Soaring USA Stobel V2 User manual

Instructions - Stobel V2

Congratulations on the purchase of your Stobel, a high end DLG-competition model from LE-composites. We

hope you will be happy and successful. To ensure the optimum build we ask you if possible to follow in

accordance with instructions and work towards the completion carefully and accurately. Read the Instructions

carefully and build in the recommended order.

This model is designed for maximum flight performance and should be built as light as possible.

Always use only as much adhesive as is absolutely necessary!

2 hour build per LE-Composites Team instructions (not including cure time)-

Part included with delivery:

- Wing

- Fuz

- Rudder

- Elevator

- Hood

- 2x fiber rods

- Surface Bags

- Small parts consisting of:

•

2x M3 nylon screws

•

0.5 mm Steel wire

•

2 M4 aluminum screw

•

Male / Female 4-pole

•

1.5 mm CFRP rod

•

3x0, 08mm

•

GRP rudder horns

•

2

•

Kevlar cord

•

Cables

•

Throwing Blade

•

Servo board

•

2x control horns

•

2x former for ballast system

•

0.3 mm steel wire

•

large former

Completion of the WING

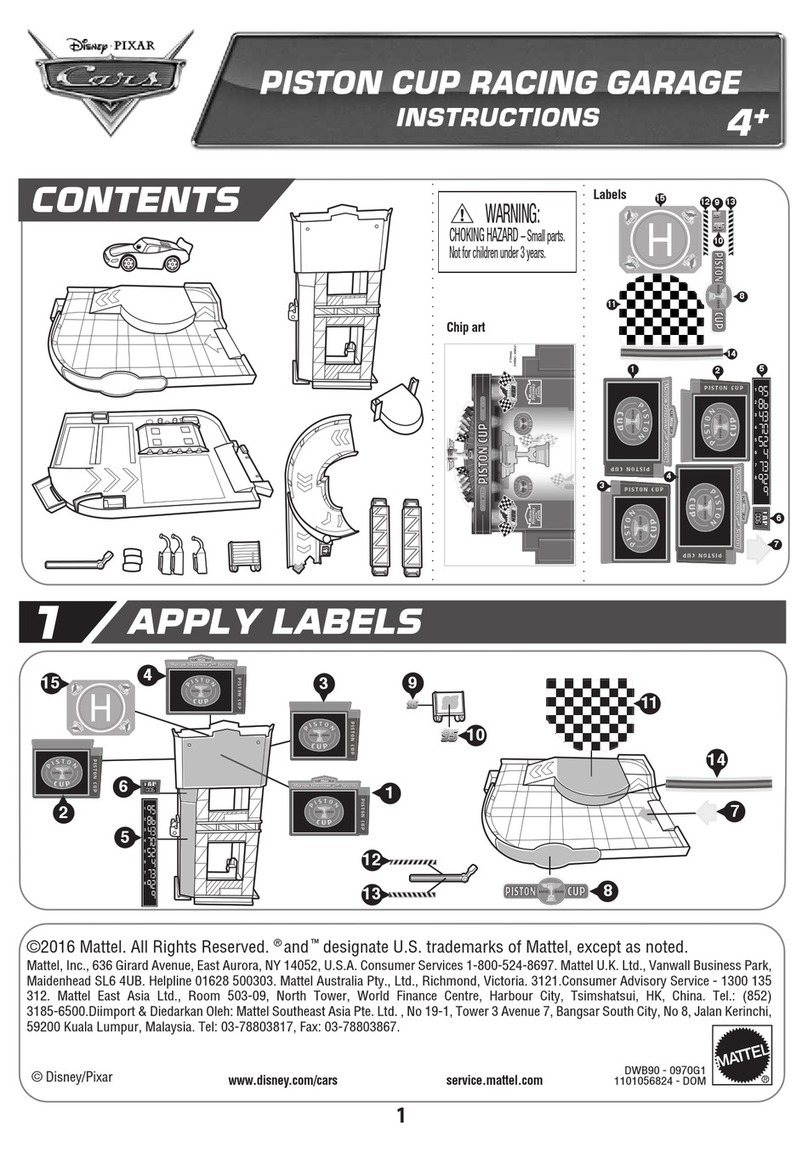

Throwing blade mounting:

