Table of Contents

ULTRAFEEDER - i -

TABLE OF CONTENTS

INTRODUCTION

The device that meets the current and future production needs ............................................................................I.1

How to use this manual ..............................................................................................................................................I.2

Symbols used ...............................................................................................................................................................I.2

Reference Documentation ..........................................................................................................................................I.2

Chapter 1 - OVERVIEW

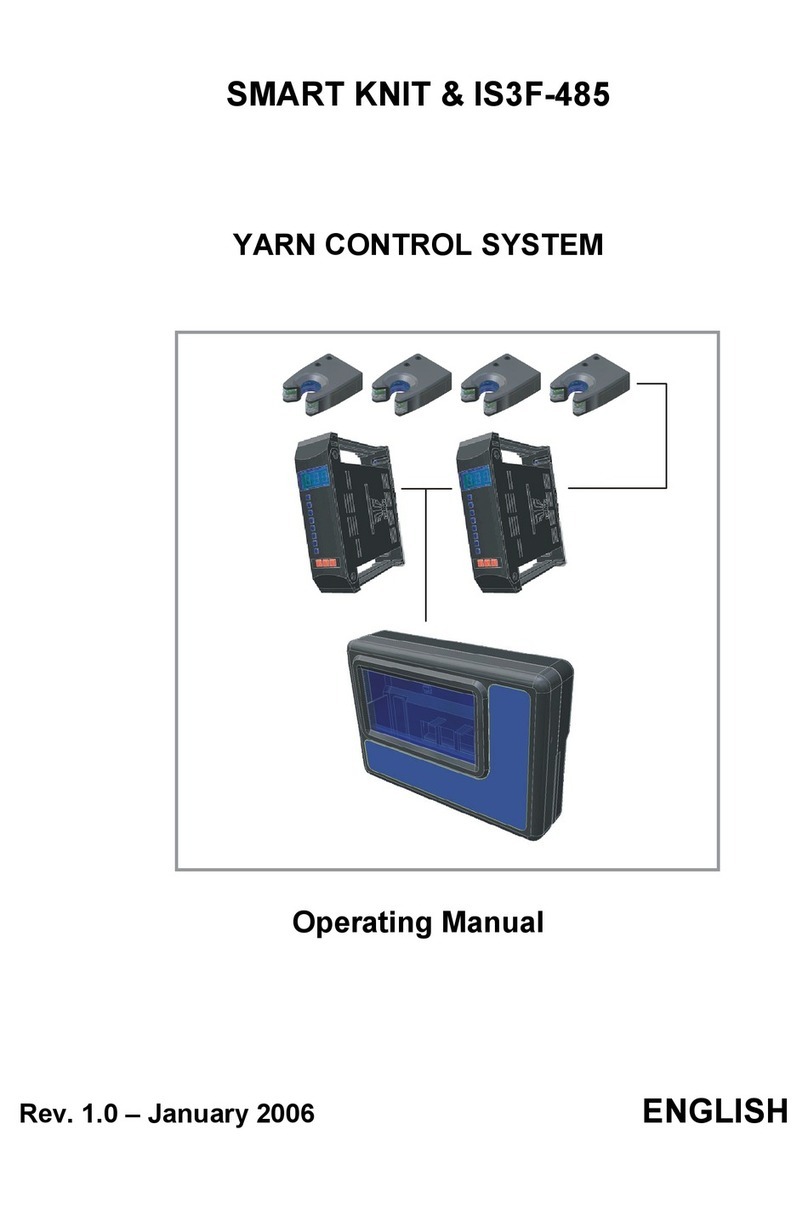

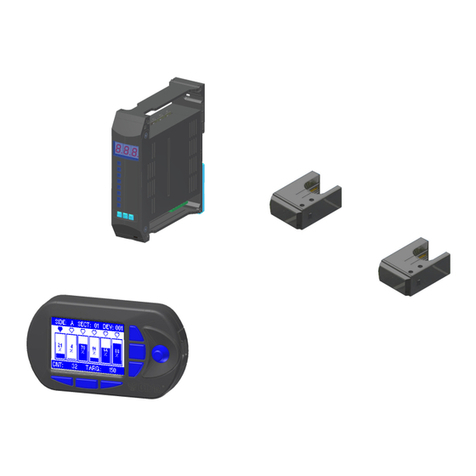

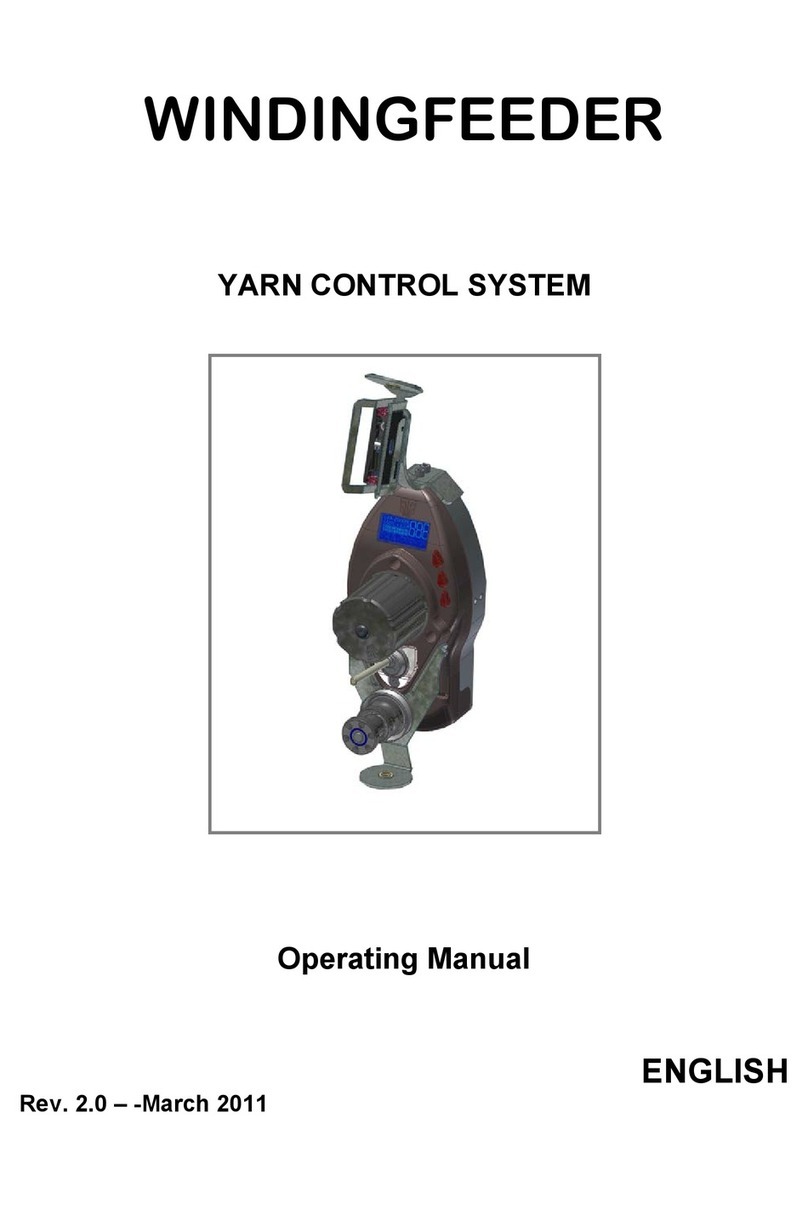

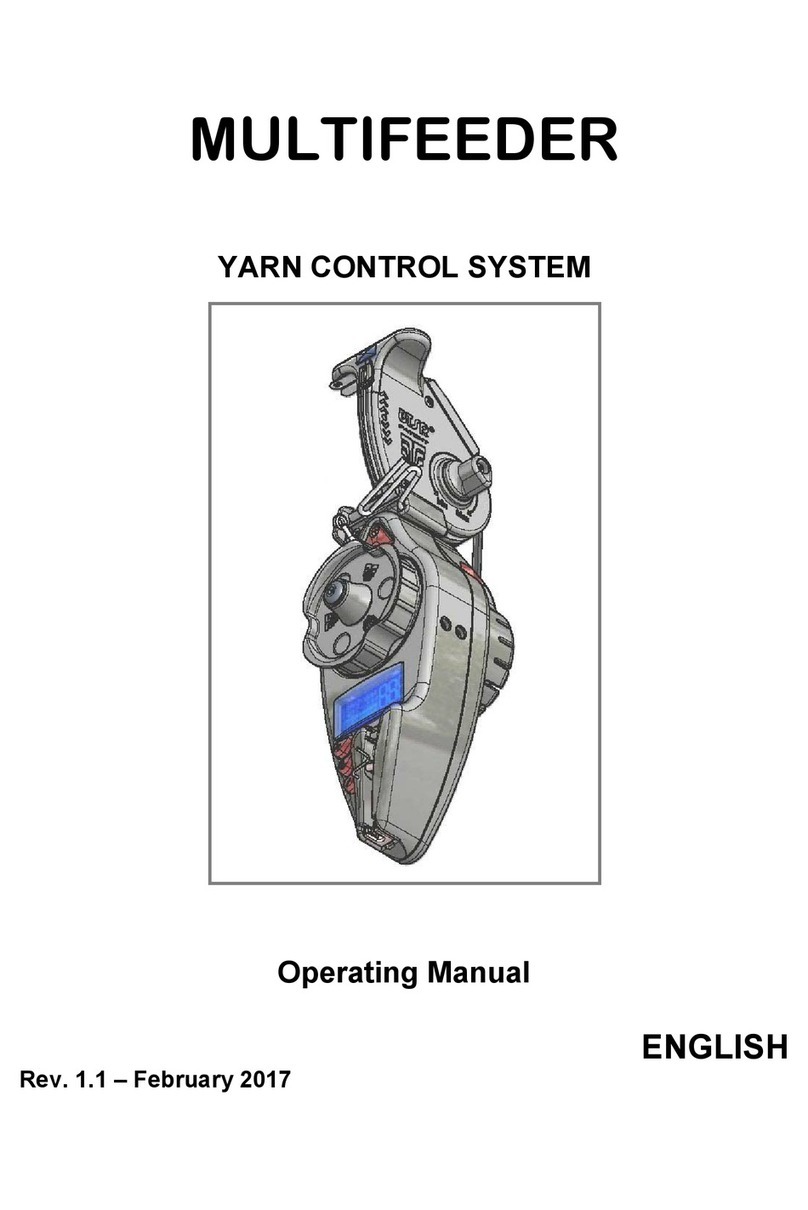

System Components................................................................................................................................................... 1.1

Main Characteristics of ULTRAFEEDER Devices ................................................................................................ 1.1

Advantages obtained by using the ULTRAFEEDER devices................................................................................ 1.3

Advantages obtained by using the SMART MATRIX FEEDER Terminal combined with ULTRAFEEDER

Devices ........................................................................................................................................................................ 1.4

Further Advantages obtained by using a PC or Notebook Connected to the ULTRAFEEDER Device via

Serial Line .................................................................................................................................................................. 1.4

Chapter 2 – TECHNICAL DATA AND INSTALLATION

Technical Features .................................................................................................................................................. 2.1

