Smiths Hotline User manual

Blood and

Fluid Warmer

®

Maintenance, Testing

and Calibration

HOTLINE®Blood and Fluid Warmer Technical Service Pack 46

SECTION 5

Maintenance

Maintenance

Before each use

Carefully inspect the HOTLINE®for signs of damage, cracked or

split case, insecure poleclamp, damaged mains cable, etc.

If the Disposable Set does not install easily, lubricate the O-

Ring Seals.

Lubricating the O-Ring Seals

Using a cotton swab, apply a small amount of silicone grease

(Smiths Medical Part Number EZL 80-04-002) to the O-Rings in the

Disposable Set connector block.

If this does not solve the problem, reject the unit.

After each use

Wipe all external surfaces of the HOTLINE®with a soft cloth,

using an aqueous solution of mild detergent. If necessary, the

external surfaces may be disinfected using a solution of 10% bleach

in distilled water.

■Do not autoclave.

■Do not use alcohol or solvents.

■Do not use abrasive cleaning agents.

■Do not use cold sterilants.

■Do not immerse any part of the HOTLINE®in liquids.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 47

SECTION 5

Maintenance

Routine Maintenance Tasks

Smiths Medical recommends that preventative maintenance

be carried out at specified intervals. Some maintenance tasks need

to be repeated at 30-day intervals and others at annual intervals,

depending on your choice of recirculating solution.

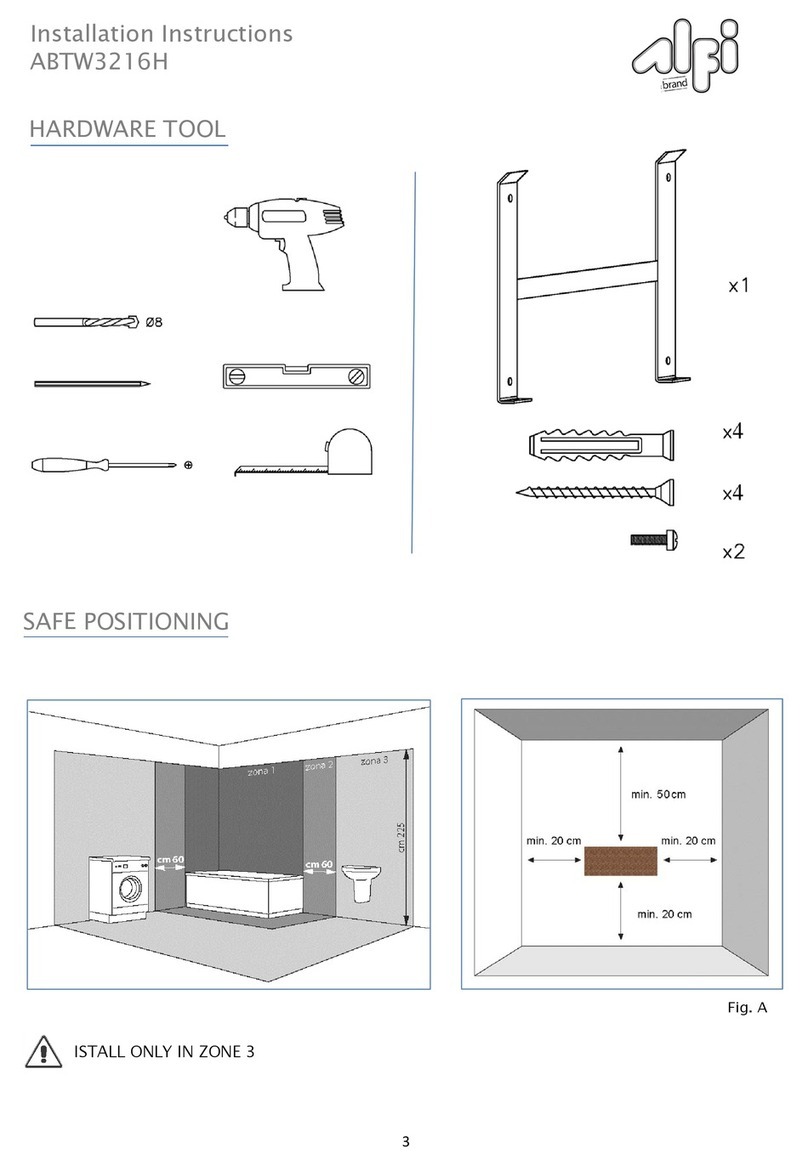

The three approved recirculating solutions and their

associated maintenance protocols are:

Precise directions for mixing the above solutions to the correct

strength are given on page 54.

Exceptionally, if the unit has had any non-routine servicing or

repair work, it will need to undergo a more thorough test and

recalibration sequence. This is detailed on page 64 and onwards.

