Socla Sylax User manual

• Sale leaflet p.2

• Nomenclature p.3

• Overall dimensions p.4

• Top connections of the actuators p.5

• Actuators p.6

• Connecting flanges p.7-8

• Normalisation p.9

• Pressure p.10

•

Torque values - Pressure/Temperature diagram

p.11

• Flow rate (Kv) p.12

• Head loss chart (∆p) p.13

• Type of flange/ Tag/Traceability p.14

• Bolts and nuts

p.15-17

• Installation p.18

Technical manual

Sylax butterfly valves (DN 25-350 mm)

Summary

uksylax25_350 - Updated 20/09/2016 1

Industrial processes and general services

Applications :

• Water distribution and supply with the main

European approvals, water treatment, most of

the fluids of general services.

• Industrial applications such as :

Metallurgical, mining, paper-making, shipbuil-

ding, nuclear, environmental and mechanical, food

industry (see our list of approvals).

• For special applications, especially for parti-

cularly difficult media, contact our technical

back office team.

• For vacuum and frequencies above 1 cycle /

min, the headline will be pasted.

Main characteristics :

• Multiple connections : centering lugs,

tapped lugs.

• Vertical and horizontal operating position.

• High power transmission with robust groo-

ved connection between the shaft and the

disc.

• Easy maintenance by removing the circlips

• Interchangeable disc and liner.

• Complete recyclability of the butterfly valve

• Body in cast iron GJL1040, ductile iron

GJS1030 , steel and stainless steel.

• Body epoxy coated 80

µm colour blue RAL

5017 (a lot of other coatings on option, please ask

our sales department)

• Wide choice of actuations.

Applications and main

characteristics

•

•

A mounting instruction specifying the installation characteristics and the commission of the Sylax is available on our web site

www.socla.com or on request by our sales department.

Technical manual Sylax DN 25-350 mm

Sale leaflet

By concentrating the technologies and by integrating technical solutions of the highest levels,

Socla fulfils its ambition :

• competitiveness of a standard range,

• reliability,

• comprehensive range thanks to a multiplicity of solutions.

uksylax25_350 - Updated 20/09/20162

•

Safety anti-ejection circlip keeps shaft in

place and allows easy maintenance

• Safety reinforced by a secondary water-

tightness.

• Spline driven one piece shaft connected

to floating disc :

. high reliability of tightness and torque trans-

mission in the long term.

•

High power transmission with robust grooved

connection between the shaft and the disc.

• Complete protection of the shaft and valve

body from fluids.

• Reliability of movements with self-lubricating

bearings.

• Identification and traceability ensured by

riveted metal tag : see on page 14.

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 3

Spare parts list

Nb

DESCRIPTION

Qty

MATERIALS ACCORDING TO NORMS

Materials EN ASTM JIS

1Body

1

Ductile iron

EN GJS 400-15 (JS 1030)

- FCD40

Cast iron

EN GJL 250 (JL 1040)

- FC25

Steel* GE 280 (E280 - 480M) gr WCB -

Stainless steel* GX5 CrNiMo 19-11-2 (1.4408) 316 SUS 316

2Liner

1

EPDM - - -

White EPDM - - -

High content nitrile - - -

White nitrile - - -

Carboxylated nitrile - - -

CSM (Polyethylen chloro-sulfonated) - - -

Silicone - - -

FKM - - -

Buthyl - - -

Natural rubber - - -

3Disc

1

Ductile iron EN GJS 400-15 (JS 1030) - FCD40

Stainless steel GX5 CrNiMo 19-11-2 (1.4408) 316 SUS 316

Alu-bronze* CuAl10Fe5Ni5 (CC333G) - -

4Stem

1

Stainless steel X5 CrNiCuNb 16-4 (1.4542) 630 SUS 630

Stainless steel° X2 CrNiMo 17-12-2 (1.4404) 316L SUS 316L

Stainless steel X30 Cr13 (1.4028) 420 SUS 420 J2

5 - 6 Anti-friction bearing

1Zinc coated steel + PTFE - - -

7Sealing and anti-

extrusion bush

2 Plastic

Grivory XE3883 black 9915 GV4

- -

8O-ring seal

1 Nitrile/FKM - - -

9Circlips

1Stainless steel X30 Cr13 (1.4028) 420 SUS 420 J2

Steel XC 75 - -

10 Identification plate

1 Aluminium EN AW - AL995 (EN AW - 1050A) - -

11 Rivet

2Alu / Stainless steel - - -

9

8

7

10

11

6

2

4

3

5

1

9

8

7

1

6

5

2

3

4

10

11

12

13 14 1516

ATEX special spare parts list

12 Braid 1 Tinned copper - - -

13

Discharge electro-static braid

1 Tinned copper - - -

14 Screw 1 Stainless steel A2 - 70 304 SUS 304

15 Stop washer 1 Stainless steel X5 CrNi 18-10 (1.4301) 304 SUS 304

16 ATEX identification plate 1 Aluminium EN AW - AL995 (EN AW - 1050A) - -

* Except DN200

° Except DN200 and 250

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016

Overall dimensions

4

H1

H2

E

D1

D2

ØT

plat P N trous ØR sur ØS

Carr

é CxC

4

ØU

H3

H4

L1

H5 H1

L5

L6

• 4 Centring lugs

(1) Ductile iron body (JS1030), ductile iron disc (JS1030), EPDM liner. - (2) Cast iron body (JL1040), ductile iron disc (JS1030), EPDM liner.

