Monitoring

Under normal conditions the Sensor, Sounder & Strobe devices

are monitored regularly and the data is used to create a

background performance record. When there is a potential event,

the Sensor, Sounder & Strobe device will flag the control panel

for attention. The control panel will take further readings from the

device and compare all the measurements with patterns and

rules to determine if it is a fire event.

Device functionality

All Sensor, Sounder & Strobe devices are monitored periodically

to check if they are working correctly, an indication of a fault is

given if there is a failure. For example the infrared signals

through the optical chamber is regularly checked, the thermistor

is checked for failure. The strobe and sounder circuits are

monitored for failure.

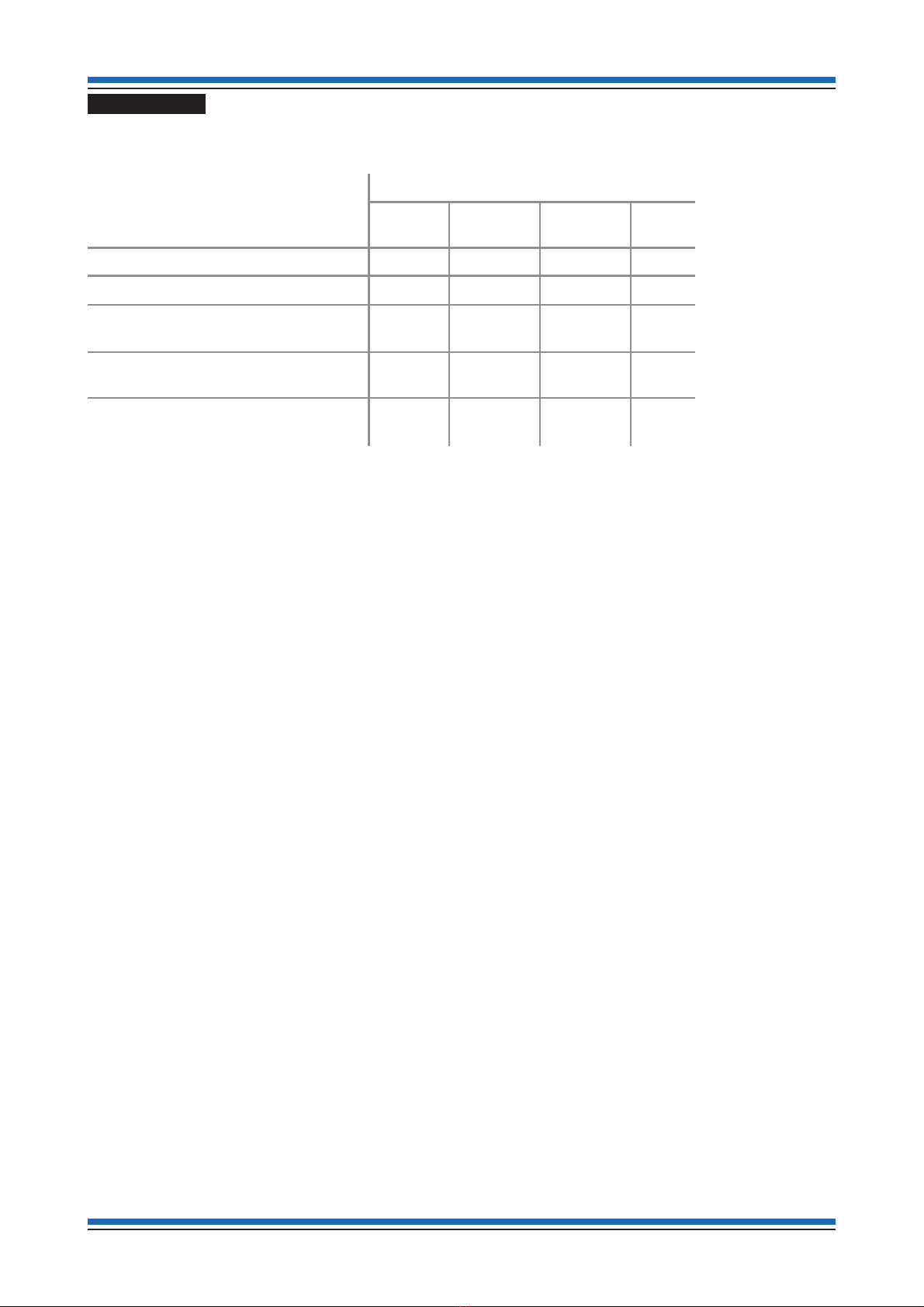

Heat sensor (H)

The heat sensing is provided by a thermistor. The temperature at

which the device goes into fire is defined by the configuration

settings in the control panel. The control panel also calculates

any rate of rise elements required in the fire decision.

