Introduction Service Diagrams Parts Accessories Reference

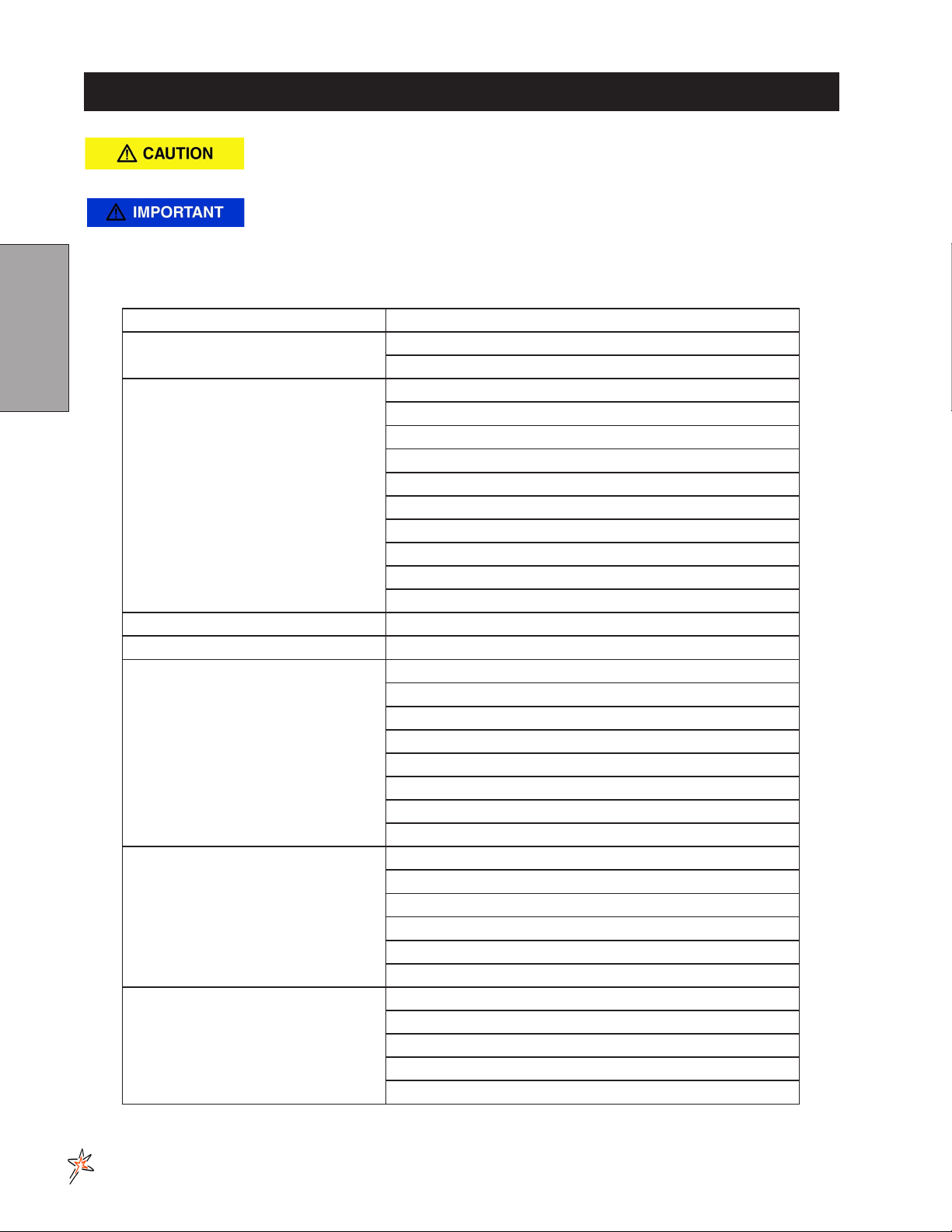

CONTENTS

Introduction..........................................................1-3

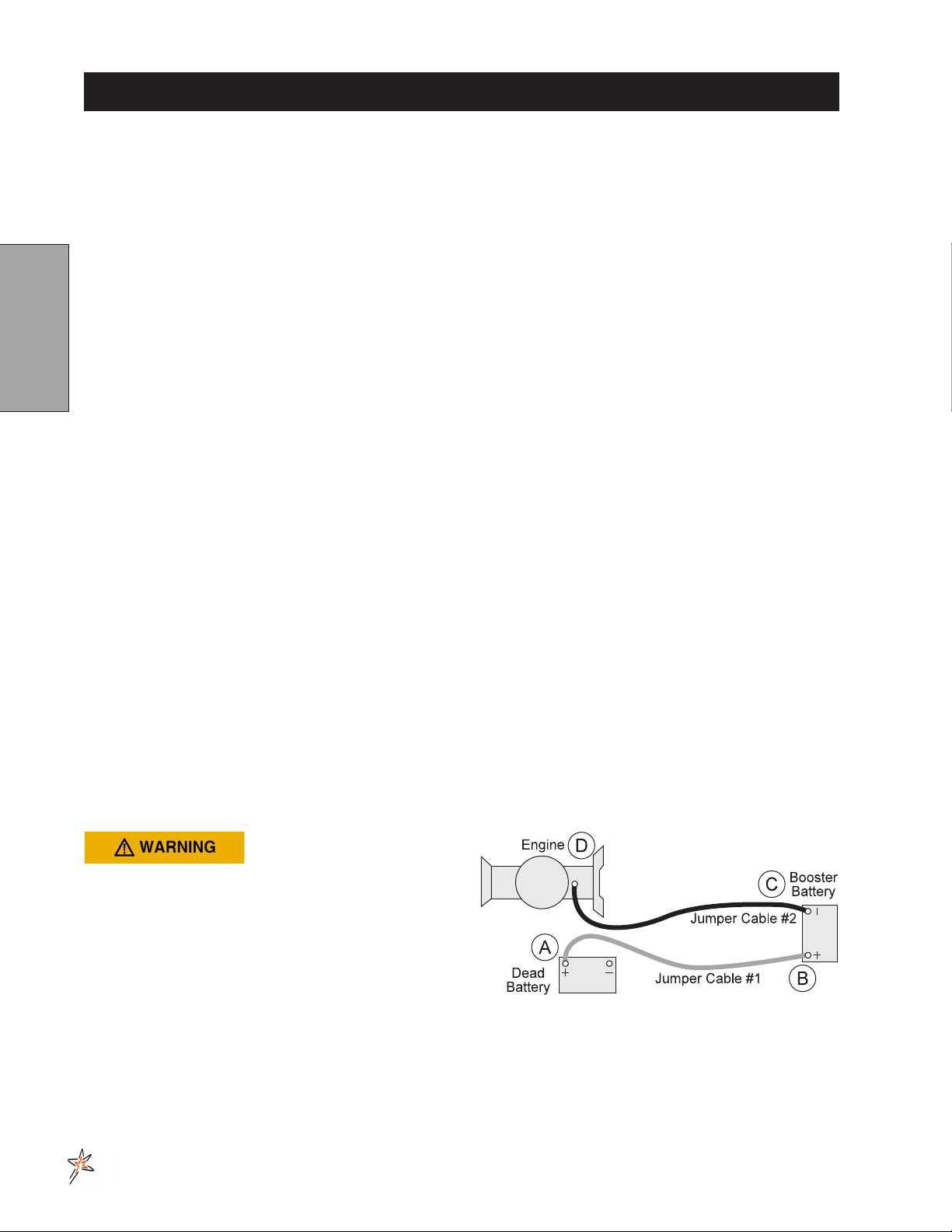

Safe Practices ..........................................................2

...........................................................3

..................................................3

Service................................................................4-11

..........................................................4-6

Service Chart ........................................................7-8

....................................9-10

............................................................ 11

................................................................... 11

Diagrams ..........................................................12-17

.......................................12-13

..........................................14-15

.............................................16-17

Parts................................................................18-115

................................................18-19

.............................20-21

.............................................................22-23

..........................................................24-25

...............................................26-27

...............................................28-29

...................................................30-31

......................................................32-33

..................................................34-35

......................................36-37

......................................38-39

..................................................................40

.............................................41

....................................................42

.....................................................43

....................................................44

..................46-47

...................48-51

........................52-53

.............................................54-55

..........................................................56-59

..............................................................60-63

..............................................................64-65

...................................................66-69

..........70-71

..............72-73

...............74-84

.................................................85

.........................86-91

......................................92

.....................93-114

............................ 115

Accessories .................................................116-118

.................... 116-117

.................................. 118

Reference .....................................................119-120

.............................................................. 119

...................120

.....................................................................