Diameter Face to

face Overall dimensions ISO Top according to

ISO 5211

Square drive

outlet

Travel

of the disc

Weight

kg

DN NPS E L1 H1 H2 H4 N øR øS øT øU N°

o

C H3 Plat P D1 D2 (1) (2)

25 1 32 100 125 50 12 4 6,5 50 65 36 F05 11 16 11 6 1 - 1,6

32/40 1 1/2 32 144 130 57 12 4 6,5 50 65 36 F05 11 16 11 31 6,5 1,9 1,7

50

2 43 121 136 62 12 4 6,5 50 65 36 F05 11 16 11 35 6 2,6 2,6

65

2 1/2 46 136 145 84 12 4 6,5 50 65 36 F05 11 16 11 55 13 2,9 2,9

80

3 46 127 151 89 12 4 6,5 50 65 36 F05 11 16 11 73,5 20 3,6 3,6

100

4 52 149 175 106 10 4 6,5 50 65 36 F05 11 16 11 87 25 4,4 4,4

125 5 56 182 190 120 12 4 8,5 70 90 56 F07 14 19 14 118,5 37,5 6,2 6,3

150 6 56 209 203 131 12 4 8,5 70 90 56 F07 14 19 14 146,5 50,5 7,1 7,3

200 8 60 265 225 165 12 4 8,5 70 90 56 F07 14 19 14 190 70 11,2 11,2

250 10 68 316 266 196 14 4 10,5 102 125 71 F10 17 24 20 242 92 17,1

300 12 77 368 290 238 14 4 10,5 102 125 71 F10 22 29 16 292,5 112,5 23,8

350 14 77 421 305 270 16 4 12,5 125 150 87 F12 27 29 - 333 132,5 33,2

• 2 Centring lugs

(1) Stainless steel body (1.4408), stainless steel disc (1.4408), EPDM liner. - (2) Steel body (WCB), stainless steel disc (1.4408), EPDM liner.

Diameter Face

to face Overall dimensions ISO Top according to

ISO 5211

Square drive

outlet

Travel

of the disc

Weight

kg

DN NPS E L1 H1 H2 H4 N øR øS øT øU N°

o

C H3 Plat P D1 D2 (1) (2)

32/40 1 1/2 32 106/99 130 56 12 4 6,5 50 65 36 F05 11 16 11 31 6,5 1,7 1,6

50

2 43 121/99 136 73 12 4 6,5 50 65 36 F05 11 16 11 35 6 2,6 2,1

65

2 1/2 46 136/117 145 82 12 4 6,5 50 65 36 F05 11 16 11 55 13 3,1 2,4

80

3 46 150/136 151 93 12 4 6,5 50 65 36 F05 11 16 11 73,5 20 3,2 2,8

100 4 52

166/167

175 106 12 4 8,5 70 90 56 F07 14 19 14 87

25

5,3 4,4

125 5 56

132/194

190 127 12 4 8,5 70 90 56 F07 14 19 14 118,5 37,5 6,6 5,7

150 6 56

139/225

203 147 12 4 8,5 70 90 56 F07 14 19 14 146,5 50,5 8,1 6,8

L2

• Tapped lugs and lugs with unthreaded holes*

*the version «lugs with unthreaded holes» replaces the double flange version

(1) Ductile iron body (JS1030), ductile iron disc (JS1030), EPDM liner - (2) Stainless steel body (1.4408), stainless steel disc (1.4408), EPDM liner.

Diameter Face

to face Overall dimensions ISO Top according to

ISO 5211

Square drive

outlet

Travel

of the disc

Weight

kg

DN NPS E L2 H1 H2 H4 N øR øS øT øU N°

o

C H3 Plat P D1 D2 (1) (2)

32/40 1 1/2 32 146 130 57 12 4 6,5 50 65 36 F05 11 16 11 31 6,5 1,9 2,7

50

2 43 121 136 62 12 4 6,5 50 65 36 F05 11 16 11 35 6 3 3,3

65

2 1/2 46 135 145 70 12 4 6,5 50 65 36 F05 11 16 11 55 13 3,3 3,9

80

3 46 179 151 89 12 4 6,5 50 65 36 F05 11 16 11 73,5 20 4,2 4,8

100

4 52 206 175 103 10 4 6,5 50 65 36 F05 11 16 11 87 25 6

125 5 56 238 190 119 12 4 8,5 70 90 56 F07 14 19 14 118,5 37,5 6,2 9,7

150 6 56 265 203 133 12 4 8,5 70 90 56 F07 14 19 14 146,5 50,5 7,1 11,2

200 8 60

325(1)-

313(2)

225

163(1)-

157(2)

12 4 8,5 70 90 56 F07 14 19 14 190 70 15,7 14,3

250 10 68 397 266 198 14 4 10,5 102 125 71 F10 17 24 20 242 92 23

300 12 77 454 290 227 14 4 10,5 102 125 71 F10 22 29 16 292,5 112,5 34

350 14 77 497 305 248 16 4 12,5 125 150 87 F12 27 29 - 331 132 46

• Double flanges

Diameter Face

to face Overall dimensions ISO Top according to

ISO 5211

Square drive

outlet

Travel

of the disc

Weight

kg

DN NPS E L3 H1 H2 H4 N øR øS øT øU N°

o

C H3 Plat P D1 D2 (1) (2)

