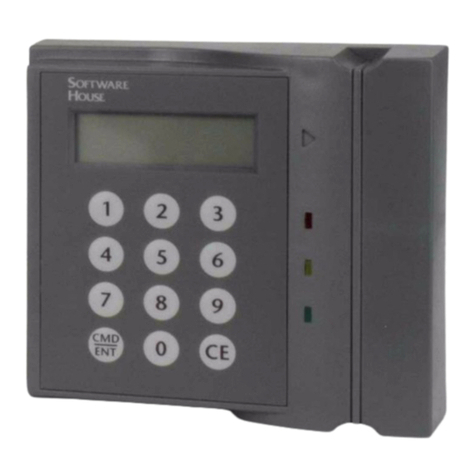

Software House iSTAR Edge User manual

1

iSTAR Edge

Quick Start Installation and

Operating Instructions

Version A4

Document Part Number UM-223

February 2010

OVERVIEW iSTAR Edge is a smaller, cost effective, two reader iSTAR that can be powered

over its Ethernet connection using Power over Ethernet (PoE), and is suitable

for placement above or near the door. iSTAR Edge can be clustered with other

iSTAR Edges and iSTAR eX’s.

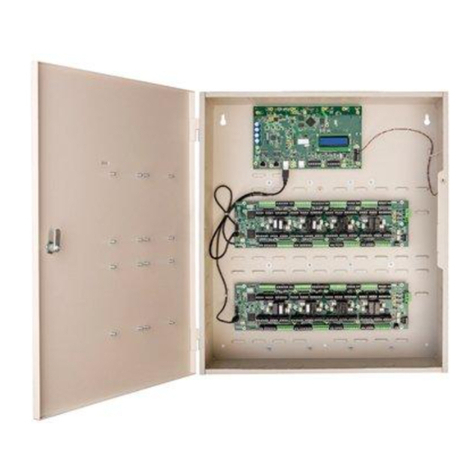

Figure 1 shows a photograph of the iSTAR Edge with an optional PoE board

along with I8 and R8 modules mounted on the door.

FIGURE 1. iSTAR Edge with optional I/O Modules

I8 R8

PoE

Ethernet

Tamper

Module

(I8 and R8 not included)

(Optional)

Overview

2

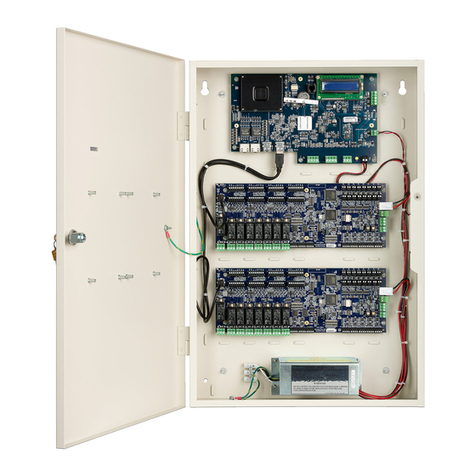

iSTAR Edge Layout

FIGURE 2. iSTAR EDGE Layout

4 Inputs

AUX Power

Connector 1

RM Port 1

Relay 1

4 Inputs

AUX Power

Connector 2

Wiegand

RM Port 3

Relay 2 Relay 4

Relay 3

USB Host Ports

Power Fail Power

E-net

Tamper FAI Inputs

Low Batt

USB Device Port (Not used)

In

Output 1 Output 2

(1-4) (5-8)

RM Port 2

Wiegand

Overview

3

Main Features Main features of iSTAR Edge include:

Storage

> 250k cards.

64 MB of RAM.

128 MB of onboard flash.

Power

Powered by

Ethernet connection: PoE or PoE Plus using optional add-on board

(EdgePower) or

apS or other 12/24VDC external power source.

Provides power for:

Wiegand readers

RS-485 ports

Two 2-pin Aux 12VDC power connectors for PIRs and motion sensors.

Provides optional power to relays:

Upon loss of external power, data is written to onboard flash.

Four onboard non-rechargeable alkaline AA batteries provide power for

the backup process and maintaining the clock afterwards.

Backup is valid for > 3 days, the period the onboard batteries can

maintain the clock.

Readers

2 readers total.

2 Wiegand connectors are available.

2 RM Readers are available to be configured.

3 RS-485 serial ports are available.

Readers can be any combination of 2 from Wiegand ports and/or RMs

on any of 3 serial ports.

NOTE Onboard battery backup was tested for 3 days, but will last for weeks in

actual practice.

Overview

4

I/O

8 General Purpose Inputs.

4 General Purpose Relays:

Dry or Wet contact controlled by a jumper for each relay.

4-pin connectors to support NO/NC and Dry/Wet configurations.

4- I8 and 4- R8 allowed to be configured on any of the three RS-485 ports.

Special purpose inputs:

Tamper (from enclosure door)

Main AC fail (from apS)

Low external battery (from apS))

PoE board present

Onboard battery low

USB Ports

A USB port is used to import encryption keys, in the same way as iSTAR

eX.

Communications

One 10/100 Ethernet port.

Full 256 bit (FIPS-197) AES encryption, as with iSTAR eX

Onboard controls

LCD with backlight for diagnostics.

Rotary switch for diagnostics, as with iSTAR eX.

LEDs for serial, Ethernet, power and relay state.

Two power LEDs: one super bright LED that is on when the enclosure

door is closed, and one green LED that is always on when main power is

present.

