EEWH326A Tire Changer Operation Manual

- Page 10 -

1.0 INTRODUCTION

Congratulations on purchasing the Snap-on EEWH312A

Series air, or air-electric tire changer. This tire changer

is designed for ease of operation, safe handling of rims,

reliability and speed. This combination of features means

more profit and added versatility for your shop, enabling you

to work with aluminum or magnesium alloy wheels without

damagingcustomer’srims. Withaminimumof maintenance

andcare your Snap-onEEWH312ASeriesTireChanger will

provide many years of trouble-free operation.

Pleasereadthismanualthoroughly before operating the unit.

Instructions on use, maintenance and operational require-

ments of the machine are covered in this manual.

1.1 SPECIFICATIONS

Operation temperature range +41/+122 F (+5/50 C)

Air and Air-Electric tire changers for car, light commercial

vehicle and motorcycle tires designed for one-piece rims.

EEWH306A

Weight: EEWH306A 450 lbs (204 kg)

Air pressure required 110-170 psi (8-12 bar)

Bead breaker force 3300 lbs (kN 15)

Max. wheel diameter 40” (mm 1016)

Max. wheel width 12” (305mm)

Rim diameter outside locking 10”-18”(254-457mm)

Rim diameter inside locking 12”-20”(305-508mm)

Motorcycle wheels with adapters 15”-27”(381-584mm)

Motor 110 VAC 60Hz (air/electric models) 1 Hp (kw .75)

EEWH312A Series

Weight: EEWH312A 530 lbs (204 kg)

Air pressure required 110-170 psi (8-12 bar)

Bead breaker force 3400 lbs (kN 15)

Max. wheel diameter 40” (mm 1016)

Max. wheel width 12” (305mm)

Rim diameter outside locking 10”-20”(254-508mm)

Rim diameter inside locking 12”-22”(305-558mm)

Motorcycle wheels with adapters 15”-27”(381-686mm)

Motor 110 VAC 60Hz (air/electric models) 1 Hp (kw .75)

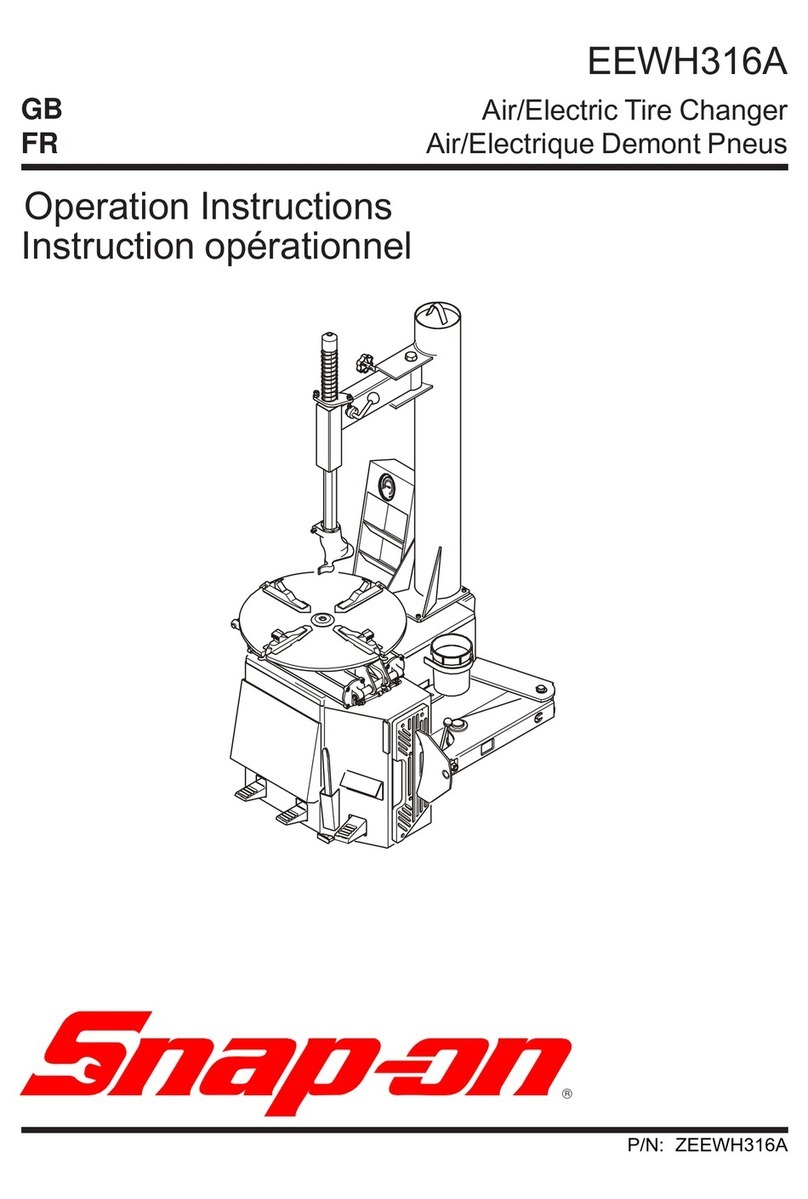

1.2 NOMENCLATURE

Beforeinstalling and usingtheSnap-on EEWH312A Series

Tire Changer it is suggested that you become familiar with

the nomenclature of the machine’s components.

1 Vertical slide

2 Swing arm

3 Swing Arm Adjustment knob

4 Lock lever

5 Mount/demount head

6 Tower or column

7 Turntable

8 Clamping Jaws

9 Bead breaker arm

10 Bead breaker blade

11 Bead breaker pads

12 Foot pedal controls

13 Inflation gauge

14 Bead seater/inflator pedal

15 Inflation jets

16 Safety restraint arm (Standard Models Only)

17 Safety restraint positioning knob

(Standard Models Only)

18 Inflation hose

19 Lube bottle

20 Mount/Demount Tool

21 Safety Restraint Arm Anti-rotation Lock

(Standard Models Only)

912

Figure 1