DOO0RXQW+LWFK

UHTXLUHG

SHOWN ON SPS10, SPS8 COMPATIBLE

20

20 p1800 422 992

Wwww.allprep.com.au

E sales@allprep.com.au

A1/40 rivergate place, murarrie

Table of contents

Other Smith Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Bartell

Bartell CONTEC CT320 Owner's manual and parts book

Peco

Peco PRO 3 BAGGER Operator's manual

Volpi

Volpi Giulivo Operation and maintenance manual

Buhler

Buhler Landscape Rake FK349 Operator's & parts manual

Poulan Pro

Poulan Pro 917GWN42A installation instructions

Lil Gro

Lil Gro Veg Wedge Assembly manual