Snap-on Equipment EEWA717A User manual

Form ZEEWA717A

Operators Manual

EEWA717A and EEWA719A Aligner Systems

Blank page

Safety

Safety Information

For your safety, read this manual thoroughly before operating the equipment.

TheAligner is intended for use by properly trained skilled automotive technicians. The safety messages

presented in this section and throughout the manual are reminders to the operator to exercise extreme

care when performing wheel alignments with this product.

There are many variations in procedures, techniques, tools, and parts for servicing vehicles, as well

as the skill of the individual doing the work. Because of the vast number of vehicle applications and

potential uses of the product, the manufacturer cannot possibly anticipate or provide advice or safety

messages to cover every situation. It is the automotive technician’s responsibility to be knowledgeable

of the vehicle to be aligned. It is essential to use proper service methods and perform wheel alignments

in an appropriate and acceptable manner that does not endanger your safety, the safety of others in the

work area or the equipment or vehicle being serviced.

It is assumed that, prior to using the Aligner, the operator has a thorough understanding of the vehicle

systems being serviced. In addition, it is assumed he has a thorough knowledge of the operation and

safety features of the alignment rack or lift, and has the proper hand and power tools necessary to

perform wheel alignments.

When using your garage equipment, basic safety precautions should always be followed, including:

1. Read all instructions.

2. Care must be taken as burns can occur from touching hot parts.

3. Do not operate equipment with a damaged power cord or if the equipment has been dropped or

damaged until it has been examined by a qualied serviceman.

4. Do not let cord hang over edge of table, bench or counter or come in contact with hot manifolds or

moving fan blades.

5. If an extension cord is necessary, a cord with a current rating equal to or more than that of the

equipment should be used. Cords rated for less than the equipment may overheat. Care should be

taken to arrange the cord so that it will not be tripped over or pulled.

6. Always unplug equipment from electrical outlet when not in use. Never use the cord to pull the plug

from the outlet. Grasp plug and pull to disconnect.

7. Let equipment cool completely before putting away. Loop cord loosely around equipment when

storing.

8. To reduce the risk of re, do not operate equipment in the vicinity of open containers of ammable

liquids, such as gasoline.

9. Adequate ventilation should be provided when working on operating internal combustion engines.

10. Keep hair, loose clothing, ngers, and all parts of body away from moving parts.

11. To reduce the risk of electrical shock, do not use on wet surfaces or expose to rain.

12. Use only as described in this manual. Use only manufacturer’s recommended attachments.

13. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

IMPORTANT!! SAVE THESE INSTRUCTIONS

DO NOT DISCARD!!

1

Safety

.................................................................................................................................................

Safety Instructions

IMPORTANT!! SAVE THESE INSTRUCTIONS

Risk of electrical shock.

• Do not operate equipment with a damaged power cord or if the equipment

has been dropped or damaged, until it has been examined by a qualied

service person.

• If an extension cord is necessary, a cord with a current rating equal to or

greater than that of the equipment should be used. Cords rated for less

current than the equipment can overheat.

• Unplug equipment from electrical outlet when not in use. Never use the

cord to pull the plug from the outlet. Grasp plug and pull to disconnect.

• Do not expose the equipment to rain. Do not use on wet surfaces.

• Plug unit into correct power supply.

• Do not remove or bypass grounding pin.

Contact with high voltages can cause death or serious injury.

Risk of electrical shock. High voltages are present within the console unit.

• There are no user serviceable items within the console other than the

keyboard and printer.

• Service on the unit must be performed by qualied personnel.

• Do not open any part of the console other than noted areas.

• Turn power switch off and unplug the unit before servicing.

Contact with high voltages can cause death or serious injury.

Risk of eye injury. Debris, dirt, and uids may drop from vehicles.

• Knock off any loose debris. Clean surfaces as needed to avoid any

materials from falling.

• Wear approved safety glasses when servicing.

Debris, dirt, and uids can cause serious eye injury.

Risk of crushing. Vehicles may roll off alignment lift if not secured.

• Leave automatic transmission in park or manual transmission in gear

unless equipment operation steps require vehicle in neutral.

• Apply parking brake unless equipment operation steps require wheel

movement.

• Use wheel chocks whenever vehicle is positioned on the lift.

• Follow rack or lift manufacturer’s safety recommendations when lifting a

vehicle.

