2

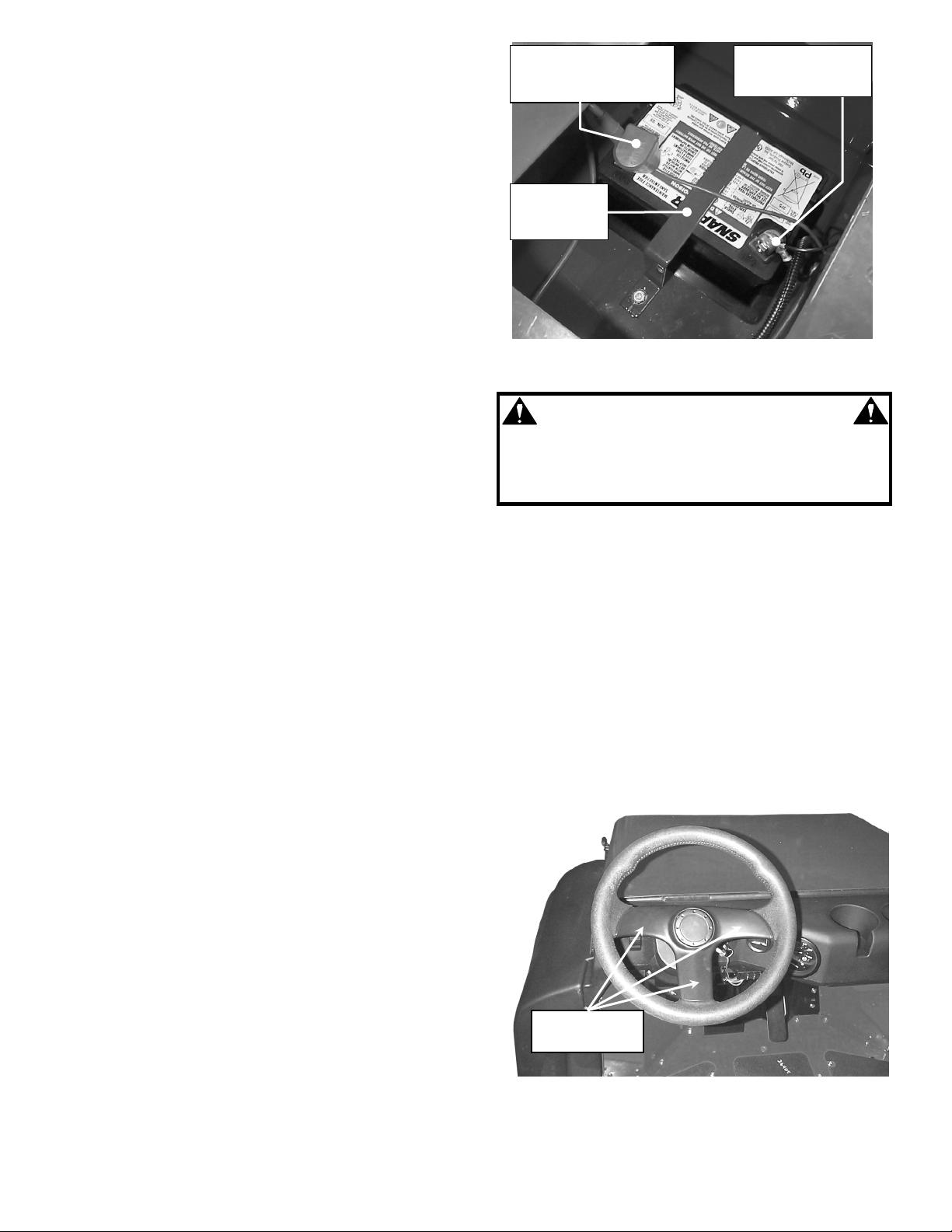

STEP 2

INSTALL FRONT TIRES

(NOTE: The front bumper can be used to lift the front of

the machine.)

1. Loosen (do not remove) the two lug nuts securing

each support plate to the left and right front wheel

hubs. See Figure 1.1.

2. Remove the hardware securing the support plates

to the crate bottom.

3. Lift front of machine only high enough to install front

tires. Block machine securely to prevent it from

falling. Remove lug nuts loosened in operation #1

of this assembly step, and remove and discard

support plates. Set lug nuts aside for future

operation.

4. REMOVE OPERATOR PROTECTIVE STRUCTURE

FROM CRATE BOTTOM AT THIS TIME.

5. Check front wheel hubs to insure that they rotate freely.

Also check to make sure that the castle nuts are tight,

and the cotter pins are inserted fully and have at least

one leg bent back to secure in place.

6. Install left and right front tires (valve stems facing

outward) and secure each with 5 lug nuts (including

lug nuts removed in previous operation). NOTE for

Trail Cruisers only: Tires are directional. Install with

points of the chevron treads pointing forward. See

Figure 1.2.