250 10 68 406 266 201 14 4 10,5 102 125 71 F10 17 24 20 242 92 27

300 12 77 483 290 242 14 4 10,5 102 125 71 F10 22 29 16 292,5 112,5 43

350 14 77 534 305 256 16 4 12,5 125 150 87 F12 27 29 - 331 132 56

L3

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 5

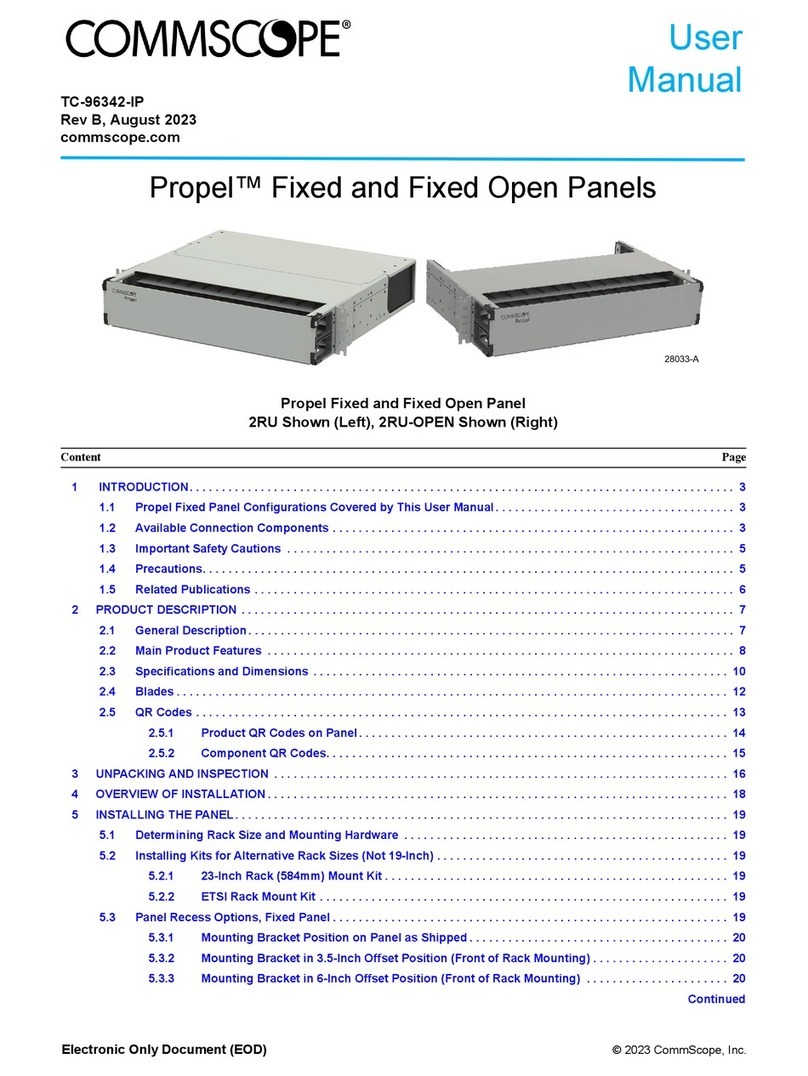

Connecting kit

for actuations

H1

H3

H2

N trous ØR sur ØS

DN NPS Iso top of

the valve

Iso top of the actuation

F03 F04 F05 F07 F10 F12 F14 F16

H1 H2 H1 H2 H1 H2 H1 H2 H1 H2 H1 H2 H1 H2 H1 H2

32 1 1/4

F05/o11

190

60

190

60

190

60

190

60

210

80

40 1 1/2 190 190 190 190 210

50 2 199 199 199 199 219

65 2 1/2 205

205

205 205 225

80 3 210 210 210 210 230

100 4 235

235 235 235 255

125 5

F07/o14

249 249

60

249

60

269

150 6

262 262

262

282

200 8

285

285 285 305

250 10 F10/o17

346

80 346 80

346

80

346 80 356

90

356

90

300 12 F10/o22

370

370

370 370 380 380

350 14 F12/o27

395

90

395 90 395 395

DN NPS Iso top of

the valve

Exceeding length fo the shaft H3

Kit o9o11 o14 o17 o22 o27 o36 o46

32 1 1/4

F05/o11

F03

F04

F05

F07

F10

7 9 12 15 20 25

40 1 1/2

50 2

65 2 1/2

80 3

100 4

125 5

F07/o14

F04

F05

F07

F10

F12

F14

9 12 15 20 25 34

150 6

200 8 F07/o14

F04

F05

F07

F10

F12

F14

9 12 15 20 25 34

250 10 F10/o17

F05

F07

F10

F12

F14

9 12 15 20 25 34

300 12 F10/o22

F05

F07

F10

F12

F14

12 15 20 25 34

350 14 F12/o27

F07

F10

F12

F14

F16

15 20 25 34 48

N° N øR øS

F03 4 5,5 36

F04 4 5,5 42

F05 4 6,5 50

F07 4 8,5 70

F10 4 10,5 102

F12 4 12,5 125

F14 4 17 140

F16 4 22 165

We recommend direct mounting of the actuation, otherwise see table below.

Reminder of the iso top dimensions EN

ISO 5211 (see also the overall dimen-

sions).

Other special executions on request :

actuated by par square drive and flat

according to EN ISO 5211, subjected

to technical feasibility.

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/20166

(1) Pneumatic actuator only

Actuations

HAND LEVER PNEUMATIC

ACTUATOR

ELECTRIC

ACTUATOR

• 1 or 2 mechanical limit switch

For other options, please

consult us.