Vehicles rolling off lifts can cause death or serious injury.

2

Safety

Riskofentanglementorcrushing. Therearemoving partsonvehiclelifts during

operation.

• Keep all persons clear of lifts.

• Read lift manufacturer’s operation instructions carefully.

• Follow lift manufacturer’s safety recommendations.

Contact with moving parts could cause injury.

Risk of pinching or crushing body parts when jacking vehicles.

• Keep hands and other body parts away from jacking surfaces.

• Do not use unapproved adapters (i.e. wooden blocks) when jacking a

vehicle.

• Do not bypass any jack manufacturer’s safety features.

• Read jack manufacturer’s operation instructions carefully.

• Follow jack manufacturer’s safety recommendations.

Improperly used or maintained jacks can cause injury.

Risk of burns.

• Do not touch hot exhaust systems, manifolds, engines, radiators,

etc.

• Wear gloves whenever performing a service near hot components.

Hot components can cause burns.

Risk of injury. Tools may break or slip if improperly used or maintained.

• Use the correct tool for the task.

• Frequently inspect, clean, and lubricate (if recommended) all tools.

• Follow recommended procedures when performing vehicle services.

Tools that break or slip can cause injury.

3

Table of Contents

Table of Contents

Safety Instructions ............................................................................................ 2

Introduction................................................................................................................................8

Getting started...........................................................................................................................8

Assembly and Setup..................................................................................................................8

Aligner Location.........................................................................................................................8

Power ON..................................................................................................................................8

Aligner Components..................................................................................................................9

Console .....................................................................................................................................9

Computer Connections..............................................................................................................9

Wheel Clamps.........................................................................................................................10

Measuring Pods.......................................................................................................................10

Aligner Software......................................................................................................................10

Screen Layout and Navigation ................................................................................................11

Toolbar Buttons........................................................................................................................13

Setup - Preferences.............................................................................................................. 15

Preferences Screen.................................................................................................................15

Interaction................................................................................................................................16

Security....................................................................................................................................16

Units ........................................................................................................................................16

Resolution................................................................................................................................17

Angle Units..............................................................................................................................17

Linear Units ............................................................................................................................17

Loading Units...........................................................................................................................17

Pressure Units.........................................................................................................................17

Connectivity Options................................................................................................................18

Romess Inclinometer...............................................................................................................18

Store Name .............................................................................................................................18

Regional Settings ....................................................................................................................19

Languages ..............................................................................................................................19

Specications ..........................................................................................................................19

Shutting Down the Computer ..................................................................................................20

5

Table of Contents

Steps to Performing a 4-Wheel Alignment..........................................................................21

Positioning the Vehicle on the Lift............................................................................................22

Attach the Targets/Pods ..........................................................................................................23

Home Alignment Tab ...............................................................................................................25

Begin a New Alignment ...........................................................................................................26

Vehicle Manufacturer, or Make................................................................................................26

Vehicle Year ............................................................................................................................27

Vehicle Model..........................................................................................................................27

Custom Specications.............................................................................................................27

View Specications..................................................................................................................28

Editing Specications ..............................................................................................................28

Adjustment Animations............................................................................................................29

Additional Assistance...............................................................................................................29

Enter Customer Data...............................................................................................................29

Adding Customer Information..................................................................................................30

Selecting a Stored Record.......................................................................................................30

Adding a New Customer..........................................................................................................30

Editing an Existing Record ......................................................................................................31

Backup and Restore................................................................................................................31

Charging the Pods...................................................................................................................32

Powering the Pods ..................................................................................................................32

Runout Compensation.............................................................................................................33

Left Rear Runout.....................................................................................................................34

Front Wheel Compensation.....................................................................................................35

Lower Wheels and Bounce (settle) the Suspension ...............................................................35

Readings Screen.....................................................................................................................36

Rear Readings Screen............................................................................................................37

Readings Toolbar Buttons ......................................................................................................37

Aftermarket Products...............................................................................................................38

Default Part Vendor.................................................................................................................38

INFO........................................................................................................................................38

Print Parts Report....................................................................................................................38

Cross Values / Total Toe ........................................................................................................39

Level and Lock Steering Wheel...............................................................................................39

Front Meter Readings Screen .................................................................................................40

All Readings Screen................................................................................................................41

Loop Button.............................................................................................................................41

