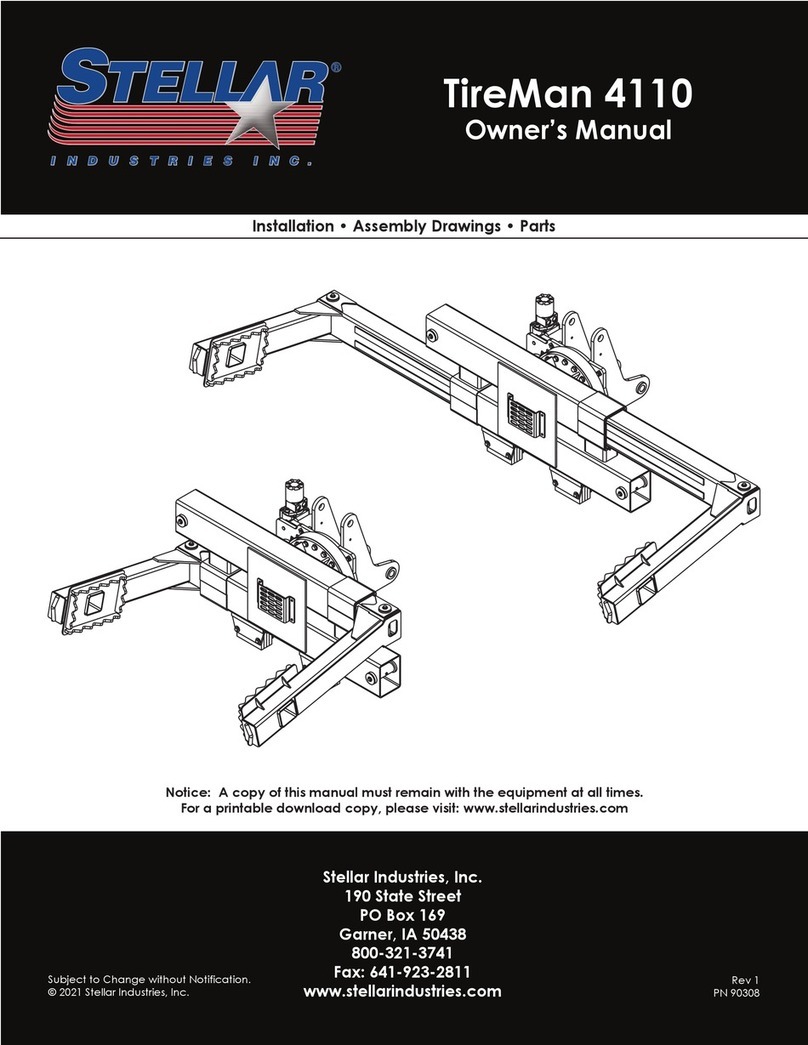

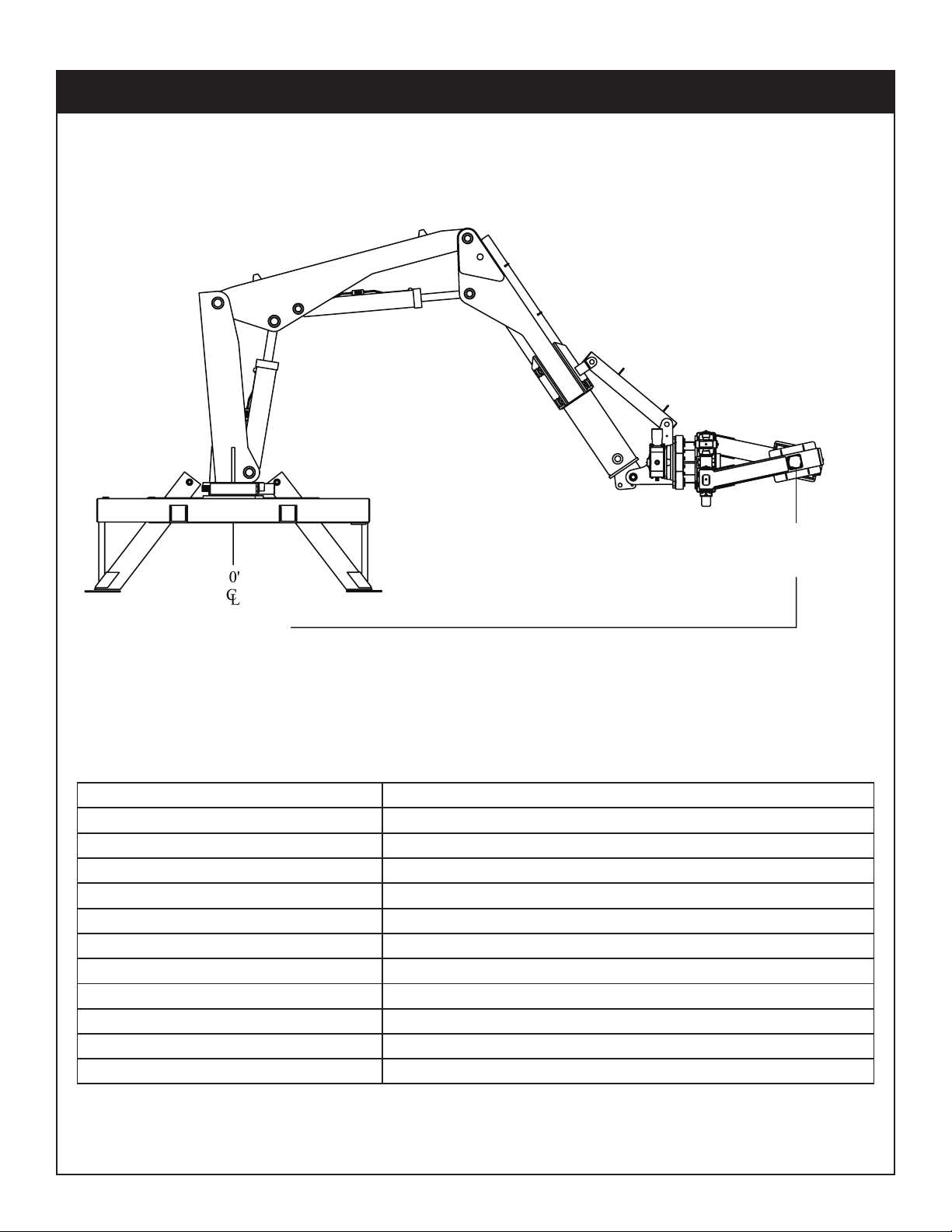

4Stellar TM4110 Owner’s Manual

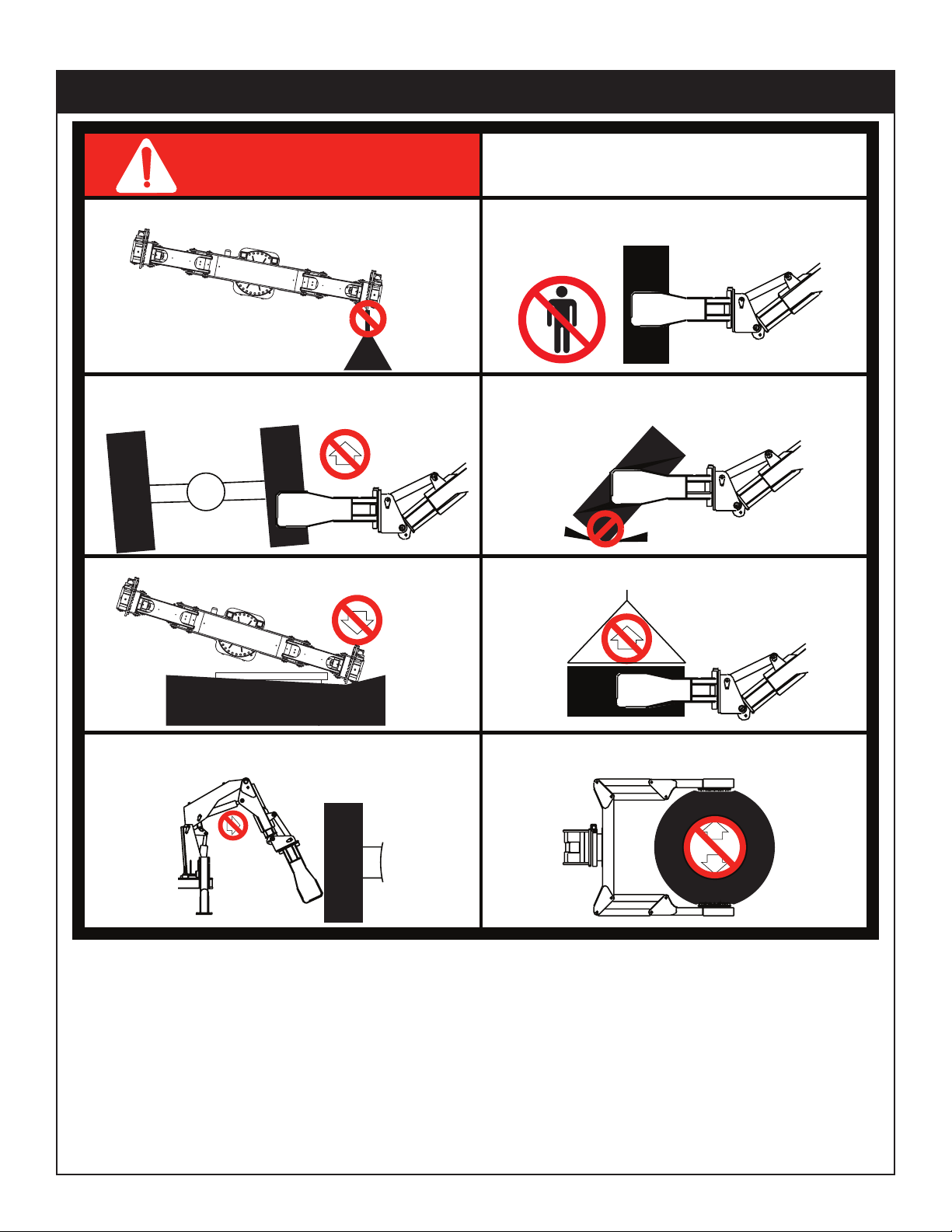

TireMan Safety Notes

General

It is the responsibility of the owner to instruct

the operator in the safe operation of your

equipment and to provide the operator

with properly maintained equipment.

Trainees or untrained persons shall be under

the direct supervision of qualified persons.

Do not operate equipment under the

adverse influence of alcohol, drugs, or

medication.

ersonal Safety

eep clear of all moving parts.

Always wear the prescribed personal safety

devices.

Always wear approved accident-preven-

tion clothing such as: protective helmets,

anti-slip shoes with steel toes, protective