• Switchbox :

. mechanical

. inductive

. inductive + solenoid valve

. mechanical + solenoid valve

• Inductive limit switch

• Positioners (1)

. BURKERT 1067

• Remote control +

emergency hand

wheel

• Auma • Bernard

• Socla

• Belimo

• Rotork

• Notched hand

lever polyamide

(PCX)

GEAR BOX

• Manual gearbox in

cast iron

• Adjustable ductile iron

hand lever (PRF)

• Notched ductile iron hand

lever (PCF)

ASSEMBLY LEVEL 1 ASSEMBLY LEVEL 2

• Socla

Find below the different standard assembly combinations.

For any other information, please ask our technical Department.

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 7

Connecting flanges The Sylax 25-350 mm butterfly valve can be mounted with the following connections

(other types on request) :

• 4 Centering lugs

(1) Cast iron body GJL-250 (JL1040) only.

(2)

Cast iron body GJL-250 (JL1040) only;

re-machining for ductile iron body GJS

400-15 (JS1030)

o

4: possible mounting

l: possible mounting with re-machining

: possible mounting

but special reference

: impossible mounting

Diameter EN1092-1 & EN1092-2

ASME/ANSI

B16.1

Class 125

ASME/ANSI

B16.5

Class 150

ASME/ANSI

B16.5

Class 300

BS10

JIS B2238 et JIS B2239

DN NPS PN6 PN10

PN16

PN25 PN40

Table D

Table E

5K

10k 16k

25 1

4(1) 4(1) 4(1) 4(1) 4(1) 4(1) 4(1) 4(1) 4(1) 4(1)

l 4 l

32 1 1/4

4 4 4 4 4

4(2) 4(2)

4 l l l 4 l

40

1 1/2

4 4 4 4 4 4 4 l 4 4 l 4 l

50

2

4 4 4 4 4 4 4 l 4 4 l l l

65

2 1/2

4 4 4 4 4 4 4 l l l 4 4 l

80

3

4 4 4 4 4 4 4 l 4 4 4 l l

100

4

4 4 4 4 4 4 4 l 4 4 l l 4

125

5

4 4 4 l l 4 4 l 4 4 4 4 l

150

6

4 4 4 l l 4 4 l 4 4 4 4 l

200

8

4 4 4 l l 4 4 l 4 4 l l l

250

10

4 4 4 l l 4 4 l 4 4 4 l

300

12

4 4 4 4 l 4 4 l 4 4 4 4 4

350

14

4 4 4 4 l 4 4 4 4 l l 4

• 2 Centering lugs (3)

Diameter EN1092-1 & EN1092-2

ASME/ANSI

B16.1

Class 125

ASME/ANSI

B16.5

Class 150

ASME/ANSI

B16.5

Class 300

BS10

JIS B2238 et JIS B2239

DN NPS PN6 PN10

PN16

PN25 PN40

Table D

Table E

5K

10k 16k

32 1 1/4

4 4 4 4 4 4 4 o4 4 4 4 4

40

1 1/2

4 4 4 4 4 4 4 o4 4 4 4 4

50

2

o4 4 4 4 4 o o o o o o o

65

2 1/2

o4 4 o o 4 4 o4o o 4o

80

3

o4 4 4 4 4 o o o o o o o

100

4

o4 4 o o 4 4 o o o o o o

125

5

o4 4 o o 4 4 o o o o o o

150

6

o4 4 o o 4 4 o4o o o o

(3) Body in stainless steel (1.4408) and

in steel (WCB)

• Tapped lugs

DN65 PN10/16 4 holes

(4) Possible mounting for ductile iron body GJS 400-15

(JS1030) , impossible mounting for body in cast iron

GJL-250 (JL1040) and in stainless steel.

(5) Possible mounting if the butterfly valve is inclined

at 22,5° Attention : the Sylax 25-350 mm lug type body is not a multi-connection body (connection to many flanges of different sizes). Generally, every connection relates to a different reference

of finished products.

Diameter EN1092-1 & EN1092-2

ASME/ANSI

B16.1

Class 125

ASME/ANSI

B16.5

Class 150

ASME/ANSI

B16.5

Class 300

BS10

JIS B2238 et JIS B2239

DN NPS PN6 PN10

PN16

PN25 PN40

Table D

Table E

5K

10k 16k

32 1 1/4

o4 4 4 4 o o o o o o o o

40

1 1/2

o4 4 4 4 o o o o o o o o

50

2

o4 4 4 4 o o o o o o(4)

65

2 1/2

o4 4 o o o o o o o o o

80

3

o4 4 4 4 o o o o o o o

100

4

o(5) 4 4 o o o o o(5) o o o o

125

5

4 4 4 4 4 4 4 4 4 4 4 4 4

150

6

4 4 4 4 4 4 4 4 4 4 4 4 4

200

8

4 4 4 o o o o o o(1)

250

10

o4 4 о о о о о о

300

12

о4 4 о о о о о

350

14

4 4 о

• Double flanges

Diameter EN1092-1 & EN1092-2

ASME/ANSI

B16.1

Class 125

ASME/ANSI

B16.5

Class 150

ASME/ANSI

B16.5

Class 300

BS10

JIS B2238 et JIS B2239

DN NPS PN6 PN10

PN16

PN25 PN40

Table D

Table E

5K

10k 16k

250

10

о4 4 о о о о о о

300

12

о4 4 о о о о о о о о

350

14

о4 4 о о о о о о о

Technical manual Sylax DN 25-350 mm

Connecting flanges • End of line mounting and downstream removing

The end of line mounting and the downstream removing, at ambient temperature, of the Sylax 25-350 mm butterfly valve is

limited to the pressure mentioned on page 11 according to the PED directive 2014/68/UE.

