Sno-Way ProControl 2 Plus User manual

97102196B

INSTALLATION MANUAL

ProControl 2 Plus™ and

Energy Smart System (ESS

®

)

Upgrade Package

For use with Halogen Lamps:

99101431,99101432, 99101433,99101434

For use with LED Lamps:

96117833,96117834, 96117835,96117836

Sno-Way

®,

Down Pressure

®

and EIS

®

are registered trademarks of Sno-Way International, Inc.

ProControl

™

, MegaBlade

™

, V-Wing

™

, E-Z Switch

™

, Revolution

™

, MaxAdjust

™

, SpeedLock

™

, and QuickJack

™

are trademarks of Sno-Way International, Inc.

©2020 Sno-Way

®

International

1

TABLE OF CONTENTS

Page

INTRODUCTION ......................................................................................................... 2

SAFETY ...................................................................................................................... 3

INSTALLATION INSTRUCTIONS ............................................................................... 4

Energy Smart System (ESS®) Vehicle Harness Installation ......................... 4

Check Connections .......................................................................................... 6

Receiver Installation on Plow .......................................................................... 6

Harness Installation for Keeping my Halogen Plow Lamps.......................... 7

Harness and Lamp installation for Upgrading to LED Plow Lamps ............ 8

Headlight Aiming Procedure............................................................................ 9

2

This manual was written for the installation of your

upgraded plow control and lighting system. Refer to the

Table of Contents for an outline of this manual.

Please keep this manual with your machine at all times as

reference material and so it can be passed on to the next

owner if the machine is sold.

We require that you read and understand the contents of

this manual COMPLETELY, especially the chapter on

SAFETY, before attempting any procedure contained in

this manual.

The Society of Automotive Engineers has adopted

this SAFETY ALERT SYMBOL to pinpoint character-

istics that, if NOT carefully followed, can create a

safety hazard. When you see this symbol in this man-

ual or on the machine itself, BE ALERT!, your per-

sonal safety and the safety of others, is involved.

• Defined in the next column, are the SAFETY ALERT

messages and how they will appear in this manual.

NOTE: Additional information concerning the equipment

or the procedure that may or may not be contained else-

where in this manual.

We reserve the right to make changes or improve the

design or construction of any part(s) without incurring the

obligation to install such parts or make any changes on

any unit previously delivered.

Graphics and illustrations may be used which may show

equipment and/or options not included in every

installation without incurring the obligation to install such

parts or make changes on units previously delivered.

Sno-Way Service Parts Manuals are available on-line or

at your authorized Sno-Way dealer. Factory contact

information is available at www.snoway.com.

WARNING

INDICATES A HAZARDOUS SITUATION WHICH,

IF NOT AVOIDED, COULD RESULT IN DEATH

OR SERIOUS INJURY.

CAUTION

INDICATES A HAZARDOUS SITUATION WHICH,

IF NOT AVOIDED, COULD RESULT IN MINOR

OR MODERATE INJURY.

NOTICE

IS USED TO ADDRESS PRACTICES NOT

RELATED TO PHYSICAL INJURY. FAILURE TO

FOLLOW COULD LEAD TO PROPERTY

DAMAGE.

INTRODUCTION

3

BEFORE ATTEMPTING ANY PROCEDURE IN THIS

BOOK, READ AND UNDERSTAND ALL THE SAFETY

INFORMATION CONTAINED IN THIS SECTION. IN

ADDITION, ENSURE ALL INDIVIDUALS WORKING

WITH YOU ARE ALSO FAMILIAR WITH THESE

SAFETY PRECAUTIONS.

For your safety Warning and Information Decals have

been placed on this product to remind the operator

to take safety precautions. It is important that these

decals are in place and are legible before operation

begins. New decals can be obtained from Sno-Way or

your local dealer.

REMEMBER

The careful operator is the best

operator. Most accidents are caused by human error.

Certain precautions must be observed to prevent the

possibility of injury to operator or bystanders and/or

damage to equipment.

NEVER

operate plow when under the influence of

alcohol, drugs or other medications that could hamper

your judgement and reactions. An accident may result in

serious injury or death to other persons or yourself.