Print Results............................................................................................................................42

6

Table of Contents

Measurement Menu...............................................................................................................42

Single Wheel Positioning.........................................................................................................43

Measuring Steering Angles......................................................................................................44

Measuring Steering Angles......................................................................................................45

Measuring Caster and SAI ......................................................................................................45

Toe-Out-on-Turns (TOOT).......................................................................................................46

Maximum Turn Angle (Lock to Lock).......................................................................................47

Adjust Menu...........................................................................................................................48

Adjust Caster and/or Camber..................................................................................................48

Adjust Rear Camber Elevated.................................................................................................51

Adjust A-Arms..........................................................................................................................52

EZ Toe.....................................................................................................................................53

Shims and Kits .......................................................................................................................54

Default Part Vendor.................................................................................................................54

INFO........................................................................................................................................54

Offset Cams and Bushings......................................................................................................55

Maintenance Menu ................................................................................................................56

Calibration ..............................................................................................................................57

Calibration Utilities.................................................................................................................. 60

Calibration factors...................................................................................................................62

Calibration history...................................................................................................................62

7

Introduction

Introduction

Thefollowingchaptersdetailallvariationsofsoftwarefeatureswhichmayormaynotbeincluded

in all aligner models. This document primarily is designed to cover software navigation and

features with minimum regard to the hardware platform in which it resides. There are many

variations of aligner models each of which may utilize different features of the base software

package.

Getting started

The aligner software offers extraordinary power and versatility. This section of the manual

describes how to begin enjoying the many features and benets. References are often made

to other sections of the Operator’s Manual.

Assembly and Setup

Installation and setup of a new aligner is best handled by a qualied Representative. If unsure

of who to contact, refer to the back page of this manual.

The aligner must be calibrated to at least one rack, lift, or other surface where wheel alignments

are to be performed.

All software is loaded onto the computer’s hard drive. The Software Discs shipped with the unit

containsthealignmentsoftwareasabackup,andisnotneededwhenperformingalignments. All

standard alignment features are activated at manufacture. Advanced features when available,

are activated as they are purchased with “Activation Codes”.

Setups for the PC hardware and Microsoft® Windows® are preset at the factory to maximize

performance and should not be altered.

Aligner Location

Locate the aligner in a location that provides the most convenience for the operator. Visual

contact with the monitor is necessary during most steps of a wheel alignment.

Power ON

The main power switch for the aligner is located on the rear of the cabinet. This switch applies

power to all of the aligner’s components except the WAP. Most of the individual electronic

components contain a power switch as well. Make sure the monitor’s power switch and the

computer’s power switch (in cabinet drawer) are left in the ON position at all times.

When the power switch is turned on, the unit initiates the computer boot-up. The boot sequence

maytakeseveralminutes. Ifanyproblemsareencounteredduringtheboot-upsequence,consult

theMaintenanceand Service sectionofthis Operator’sManual.The computer willautomatically

load the alignment software beginning with the logo screen. Click OK to advance to the Home

Alignment screen indicating the aligner is ready for operation.

8

Introduction

Aligner Components

Console

The console houses many of the aligner components

including the power supplies, the computer system

andprovidesplacesforthedisplaymonitor, keyboard,

andprinter. ThemeasurementPodsarestoredonthe

sides of the cabinet when not in use.

The upper shelf of the console provides a location

for the display monitor and space for a mouse and

keyboard.

The console also houses the computer system and

a printer.

NOTE: Do not expose the aligner or measuring

Pods to water, heavy dust environments,

or operations that produce metal chips.

Do not block the rear of the computer or

disable the cooling fan.

Computer Connections

Installation of the aligner includes connection of

devices to the computer. Care should be taken if

therebeanyreasonto examinethoseconnections,or

change a component such as the pointing device.

Note: Refer to the manuals supplied with the

computerandthemaintenancechapter for

computer connections.

CAUTION! THERE ARE NO SERVICEABLE PARTS

INSIDE THE COMPUTER. DO NOT ATTEMPT TO OPEN

THE COMPUTER CASE FOR ANY REASON. CALL FOR

SERVICE IFA COMPUTER PROBLEM IS SUSPECTED.