7. Remove blocks and lower machine.

8. Torque lug nuts to 75 ft-lbs, using sequence shown

in Figure 1.2.

9. Install dust caps onto front wheel hubs.

STEP 3

ADJUST TIRE PRESSURE

IMPORTANT! Correct tire inflation pressure is critical to

the proper handling and braking of the machine.

1. Using a low-pressure tire gauge, check tire

pressure.

2. Adjust tire pressure to 15 psi. front and rear as

needed.

STEP 4

INSTALL OPERATOR PROTECTIVE

STRUCTURE (OPS)

NOTE: Assistance is required when installing the

Operator Protective Structure.

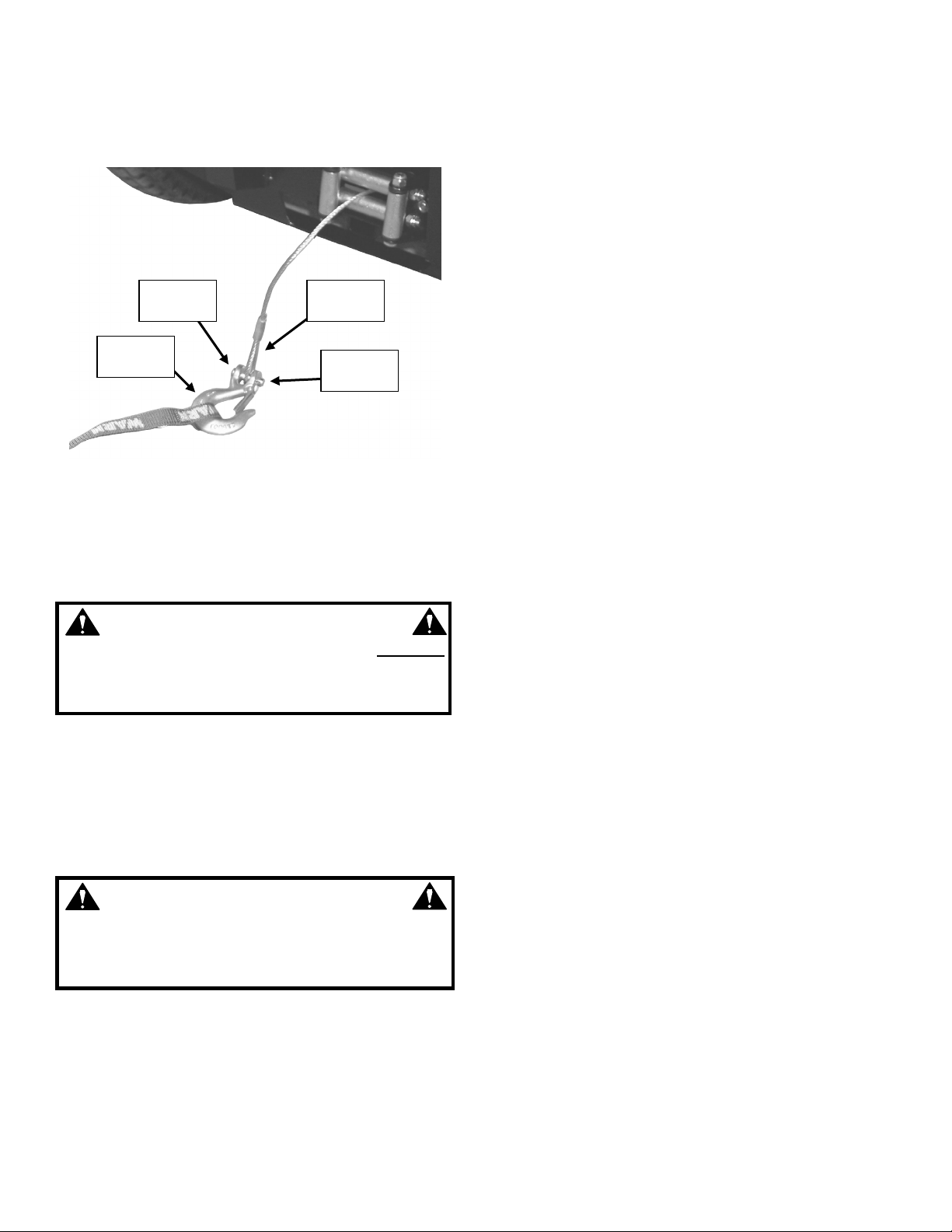

WARNING

Operator Protective Structure must be installed and

all mounting hardware tightened securely before

starting or operating machine.

WARNING

Do Not modify the OPS in any way before, during or

after installation. Modifying the OPS can result in

serious injury or death.