Recirculating

Solution At 30-day Intervals At 12-month Intervals

Sterile

Distilled

Water

Visual Inspection

Lubricate O-Ring Seals

Replace Recirculating

Solution

Test All Alarms

Replace O-Ring Seals

Replace Recirculating Solution

Verify Temperature Calibration

Electrical Safety Test

Isopropyl

Alcohol

Solution

Visual Inspection

Lubricate O-Ring Seals

Replace Recirculating

Solution

Test All Alarms

Replace O-Ring Seals

Replace Recirculating Solution

Verify Temperature Calibration

Electrical Safety Test

Hydrogen

Peroxide

Solution

Visual Inspection

Lubricate O-Ring Seals

Test All Alarms

Replace O-Ring Seals

Replace Recirculating Solution

Verify Temperature Calibration

Electrical Safety Test

HOTLINE®Blood and Fluid Warmer Technical Service Pack 48

SECTION 5

Every 30 days

Every 30 days

■Perform a Visual Inspection looking for damage to the case,

poleclamp, mains cable, etc.

■Lubricate O-Ring Seals with a cotton swab, applying a small

amount of silicone grease to the O-Rings.

Either, if using DISTILLED WATER as the

recirculating solution:

■Drain and replace the recirculating solution as described on

page 54.

or, if using ISOPROPYL ALCOHOL as the

recirculating solution:

■Drain and replace the recirculating solution as described on

page 56.

Finally

■Fill in, sign, and date the maintenance log record!

HOTLINE®Blood and Fluid Warmer Technical Service Pack 49

SECTION 5

Every 12 Months

Every 12 Months

Alarm Testing

Place the HOTLINE®on a suitable firm surface. Visually check

that the recirculating solution level in the reservoir is above the MIN

mark. Attach a Disposable Set, ensuring that it is free from kinks and

twists.

Plug the unit into the electricity supply and switch on. Verify

that the unit is working normally (recirculating solution circulating,

temperature display gradually rising towards 41°C).

General Alarm Test

Press the General Alarm Test button. Observe:

■the GREEN LED extinguishes.

■the THREE RED LEDs light up.

■the AUDIBLE ALARM commences beeping.

■the RECIRCULATING SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 50

SECTION 5

Every 12 Months

Over Temperature Alarm Test

Allow the unit to run for sufficient time to stabilise the

temperature. Press and hold the Over Temperature Alarm Test

button. Observe:

■the DISPLAY rises to 43°C - 44°C .

■the GREEN LED extinguishes.

■the RED Over Temperature LED lights up.

■the AUDIBLE ALARM commences beeping.

■the RECIRCULATING SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired.