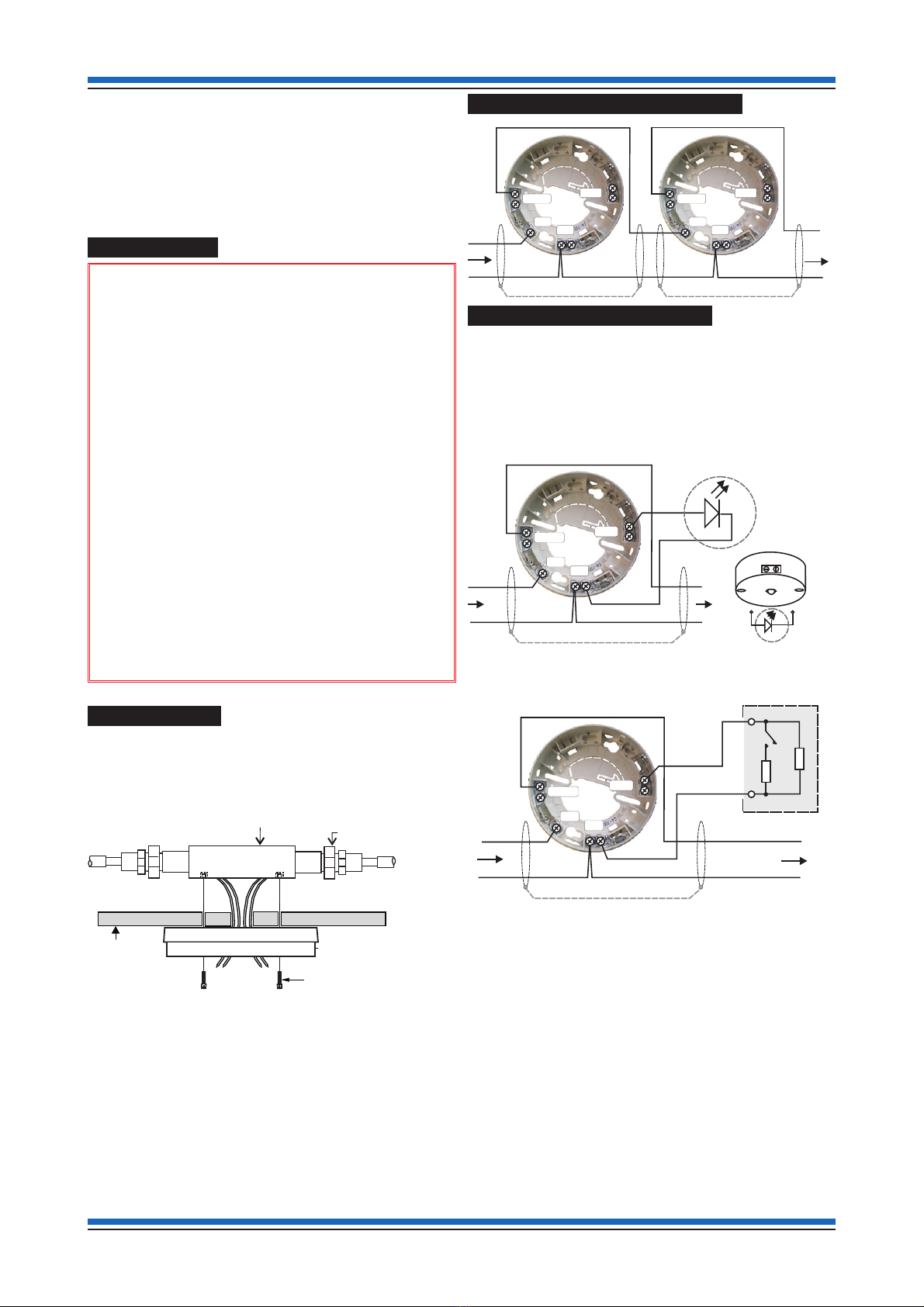

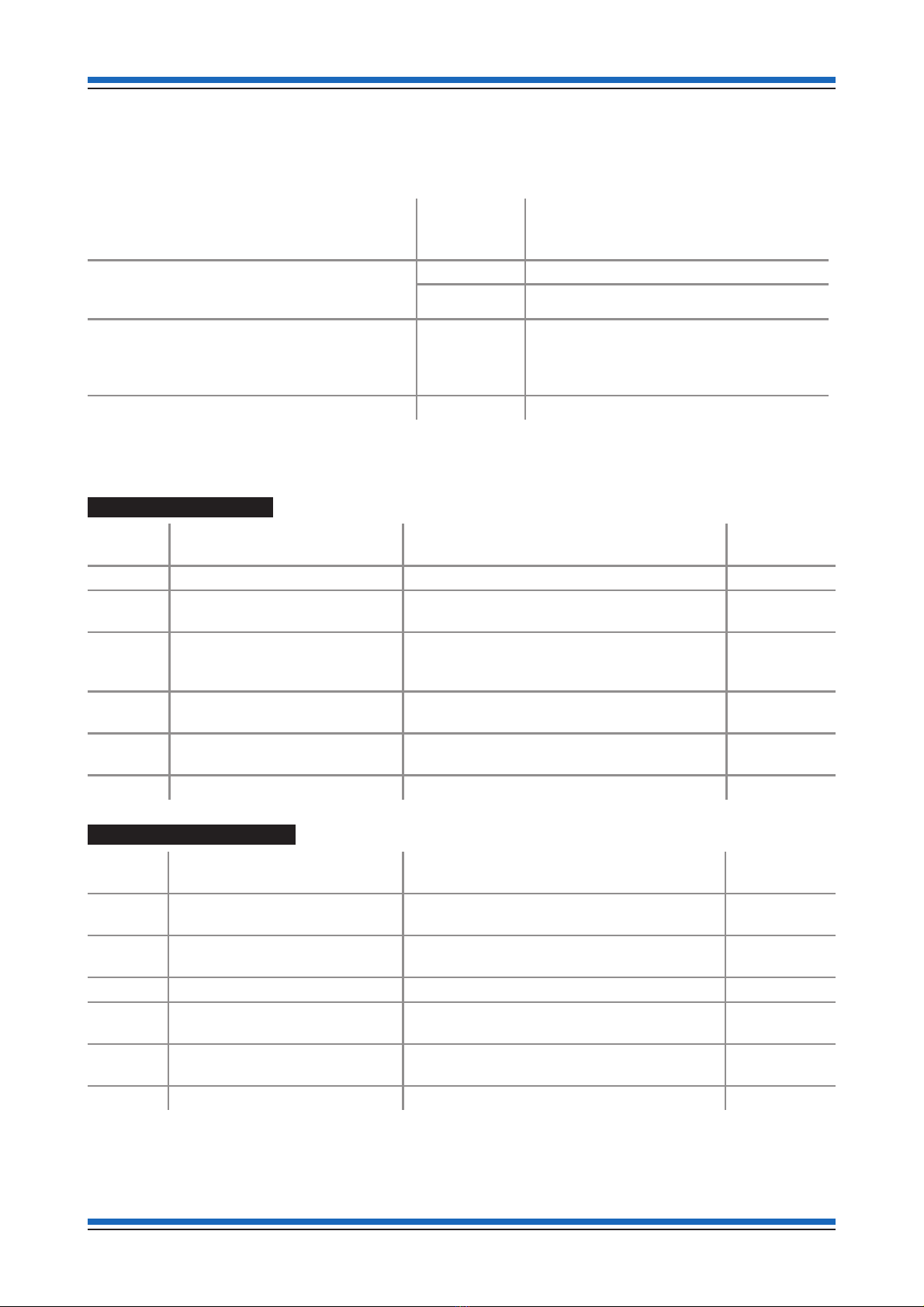

Optical sensors

Single Optical Sensor

The optical sensing is performed in the optical chamber using

transmitting LED 1 and an infrared receiver. Measurements are

taken at regular intervals. The control panel uses these readings

to detect the presence of smoke.

Bell tone

The bell tone function is stored on a flash memory chip within the

assembly of Sensor, Sounder & Strobe device .

Message 1 Bell tone

Sounder (S)

The sounder function in a Sensor, Sounder & Strobe device is

designed to meet the requirement of EN54 : Part 3. The EN54 :

Part 3 average output from the sounder is 85dBA at 1m or

75dBA at 3m at a bedhead, making it suitable for installation in

hotel bedrooms. The sounder can operate a turbo mode if

configured during commissioning to provide further 3dB output.

The sound outputs are based on the settings of the FABs and

SABs at the panel that gives changing levels over 2 seconds

duration in 8 time slots. The standard outputs are synchronised

with the S3devices installed in the same system.