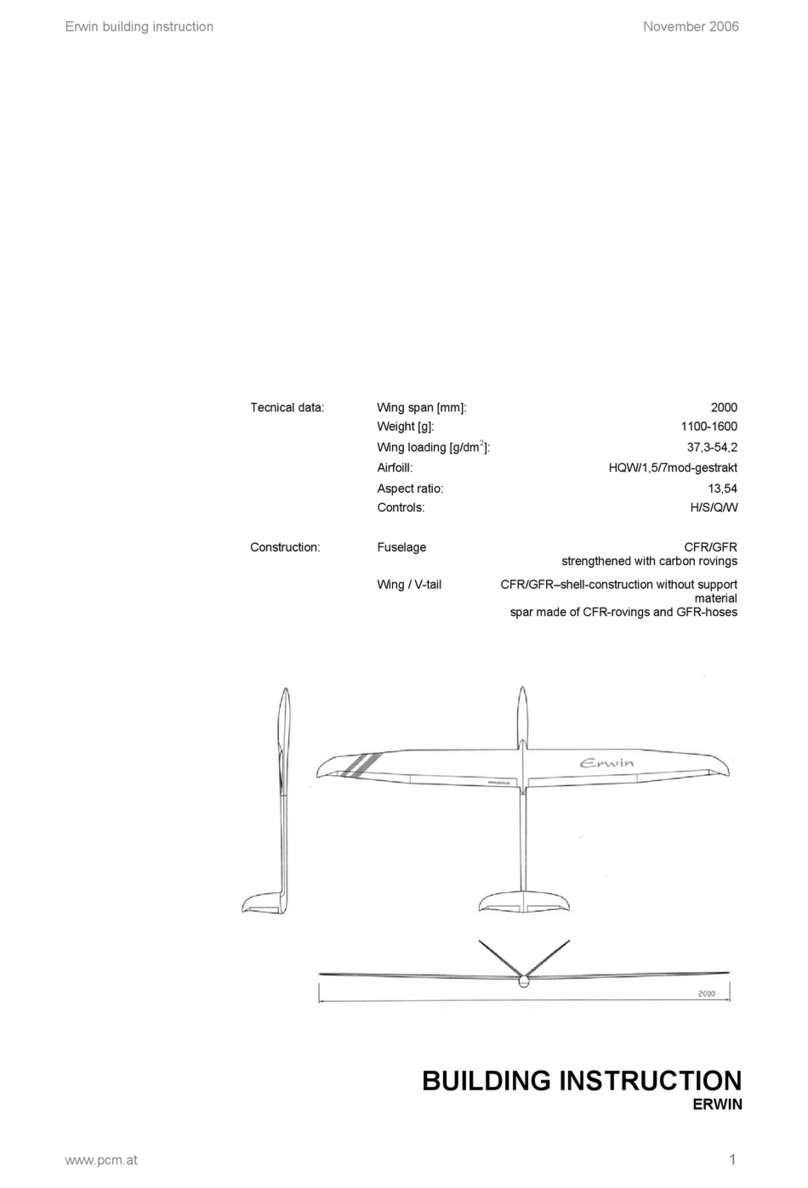

The area has been reinforced for installation of the throwing blade provided. Per the diagram below, mark the

position to insert your throwing blade. Next, mark the outline of the throwing blade on the wing surface and

make the incision with a small milling cutter, make a neat cut to the contour of the blade. MEASURE TWICE,

cut once. It is recommended you Chamfer the throwing blade edges to customize the blade to your grip and to

take the edge off. Harden the support material by soaking with Superglue. After grinding the throwing blade,

yglue it in with 24 hour epoxy. A small glue bead around the blade ensures a greater stability and strength.

Now you need to install the 4-pin connector for the wing to fuz wiring harness. Using the 4 pin connector

provided, complete the wiring harness allowing enough length to reach the connecting harness from your

receiver.