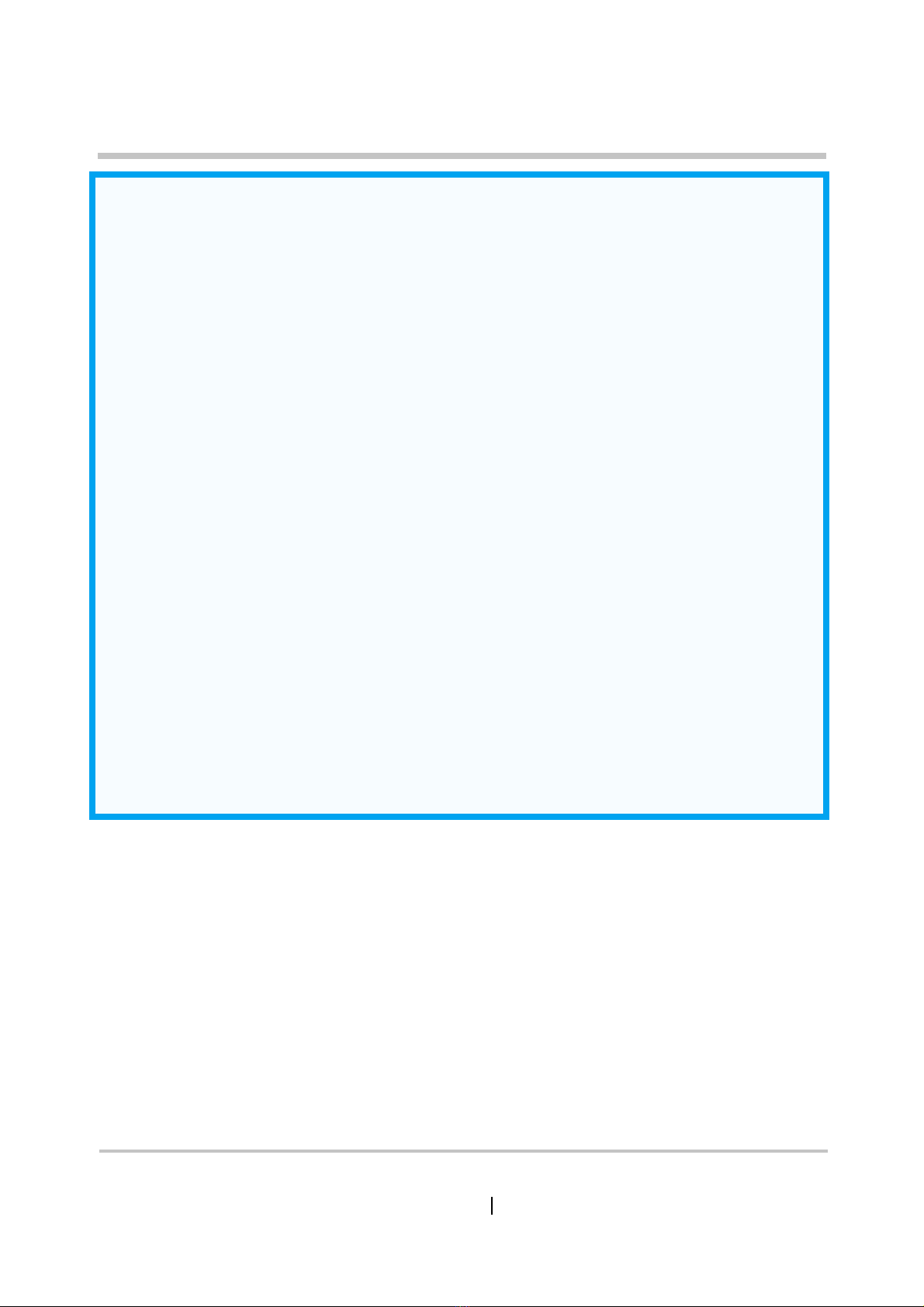

Recirculating Solution Level Alarm

Remove the Fill Port plug. Using a non-magnetic tool, gently

depress the float switch arm.

Figure 5 - 1: Depressing the float

switch. Here you see an offcut of

scrap Disposable Set performing

excellently as a non-magnetic probe.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 51

SECTION 5

Every 12 Months

Observe that:

■the GREEN LED extinguishes.

■the RED recirculating Solution Level LED lights up.

■the AUDIBLE ALARM commences beeping.

■the RECIRCULATING SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired. The unit should return to

normal operation upon releasing the float switch.

Disposable Set Interlock Alarm

While the unit is working normally, gently ease the Disposable

Set away from the interlock block. Be aware that a small amount of

recirculating solution may escape during this test. Before the

Disposable Set is fully disconnected, the alarm should operate.

Observe that:

■the GREEN LED extinguishes.

■the RED Interlock Alarm LED lights up.

■the AUDIBLE ALARM commences beeping.

■the recirculating SOLUTION ceases circulating.

If any of the above responses are missing, the unit must be

removed from service and repaired. The unit should return to

normal operation upon correctly reattaching the Disposable Set.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 52

SECTION 5

Every 12 Months

Replace O-Ring Seals

■Remove the socket head screws with an 1/8-inch Allen key.

■Remove the disposable interface block, being careful of the

microswitch lever.

■Using a cotton swab, remove the old O-Rings, and clean out

the empty sockets.

GM-0163_8501-GB-A

Figure 5 - 3: Revealed: the O-Rings in their niches

Figure 5 - 2: Getting access to the O-Ring Seals

HOTLINE®Blood and Fluid Warmer Technical Service Pack 53

SECTION 5

Every 12 Months

■Apply a smear of silicone grease (Smiths Medical Part

Number EZL 80-04-002) to two new O-Rings, and locate

them in the sockets.

■Re-attach the disposable interface block.

■Re-fit the socket head screws. Again, take care not to

damage or bend the microswitch operating lever.

A kit of parts is available to make this task simpler. Please ask for

part number reference EZL 80-04-001.

Either, if using DISTILLED WATER as the

recirculating solution:

■Drain and replace the recirculating solution as described on

page 54.

or, if using ISOPROPYL ALCOHOL as the

recirculating solution:

■Drain and replace the recirculating solution as described on

page 56.

or, if using HYDROGEN PEROXIDE as the

recirculating solution:

■Drain and replace the recirculating solution as described on

page 57.

Finally

■Fill in, sign, and date the maintenance log record!

HOTLINE®Blood and Fluid Warmer Technical Service Pack 54

SECTION 5

Maintenance Solutions

Changing Recirculating Solution (Distilled Water)

If using plain distilled water as the recirculating fluid, then this

must be changed at the 30-day service interval, using the procedure

given here. Smiths Medical currently recommends using the

Hydrogen Peroxide based recirculating solution which allows a

12-monthly recirculating solution change protocol, resulting in a

significant reduction of service time.

Maintenance Solutions

At service intervals of either 12-months or 30-days, depending on the

composition of your recirculating solution, you will need supplies of ready mixed

solutions to perform maintenance. To make up a batch (1.4 litres) of solution, you

will need:

Formula 1

140ml of 3% Hydrogen Peroxide PLUS 1260ml distilled water

This may be used as a disinfectant fluid for flushing the recirculating solution

path during routine maintenance, or as a long-life recirculating solution enabling

fluid change intervals to be extended to 12-monthly.