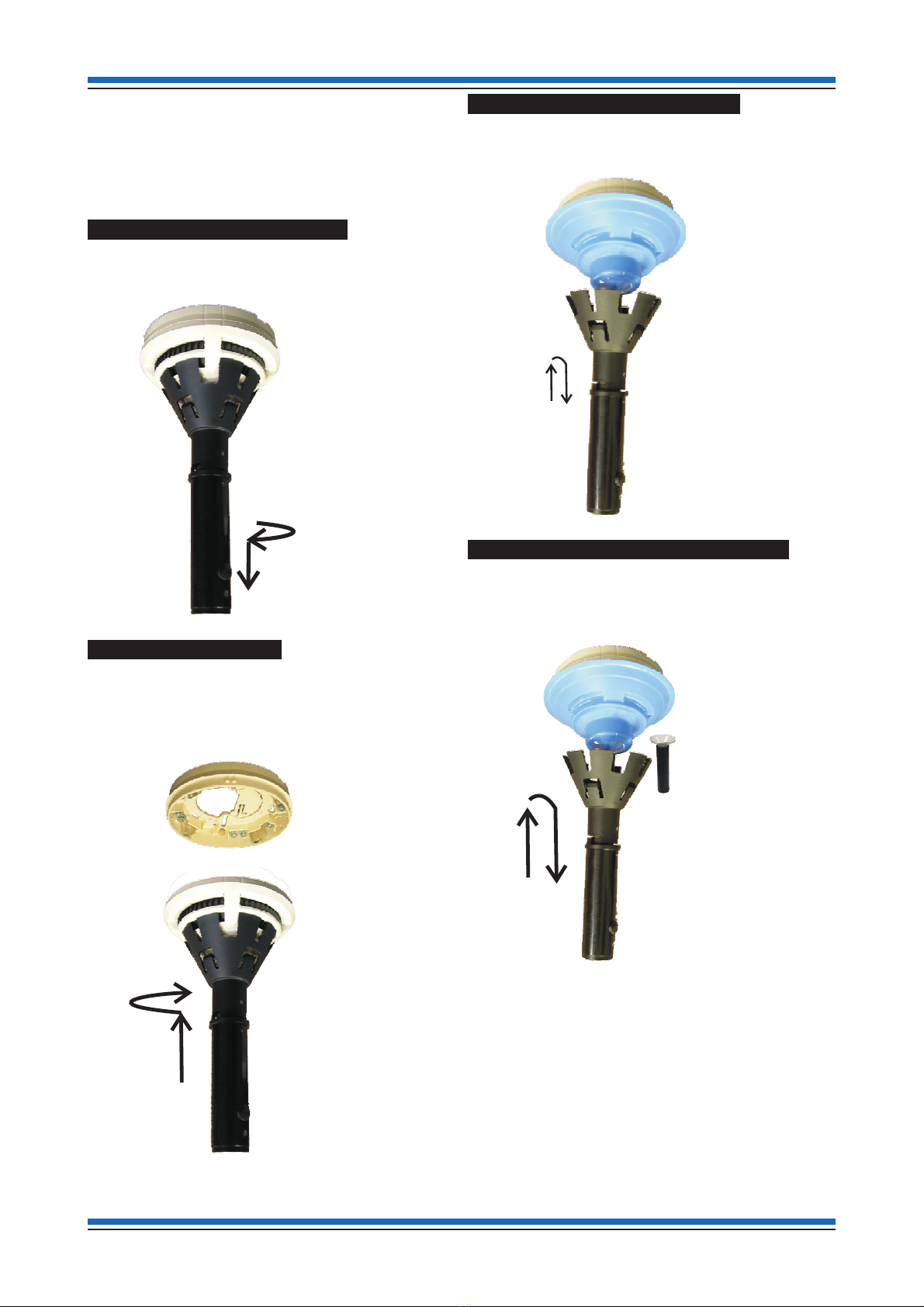

A piezo disk within a Sensor, Sounder & Strobe device assembly

outputs the sound via a horn, which is constructed in the

chamber moulding. The volume of the sound output can be

individually set at the device, note that the sound level should not

be set lower than 65dBA at 1m for standards compliance. The

system prevents adjustment of volume down to zero. Another

feature that can be configured is the soft start that ramps the

sound volume gradually to the maximum level set at the device.

The Sensor, Sounder & Strobe device will have a white baffle to

identify it as having Sound functionality.

"The Sound Pressure Level at 90°will far

exceed the more useful average Sound Pressure Level

quoted.