ALWAYS

operate vehicle in a well-ventilated area. The

carbon monoxide in exhaust gas is highly toxic and can

cause serious injury or death.

NEVER

allow hands, hair or clothing to get near any

moving parts such as fan blades, belts and pulleys. Never

wear neckties or loose clothing when working on the

vehicle.

NEVER

wear wrist watches, rings or other jewelry when

working on the vehicle or individual equipment. These

things can catch on moving parts or cause an electrical

short circuit that could result in personal injury.

ALWAYS

wear safety goggles when working on the

vehicle to protect your eyes from battery acid, gasoline,

and dust or dirt from flying off of moving engine parts.

ALWAYS

be aware of and avoid contact with hot

surfaces such as engine, radiator, and hoses.

ALWAYS

wear safety glasses with side shields when

striking metal against metal! In addition, it is

recommended that a softer (non-chipable) metal material

be used to cushion the blow. Failure to heed could result

in injury to the eye(s) or other parts of the body.

NEVER

allow children or unauthorized person to

operate this unit.

ALWAYS

lock the vehicle when unattended to prevent

unauthorized operation of the plow.

ALWAYS

check the job site for terrain hazards,

obstructions and people.

ALWAYS

shut off the vehicle engine, place the

transmission in Neutral or Park, turn the ignition switch to

the “OFF” position, firmly apply the parking brake of the

vehicle and turn "OFF" the plow controller before

attaching or detaching the blade from the vehicle or when

making adjustments to the blade.

ALWAYS

inspect lift system bolts and pins whenever

attaching or detaching the plow, and before traveling.

Worn or damaged components could result in the plow

dropping to the pavement while driving, causing an

accident.

ALWAYS

keep hands and feet clear of blade and A-

Frame when attaching or detaching plow.

NEVER

place fingers in A-frame or mount lug holes to

check alignment when attaching snow plow. Sudden

motion of the plow could severely injure a finger.

NEVER

stand between the vehicle and blade or directly

in front of blade when it is being raised, lowered or

angled. Clearance between vehicle and blade decreases

as blade is operated and injury or death can result from

blade striking a body or dropping on hands or feet.

NEVER

work on the vehicle without having a fully

serviced fire extinguisher available. A 5 lb or larger CO

2

or dry chemical unit specified for gasoline, chemical or

electrical fires, is recommended.

NEVER

smoke while working on the vehicle. Gasoline

and battery acid vapors are extremely flammable and

explosive.

REMEMBER

it is the owner’s responsibility for

communicating information on the safe use and

proper maintenance of this machine.

SAFETY

4

Energy Smart System (ESS®) Vehicle

Harness Installation

NOTE: Some vehicles have a Snow Plow Interface Mod-

ule (SPIM). If you choose to utilize that system, please

see the Sno-Way website for details and kit part num-

bers. The instructions for installing the ESS Vehicle Har-

ness with an SPIM adapter can be found in the adapter

kit.

1. If you do not have any other plows that require the

EIS harness, remove it from your truck. Multiple light

systems could complicate the ability to trouble shoot the

ESS system in the future.

2. Remove the ESS Vehicle Harness from the box.

(See Figure 1-1)

Figure 1-1

3. Find the spot on the harness where the Green, Blue,

Red/white, Brown, Yellow, and Gray wires all come out

from the loom. Cut off the green wire labeled "Low Beam"

and blue wire labeled "High Beam". Removed wires are

utilized with the SPIM only.

4. If your vehicle is equipped with daytime run lights that

are separate from your marker lights, continue to the next

step. If your vehicle is NOT equipped with daytime run

lights that are separate from your marker light, cut off the

red/white wire labeled "DRL".

5. Remove the ESS Vehicle Receiver from the box (See

Figure 1-2). Connect the 14 pin connector to the ESS

Vehicle Harness. Also, attach the 4 pin female dust cap to

the 4 pin connector of the ESS Vehicle Receiver.

Figure 1-2

6. Attach the red wire of the ESS Vehicle Harness to the

positive terminal of the primary battery or vehicle specific

accessory power post.

NOTE: Some vehicle manufacturers request to attach

any power cables for accessories to a specified location

near the battery, rather than attaching directly to the posi-

tive battery post.

7. Attach the black wire of the ESS Vehicle Harness to

the NEG (-) terminal of the battery.