Formula 2

700ml of 70% Isopropyl Alcohol PLUS 700ml distilled water

This may be used as a disinfectant fluid for flushing the recirculating

solution path during routine maintenance, or as a recirculating solution. It is NOT

suitable for long-term use, and must be replaced at 30-day intervals.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 55

SECTION 5

Maintenance Solutions

■Unplug the HOTLINE®.

■(Old case) Remove the Fill Port plug and hold the Unit over a

sink to empty the water.

(New case) Deploy the drain tube to empty the Unit.

■Rinse reservoir with distilled water twice.

■Refill the reservoir with 1.4 litres of disinfectant flushing

solution made to one of the formulae shown in the blue

panel above. Do not fill the HOTLINE® reservoir with a

Disposable Set in place, as this may result in an airlock in the

HOTLINE® warmer.

■Connect a Disposable Set to the HOTLINE®.

■Plug the Unit in and switch on.

■Allow the disinfectant solution to circulate for 30 minutes.

Drain Tube

(in deployed posn)

Drain Tube End Cap

Fill Port

Pole Clamp

Interlock Block

disposable connector

Stowage Clip

(for drain tube when

not deployed)

GM-HL90-8508-en

Figure 5 - 4: Rear view of new-style HOTLINE case, showing drain tube

HOTLINE®Blood and Fluid Warmer Technical Service Pack 56

SECTION 5

Maintenance Solutions

■Switch off and disconnect the Unit.

■Empty the unit once more.

■Rinse reservoir with distilled water again.

■Refill the unit with 1.4 litres of sterile distilled water.

■Replace the Fill Port plug.

NOTE: Unless using one of the approved maintenance solutions, use only

sterile distilled or de-ionised water. Failure to do so may lead to a

build-up of mineral deposits in the recirculating solution path which

may impair heater performance.

Changing Recirculating Solution (Isopropyl Alcohol)

Since the Isopropyl Alcohol solution gradually loses potency,

it must be replaced at the 30-day service interval using the

following procedure:

■Prepare two batches of 1.4 litres of recirculating solution

according to formula 2 above for 35% Isopropyl Alcohol

maintenance solution.

■Drain the HOTLINE®, and refill with one of the prepared

batches.

■Install an L-70 or L-70 NI Disposable Administration Set in

the HOTLINE®’s Disposable Set connector.

■Turn on the HOTLINE® and allow the fresh fluid to circulate

for 30 minutes.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 57

SECTION 5

Maintenance Solutions

■Switch off the HOTLINE® and dispose of the Disposable Set

in accordance with the usual procedures for your

establishment. Drain the Fluid from the HOTLINE® and

discard.

■Refill the HOTLINE® with the second of the Isopropyl Alcohol

solution batches you made earlier.

NOTE: If the HOTLINE

®

requires topping up at any time before the next

routine recirculating solution change, make sure you always use the

correct mix of Isopropyl Alcohol and Distilled water.

Changing Recirculating Solution (Hydrogen Peroxide)

At the annual routine service interval the Hydrogen Peroxide

solution must be replaced as follows:

■Prepare two batches of 1.4 litres of recirculating solution

according to formula 1 above for 0.3% Hydrogen Peroxide

maintenance solution.

■Drain the HOTLINE®, and refill with one of the prepared

batches.

■Install an L-70 or L-70 NI Disposable Administration Set in

the HOTLINE®’s Disposable Set connector.

■Turn on the HOTLINE® and allow the fresh fluid to circulate

for 30 minutes.

■Switch off the HOTLINE® and dispose of the Disposable Set

in accordance with the usual procedures for your

HOTLINE®Blood and Fluid Warmer Technical Service Pack 58

SECTION 5

Maintenance Solutions

establishment. Drain the fluid from the HOTLINE® and

discard.

■Refill the HOTLINE® with the second of the recirculating

solution batches you made earlier.

NOTE: If the HOTLINE

®

requires topping up at any time before the next

routine recirculating solution change, make sure you always use the

correct mix of Hydrogen Peroxide and Distilled water.