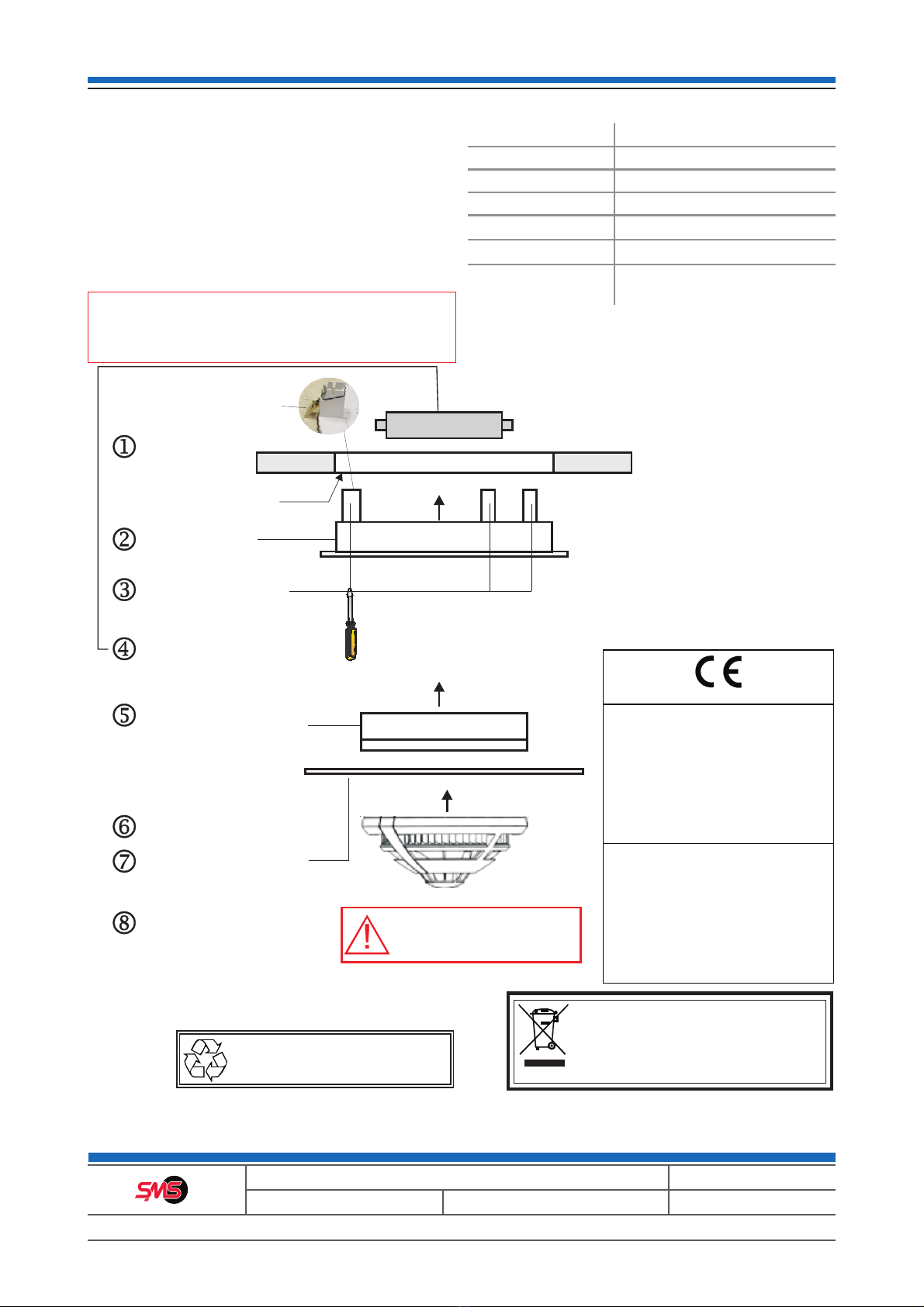

Strobe (St)

The Strobe utilises a high-power red LED that receives its power

from a super capacitor in the Sensor, Sounder & Strobe device

assembly. The high light output from the LED is made possible

by the low impedance of the capacitor. When compared with the

conventional Xenon flasher the Sensor, Sounder & Strobe

device, the strobe outputs a lower level of light over longer

duration to achieve the same intensity. The strobe is designed for

installation on a ceiling and provides a wide viewing angle to

allow the light to be seen all around. As factory set the strobe

provides a pulsed output every 2s with signal 1, 1 second with

signal 2 and 1 second with signal 3, however the operation of the

strobe with the signals 1, 2 and 3 can be changed at the

commissioning stage. The strobe is synchronised with any

S-Cubed strobe installed in the same system.

The Disability Act 1995 recommends visual alarms, like the

Strobe when installed in the protected premises to warn

occupants who are hard of hearing.