8. Spray all terminal connections with a battery terminal

protective coating.

NOTE: Take extra time to plan the routing of wiring har-

nesses and placement of the receiver. Make sure har-

nesses do not interfere with or contact any moving parts

and route wires away from excessive heat areas. Read

all the instructions carefully to ensure a safe and profes-

sional installation.

9. Route the Red/white (If not removed), Brown, Yellow,

and Gray wires of the harness to a convenient point

where the positive voltage for the Marker, DRL, and Left

Turn or Right turn can be accessed. Typically, right

behind the headlight is a good source to find those wires.

10. Keep in mind a location to mount or stash the vehicle

receiver.

RED AND BLACK

POWER WIRES

14 PIN

4 PIN

GREEN, BLUE,

RED/WHITE, BROWN,

YELLOW, GRAY WIRES

CONNECTOR

CONNECTOR

10 PIN

CONNECTOR

14 PIN

CONNECTOR

4 PIN

CONNECTOR

ESS VEHICLE

RECEIVER

LED

INSTALLATION INSTRUCTIONS

5

11. Source the positive voltage for the Marker light. (See

Figure 1-3) Apply Dielectric grease to a splice tap

connector. Then connect the vehicles marker wire to the

brown wire from the harness.

(See Figure 1-4 to Figure 1-6)

Figure 1-3

Figure 1-4

Figure 1-5

Figure 1-6

12. Source the positive voltage for the Turn light. Apply

Dielectric grease to a splice tap connector. Then connect

the vehicles turn wire to the yellow wire if on the Driver

Side (Left) or gray wire if on the passenger side (right) of

the vehicle. Any excessive length of wire can be cut off

before connection.

13. If you still have the red/white wire from step 3, source

the positive voltage for the Daytime Run Light. Apply

Dielectric grease to a splice tap connector. Then connect

the vehicles daytime run light wire to the red/white wire

from the harness.

14. Source the positive voltage for the opposite turn

signal from Step 11. Apply Dielectric grease to a splice

tap connector. Then connect the vehicles turn wire to the

yellow wire if on the Driver Side (Left) or gray wire if on

the passenger side (right) of the vehicle. Any excessive

length of wire can be cut off before connection. Protect

the turn signal wire as its routed through the engine the

corrugated loom found in the kit.

15. Route the 10 pin connector from the harness to a

convenient point out to the front of the vehicle for

connection to a plow. Also, attach the 10 pin dust cap to

the end of the harness.

16. Install the plow control harness now if equipped with

a wired version. If installing a wireless, connect the 4 pin

male dust cap from the ESS. Install Kit onto the 4 pin

female connector on the ESS Vehicle Harness.

WARNING

Be sure to attach the brown wire to a marker

light. A marker light would be a light that turns

on when the vehicle light switch is turned to the

Park position.

FAILURE TO FOLLOW CAN RESULT IN DEATH

OR SERIOUS INJURY.

OFF AUTO

LOW

PARK

POSITION BEAM

DIELECTRIC

GREASE

VEHICLE WIRE

ESS HARNESS

SENSE WIRE

6

17. Secure the Battery Power Harness and ESS Vehicle

Harness with cable ties.

18. Securing the vehicle receiver can be done in various

ways, depending on your possible placement under your

vehicle hood.

A. Use the supplied Velcro™ to hold the receiver in

place.

B. Use the cable ties to hold the receiver in place.

C. Use a combination of cable ties and the adhesive

mounted base. (See Figure 1-7)

D. Use a combination of cable ties and the fir tree

mounted base. (See Figure 1-7) The fir tree mount

requires a 1/4 inch diameter hole to be drilled into a

suitable location on the truck. Push the base into

place in the drilled hole.

Figure 1-7

Check Connections

1. Review the LED on the ESS Vehicle Receiver to

check if you have power and proper connections.

2. There should be a Red blink every 3 seconds if you

have power and no lights on.

3. The LED will stay red when it is sensing a signal.

Look for this when you operate your trucks left turn, right

turn, marker, and DRL (if equipped).

Receiver Installation on Plow

1. Disconnect the power harness.

2. If the plow is not attached to the truck, place a jack

under the rear of the A-frame.