These mountings are only possible on tapped lugs and lugs with unthreaded holes.

Downstream

removing

End of line

mounting

For wafer type bodies with 4 centering lugs, the end of line mounting can be done

in the following conditions :

- ambient temperature

- For water or non dangerous liquids (L2)

- For butterfly valves PFA 16 bar between flanges

- For butterfly valves with ductile iron body

- For butterfly valves with liners in EPDM or high content nitrile

- Within a short period (such as maintenance, ...), 15 days maximum

- In pressure conditions (PFA or PS) such as : see table

Use nuts with reduced face-to-face dimensions between the flange to be dismounted and the centering lugs.

Use washers, wide ones if needed, in order to mount the nuts on the lugs.

The mounting and the removing must be done successively and in opposite way on each nut.

For the mounting, apply a reasonable torque on the nuts, in order not to damage the lugs, until metal-metal contact between

flange and body.

For flanges with 8 rods, only 4 are used to maintain the valve in downstream removing ; the 8 rods must be re-mounted for a

normal use between flanges .

In case of unexpected downstream removing, integrate and screw successively and in opposite way, between the lugs and the

flange to be removed, the 4 nuts which hold the butterfly valve.

Downstream

removing

Mounting

between flanges

8uksylax25_350 - Updated 20/09/2016

DN PFA or PS

(bar)

32 to 150 10

200 to 300 8

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 9

Normalisation

A mounting instruction specifying the installation characteristics and the commission of the Sylax is available on our web site

www.socla.com or on request by our sales department.

• Iso top connection for actuations :

According to EN ISO 5211

• Face to face :

According to 558-1 series 20

ISO 5752 series 20

API 609 table 2

• Connecting flanges : see on page 8

According to EN1092-1 and EN1092-2

ASME/ANSI B16.5

BS10-d and BS10-e

JIS B2238 and JIS B2239

• Tests :

According to

EN12266-1

Resistance and tightness of the body : test P11(1,5 x allowable operating pressure)

Tightness of the seat : test P12 rate A (1,1 x

allowable operating pressure

)

According to EN12266-2

Anti-static design : test F21

• European Directives :

Our butterfly valves are in accordance to the safety requirements of the following directives.

:

Directive 2014/68/UE : Equipments under pressure PED

(Pressure Equipment Directive)

Applies to the design, manufacturing and the assessment of the conformity of pressure equipment, the maximum allowable pressure of

which is 0.5 bar.

Pressure equipment for water supply, distribution, and disposal of water is excluded.

Depending on the type of pressure equipment, maximum allowable temperature (PS), DN, physical nature of the fluid (liquid, gas

or vapour) and the degree of danger of the fluid (group1/2)*, the directive classifies this same equipment into different categories

(article 3.3, I, II, III, IV), required for the assessment of conformity with CE marking.

The equipment defined in article 3.3 of the directive must not bear the CE marking.

(*) Group 1 : hazardous fluids (directive 67/548/EEC) / explosive / highly flammable /easily flammable / flammable / very toxic / toxic /

combustion agents.

Group 2 : all other fluids

Important notice : the indicated pressure for the different categories of fluids (L1/L2/G1/G2) is under no condition a guarantee of use.

Therefore, it is essential to validate the use of products under given operating conditions. Socla is not responsible for alteration of the pro-

ducts to working conditions not previously specified by the customer.

In order to facilitate your choice regarding these new regulatory requirements, Socla has put the necessary information

concerning products with CE marking, specification sheets and product identification plates at your disposal in the price list (+ see additional

explanations on the detachable slip).

In addition, the operating instructions are available on our web site www.socla.com or by simple request from our sales department.

Machinery Directive 2006/42/CE : Machinery Directive

In its Appendix I it sets a certain number of Essential Health and Safety Requirements which must be met. It applies to motorised butterfly

valves, (with electric, pneumatic or hydraulic actuators). According to this Directive, these sets are “Partly Completed Machineries” designed

for being integrated into a machine.

“Partly Completed Machinery” means an assembly which is almost machinery but which cannot in itself perform a specific application. A drive

system is partly completed machinery. Partly completed machinery is only intended to be incorporated into or assembled with other machi-

nery or other partly completed machinery or equipment, thereby forming machinery to which this Directive applies.

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/201610

Pressure

DIRECTIVE 2014/68/UE Equipments under pressure.

Products manufactured in conformity with the requirements of the directive, according to pressure, DN

and fluid (see on the precedent page )

.

PS :

Maximum allowable pressure (in bar) according to Directive 2014/68/UE

PFA :

Allowable operating pressure (in bar) for supply, distribution and disposal of water.

LINERS DN mm Cat.MOUNTING PFA PS

L1

L2 G1 G2

6 bar

EPDM, Nitrile (CC333G disc), White

EPDM

32 to 150

3.3

Flanges 6 6 6 6

End of line 4 4 4 4

200 to 350

I

Flanges 6 6 6 6

End of line 4 4 4 4

Nitrile (except CC333G disc),

Neoprene, Butyl, Hypalon, Natural

rubber, White natural rubber.