9

Introduction

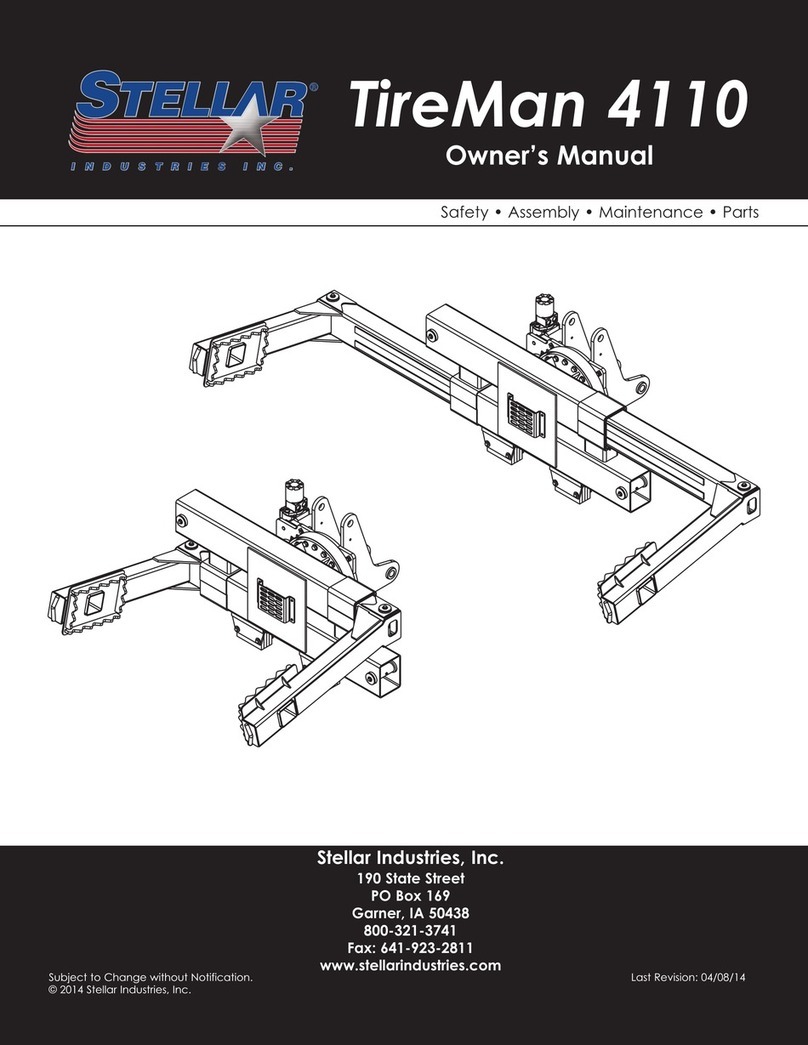

Wheel Clamps

Wheel clamps are adjustable to different wheel sizes

and types.

Two types of rim claws are supplied, one standard set

and a set used for those vehicles with lug mounted

wheel covers.

Measuring Pods

EachMeasuringPodismountedtoawheelclamp. To

attach,make surethe pivotshaftkey wayis facingup,

then insert the shaft into the hole in the clamp center

slide. Tighten the Hex Head Cap Screw, then tighten

the jam nut to prevent loosening. There are 2 Pods,

a right rear and a left rear.

Some functions of the aligner can be controlled from

the measuring Pods. Study the keypad to become

familiar with the layout of the Pod controls which

are:

1 Battery condition/Front Runout indicator LEDs

2 On/Off

3. Runout

4. Diagnostics LEDs

5. Master reset - not shown

Aligner Software

Operation from the console is accomplished primarily

by a single mouse click to initiate each function. The

right mouse button is not utilized within the alignment

software.

A standard keyboard is included for data entry. All

aligner functions can also be controlled from the

keyboard similar to the remote and the measuring

Pods. The function keys (F1 - F12) located on the

top row of the keyboard have decals that are the

equivalent screen icons.

In addition, the keyboard has a “Print Screen” key.

When this key is pressed the currently displayed

screen will be captured and printed.

10

3

1

2

5

4

Introduction

Screen Layout and Navigation

Thesoftwarefeaturesacommoninterfacethroughout

its many screens. Becoming familiar with the various

screen navigation functions is essential for efcient

use of the aligner.

1-Toolbar – these buttons appear on every screen,

and correspond to the F1-F12 keys on the keyboard.