3. Remove the pump cover.

4. Remove the Receiver and discard the ¼ inch

hardware holding it in place.

5. Replace the pump harness. Be sure to assemble the

harness according to the new schematic decal.

6. Replace the schematic on the inside of the pump

cover.

7. Open your ProControl 2 Plus package and pull out

the receiver.

8. Slide the receiver module into the receiver mounting

channel with the exposed wires of the receiver box

positioned toward the hydraulic power unit

(See Figure 1-8 and Figure 1-9).

Figure 1-8

9. You will notice that the receiver is larger than the old

one and will fit only one way. To keep it in place, thread

the 5/16 x 1/2" Hex Washer Head screw into the hole

where the discarded 1/4" hardware was removed

(See Figure 1-9). Tighten it just enough so it binds

against the receiver and keeps it from sliding out.

Figure 1-9

FIR TREE ADHESIVE

MOUNT

MOUNT

4 PIN

CONNECTOR

6 PIN

CONNECTORS

LED

14 PIN

CONNECTOR

RECEIVER

SCREW

MOUNTING

CHANNELS

7

10. Connect the 14 pin connector on the receiver module

to the snow plow power pack. For non-straight blade

plows, also connect the 4 pin connector on the receiver to

the connector on the snow plow power pack.

11. Run the 10 pin connector harness on the receiver

unit over to the main power harness. Cable tie where

necessary to the main power harness. Ensure the control

wire harness is routed in the power harness clamp and

continue running with the main power harness. Leave

enough room to connect harness to the ESS vehicle

harness. Ensure the cable is clear of pinch points and

latching mechanism. Any excess cabling should be kept

and tied under the pump cover (See Figure 1-10).

Figure 1-10

12. Attach the 10 pin dust cap from the control kit to the

end of the plow harness.

13. NOTE: Skip this step if installing a wireless control.

Roughly 2ft back from the 10 pin connector of the ESS

Vehicle Harness located on the truck, you'll find a 4 pin

connector for the 4 Pin Control Harness (See Figure 1-1

and Figure 1-11). Plug one end of the 4 pin control

harness into the ESS Vehicle Harness and route the

other end through the vehicle engine compartment to the

cab of the vehicle. If the truck already has a 4 pin wired

control harness, plug it into the ESS Vehicle Harness.

Figure 1-11

Harness Installation for Keeping my

Halogen Plow Lamps

1. Pull out the two lamp harnesses that connect the

plow lamps to the ProControl 2 Plus Receiver.

2. Attach the shorter of the two harnesses with a yellow

wire to the 6 pin connector with a yellow wire coming the

plow receiver.

3. Run the harness up the side of the a-frame and

connect to the 10 pin connector coming from the Driver

Side plow lamp harness.

4. Attach the longer of the two harnesses with a gray

wire to the 6 pin connector with a gray wire coming the

plow receiver.

5. Run the harness up the side of the a-frame and

across the lower light bar. Connect to the 10 pin

connector coming from the Passenger Side plow lamp

harness.

NOTE: The 6 to 10 pin harnesses are designed to fit all

plows. There will be extra slack in these harnesses that

will need to be tied under the pump cover when installed

on 26V and 29VHD plows.

6. Use the supplied cable ties to secure the harness

from interfering with moving components. Be sure to

leave enough slack in the harness between the a-frame a

lower light bar so the harness is not strained when the

plow is lowered.

7. Attach the pump cover and refer to the ProControl 2

Plus Owner’s Manual for transmitter installation and

operation.

CLAMP

POWER

HARNESS

4 PIN CONTROL

HARNESS

10 PIN

CONNECTOR

ESS VEHICLE HARNESS

(INSTALLED ON VEHICLE)

CONNECT

8

Harness and Lamp installation for

Upgrading to LED Plow Lamps

1. Replace the upper light bar on the unit with the new

one supplied with the kit.

2. Place Drivers Side headlamp on top of light bar with

the headlamp tabs inside of the light bar tabs. Insert (2)

5/16" x 1-1/2" screws, and (4) 5/16" washers. Screws

must be inserted from the outside of the plow to the

center. Place (2) 5/16" serrated tooth washers between

the headlamp and light bar tabs. Secure with (2) 5/16"

lock nuts. Do not tighten. (See Figure 1-12)

3. Repeat step 3 with Passengers Side headlamp

making sure screws are inserted from the outside of the

plow to the center.