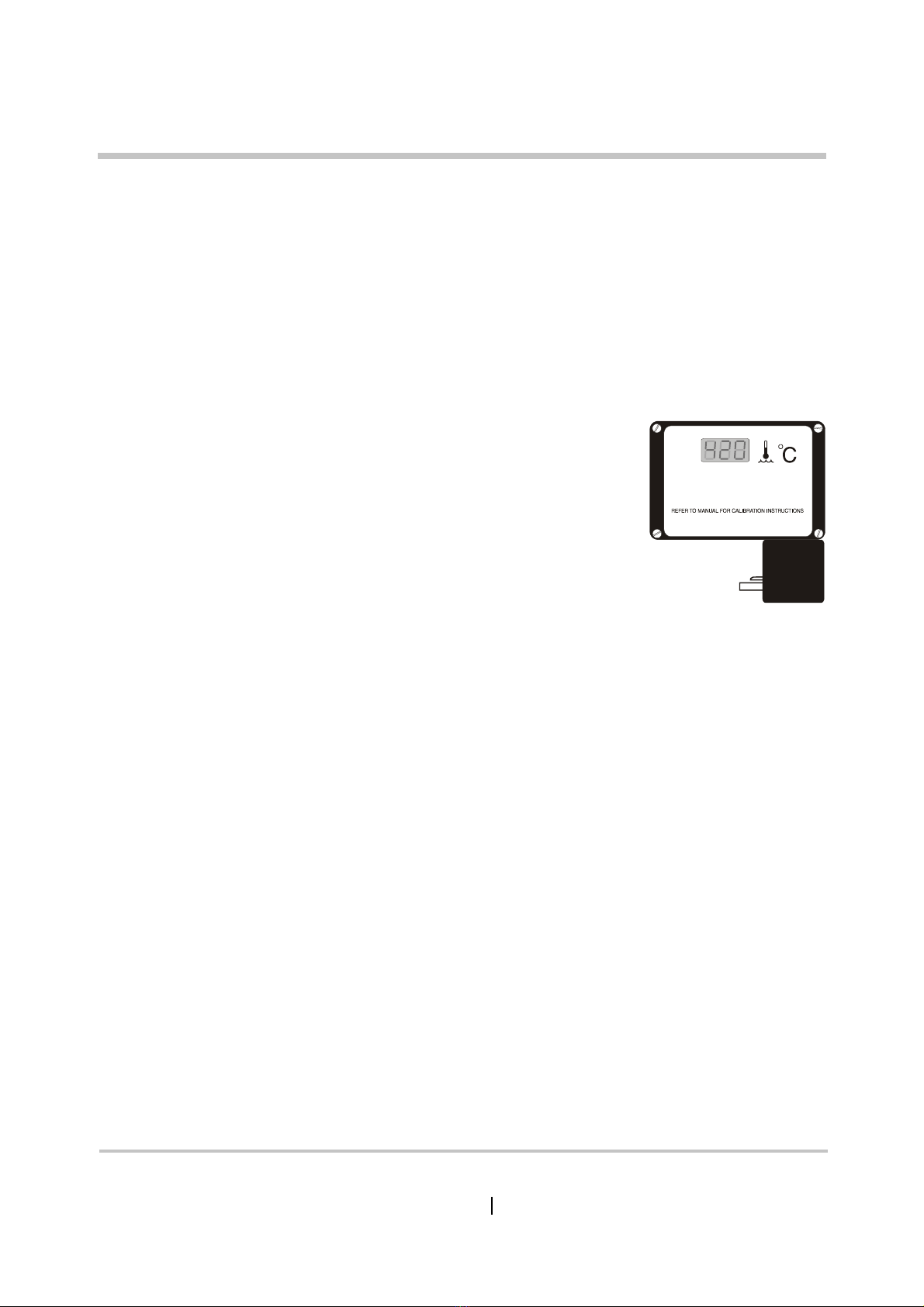

Temperature Checking

To accurately verify the displayed recirculating solution

temperature, you will need a HOTLINE® HLTA-40 TEMP CHECK

thermometer. This bespoke unit is inserted into the recirculating

solution flow and reads the temperature directly from the

recirculating solution as it leaves the heater element and internal

thermistor sensors. This is the point at which the recirculating

solution is at its highest temperature.

Measuring the temperature in the recirculating solution

reservoir is less accurate. Typically the temperature here may be

several degrees cooler, dependent on ambient temperature and

other factors.

TEMP

CHECK

GM-HL90-8502

Figure 5 - 5: A HOTLINE® HLTA-40 TEMP CHECK wet thermometer

HOTLINE®Blood and Fluid Warmer Technical Service Pack 59

SECTION 5

Maintenance Solutions

If you do not have a HOTLINE® TEMP CHECK thermometer,

units may be returned to Smiths Medical for temperature

verification.

Set up the HOTLINE® ready for use as before. Attach the TEMP

CHECK thermometer to the interlock block of the HOTLINE® and

connect the Disposable Set to the TEMP CHECK.

Carefully unpeel the black sticker from the back of the

HOTLINE®, and loosely attach it in a safe place ready for re-use. Plug

the TEMP CHECK ’s Mains cable into the Auxiliary Outlet socket of

the HOTLINE®.

NOTE: The Auxiliary Outlet is for use only with approved accessories

supplied by your Smiths Medical distributor for that purpose.

Run the HOTLINE® for 15 minutes to allow the temperature to

stabilise. Verify that:

■the TEMP CHECK indicates a recirculating solution tempera-

ture between 41°C and 42°C

■The HOTLINE®’s display indicates the same temperature.

If either of these conditions is not met, the unit will require

either recalibration or repairing and recalibration before it can be

returned to active service.