The functions for F1-F4 are common to every screen,

while the functions of F5-F12 vary depending on the

screen

2-Screen Tabs – these tabs move to other major

areas of aligner operation. Each tab contains a new

set of Function Icons to perform functions related to

the title on the tab

3-Status Bar –containsalignersetupandinformation

on the vehicle selected

4-Radio Buttons – enables the selection of one item

among a list. Click on the button to the left of the

description to enable that function

5-OK and Cancel Buttons –mostscreenshavethese

twobuttons.OK saves theinformation and/ortells the

software the user is ready to move to the next step.

Cancel leavesthescreen, losing theinformation and/

or moving back a step, or possibly skipping the step

shown on-screen

11

3 4

5

1

2

Introduction

6-Drill Down Selections – on the Vehicle Selection

screen there are a series of choices with an arrow

next to them. To make a manufacturer selection,

double-click with the pointing device to expand to the

next level. Double-click on the year to further expand

for the model selections. To completely contract the

selection, double-click on the arrow or name of the

manufacturer

7-Scroll Bars – when these are present on the

screen, either vertical or horizontal, clicking on the

arrow moves the screen view in that direction to show

additionalselectionsorinformation. Youcanalsoclick

and hold the center slider and move it up or down to

create large movement.

8-FunctionIcons–whenthepointerispositionedover

anyfunctionicon,atext pop-upappearsdescribingits

function. When the left mouse button is clicked, this

function begins

9-Text Fields – some screens have text blocks that

allow the user to type information

Click to Select – some screens feature columns and

rows where a specic action is indicated. To use these,

click in the box as desired

12

6 7

8

9

Introduction

Toolbar Buttons

Toolbarsarefoundoneveryscreenwithinthesoftware.

The following legend identies the button and refers to

the pages where the button’s function is described.

Help – launches context-sensitive help screens.

Meters – jumps directly to the alignment meter screens.

Home – jumps directly to the Home Alignment tab.

Print – launches the Print Report screen.

Measure – from any readings screen, launches the Measure

screen.

Adjust – from any readings screen, launches the Adjust

features.

Animation – launches help with performing angle

adjustments.

Zoom – makes the selected meter ll the entire screen.

Unzoom – returns from a zoomed meter to the standard meter

screen.

Custom Specications – when selecting a vehicle, brings up

any custom vehicles that have been saved.

Restore OEM – during editing of specs, returns to OEM

values.

Plus and Minus – when editing specs, values increase or

decrease.

Delete – during custom specs, deletes the highlighted record.

Languages – allows the on-screen or printout languages to be

changed.

Edit Setup – allows changing of system setup items

13

Introduction

Information System – if equipped, calls up vehicle repair

information.

About - Gives information regarding software revision and

options along with copyright statement.

Logo Screen - Selecting this button displays the Logo screen

for display during idle time.

Aligner Diagnostics - Podvaluescanbeobservedandanalyzed

during readings display in the event of concern.

Find - During the customer data entry process, selecting this

button allows the user to search for an archived le using “Name”,

“Phone” or vehicle “License” number.

Sensor Update - Occasionally, rmware updates are made

available for enhanced Pod operation or addition of features.

Select this button to begin the load process.

Current Record - Recall the Customer record that is currently

stored in memory.

Clear All Fields - Select this button to clear all elds within the

data le currently open.

Pod Voltage - This displays a screen showing values critical for

proper cordless operation.

Recall the Current Alignment - Displays the current alignment

stored values.

Toggle Editing Mode - Select this button to toggle the method

of editing a displayed specication. A custom specication can

be edited by either using the +/- keys or by directly entering

desired values.

Calibration Utilities -Storedcalibrationfactorscanbesavedand

retrieved. Files containing factors and other data can be saved

to a oppy for retrieval or restoring to a machine.

Setup - The Preferences Menu is selected from the toolbar

icon when a basic software package is used as the operating

system.

A-Arm Toggle - Click to change from adjusting the upperA-Arm

to the Lower A-Arm.

14

Setup - Preferences

Setup - Preferences

The Preferences Tab is used to setup various

functionsandfeatureswithinthesoftware. Numerous

operating attributes or “preferences” can be altered

to suit the operator’s individual tastes. Although the

aligner is shipped with the most common elements

selected as default, an operator is able to tailor

several elements of the alignment process as well

as the display features to customize his machine.