Completion of the Elevator and Rudder

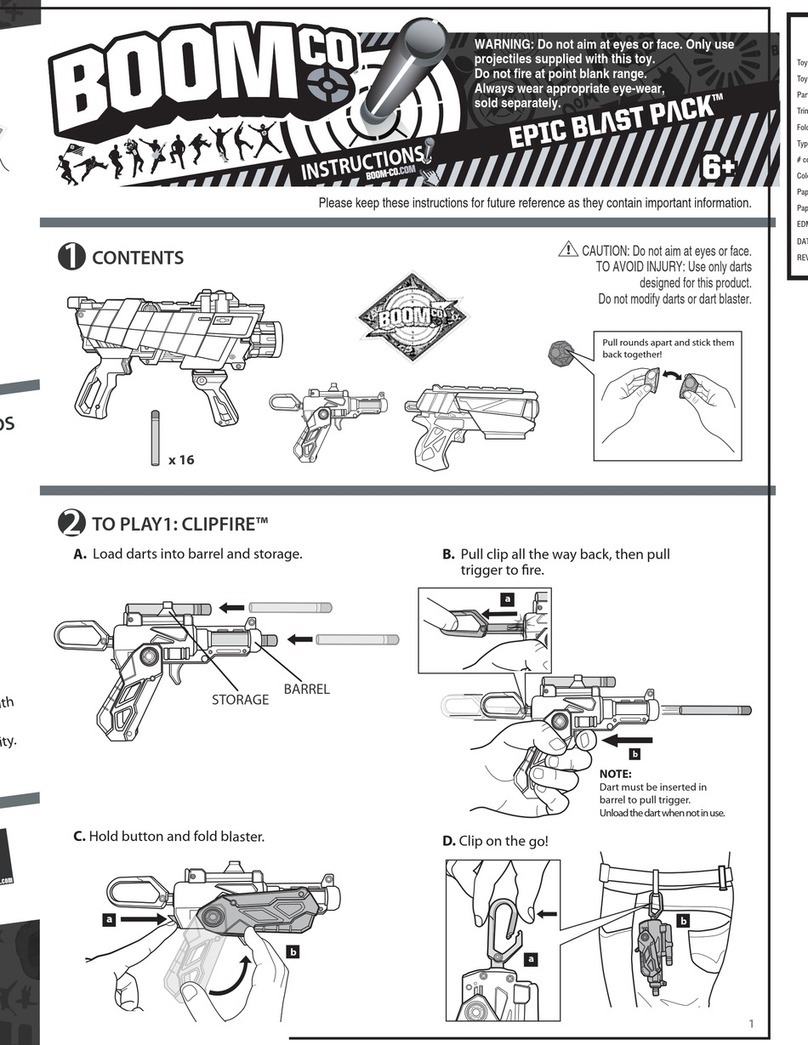

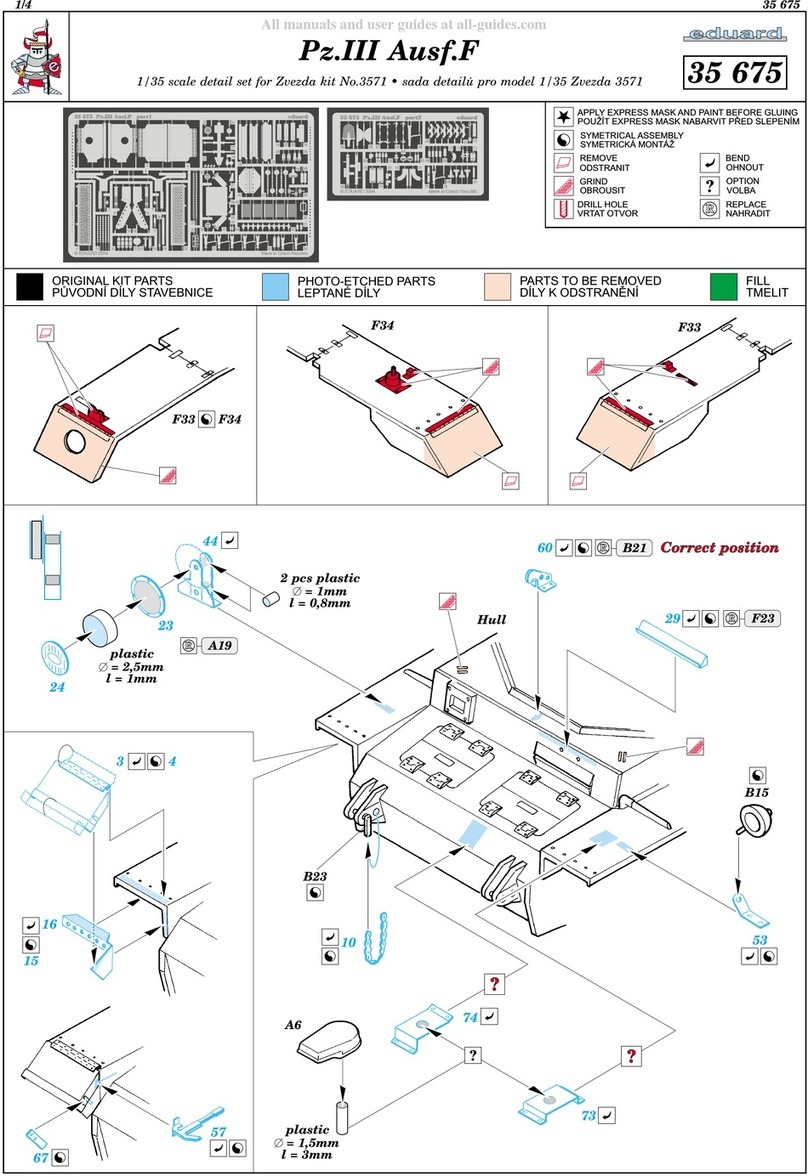

The tail feathers of Stobel V2 are a high quality prefabrication. The springs provided (see diagram below) are

designed to optimize precise control of the tail feathers via the supplied control horns. This type of linkage has

been 100% proven and should be installed as illustrated and described.

Turn the corresponding feathers from the attached wire.

For the vertical stabilizer use the thin 0.3 mm provided,

and for the horizontal stabilizer use the 0.5 mm spring

provided.

The small tube pieces should be in inserted into the tails

per the diagram on the next page and be glued in. These

absorb the force and prevent friction of the steel wire at

the Tail surface

Fold the rudder over as much as possible and twist the wire until you put it in the tail (per diagram below) The

spring force of the wire should now press the moveable part permanently to the outside

Completion of the Fuz

First, the positions of the RC equipment need to be identified. A battery comprising 4x GP350

Cells, or 350Mah lipo and a 2x D47 servos, about 10g heavy receiver should be suitable to ensure the CG is

approximately right. Smaller amounts of lead are then only for the required for trimming CG.

Once you have established the layout of your RC components, we then complete the wiring harness in the fuz.

Take the 4 pin connector as supplied and use to finish the wiring harness. Make sure the wiring harness is an

appropriate length to reach the receiver. Connect to the wing wiring harness per our earlier work. Next bolt the

wing with the harness to the fuz and you can lock the connector in place using an adhesive such as silicon.

opening in the fuz should be as small as possible Now, the connector can be glued

