EEWH311C 9

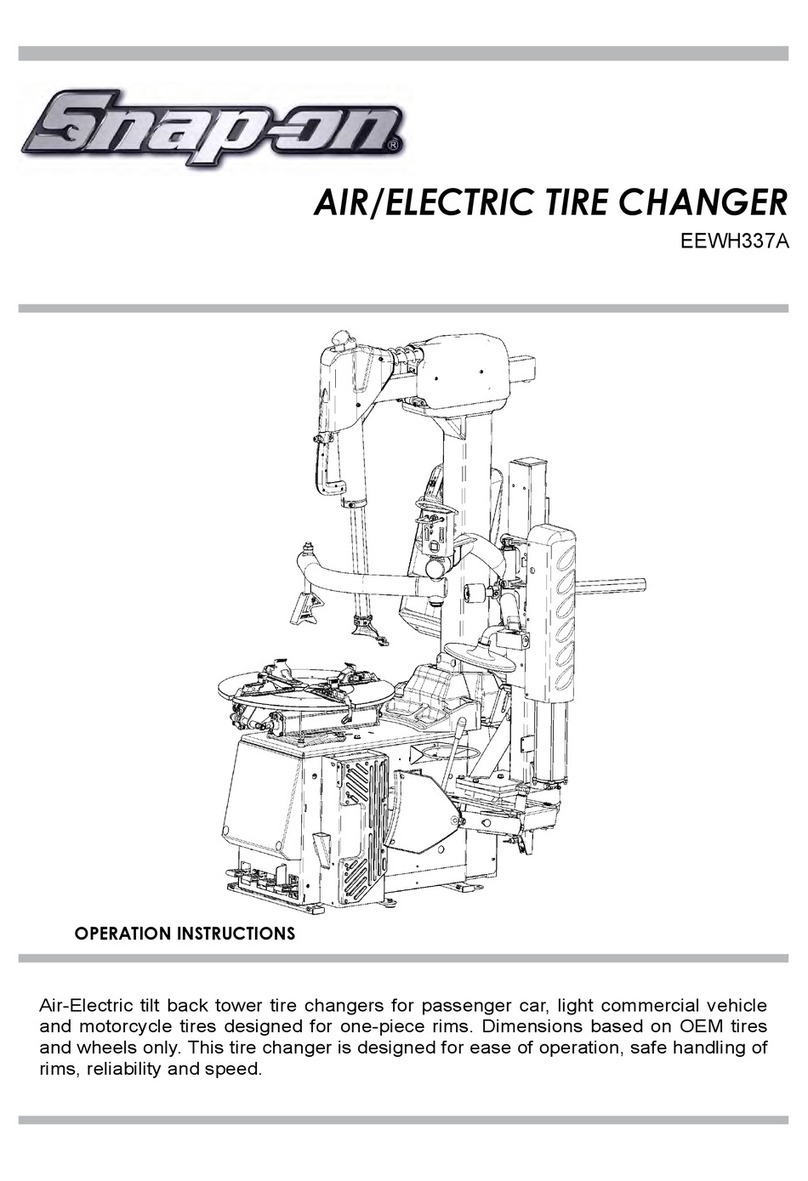

1.2.1 TURNTABLE & CABINET FEATURES

EEWH311C

INTEGRATED BEAD SEATING JETS - Air in!ation jets are integrated into

the turntable clamping jaws to insure full bead seating force directly into the

tire cavity regardless of tire diameter.

3-position Bead Breaker

Position one covers the range of popular tires (3.5” to 13”). Position two

covers many tailer sidewall light truck and SUV tires (4” to 14.5”). Position

three covers the larger wheel diameters with low pro"le performance tires

(4.5” to 15”).

Turntable with Reverse

Forward speed of 7 RPM providing precise control and minimizes tear-

ing of tires. In the event the bead becomes jammed up on lower pro"le

performance tires, the 7 RPM reverse mode quickly relieves the mount/

dismount head to minimize wheel damage from using a prybar.

TWIN CYLINDER CLAMPING POWER - Two 3” clamping cylinders provide

uniform clamping pressure throughout the stroke (regardless of rim sizes)

as well as providing 25% more clamping power than most single clamping

cylinder tire changers. Additionally these two smaller cylinders reduce the

critical turntable to cabinet distance, reducing the stress on the transmission.