gloves, anti-noise headphones, protective

glasses, and reflective jackets with breath-

ing apparatus. Consult your employer

regarding current safety regulations and

accident-prevention equipment.

Do not wear rings, wristwatch, jewelry,

loose-fitting or hanging clothing such as

ties, torn garments, scarves, unbuttoned

jackets or unzipped overalls, which could

get caught up in the moving parts of the

tire manipulator.

eep a first-aid box and a fire extinguisher

readily available on the truck. Regularly

check to make sure the fire extinguisher is

fully charged and the first-aid kit is stocked.

Do not use controls and hoses as hand-

holds. These parts move and cannot pro-

vide stable support.

Never allow anyone to ride the tire manipu-

lator arms or load.

Maintenance Safety

Never modify or alter any of the equip-

ment, whether mechanical, electrical, or

hydraulic, without explicit approval from

Stellar Industries.

Do not perform any maintenance or repair

work on the tire manipulator unless author-

ized and trained to do so.

Release system pressure before attempting

to make any adjustments or repairs.

Do not attempt service or repair when the

PTO is engaged.

Decals are considered safety equipment.

They must be maintained, as would other

safety devices. Do not remove any Decals.

Replace any Decals that are missing, dam-

aged, or not legible.

The safety instruction plates, notices, load

charts and any other sticker applied to the

tire manipulator, crane or service body must

be kept legible and in good condition. If

necessary, replace them.