Electrical Interface of ULTRAFEEDER Devices.................................................................................................... 2.3

Installation of ULTRAFEEDER with KTF/PW4 Power Supply...........................................................................2.4

Connection of ULTRAFEEDER Devices with KTF/PW4 Power Supply to the Textile Machine and Related

Functions................................................................................................................................................................. 2.4

Principle of operation of INC/DEC commands....................................................................................................... 2.5

NPN Programmable Outputs Machine Connections................................................................................................ 2.6

PNP Programmable Outputs Machine Connections ................................................................................................ 2.6

Connection Example of a Complete System including ULTRAFEEDER Devices, KTF/PW4 Power Supply and

SMART MATRIX FEEDER Terminal ................................................................................................................... 2.7

Connection Example of a Complete System including ULTRAFEEDER Devices, KTF/PW4 Power Supply and

Notebook with PC-LINK KTF Studio Analysis/Monitoring Software.................................................................... 2.8

Connection Cables and Power Supply Devices ....................................................................................................... 2.8

Connecting Cables and Accessories in case of Installation with KTF/PW4 Power Supply .................................... 2.8

Installation of ULTRAFEEDER with PFU/32S power supplier ........................................................................ 2.10

Connection Example of a Complete System including ULTRAFEEDER Devices,

PFU/32S Power Supplier and SMART MATRIX FEEDER terminal................................................................... 2.10