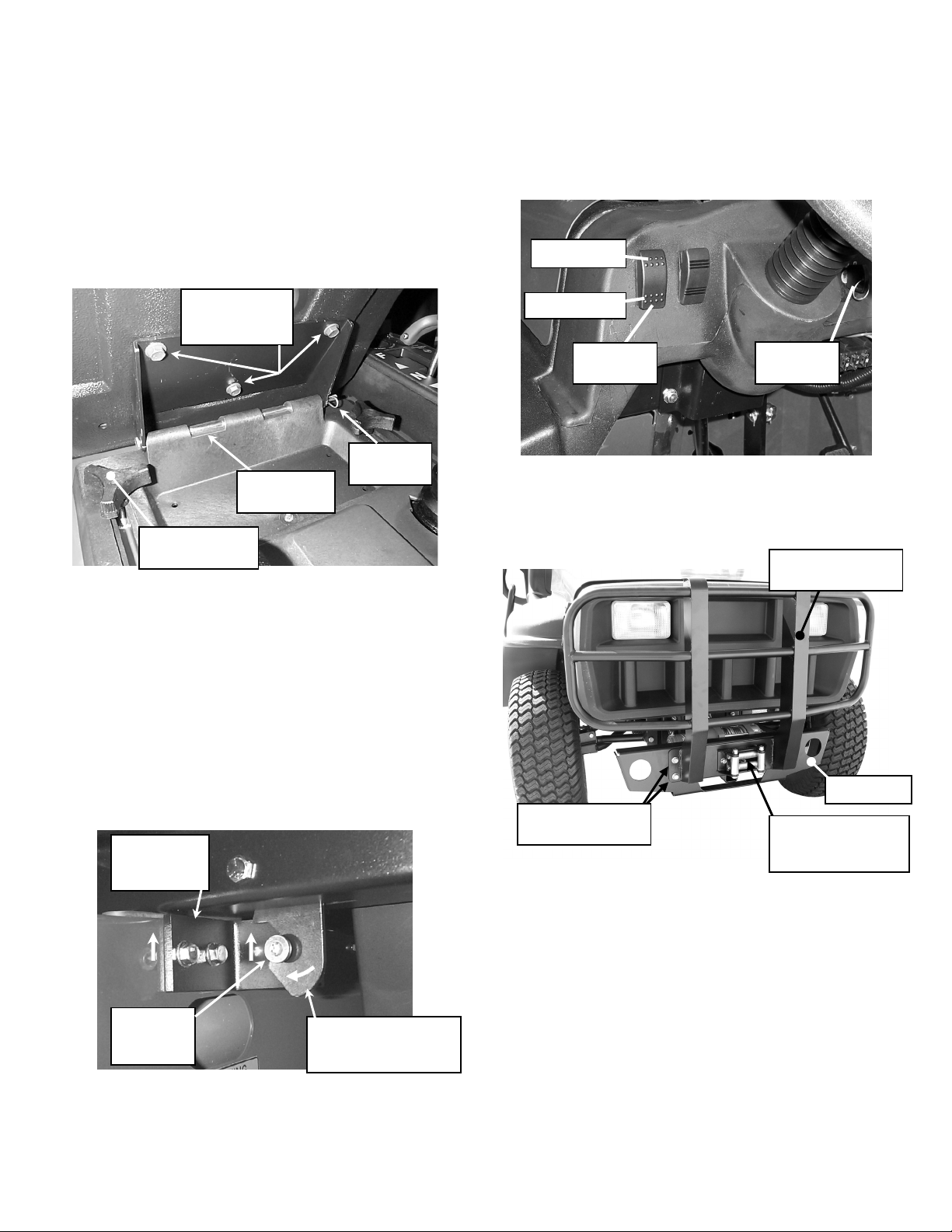

1. Locate and identify OPS mounting hardware –

twelve 3/8-16 x 1” carriage bolts and twelve 3/8-16

nyloc nuts. Place six of each on either side so they

will be in easy reach when attaching OPS to frame.

2. With assistance, raise OPS to vertical position and

orient structure so that the “WARNING” decal,

located on the side of the OPS, is on the right

(passenger) side of the machine.

3. Align holes in OPS with corresponding holes in

frame. Get one carriage bolt started on each side.

NOTE: Insert bolt from inside, as shown in Figure

1.3. Secure with 3/8-16 nyloc nut. Do not tighten at

this time.

FIGURE 1.3

4. Install remainder of bolts as per operation #3 in this

step, securing each with a nyloc nut.

5. Torque all OPS mounting hardware to 30-35 ft-lb.

NOTE: ALL OPS hardware must be properly

torqued to prevent inadvertent loosening and

subsequent failure of structure in a rollover.

6. Attach upper and lower heat shields to OPS using

two 5/16-18 self-tapping bolts. Do not tighten at this

time.

7. Attach side tabs of lower heat shield to left and right

frame rails using two 5/16-18 x 7/8” bolts and two

5/16-18 nyloc nuts.

8. Tighten all heat shield hardware securely.

CARRIAGE

BOLTS (6 EACH

SIDE). INSTALL

FROM INSIDE.

LOWER HEAT

SHIELD

UPPER HEAT

SHIELD

HEAT SHIELD

HARDWARE (x2)

OPS