If both conditions are satisfied, dismantle the test assembly,

and replace the black sticker over the Aux socket. Document the

date and results of your tests and return the HOTLINE® to active

service.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 60

SECTION 5

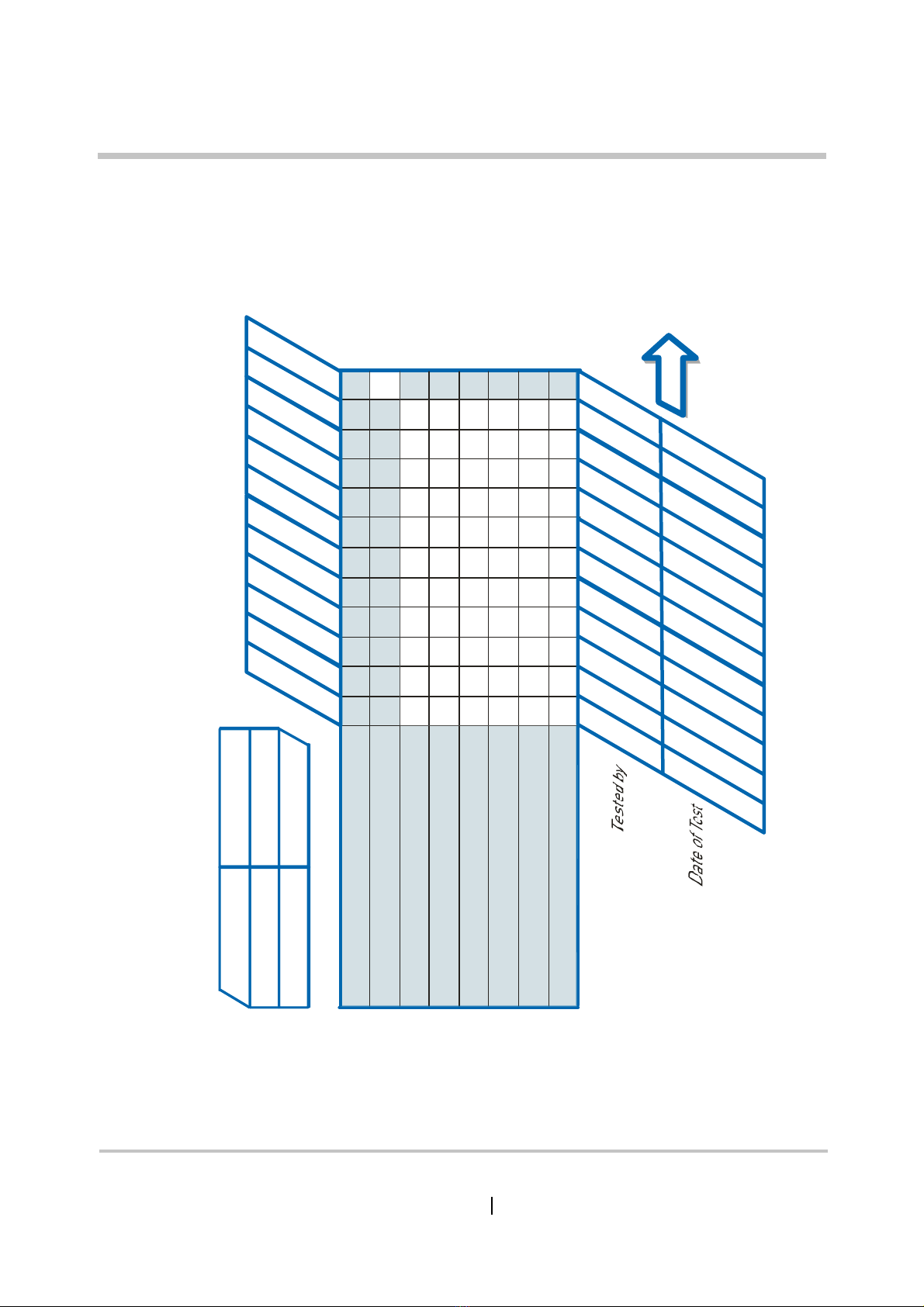

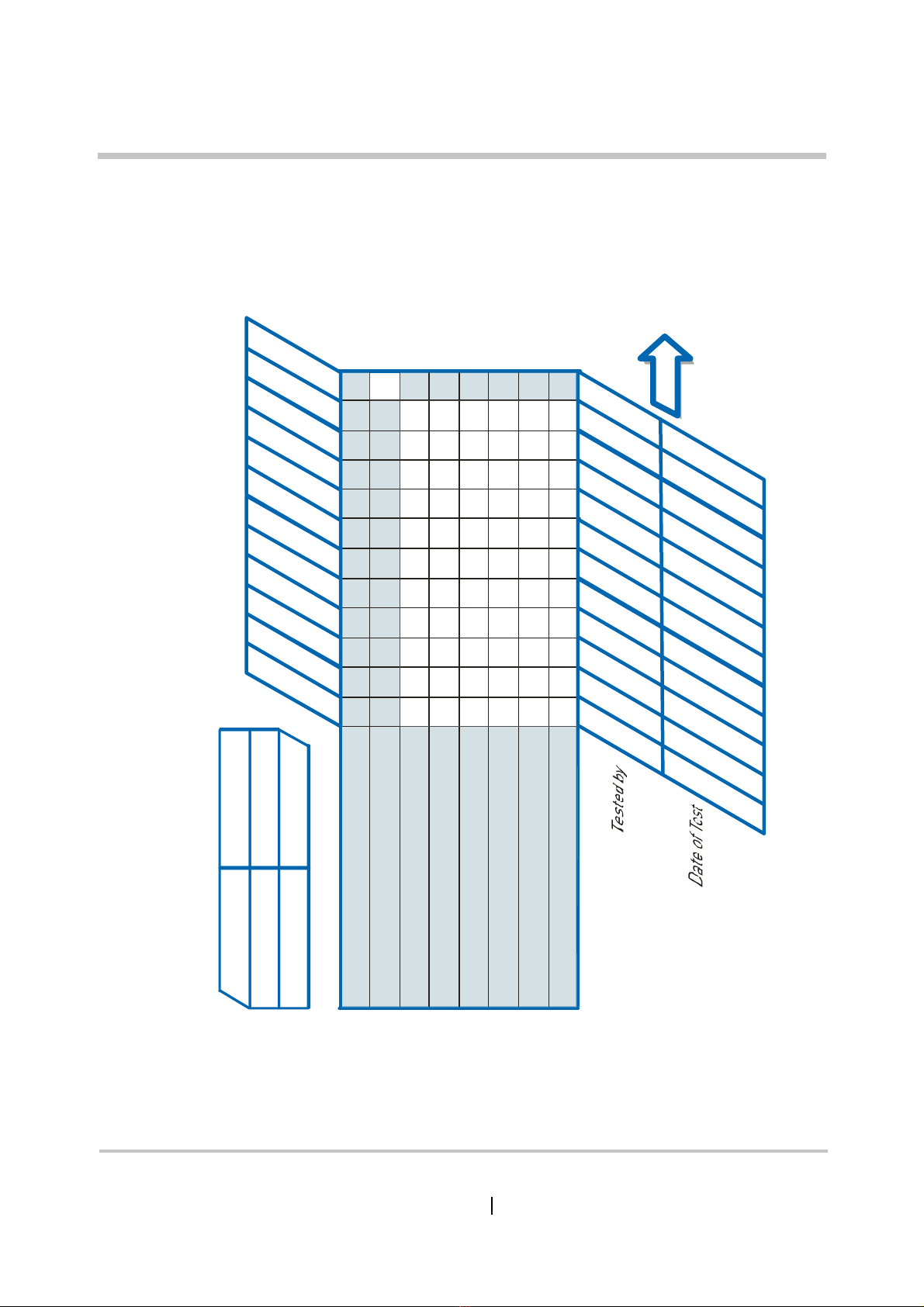

Routine Maintenance Checklists

Routine Maintenance Checklists

You may freely photocopy the checklists on the next three

pages to act as a continuing record of your routine HOTLINE® HL-90

maintenance.

The correct checklist to use is dependent on the choice of

protocol used for maintenance on the HOTLINE®s in your care. If

you choose to stick to the traditional distilled water recirculating

solution, you will need the first checklist. This allows for the

changing of the recirculating solution on a monthly cycle.

Otherwise, the third checklist corresponds with Smiths

Medical’s recommended protocol of having a 12-month interval

between solution changes, and using a disinfectant mixture as the

recirculating solution on a permanent basis.

In some territories, Hydrogen Peroxide may not be readily

available, or it may be that it is not included in the establishment’s

preferred protocols. If that is the case, and it is still necessary to

maintain a disinfectant recirculating solution, then the second

checklist gives the correct pattern when using Isopropyl Alcohol

solution with a 30-day replacement cycle. It is not permitted to use

the Isopropyl Alcohol solution on a 12-monthly replacement cycle

as it loses its potency much more rapidly than the recommended

Hydrogen Peroxide solution. For this reason, batches of Isopropyl

Alcohol solution (Formula 2) should ideally be freshly mixed

immediately before use.

HOTLINE®Blood and Fluid Warmer Technical Service Pack 61

SECTION 5

Routine Maintenance Checklists

GZX^gXjaVi^c\Hdaji^dc^hHiZg^aZ9^hi^aaZYLViZg

HI6GI

6;G:H=

G:8DG986G9

;DGI=>H

=DIA>C:

CDL

<B"%&+(T-*%("<7"6

BDCI=&

BDCI=(

BDCI='

BDCI=)

BDCI=*

BDCI=+

BDCI=,

BDCI=.