32 to 100

I

Flanges 6 6 6 6 6

End of line 4 4 4 4

125 to 350

II

Flanges 6 6 6 6 6

End of line 4 4 4 4

10 bar

EPDM, Nitrile (CC333G disc), White

Nitrile, Carboxylated Nitrile , White

EPDM

25 to 100

3,3

Flanges 10 10 10 10

End of line 6 6 6 6

125 & 150

I

Flanges 10 10 10 10

End of line 6 6 6 6

200 to 350

I

Flanges 10 10 10 10

End of line 6 6 6 6

Nitrile (except CC333G disc),

FKM

25

3,3

Flanges 10 10 10 10 10

End of line 6 6 6 6

32 to 100

I

Flanges 10 10 10 10 10

End of line 6 6 6 6

125 to 350

II

Flanges 10 10 10 10 10

End of line 6 6 6 6

Silicone

32 to 100

I

Flanges 10 10 10 10 10

End of line 6 6 6 6

125 to 150

II

Flanges 10 10 10 10 10

End of line 6 6 6 6

200 to 350

II

Flanges 6 6 6 6 6

End of line 4 4 4 4

16 bar

EPDM, Nitrile (CC333G disc)

32 to 100

3,3

Flanges 16 16 16 10

End of line 12 12 12 10

125

I

Flanges 16 16 16 10

End of line 12 12 12 10

150

I

Flanges 16 10 16 10

End of line 12 6 12 10

200 to 300

I

Flanges 16 10 16 10

End of line 10 6 10 10

350

I

Flanges 16 10 16 10

End of line 8 6 8 8

Nitrile (except CC333G disc),

Neoprene, Butyl, Hypalon, Natural

rubber, White natural rubber

32 to 100

I

Flanges 16 16 16 10 16

End of line 12 12 12 12

125 & 150

II

Flanges 16 16 16 10 16

End of line 12 12 12 12

200 to 300

II

Flanges 16 16 16 10 10

End of line 10 10 10 10

350

II

Flanges 16 16 16 10 10

End of line 8 8 8 8

20 bar

EPDM, Nitrile (CC333G disc)

32 to 250

3,3

Flanges 20 20

End of line 12 12

300 & 350

I

Flanges 20 20

End of line 12 12

Nitrile (except CC333G disc), Neo-

prene, Butyl, Natural rubber, White

natural rubber

32 to 100

3,3

Flanges 20 20 20

End of line 12 12 12

125 to 350

II

Flanges 20 20 20

End of line 12 12 12

25 bar

EPDM, Nitrile (CC333G disc) 32 to 150

3,3

Flanges 25 25

End of line 16 16

Nitrile (except CC333G disc)

32 to 80

3,3

Flanges 25 25 25

End of line 16 16 16

100 to 150

II

Flanges 25 25 25

End of line 16 16 16

ATTENTION

Gas G1 and G2 : The max.

pressure is 6 bar when

using cast iron 5.1301(EN-

GJL-250).

NOTE : Butterfly valves of

category II used as «end

of line», please consult us.

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 11

Torque values

NOTE :

One actuation minimum per month.

Pressure/temperature

diagram

EPDM liner DN 25 up to 350

Pressure in bar

Temperature in °C

For every other elastomer, please ask our sales department.

Wet torques

(Nm)

25 32 40 50 65 80 100 125 150 200 250 300 350

PS6

EPDM

10 10 10 10 10 20 22 40 45 85 200 280 400

NBR

10 12 12 12 20 22 30 55 85 115 255 380 560

PS16

EPDM

10 10 10 10 18 25 46 50 60 120 280 430 500

NBR

10 12 12 12 28 32 55 80 100 150 450 600 720

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/201612

Flow rate (Kv)

The butterfly valve is not the best product for regula-

ting Nevertheless, the Sylax 25-350 mm butterfly valve

can be used to regulate by an opening stage between

30° and 90°.

A regulation in the opening stage lower than 30° is

not advisable because of over speed, cavitation effect,

which could damage prematurely the valve.

Kv = volume of water in m3/h through a valve at a preset

opening stage and under a head loss of 1 bar.

The maximum flow velocity of the fluid through the valve must not exceed :

- 3 m/s for liquid fluids. Between 3 and 5m/s, the use of the Sylax 25-350 mm butterfly valve is possible, but the phenomena

of cavitation, noise, vibration and water hammering increase.

- 20m/s for gas. Between 20 and 25m/s, the use of the Sylax 25-350 mm butterfly valve is possible, but the phenomena of

cavitation, noise, vibration and water hammering increase.

- for pulverulent or paste fluids : please consult us.

OPENING STAGES

OPENING STAGE - Stainless steel disc

DN 10° 20° 30° 40° 50° 60° 70° 80° 90°

25 - - - 3 8 16 27 35 40

32/40 - - - 5 12 25 40 56 62

50

- - 1 8 18 33 54 71 79

65

- - 6 19 41 76 118 158 174

80

-

3 18 43 79 138 211 252 275

100

-

15 38 83 154 253 368 458 496

125

-

20 61 134 249 399 599 792 883

150

5

37 100 200 374 600 863 1109 1212

200

15

76 200 399 680 1099 1666 2196 2500

250

40

150 333 621 1084 1765 2452 3517 3948

300

60

219 500 989 1736 2770 4097 5118 5635

350

145

420 882 1676 2850 4462 6000 7431 8520

DEGRES D'OUVERTURE

DN

0ϒ10ϒ30ϒ20ϒ60ϒ70ϒ50ϒ40ϒ90ϒ80ϒ

Kv

8

6

5

4

3

2.5

2

1.5

10

1

100

15

20

25

30

40

50

60

80

800

600

500

400

300

250

200

150

1000

10000

1500

2000

2500

3000

4000

5000

6000

8000

8000

6000

5000

4000

3000

2500

2000

1500

10000

1000

150

200

250

300

400

500

600

800

80

60

50

40

30

25

20

15

100

10

4

5

6

8

1500

2000

2500

3000

4000

GALLON/MIN M3/H

125

200

250

300

65

50

100

80

150

350

32/40

25

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 13

Headloss diagram (Δp)