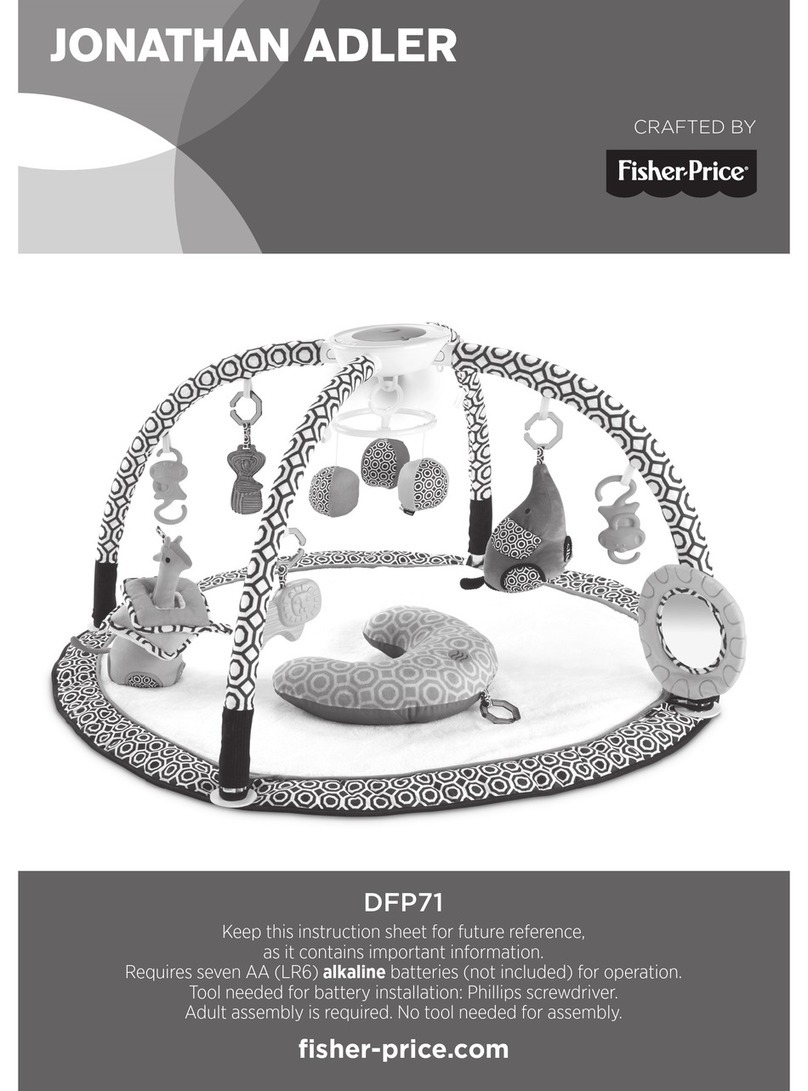

Next, the ballast system is prepared. It consists of three milled formers. Tape the two small formers together

so that a 6mm deep end point for the ballast is established. The angle is formed (see picture). A rounding of the

inside edge after makes for easier insertion of the ballast. The recesses on the left and right of the bulk head

formers are for the Kevlar pull cord from the servo’s, and end about 1cm behind the end of the ballast formers.

The bottom recess is for the antenna (unless using 2.4Ghz)

Secure the rod with a little 5 min epoxy on the formers and position the ballast system in addition to the

fuselage. The bulkhead is then glued so the rear bulkhead is located directly below the end of the nose bar and

the notch in the ballast bar is directly under the wing surface screw. Locate by screwing in the wing screw – the

ballast bar is secured. For the front former position at the top of the canopy opening use the ballast bar, so you

have an exact location for the bulkhead. Spread 24 hour epoxy on the bulkhead and slide into place. Secure the

other components.