PFU/32S power supplier electrical interface ......................................................................................................... 2.11

PFU/32S configuration .......................................................................................................................................... 2.13

PFU/32S Software mode ....................................................................................................................................... 2.15

PFU/32S Hardware mode ...................................................................................................................................... 2.17

Installation of ULTRAFEEDER with Flat Cable KTF/FLAT ............................................................................ 2.21

Connection cables and accessories in case of installation with flat cable KTF/FLAT .......................................... 2.22

Connection Example of a Complete System Including ULTRAFEEDER Devices, External Power Supply,

Flat Cable KTF/FLAT, SMART MATRIX FEEDER Terminal and BX4030RTP-X4 power supplier ................ 2.23

Connection Example of a Complete System Including ULTRAFEEDER Devices, Flat Cable KTF/FLAT and

Notebook with PC-LINK KTF Studio Analysis/Monitoring Software.................................................................. 2.24

Connection Example of a Complete System including ULTRAFEEDER Devices, KTF/FLAT cable, SMART

MATRIX FEEDER Terminal and PFU/32S Power supplier................................................................................ 2.25

Installation of ULTRAFEEDER in Master/Slave configuration......................................................................... 2.26

Instructions for Correct Yarn Threading.............................................................................................................. 2.27

Chapter 3 –OPERATION

Operating Characteristics of ULTRAFEEDER Devices........................................................................................ 3.1

Symbols shown on LCD ............................................................................................................................................ 3.2