Table

of

Contents

Εις

ιο

ee

eee

ee

eee

Technical

Competence

.

5/Disassembiy

and

Repair

_..................

5.1

Heater

Module

Repairs

........

…

Repair

Policy

.....................44........

A.

Heater

Housing

Disassembly

...

..

Precautions

iv

B.

Heater

Replacement

....................

Torres

assesses

cee

secs sess

teres

C.

Heater

Housing

Assembly

...............

1/Functional

Description

....................

1-1

D.

Alarm

Lamp

Replacement

........

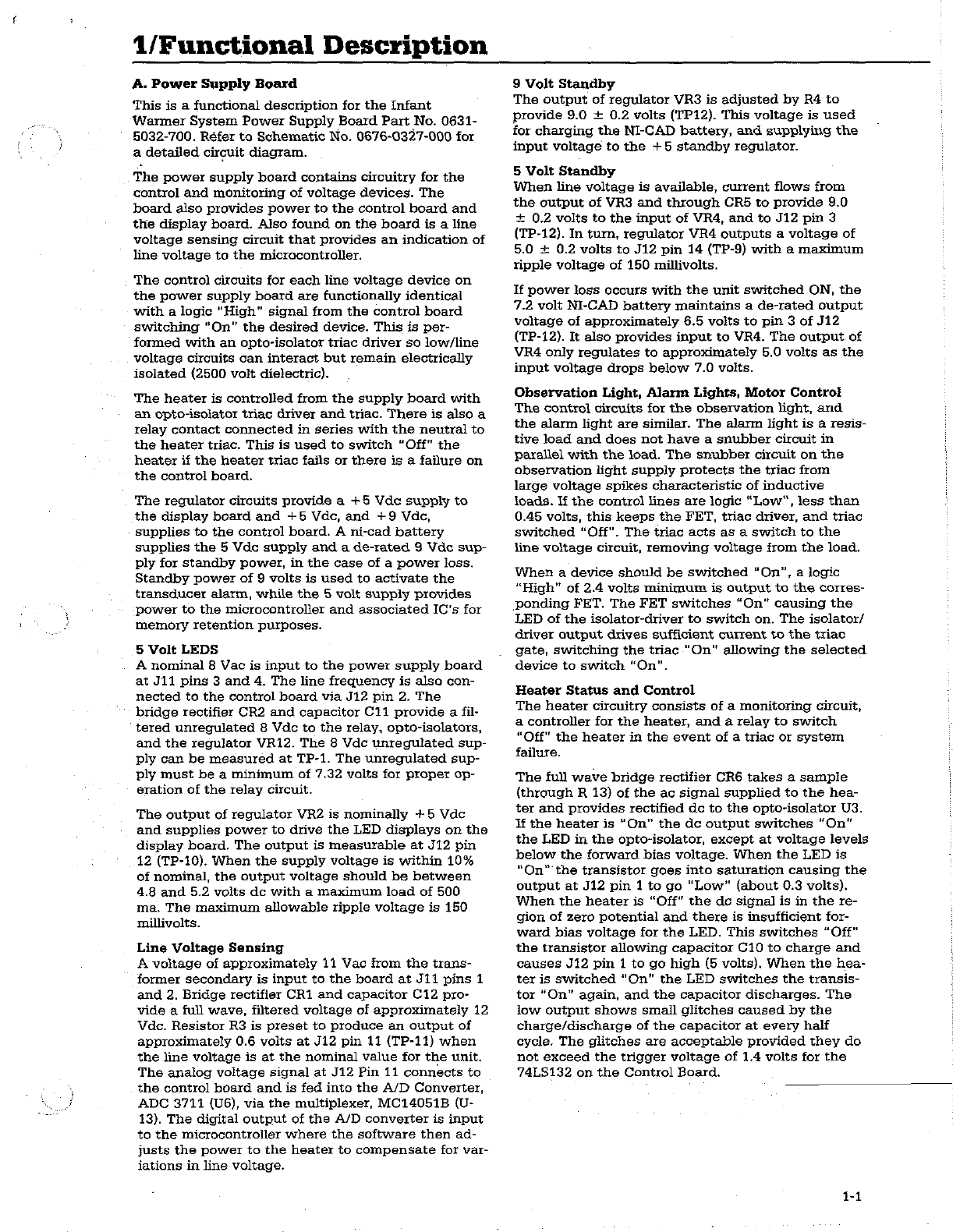

A.

Power

Supply

Board

....................

1-1

E.

Examination

Lamp

Replacement

.. ..

B.

Control

Board

.........................

1-2 5.2

Control

Module

Repairs

.................

C.

Display

Board

.........................

1-8

A.

Control

Module

Removal

................

B.

Control

Board

and

Power

Supply

Board

2/Specifications

に

で

に

た

と

た だ

とまと すすま

たま

たま

と

た

まま

まま

まま

2-1

Replacement

..

ον

εντ

νωνν

ενω

κε

ων

εως

2.1

Electrical...

-.

24

C.

Display

Module

Disassembly

2.2

Controller

.............................

2-1

D.

Display

Module

Assembly

...............

2.3

Alarms

...............................

2-1

E.

Control

Module

Replacement

...

2.4

Environmental

................

2-2

F.

Battery

Replacement

.........

2.5

Mechanical

(without

accessories)

22

G.

Circuit

Breaker

Reset

..

2.8

Accessories

...................

2-2

5.3

Bed

Platform

Repairs

....

3/Setup

and

Checkout

Procedure

....

.

34

A.

Side

Panel

Replacement.

3.1

Setup......................

...

34

3.

Side

Panel

Repairs

.......

3.2

Checkout

Procedure

....................

34

5

Bed

Flatform

Disassembly

-

i .

Be

form

Asse

yo...