Operator preferences can be altered before the

alignment process begins or any time thereafter.

Preferences Screen

ThePreferenceScreenallowsaccesstothefollowing

setup selections, each identied by an icon.

1- Interaction – controls several functions, which

alters interaction between the software and the

user

2- Units – selects the units to be displayed for angle

and linear measurements

3- Connectivity – activates access to a shop

management networking system

4- Store Name – allows a store name and address

to be entered for the customer printout

5- Languages – selects from various languages

for the screen and printout, also selects alignment

database

6 - System - Selects the desired rack to use

15

1 2 3

4 5 6

Setup - Preferences

Interaction

Security

Securityisa utilityscreenusedto activateadvanced

or optional features. Some software options may

be purchased after the initial sale of the Aligner. To

activate optional features, an operator or factory

representative will be required to obtain “activation

codes” which enables software features. Activation

codesareuniquetoonealignerandmaynotbeused

on other machines.

Units

There are many different units of measurement

for wheel alignment angles and dimensions

depending on local practices, vehicle manufacturer

requirements, or operator preference. Choose the

Units icon from the Preferences tab. Click on the

radio button next to the desired selection of units of

measure. Once a prescribed unit of measure has

been chosen, all readings and specications will be

stated in those units on all readings screens.

Toe Units – movethepointer over thetoeunitsbest

suited to the operator’s requirements and highlight

the button left of the desired unit. The choices are,

with examples:

- Degrees, Decimal – 0.5 degrees

- Degrees and Minutes – 0’ 30”

- Inch Fractional – 1/4”

- Inch Decimal – 0.25”

- mm (14” rim) – European metric display – 20

mm

- mm, (28” tire) – US metric display – 20 mm

- Input tire diameter – prior to bringing up toe

specications during the alignment program,

the Aligner will ask for the actual vehicle tire

diameter. The toe specs and readings will then

be calculated based on that input value.

16

Setup - Preferences

Resolution

Usethe Resolutionselectiontochoosehownumeric

displaysaretobereadduringthealignmentprogram.

Choices are Normal (0.10 degree or tenths of a

degree) or High (0.01 degree or hundredths of a

degree) resolution. Regardless of choice it won’t

effectthe accuracyof thealigner,simply thenumber

of digits after the decimal point and the associated

roundoff.

The selection will effect the wayAlignment readings

are viewed. Adjustments using a 0.10 degree

resolution will be easier to obtain than when using

the 0.01 degree setting. Aligning the car to within

hundredths of a degree requires a greater degree

of precision on the technician’s part to obtain exact

readings.

Angle Units

Specifythe unitsin which allangular measurements

will be displayed such as: caster, camber, SAI,

included angle, thrust angle, etc.

Examples:

- Degrees, Decimal – 0.5 degrees

- Degrees and Minutes – 0’ 30”

- Inch Fractional – 1/4”

Linear Units

Specify the units in which all linear measurements

(setback, vehicle dimensions, etc.) will be

displayed.

Loading Units

Whereapplicable,valuescanbeexpressedineither

kg (kilograms) or in lbs. (pounds).

Pressure Units

Units depicting pressure as in reference to tire

pressure can be expressed in psi or in bars.

17

Setup - Preferences

Connectivity Options

An interface is available for networking the aligner

to a shop management computer system. This

interface allows sharing of information between the

aligner and a host computer. (Optional software

required)

Romess Inclinometer

Thismenuisalsowherethe“RomessInclinomenter”

is activated for use with certain makes of vehicles,

Mercedes Benz for example. NOTE: Not available.

Store Name

Information entered into the Store Name selection

will be utilized on the alignment results printout.

Several lines of information is available for printing.

The name of the business, address, city and state

are entered. Also available for display is a phone

and fax number if desired.