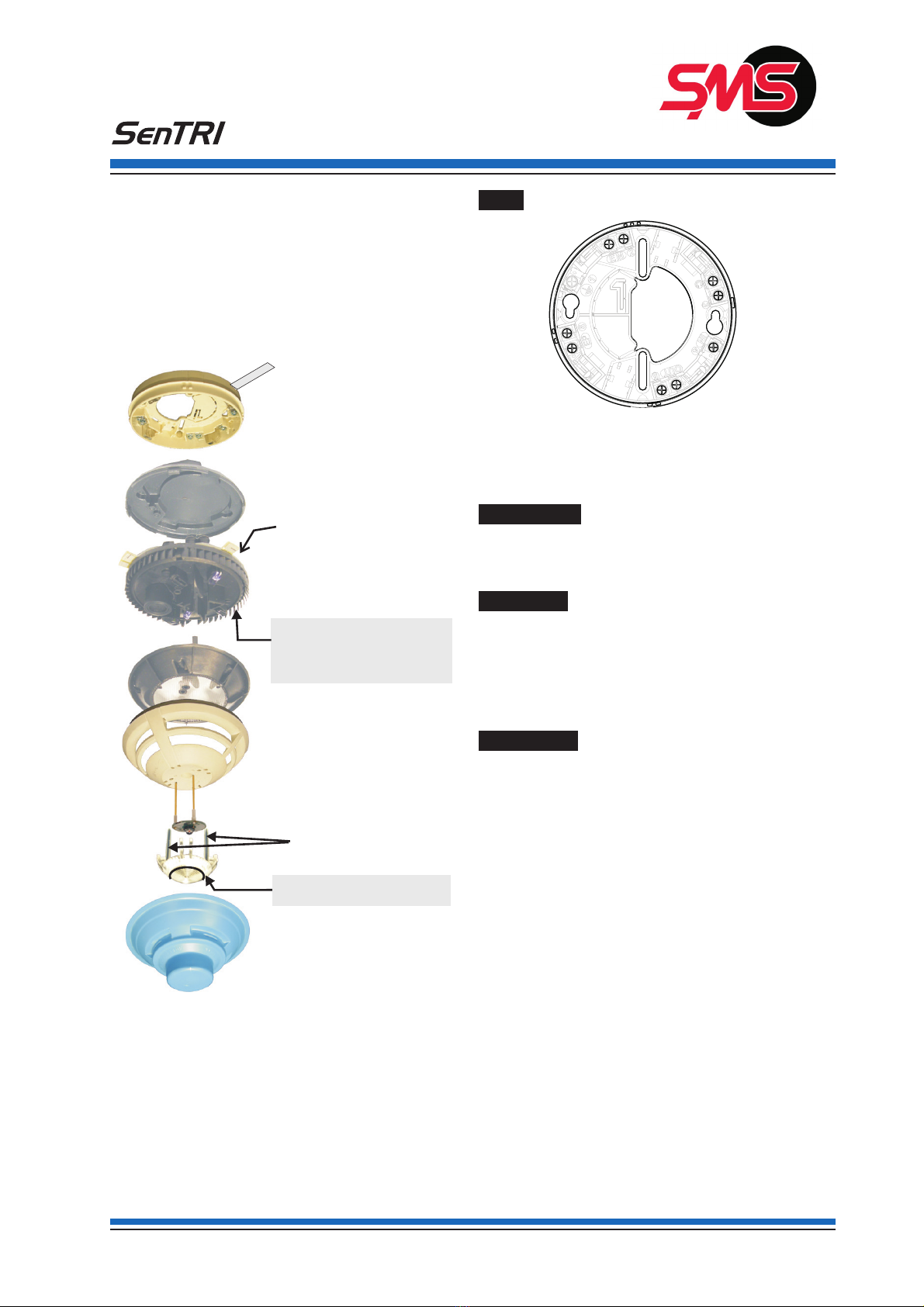

A metal back box must be used for surface and semi-flush

mounting and earth continuity must be maintained throughout the

whole loop. The earth must be securely connected to the metal

back box.

Description & Commissioning Sensor, Sounder & Strobe

2 4188-897 issue 3_12/13_SenTRI Sensor Data_PART-2

Transmitter

LED1

Receiver

Optical Chamber