WHEEL CLAMPS

UNIQUE FIFTEEN POINT CONTACT CLAMPS

Provide better gripping capability regardless of dirt and moisture.

REDUCED ANGLE CLAMPS

Increases clamping contact area with rim insuring no slippage.

NYLON INSERT SOFT TOUCH CLAMPS

The two front and rear insert in the clamping jaws provides Nonmetal touch

in critical customer visible areas.

VALVE CORE/TIRE TOOL STORAGE CABINET

On tire changer storage area for valves, tools, caulk, etc.

INCOMING AIR PRESSURE GAUGE

Ergonomically located air gauge allows easy operator monitoring of incoming

air pressure.

INTEGRATED PRESSURE LIMITER

Integrated safety pressure limiter stops air !ow once tire pressure has

reached approximately. 55 PSI preventing accidental tire over-in!ation.

MOUNT/DEMOUNT ARM ASSEMBLY

ADJUSTABLE SLIDEWAY - Unique adjustable vertical mount/demount hex

shaft slideway allows for easy operator adjustment to compensate for any

cumulative wear in the slideway causing mount/demount head movement.

NON-SCRATCH NYLON INSERT - Integrated into the mount/demount head

is a replaceable scratch resistant nylon insert protecting against accidental

rim contact.

CONSTRUCTION DESIGNED FOR DURABILITY

RUST PROOF VALVES AND CYLINDERS - Critical bead breaking cylinder

is lined with rustproof poly"ber liner for years of rust free operation. Non-lined

cylinders will pit causing bead breaker power loss.

LIFETIME LUBRICATED POLYMER VALVES - Critical foot valves fabricated

from glass/"ber self-lubricating material providing years of maintenance

free operation.

WATER SEPARATOR AND AUTOMATIC OILER - Lubricates all air used

for machine operation, does not lubricate air used for tire in!ation, as do

some competitive models.

HIGH TORQUE 1HP MOTOR - Industrial strength high torque turntable drive

motor eliminates tire remount stalling on low pro"le high performance tires.

TRANSMISSION - Designed for extremely heavy use, the critical motor to

turntable transmission linkage carries a full two (2) year replacement warranty.

PNEUMATIC BEAD ASSIST ARM

Up/Down Control Switch - Toggle switch allows single "nger operation of

all pneumatic PBA functions, with or without gloves.

Top Bead Roller - Provides easily controlled pneumatic power to drive

upper beads down into the wheel drop center (while tire is turning) for easy

lubrication prior to dismounting. Also provides pneumatic power assistance

for safely remounting second bead on extremely low pro"le and Run Flat

design tires.

Bead Depressor - Provides easily controlled pneumatic power to depress

the tires sidewall during the remount cycle. This will prevent premature bead

seating before the entire bead has been reinstalled on the wheel. Provides

an added level of safety by keeping the technicians hands away from the

bead area during this potential pinch point procedure. Additionally the Bead

Depressor “follows” the tire around while turning to guarantee successful

remount "rst time every time.

Bottom Bead Roller - Provides easily controlled pneumatic power to unseat

stubborn lower beads which may have accidentally reseated after the original

bead breaking procedure. Also allows a technician to raise and hold wider

tires up, to assist in safely and easily getting the second bead up onto the

mount/demount head.

Wheel Centering Depressor - Provides downward pressure on a rim when

working to clamp a low pro"le tire/rim combination. Will assist the technician in

correctly seating the rim clamps between the tire and the rim when clamping

from outside in where it is dif"cult to depress the tire sidewall enough to expose

the rim edge.

SAFETY RESTRAINT ARM (OPTIONAL)

TIRE/RIM ASSEMBLY RESTRAINT - Safety Restraint Arm restrains tire

and rim assembly to the tire machine during the in!ation process reducing

potential for injury caused by the unlikely event of catastrophic tire or rim

failure.

SIMPLE SWING ARM DESIGN - SRA arm easily swings to the left when

not in use, allowing the technician to quickly and safely perform the in!ation

process without disrupting the tire changing procedure.

GRAVITY LOCK - SRA lock mechanism operates without any mechanical

cam system eliminating the possibility of system deterioration or mis-

adjustment from mechanical wear.

POSITIONING SAFETY INTERLOCK SWITCH - Integrated switch insures

that SRA arm is centered on the tire/rim assembly before the in!ation process

can begin.

ANTI-ROTATION LOCK - Prevents SRA from rotating horizontally during

in!ation process.