Figure 1-12

4. Follow this step If installing on a 26V or 29VHD,

otherwise, skip. Attach the 6 pin connector with a yellow

wire coming from the ProControl 2 Plus plow receiver to

the 6 pin connector on the driver side lamp. Attach the 6

pin connector with a gray wire coming from the

ProControl 2 Plus plow receiver to the 6 pin connector on

the passenger side lamp. Then, skip steps 5 - 9.

5. Pull out the two lamp harnesses that connect the

plow lamps to the ProControl 2 Plus Receiver.

6. Attach the shorter of the two harnesses with a yellow

wire to the 6 pin connector with a yellow wire coming the

plow receiver.

7. Run the harness up the side of the a-frame and

connect to the 6 pin connector coming from the Driver

Side plow lamp harness.

8. Attach the longer of the two harnesses with a gray

wire to the 6 pin connector with a gray wire coming the

plow receiver.

9. Run the harness up the side of the a-frame and

across the lower light bar. Connect to the 6 pin connector

coming from the Passenger Side plow lamp harness.

10. Use the supplied cable ties to secure the harness

from interfering with moving components. Be sure to

leave enough slack in the harness between the a-frame a

lower light bar so the harness is not strained when the

plow is lowered.

11. Attach the pump cover and refer to the ProControl 2

Plus Owner’s Manual for transmitter installation and

operation.

12. If your plow light bar had the yellow Sno-Way Facia

plate on top of the light bar, remove it and attach it to the

new upper light bar supplied with the kit.

5/16" FLAT

5/16" x 1-1/2"

SCREW

5/16" x 1-1/2"

SCREW

5/16"

WASHERS

5/16" SERRATED

TOOTH WASHER

LOCKNUT

5/16" SERRATED

TOOTH WASHER

5/16" FLAT

WASHERS

5/16"

LOCKNUT

9

Headlight Aiming Procedure

Requirements:

An unobstructed wall that is preferably painted white with

minimum dimensions 10 feet (3 m) wide by 5 feet (1.5 m)

high. The vehicle that is having the lamps installed will

need to be parked such that the distance from the front of

the snow plow lamps to the wall is 25 feet (7.6 m). The

ground of the wall and driveway in which the vehicle is

parked must be flat and even.

Preparation for Headlamp Aim:

The vehicle must be positioned 25 feet (7.6 m) away from

the aiming wall. The center of the vehicle must be aligned

with the center of the wall. This can be facilitated by using

black tape to mark the wall. The wall will require a vertical

line that represents the center line of the vehicle and the

wall (Line 1), and a horizontal line that represents the

center line height of the snow plow lamps (Line 2),

(reference item 9 below). The wall will also require two

vertical lines bisecting the horizontal line that provides the

distance between the snow plow headlamps (Lines 3 left

and 4 right). Locate the high beam light on each snow

plow lamp and project the location onto the front lens with

the aid of a small 1/2" piece of black tape. Then, using a

tape measure, accurately measure the distance between

the black tape left and right light centers. Once the

distance has been determined, divide the distance by two.

This is the distance between Line #1 to Line #3 and Line

#1 to Line #4. (See Figure 1-13) Finally, the wall will

require a horizontal line that represents the nominal

vertical aim position down (Line 5), (reference item 10

below). (See Figure 1-13)

1. Remove ice or mud from under fenders.

2. Set tire inflation pressures to the values specified on

the tire sidewall or information label.

3. Check truck springs for sag or broken suspension

system.

4. See that there is no load on the vehicle other than the

driver, the snow plow frame, and the snow plow. The

snow plow should be in the raised position.

5. Check functioning of any automatic vehicle leveling

systems and specific manufacturer’s instructions

pertaining to vehicle preparation for headlamp aiming.

6. Clean the snow plow lamp lens.

7. Check for LED burnout and proper beam switching.

8. Stabilize suspension by rocking vehicle sideways.

9. Measure the vertical height of the center of the snow

plow lamp from ground. This dimension will be required

for comparison to Table #1 below.