18

This manual suits for next models

1

Table of contents

Popular Service Equipment manuals by other brands

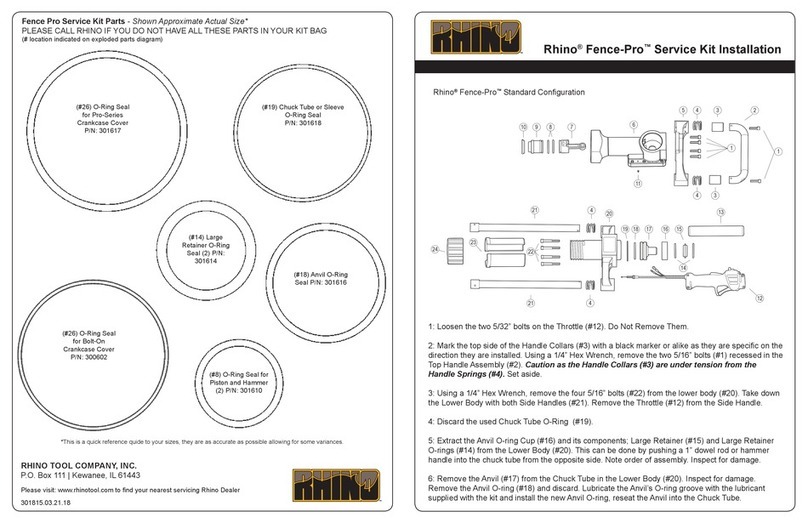

RHINO

RHINO Fence Pro Installation

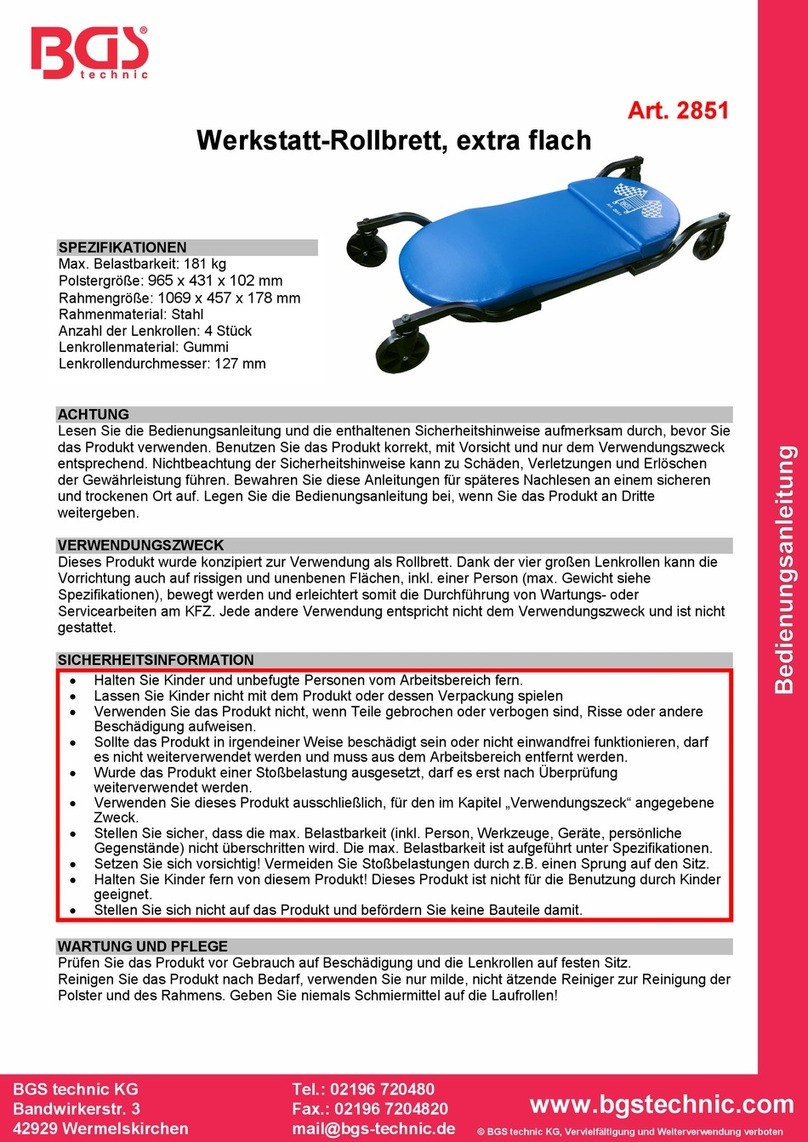

BGS technic

BGS technic 2851 instruction manual

MAHLE

MAHLE AIR-NEX 9380 Service manual

Pittsburgh Automotive

Pittsburgh Automotive 69814 Owner's manual & safety instructions

Link

Link DD2000 Operation & maintenance manual

Montezuma

Montezuma 41" TOOL CHEST AND CABINET instruction manual