OPERATING INSTRUCTIONS

TO OPERATE THE HYDRAULIC PUMP UNIT

1. Position the Pump Unit on a stable, flat and level surface close to the damaged area.

2. Firmly close the Release Valve Stem by turning it clockwise and pump the Pump Handle to apply pressure.

3. Turn the Release Valve Stem counterclockwise to release the pressure.

4. The Pump Unit may be positioned horizontally or vertically. When using the hydraulic unit in a vertical position, always

keep the hose end of the hydraulic unit downward.

TO REPAIR FRAME DAMAGE

1. Determine which direction the frame needs to be bent.

2. Remove any obstructions that could be damaged or are in the way.

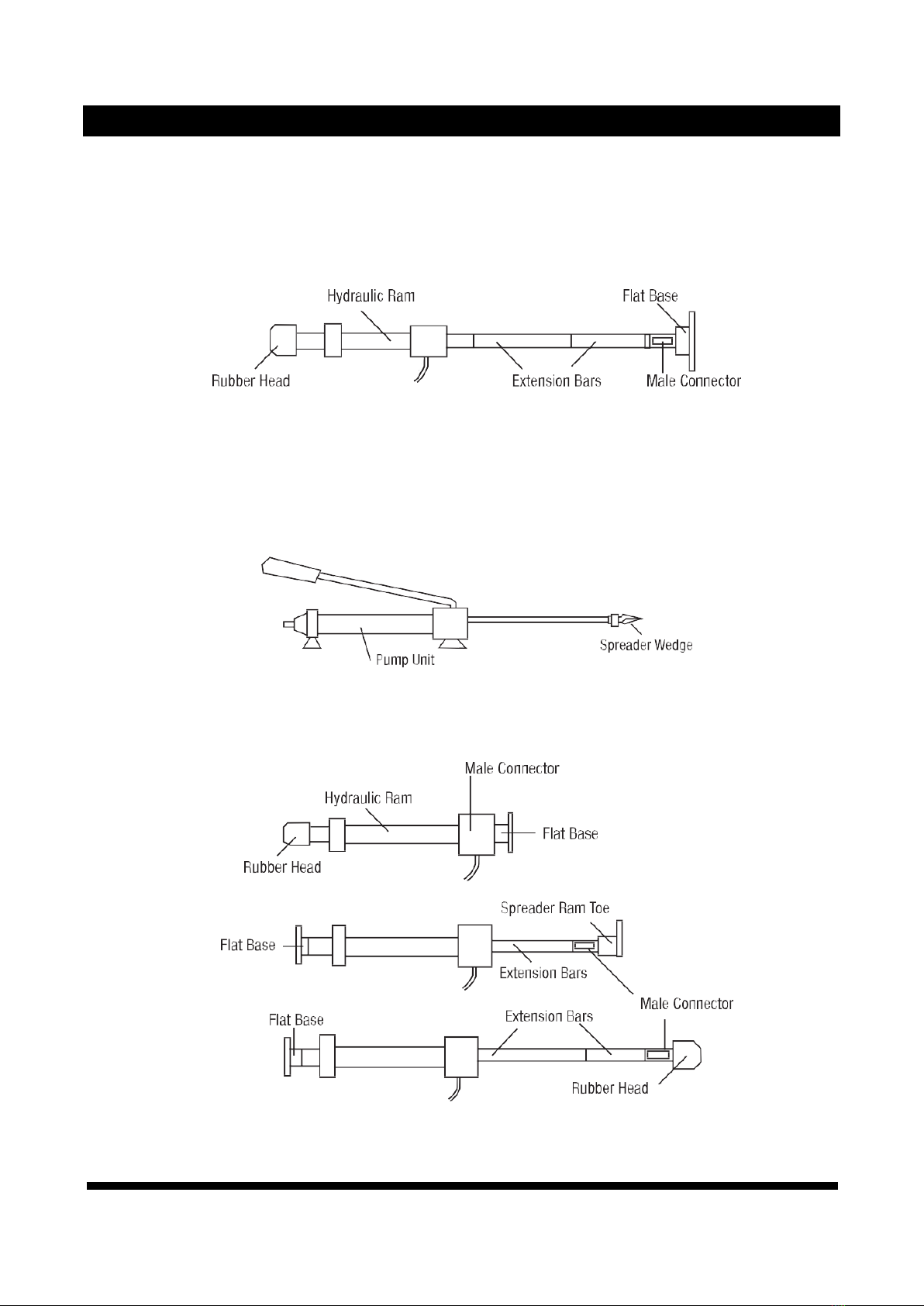

3. Connect the Flat Base to the stationary side of the Hydraulic Ram and connect the appropriate attachment to the

pushing end of the Stroke Ram.

4. Position the Hydraulic Ram so that the Flat Base is resting against a frame member opposite the damaged area. It

must also be in line with the direction in which the damaged area needs to be pushed.

5. Aim the pushing end towards the area that needs to be repaired and slowly apply pressure with the Pump Unit.

6. Once contact on either end has been made, step away as far as possible and continue to slowly apply pressure to the

damaged area until the desired bend has been made.

CAUTION: Keep hands away from contact areas and tight spaces. The Portable Power Kit may slip and cause injury.

7. When the damaged area has been bent to the desired position, slowly turn the Release Valve Stem on the Pump Unit

in a counterclockwise direction to release the hydraulic pressure and remove the Hydraulic Ram.

TO REPAIR BODY DAMAGE

1. Determine which direction the body panel should be moved.

2. Remove any obstructions that could be damaged or are in the way.

3. Connect the appropriate attachments to the Hydraulic Ram.

Note: When repairing larger body panel dents such as a dented door, fender or quarter-panel, the proper pushing

attachment will be the Rubber Head.

4. Position the Hydraulic Ram so that the Flat Base is resting against a frame or a sturdy body part opposite the

damaged area. It must also be in line with the direction in which the damaged area needs to be pushed. Make sure

the body part is stronger than the area to be bent or it may be damaged. A block of wood or a towel may be used to

protect the body part.

5. Aim the pushing end towards the area that needs to be repaired and slowly apply pressure with the Pump Unit.

6. Once contact on either end has been made, step away as far as possible and continue to slowly apply pressure to the

damaged area until the desired bend has been made.

7. When the damaged area has been bent to the desired position, slowly turn the Release Valve Stem on the Pump Unit

in a counterclockwise direction to release the hydraulic pressure and remove the Hydraulic Ram.