10. Reference Table #1 and determine the nominal

vertical aim down below the horizontal center line of the

snow plow headlamps. Using black tap, draw this

horizontal line (Line 5). (See Figure 1-13)

Figure 1-13

Alignment of Headlamp Aiming Screen

Table 1: Vertical Beam Aim Guidelines

(Line 5)

Headlamp (Centerline)

Mounting Heigh

t

Nominal Vertical

Aim Down

22 to 36 in (56 to 90 cm) 0 Vertical

36 to 48 in (90 to 120 cm) 2 in (5 cm) Down

48 to 54 in (120 to 140 cm) 4 in (6.4 cm) Down

10

Visual Headlamp Aiming Procedure:

1. Activate the snow plow lamp HIGH beams so that

they illuminate toward the wall. (See Figure 1-14)

2. Focus the left snow plow lamp hot spot beam directly

at the cross hair target that is developed by Line 5 and

Line 3.

3. There are two bolts that provide vertical aiming of the

headlamp. Adjust the lamps accordingly and tighten the

bolts.

4. Repeat the same procedure for the right snow plow

lamp. Use the hot spot beam cross hair target that is

developed by Line 5 and Line 4.

5. Confirm that each lamp has maintained the correct

aiming location. Secure the mounting bolts.

Verify Completion:

This completes the headlamp aiming process. Confirm

that the headlamps are switched back to the low beam

position before operating vehicle.

Figure 1-14

High-Intensity Zone (Shaded Area of a Properly Aimed Upper Beam

on the Aiming Screen 25 ft (7.6 m) in Front of Vehicle)

Hartford, WI 53027 USA

Website: www.snoway.com

©

2020 Sno-Way

®

International

SNO-WAY

®

INTERNATIONAL, INC.

Other manuals for ProControl 2 Plus

1

Table of contents

Other Sno-Way Control System manuals

Popular Control System manuals by other brands

schmersal

schmersal PROTECT-PSC instruction manual

Honeywell

Honeywell Excel 800 LION Installation and commissioning instructions

BriskHeat

BriskHeat LYNX instruction manual

Beninca

Beninca ZED24 operating instructions

EDP

EDP SGC Series user manual

VIA Technologies

VIA Technologies ARTiGO A3000 quick start guide

PendoTECH

PendoTECH PressureMAT PMAT1 user guide

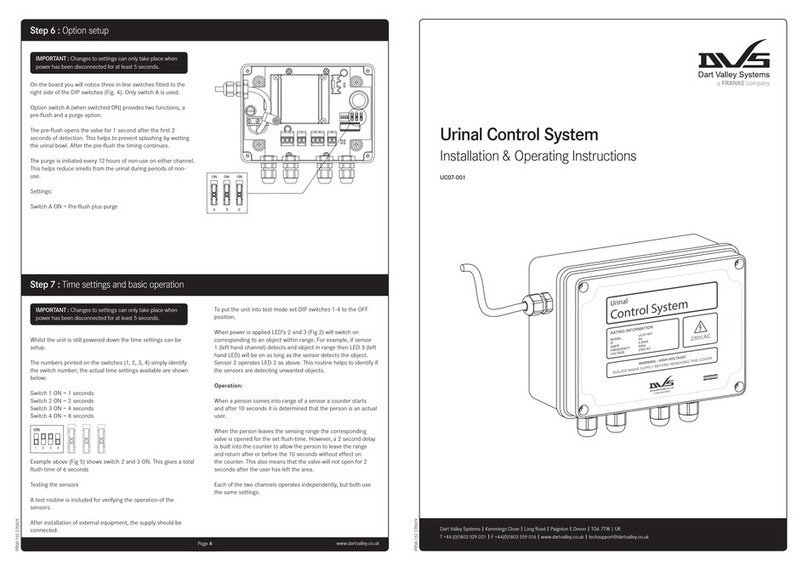

Franke

Franke DVS UC07-001 Installation & operating instructions

btsr

btsr ULTRAFEEDER operating manual

Fröling

Fröling Lambdatronic SP 3200 Service manual

Hindley Electronics

Hindley Electronics 105295-HEI installation instructions

Airzone

Airzone Aidoo Z-Wave Plus AZAI6ZW Series Integration manual