Position (the supplied servo tray suitable for D47 /

FS31 or identical), mount the servos and attach the servo tray into the

fuselage. Test before assembly to make sure enough space for the

receiver and battery

After setting,, the forward

bulkhead can be glued. It should

be placed about 5mm behind the

canopy opening

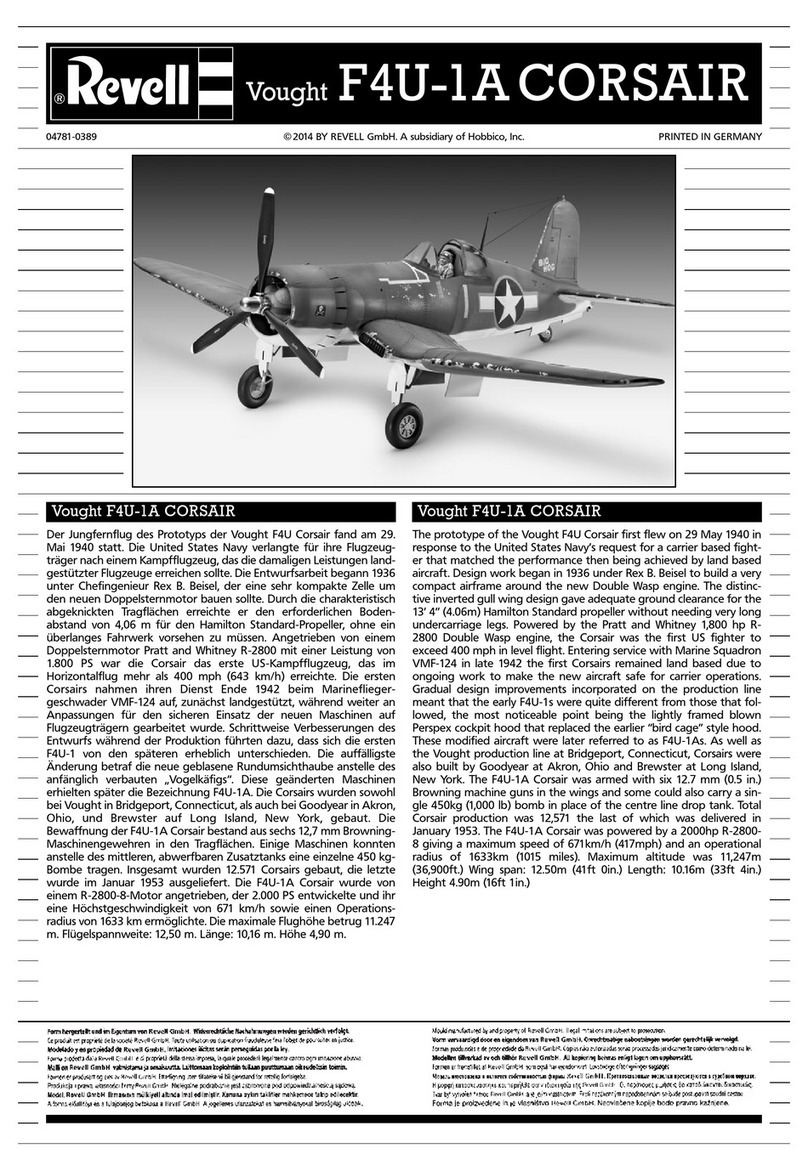

Now the Kevlar cord for the pull system can be installed. A small cutout on the side elevator pylon

is necessary for the cord sleeves. Oops! Run the cables never without sleeves outwards.

You can tear through the carbon boom very easily.

Cut-out to accommodate the pull cord sleeve Feed the Kevlar cord down the sleeve as shown

To locate the two cords in the fuze, you can use

the attached 0.3 mm steel wire. Wrap the end of

the cord around the wire and fix it with a little

CA. Now you can feed the cord for the elevator

through the sleeve and through the hole in the

pylon to the outside.

Vertical Stabaliser and Rudder

This approach prevents crossing the pull cords.

Let the cord run out directly from the fuselage

tube. Mount the surface and glue the vertical

stabilizer with 5min epoxy on the boom. Sand the

end of the boom prior to gluing.

Run the rudder pull cord, and possibly the

antenna, through the openings in the tail. (see

picture) Align the vertical stabilser and let it set.

Secure the rudder pull cord.

This leave only the canopy cover to complete. Sand the inside a bit and then glue in the supplied Carbon rod.

Allow 10-15mm on both ends of the cover. As a tip: Vary the lengths of the overlap, then you can immediately

distinguish the front and rear.

Suggested Settings for flying

Suggested cg 64-66mm

Ailerons, elevator & rudder

Up down

Rudder max. max.

Elevator 4mm 4mm

Flaps 15mm 15mm

Flight mode settings

Flap Elevator

Landing max.down aprox 25% down

Launch 3mm up normal / if need 2-5% up

elevator/flap – mix 1°elevator down = 1°Flap up

Flap for thermal mode (ballast taken into consideration)

For crashes and any resulting damage to one of our models, we can not Assume responsibility or liability as

a proper setup and operation is not

can be monitored.

For the antenna use a 25cm long piece of 0.3

mm steel wire. This can be glued well insulated

at the end of the rudder . The connection to the

receiver can be by solder or connector of choice.

260g 3,5mm down

280g

4mm down

310g

4,5mm down

Other Soaring USA Toy manuals