®

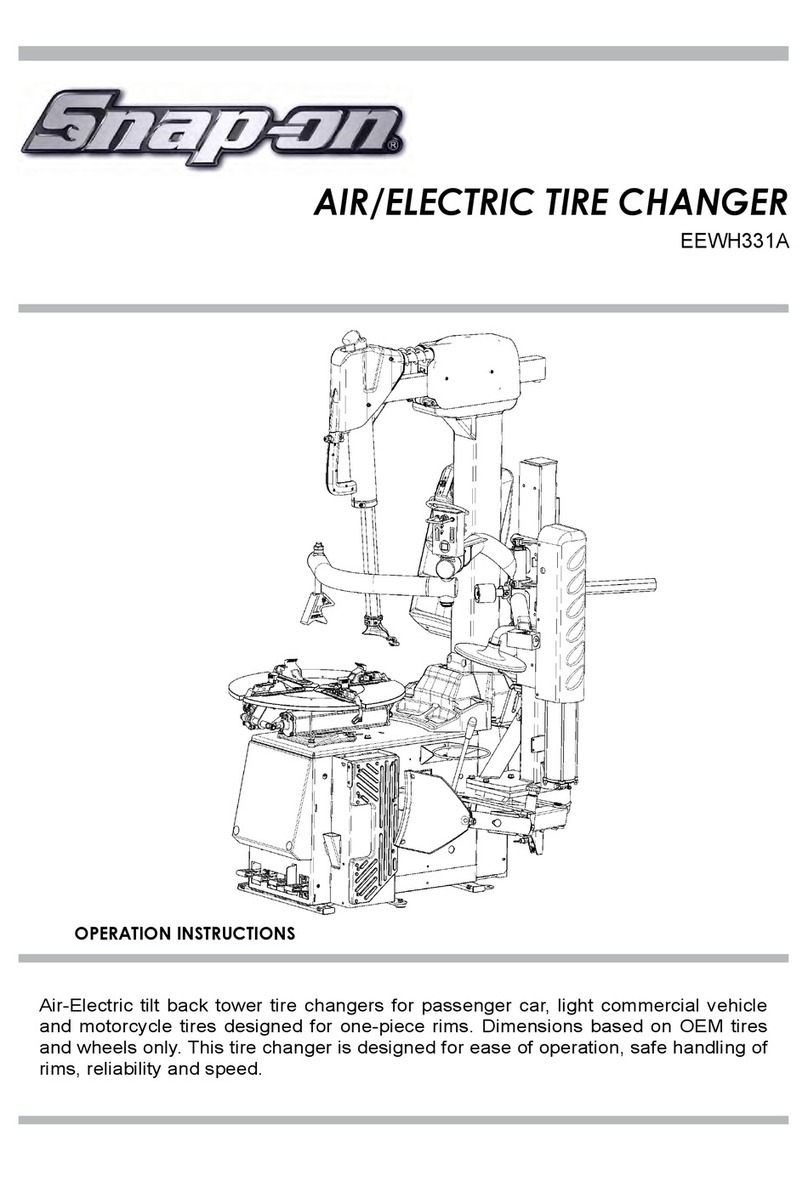

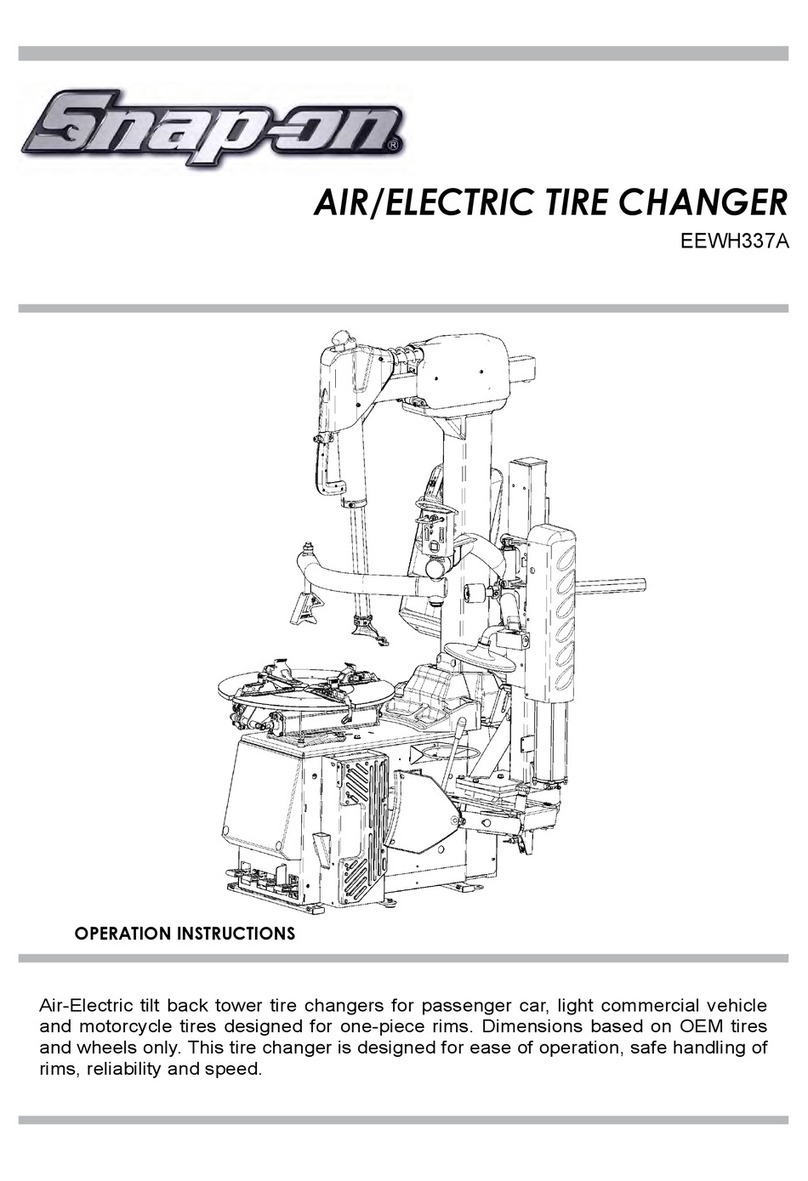

EEWH316A Tire Changer Operation Manual

Operation Manual Page 9

TABLE OF CONTENTS

SAFETY STATEMENTS ..................................................................................................................... Page 5-8

TABLE OF CONTENTS ..................................................................................................................... Page 9

1.0 INTRODUCTION ...................................................................................................................... Page 10

1.1 SPECIFICATIONS .................................................................................................................... Page 10

1.2 NOMENCLATURE .................................................................................................................... Page 10

1.2.1 FEATURES .............................................................................................................................. Page 11

1.3 MACHINE DIMENSIONS .......................................................................................................... Page 12

1.4 STANDARD ACCESSORIES .................................................................................................... Page 12

1.5 OPTIONALACCESSORIES ..................................................................................................... Page 13

1.6 GENERAL CAUTIONS ............................................................................................................. Page 13

2.0 INSTALLATION ......................................................................................................................... Page 14

2.1 ELECTRIC INSTALLATION (air-electric models) ..................................................................... Page 14

2.2 BEAD BREAKER INSTALLATION ............................................................................................ Page 14

2.3 AIR INSTALLATION .................................................................................................................. Page 14

3.0 CONTROLS .............................................................................................................................. Page 15

4.0 MOUNTING AND DEMOUNTING PRECAUTIONS .................................................................. Page 16

4.1 DEMOUNTING TUBELESS TIRES .......................................................................................... Page 16

4.2 MOUNTING TUBELESS TIRES ............................................................................................... Page 18

4.3 INFLATION OF TUBELESS TIRES .......................................................................................... Page 20

5.0 DEMOUNTING TUBE TYPE TIRES ......................................................................................... Page 21

5.1 MOUNTING TUBE TYPE TIRES .............................................................................................. Page 21

5.2 INFLATING TUBE TYPE TIRES ............................................................................................... Page 22

5.3 MOUNTING AND DEMOUNTING MOTORCYCLE TIRES ....................................................... Page 22

6.0 MAINTENANCE........................................................................................................................ Page 23

--------------------------- FR ----------------------------

À partir de la page 25

--------------------------- GB ---------------------------