μα

B.

Control

Unit

Checks

....................

31

,F.

Hydraulic

System

Installation

5.4

Caster

Replacement

................-..

5-16

4/Calibration

and

Adjustments

..............

4-1

5.5

Yoke

Manifold

Repairs

...:.............

5-16

A.

Control

Unit

Access

..............

.

41

A.

General

.............

5-16

B.

Power

Supply

Board

Voltage

Checks

...

4-1

B.

Gauge

Replacement

.....

5-16

C.

Display

Brightness

Check

...........

.

4-1

C.

Gauge

Lens

Replacement

.

5-16

D.

Alarm

Volume

Adjustment

......

.

41

D.

Strainer

Replacement

.....

5-19

E.

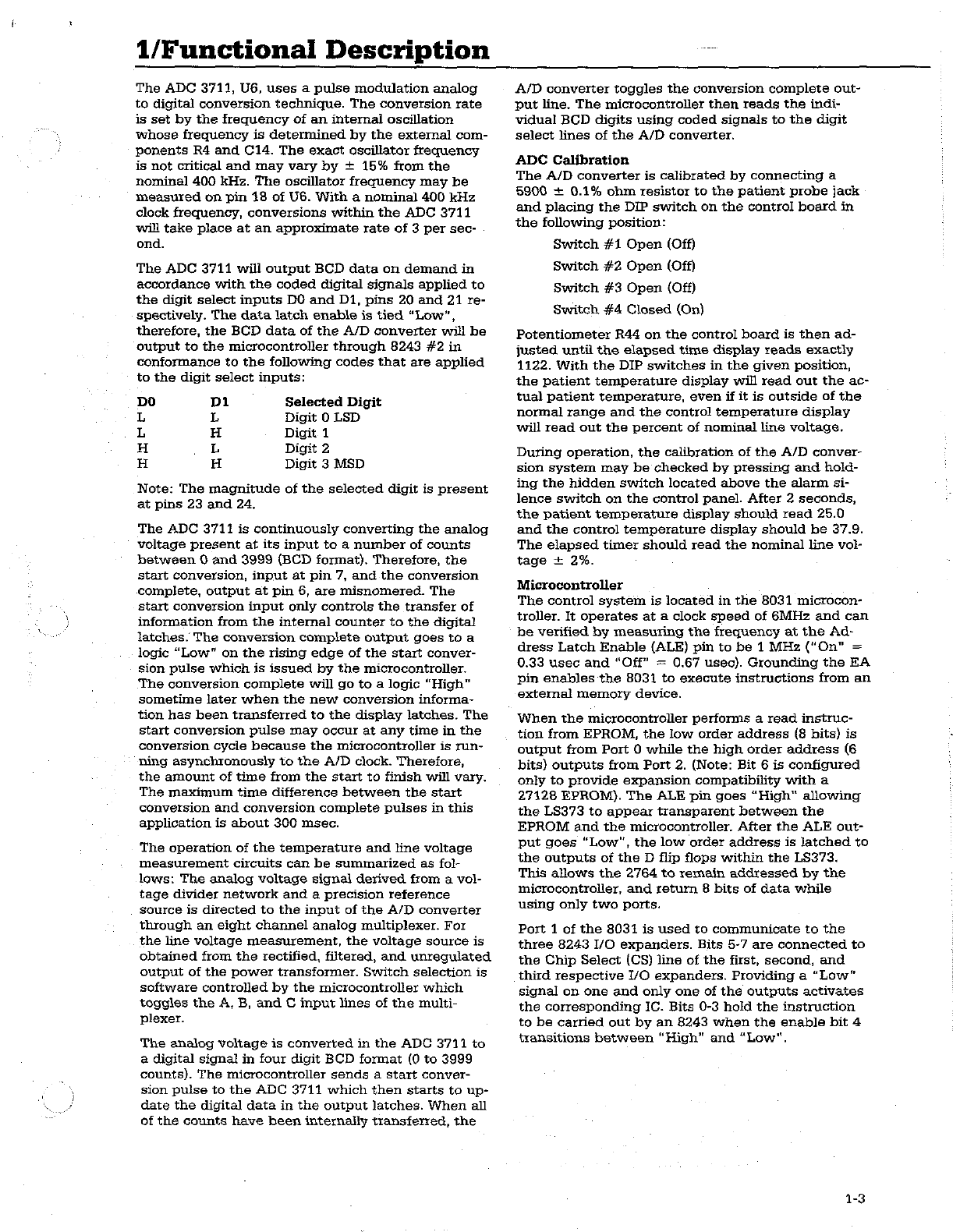

Analog

to

Digital

Converter

(ADC)

.

41

E.

Check

Valve

Replacement

.....

5-19

F.

Line

Voltage Sensing

...........

4-2

F.

High

Pressure

Regulator

Repair

.

5-19

G.

Triac

Safety

Circuit

Test

.

42

G.

Pneumatic

Troubleshocting

...

5-20

H.

Test

Loop

............................

4-3

。

。

.

L

Oxygen

Regulator

Check

and

Adjustment

.

4-3

6/Control

Unit

Troubleshooting

Guide

....

.

6-1

y.

Electrical

Safety

Check

..................

7/Illustrated

Parts

and

Parts

List

.............

71

K.

Ground

Resistance

Check

...

L.

Leakage

Current

Tests

..................

8/Schematics

and

Wiring

Diagrams

...........

31

Appendix..................

„A1

A.

Test

Eguipment

and

Special

Tools.

.

А-1

B.

Temperature

Conversion

Chart

.....

.

A-1

C.

Patient

Probe

Characteristics

..

-

A-1

D.

Drawer

Kit

Accessory

.......

..

A2

E.

O2

Yoke

and

Regulator

Assembly

Kit

......

A3