FLOW

DEBIT

M3/H

FLOW

GALLON/MIN

PSI

M/CE

100

DN

134510 15

10

2345

20

30

40

60

80

1

.7.2 .3 .4 .5

678

6 7 8

1.5

2

.6 .8

.15

P

10

1000

150

200

250

300

400

500

600

800

10000

2000

3000

4000

6000

100

80

60

40

150

200

300

400

1000

1500

2000

3000

4000

6000

10000

20000

30000

40000

25000

15000

8000

600

800

5000

2500

8000

5000

2500

1500

M/WC

25

32-40

50

65

80

100

125

150

200

250

300

350

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/201614

Type of flange The Sylax 25-350 mm butterfly valve has

been designed to be mounted on nor-

malised standard flanges. Only standard

flanges type 11, 21 and 34 according to EN

1092 are quite compatible.

For other types of flanges, refer to the table

below.

Non appropriate connections will cancel our

guarantee.

NOTE : The use of expansion seals, as well as the use of elastomer coated flanges, between the flange and the valve are

strictly forbidden.

ØA1

ØB

ØA0

ØA2

Tag / traceability

Rep Description

1

Name of the valve

2

Reference

3

Material of the disc

4

Material of the liner

5

Pressure PS between flanges L1/L2 (liquid)

6

Pressure PS between flanges G1/G2 (gas)

7

Pressure PS end flange L1/L2 (liquid)

8

Pressure PFA water 20°C

9

Pressure PS end flange G2 (gas)