BDCI=-

BDCI=&&

BDCI=&%

BDCI=&'

Jc^iHZg^VaCjbWZg

9ViZd[6Xfj^h^i^dc

Bdci]&lVhl]Zc4

GZeaVXZD"G^c\HZVah

KZg^[ n IZbeZg Vij gZ 8V a^Wg Vi ^dc

Adl G ZX^gXja Vi^c \Hdaj i^dc 6aVgbIZhi

>ciZgadX`6aVgbIZhi

8]Vc\ZGZX^gXjaVi^c\Hdaji^dc

<gZVhZD"G^c\HZVah

<ZcZgVa6aVgbIZhi

DkZgIZbeZgVijgZIZhi

HOTLINE®Blood and Fluid Warmer Technical Service Pack 62

SECTION 5

Routine Maintenance Checklists

GZX^gXjaVi^c\Hdaji^dc^h(*>hdegdena6aXd]da

HI6GI

6;G:H=

G:8DG986G9

;DGI=>H

=DIA>C:

CDL

<B"%&+(T-*%."<7"6

BDCI=&

BDCI=(

BDCI='

BDCI=)

BDCI=*

BDCI=+

BDCI=,

BDCI=.

BDCI=-

BDCI=&&

BDCI=&%

BDCI=&'

Jc^iHZg^VaCjbWZg

9ViZd[6Xfj^h^i^dc

Bdci]&lVhl]Zc4

GZeaVXZD"G^c\HZVah

KZg^[ n IZbeZg Vij gZ 8Va^ Wg Vi ^dc

AdlGZX^gXjaVi^c\Hdaji^dc6aVgbIZhi

>ciZgadX`6aVgbIZhi

8]Vc\ZGZX^gXjaVi^c\Hdaji^dc

<gZVhZD"G^c\HZVah

<ZcZgVa6aVgbIZhi

DkZgIZbeZgVijgZIZhi

HOTLINE®Blood and Fluid Warmer Technical Service Pack 63

SECTION 5

GZX^gXjaVi^c\Hdaji^dc^h%#(=nYgd\ZcEZgdm^YZ

HI6GI

6;G:H=

G:8DG986G9

;DGI=>H

=DIA>C:

CDL

<B"%&+(T-*%,"<7"6

BDCI=&

BDCI=(

BDCI='

BDCI=)

BDCI=*

BDCI=+

BDCI=,

BDCI=.

BDCI=-

BDCI=&&

BDCI=&%

BDCI=&'

Jc^iHZg^VaCjbWZg

9ViZd[6Xfj^h^i^dc

Bdci]&lVhl]Zc4

GZeaVXZD"G^c\HZVah

KZg^[nIZbeZgVijgZ8Va^WgVi^dc

AdlGZX^gXjaVi^c\Hdaji^dc6aVgbIZhi

>ciZgadX`6aVgbIZhi

8]Vc\ZGZX^gXjaVi^c\Hdaji^dc

<gZVhZD"G^c\HZVah

<ZcZgVa6aVgbIZhi

DkZgIZbeZgVijgZIZhi

GZX^gXjaVi^c\Hdaji^dc^h%#(=nYgd\ZcEZgdm^YZ

HI6GI

6;G:H=

G:8DG986G9

;DGI=>H

=DIA>C:

CDL

<B"%&+(T-*%,"<7"6

BDCI=&

BDCI=(

BDCI='

BDCI=)

BDCI=*

BDCI=+

BDCI=,

BDCI=.

BDCI=-

BDCI=&&

BDCI=&%

BDCI=&'

Jc^iHZg^VaCjbWZg

9ViZd[6Xfj^h^i^dc

Bdci]&lVhl]Zc4

GZeaVXZD"G^c\HZVah

KZg^[nIZbeZgVijgZ8Va^WgVi^dc

AdlGZX^gXjaVi^c\Hdaji^dc6aVgbIZhi

>ciZgadX`6aVgbIZhi

8]Vc\ZGZX^gXjaVi^c\Hdaji^dc

<gZVhZD"G^c\HZVah

<ZcZgVa6aVgbIZhi

DkZgIZbeZgVijgZIZhi

HOTLINE®Blood and Fluid Warmer Technical Service Pack 64

SECTION 5

Full Service Test Procedure

Full Service Test Procedure

This sequence must be used:

■either after any repair or service work where the case was

opened,

■or when the unit has failed temperature calibration

verification.

Things you will need

■Room Thermometer

■TEMP CHECK HLTA-40

■HOTLINE® Disposable Set L-70

■Small and Medium Straight Screwdrivers

■Non-magnetic Probe

CAUTION: Take care while operating the HOTLINE®with the case front open.

Mains voltages are present inside. Avoid contact with any internal

components not specified in this procedure.

CAUTION: The Auxiliary Outlet is for use only with approved accessories supplied

by your Smiths Medical distributor for that purpose.

CAUTION: Do not fill the HOTLINE®reservoir with a Disposable Set in place.

Failure to remove the Disposable Set before the fill procedure may

result in an airlock in the HOTLINE®warmer.

NOTE: When filling the HOTLINE

®

, use approved recirculating solutions

only. Failure to do so may cause damage to the equipment.

NOTE: Check the calibration due date on the back of the TEMP CHECK before

commencing this procedure.

NOTE: TEMP CHECK thermometers are designed for measuring circulating

recirculating solution flow only and are not intended for measuring

ambient (air) temperatures.

TEMP

CHECK

GM-HL90-8502

Table of contents

Other Smiths Food Warmer manuals