2

ENGLISH

TABLE OF CONTENTS

KEEP THESE INSTALLATION INSTRUCTIONS FOR FUTURE REFERENCE

Snugtop UT PRO MT3 Cap Components ...................................................................................................... 3

Cap Installation Instructions................................................................................................................................ 4

Installing Gap Filler................................................................................................................................................ 5

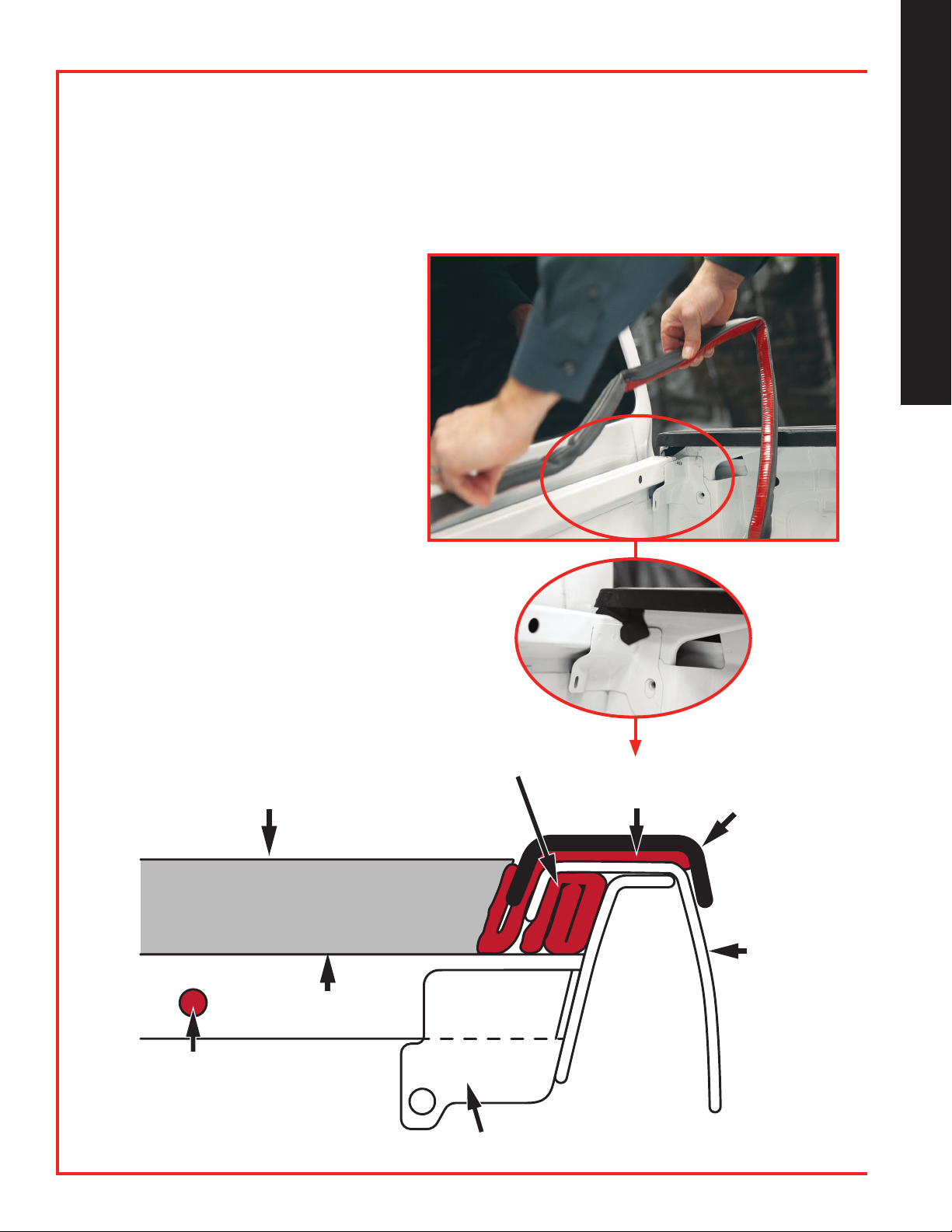

Front Seal Placement Procedure....................................................................................................................... 6

Positioning The Leveler Strips ............................................................................................................................ 6

Placing The Cap On The Truck........................................................................................................................... 7

Secure Cap To Truck............................................................................................................................................. 8

Coding Your Door Locks...................................................................................................................................... 8

Making Electrical Connections....................................................................................................................8 – 9

Final Inspection.....................................................................................................................................................10

Removing Your Truck Cap..................................................................................................................................10

Toolbox Assembly – Passenger Side....................................................................................................10 – 12

Toolbox Assembly – Driver Side.............................................................................................................13 – 14

Service Parts UT PRO MT3..............................................................................................................................15

Limited Warranty..................................................................................................................................................16

Caring For Your Truck Cap ................................................................................................................................17