Stability

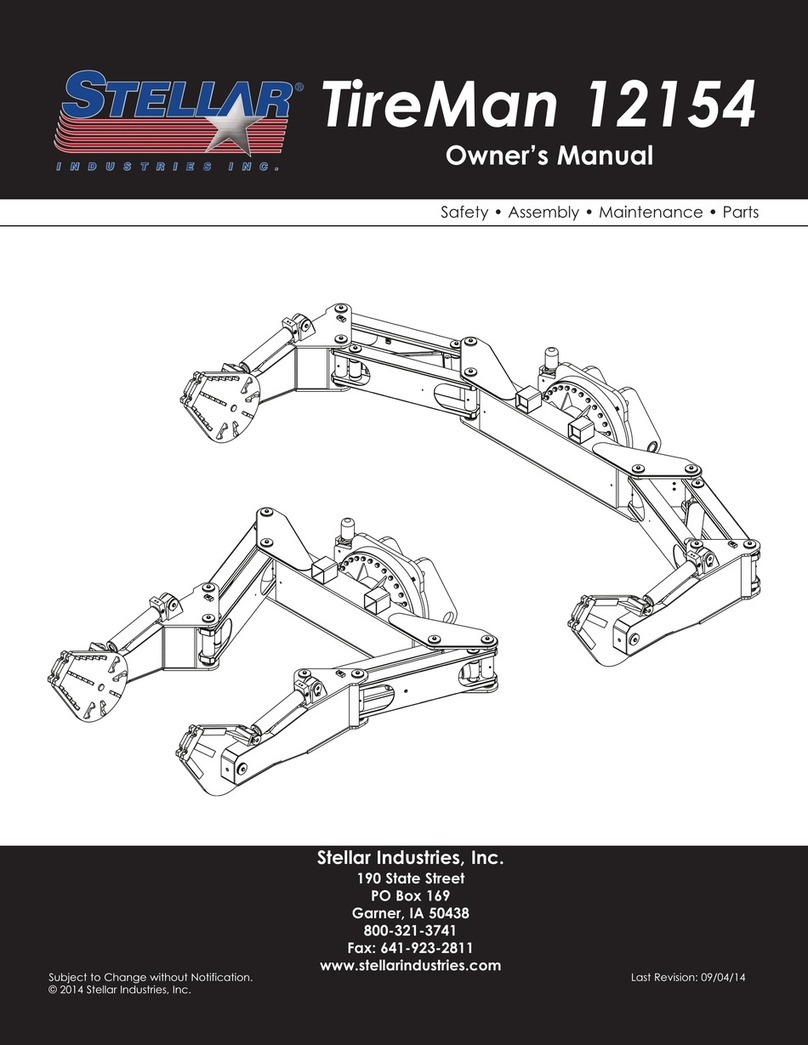

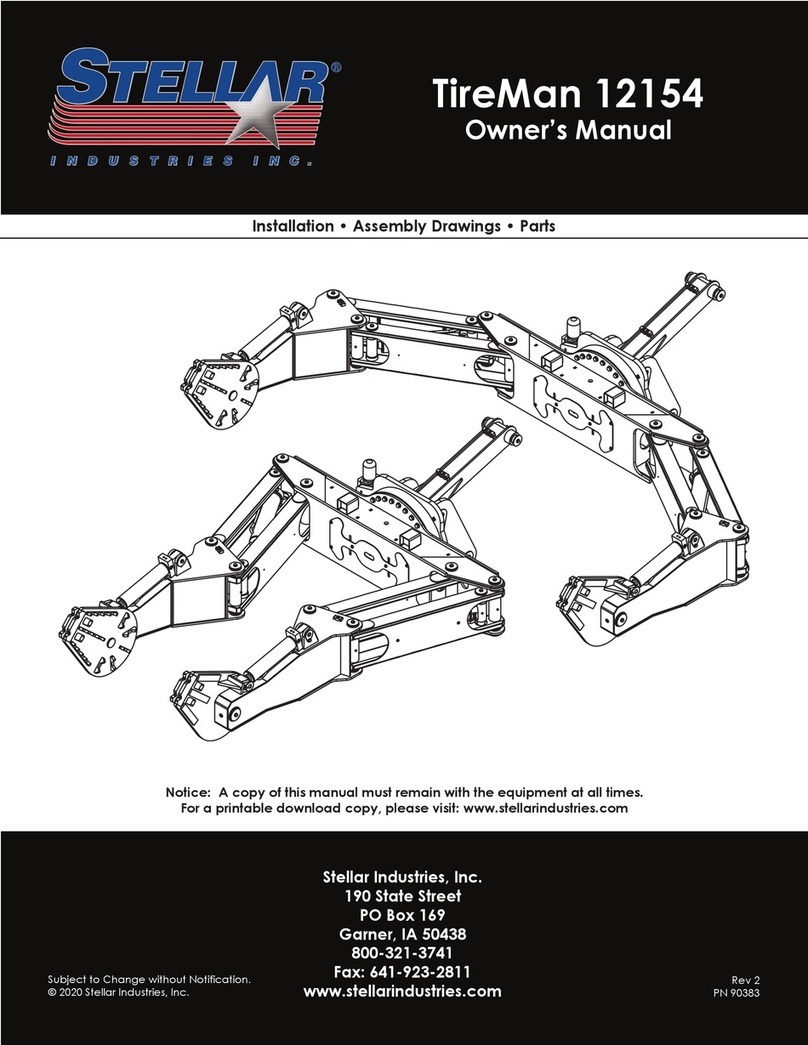

now the tire manipulator components and

their capabilities and limitations.

Overloading the tire manipulator may result

in serious injury to self and others, and dam-

age to the equipment and immediate sur-

roundings.

Never exceed manufacturer’s load ratings.

These ratings are based on the machine’s

hydraulic, mechanical, and structural

design rather than stability.

The supporting surface under the service

truck must be able to support the weight of

the machine and its load. Use outrigger

pads if necessary.