10

Number of manufacturing order

11 Notified Body Number for the Directive

PED 2014/68/UE

12

Manufacturing date

13

Connecting flanges

14

Limit of use

15

Approval information zone

2

4

6

9

12

10

11

13

14

7

5

3

1

15

8

DN Ø A0 Ø A1 mini Ø A2 maxi Ø B mini

25 1 32 - 44 60

32 1 1/4 43 35 51 80

40 1 1/2 43 35 51 80

50 2 54 42 60 90

65 2 1/2 70 62 74 110

80 3 85 82 91 128

100 4 100 97 108 148

125 5 125 128 143 178

150 6 150 156 166 202

200 8 200 200 224 258

250 10 250 252 280 313

300 12 300 303 329 365

350 14 340 344 369 418

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 15

Bolts and nuts

DN

NPS a e

EN 1092

PN6

EN 1092

PN10

EN 1092

PN16

EN 1092

PN25

ASME / ANSI B16.5

Class 150

* Nb

rods

or Nb

screw

ØV c

* Nb

rods

or Nb

screw

ØV c

* Nb

rods

or Nb

screw

ØV c

* Nb

rods

or Nb

screw

ØV c

* Nb

rods

or Nb

screw

ØV

Metric

ØV

UNC**

c

25 1 32 -- 4 M10 16 4 M12 18 4 M12 18 4 M12 18 4 M14 1/2’’ 18

32/40

11/2 32 14 4 M12 18 4 M16 24 4 M16 24 4 M16 24 4 M14 1/2’’ 18

50 2 43 18 4 M12 18 4 M16 24 4 M16 24 4 M16 24 4 M16 5/8’’ 24

65* 21/2 46 20 4 M12 18 8* M16 24 8* M16 24 8 M16 24 4 M16 5/8’’ 24

80 3 46 20 4 M16 24 8 M16 24 8 M16 24 8 M16 24 4 M16 5/8’’ 24

100 4 52 24 4 M16 24 8 M16 24 8 M16 24 8 M20 26 8 M16 5/8’’ 24

125 5 56 26 8 M16 24 8 M16 24 8 M16 24 8 M24 32 8 M20 3/4’’ 26

150 6 56 26 8 M16 24 8 M20 26 8 M20 26 8 M24 32 8 M20 3/4’’ 26

200 8 60 28 8 M16 24 8 M20 26 12 M20 26 12 M24 32 8 M20 3/4’’ 26

250 10 68 32 12 M16 24 12 M20 26 12 M24 32 12 M27 32 12 M24 7/8’’ 26

300 12 77 36 12 M20 26 12 M20 26 12 M24 32 16 M27 32 12 M24 7/8’’ 26

350 14 77 36 12 M20 26 16 M20 26 16 M24 32 16 M30 36 12 M27 1’’ 32

DN

NPS a e

BS10-d BS10-e

JIS2238 & JIS2239

5K

JIS2238 & JIS2239

10K

JIS2238 & JIS2239

16K

* Nb

rods

or Nb

screw

ØV

UNC

c

* Nb

rods

or Nb

screw

ØV

UNC

c

* Nb

rods

or Nb

screw

ØV c

* Nb

rods

or Nb

screw

ØV c

* Nb

rods

or Nb

screw

ØV c

25 1 32 -- 4 1/2’’ 18 4 1/2’’ 18 4 M10 16 4 M16 24 4 M16 24

32/40

11/2 32 14 4 1/2’’ 18 4 1/2’’ 18 4 M12 18 4 M16 24 4 M16 24

50 2 43 18 4 5/8’’ 24 4 5/8’’ 24 4 M12 18 4 M16 24 8 M16 24

65 21/2 46 20 4 5/8’’ 24 4 5/8’’ 24 4 M12 18 4 M16 24 8 M16 24

80 3 46 20 4 5/8’’ 24 4 5/8’’ 24 4 M16 24 8 M16 24 8 M20 26

100 4 52 24 4 5/8’’ 24 8 5/8’’ 24 8 M16 24 8 M16 24 8 M20 26

125 5 56 26 8 5/8’’ 24 8 5/8’’ 24 8 M16 24 8 M20 26 8 M22 26

150 6 56 26 8 5/8’’ 24 8 3/4’’ 26 8 M16 24 8 M20 26 12 M22 26

200 8 60 28 8 5/8’’ 24 8 3/4’’ 26 8 M20 26 12 M20 26 12 M22 26

250 10 68 32 8 3/4’’ 26 12 3/4’’ 26 12 M20 26 12 M22 26 12 M24 32

300 12 77 36 12 3/4’’ 26 12 7/8’’ 26 12 M20 26 16 M22 26 16 M24 32

350 14 77 36 12 7/8’’ 26 12 7/8’’ 26 12 M22 26 16 M22 26 16

M30 x 3

36

* WAFER TYPE BODY AND LUGS WITH UNTHREADED HOLES :

Assembly by rods : number of nuts and washer = 2 x Number of rods (above)

Assembly by bolts : Number of nuts = Number of screws (above) and number of washer = 2 x Number of nuts

* LUG TYPE BODY :

Assembly by screws : Number of screw per face (above) and number of washer is the same

* DOUBLE FLANGE BODY :

Assembly by rods : number of nuts and washers= 2 x Number of rods (above)

Assembly by rods + central nut : Number of nuts = 2 x Number of rods (above)

Number of washers = 4 x Number of rods (above)

Number of thin nuts for central position = 1 x Number of rods (above)

** ASME / ANSI B16.5 Class 150 : Standard version : metric threading; UNC threading : please consult us.

* For flanges in cast or ductile iron 4 holes M16 and for flanges in steel 8 holes M16 on the same drilling circle.

Note : Bolts and nuts are not part of our standard supply

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/201616

Version lug type with unthreaded holes, (permanent

downstream dismantling)

assembly by bolts

:

L3 = a/2 + b + c + j

L3 = minimum length under head of screw

a = width of the butterfly valve

(face to face dimension)

b = thickness of the flange (customer)

c =

thickness of washer + thickness of nut + exceeding length of the rod

j

=

thickness of washer under head of screw

Mounting in case of downstream pipework dismantling (see page 8).

Use nuts with reduced face-to-face dimensions between the butterfly

valve and the downstream flange.

Bolts and nuts

c b a b c

L1

ØV

L2

jb a b c

ØV

L1

c

b

a

b

c

L2

b

a

b

c

j

L3

jbac

Mounting in case of downstream pipework dismantling (see page 8).

Use nuts with reduced face-to-face dimensions between the butterfly

valve and the downstream flange.

For wafer type

and lugs with unthreaded holes ;

assembly by rods

:

L1 = a + 2(b+c)

L1 = minimum length of rods

a = width of the butterfly valve

(face to face dimension)

b = thickness of the flange (customer)

c =

thickness of washer + thickness of nut + exceeding length of the rod.

For wafer type

and lugs with unthreaded holes ;

assembly by

bolts :

L2 = a + 2b + c + j

L2 = minimum length under head of screw

a = width of the butterfly valve

b = thickness of the flange (customer)

c =

thickness of washer + thickness of nut + exceeding length of the rod

j

=

thickness of washer at the head of the screw.

Technical manual Sylax DN 25-350 mm

uksylax25_350 - Updated 20/09/2016 17

Installation

• General remarks :

For safety reasons, the installation must take place

under the supervision of authorised people taking

account of local safety instructions and advice.

The handling of butterfly valves and their controls

must be done by staff trained in all technical

aspects of their operation.

Before installation the pipes must be depressu-

rised and purged (empty of its fluid) in order to

avoid any danger to the operator.

The pipe work must be correctly aligned so that

no extra stress is exerted on the valve casing.

Check the compatibility of the connection flanges

against the operating pressure : the PN number of

the flanges must be greater or equal to the ope-

rating pressure.

The valve is a machined piece of equipment and

must not be used to prise apart the flanges.

A mounting instruction specifying the installation

characteristics and the commission of the Sylax

25-350 mm is available on our web site www.

socla.com or on request by our sales department.

• Installation conditions :

It is recommended that the distances mentioned

below be respected in order to prolong the life

time of the valve.

Mounting the valve close to pipe work junctions

places it in turbulent zones which increase its

wear.

5-6 DN

1 DN

DN

2-3 DN

DN

1 DN

DN

2-3 DN

1 DN

DN

2-3 DN

DN

1 DN

DN

Socla

sas

365 rue du lieutenant Putier

71530 VIREY LE GRAND

Postal address : CS 10273

71107 CHALON SUR SAONE Cedex

Tel : 33 3 85 97 42 52

Fax : 33 3 85 97 97 42

http://www.socla.com

Socla can accept no responsibility for possible errors in catalogue, brochures and other printed material. Socla reserve the right to alter its products without notice. This also applies

to products already agreed. All trademarks in this material are the property of the respective companies. All right reserved.

Other Socla Control Unit manuals

Popular Control Unit manuals by other brands

Aqua Environment Inc

Aqua Environment Inc 816-1 Operation and maintenance

Cooper Security

Cooper Security Scantronic i-gsm02 Installation and programming guide

L&S

L&S BLUE SMART 4 MONOl BLUE SMART 4 EDC user manual

Orno

Orno OR-GB-426 Operating and instalation instructions

Coelbo

Coelbo Speedbox Installation and operating instructions

Valcom

Valcom V-2000A user guide