Relay activation LEDs are not affected by enclosure door.

All other LEDs are active only when the enclosure door is open.

Reset button.

Switches for serial termination of RM ports.

Jumpers for relay Wet/Dry control.

NOTE The following two inputs to the host are determined by the firmware.

There is no actual wiring to the iSTAR Edge board.

Pre-Installation Planning

5

Housing

Optional metal enclosure (12” x 12” x 4”) with lock and tamper switch is

slightly smaller than the RM-DCM-2 enclosure.

iSTAR Edge board is mountable in existing apC/L enclosures.

Compliance

FCC, CE, EN50133, IEC60950 by CB Scheme (International Safety) & RoHS.

PRE-INSTALLATION

PLANNING

Pre-installation involves the following:

1. Checking equipment (hardware, software, power supply, and wiring).

2. Checking power, wiring, equipment clearances, and code compliance at the

site.

3. Ensuring the proper tools are available.

Equipment Check Verify that the contents of the shipped boxes match the packing lists. Contact

Software House if any items are missing or damaged.

The iSTAR Edge hardware does not include mounting hardware for an

installation. Mounting hardware depends upon the site and must be approved

by a structural engineer or other certified professional.

Software House recommends anchoring systems capable of sustaining a 20 lb.

load.

Site Check Ensure that the mounting site is ready:

Mounting dimensions

• The can is 12” by 12” (30.48 x 30.48 cm)

• Upper mounting holes are 9" (22.86 cm) center to center.

• Bottom mounting holes are 10.5" (26.67 cm) below the upper mount

holes.

The site has been approved and all wiring complies with UL requirements

and other codes, as appropriate.

All preliminary site work is complete.

An appropriate power supply is accessible.

The site is clean and free of dust or other contaminants.

Pre-Installation Planning

6

iSTAR Edge Mounting Requirements

The mounting dimensions and board overlay are shown in Figure 3.

FIGURE 3. Mounting Requirements

Voltage Requirements

and Distance

To operate properly, each reader must conform to voltage requirements.

A standard RM Series Reader or RM-4 board requires at least 7.5 volts.

An RM-4E board requires at least 11 volts.

Most Wiegand readers require a minimum of 9 volts

The iSTAR Edge supplies 12 volts at its reader connectors; however, the amount

of voltage that reaches the reader is impacted by the following:

– Number of devices on the bus

– Current draw of each device

(228.6)

9.00

(304.8)

12.00

(304.8)

12.00

DOOR 2

IN 1

IN 2

IN 3

IN 4

AUX 1

WIEGAND 1

RM 1

RELAY 1

RELAY 2

PWR

RM 3

10/100

RELAY 4RELAY 3

RM 2

WIEGAND 2

AUX 2

IN 8

IN 7

IN 6

IN 5

DOOR 1

LCD DISPLAY

OPTIONAL

POE MODULE

iSTAR

Edge

TEMPLATE

ENCLOSURE

INSTALL SHEET, iSTAR Edge,

MOUNTING TEMPLATE

8200-0910-01, REV A3

SHEET 2 OF 2, SCALE 1:1

DIMENSIONS IN INCHES

( )DIMENSIONS IN MM

Installation Requirements

7

– Wiring length between the devices and iSTAR Edge

– Wire gauge that connects the devices

– State of the battery (if running on apS)

– The tolerance if sourced by an external power supply

To determine the maximum distance of a reader from an iSTAR Edge, calculate

the voltage that reaches each reader. If the voltage is insufficient, you can

shorten the wire length, use a heavier wire, or add a UL294 local power-limited

power supply.

Wire resistance is as follows:

• 24 AWG = 26.0 Ω per 1000 ft.

• 22 AWG = 16.5 Ω per 1000 ft.

• 20 AWG = 10.2 Ω per 1000 ft.

• 18 AWG = 6.5 Ω per 1000 ft.

Installation Tools Antistatic floor mat, tabletop mat, and wrist strap.

Standard tool kit

3/32" (2.4 mm) screwdriver

Security screwdriver (contact Software House)

Small needle nose pliers; small Phillips screwdriver; wire strippers

5/16" (#10) nut driver (for securing shield wires to a ground stud)

INSTALLATION

REQUIREMENTS

This section describes iSTAR Edge hardware, software, environmental, and

configuration requirements.

Host System

Requirements

iSTAR Edge requires a host computer configured as a C•CURE 9000 system

server/host that meets all the hardware and software requirements for servers

described in the C•CURE 9000 Installation Guide.

iSTAR Edge Cabinet

Requirements

The iSTAR Edge cabinet conforms to the specifications shown in Table 1.

TABLE 1. Cabinet Assembly Specifications

Item Specification

Weight <10 lbs. (<4.6 kg)

Height 12" (30.48 cm)

Width 12" (30.48 cm)

Installation Requirements

8

Environmental

Requirements

Table 2 shows the iSTAR Edge environmental requirements.

Power Requirements The standard iSTAR Edge uses a UL Listed 603 External Power Supply, such as

the Software House apS or uses a Power Over Ethernet (PoE or PoE+) injector.

To ensure adequate power, calculate the total power requirements of iSTAR

Edge and its related hardware, as follows.

Add the total current power for components in the system (modules, relays,

optional modules, readers, and wire resistance).

Tables 3 through 6 are provided to compute the current draw of components

attached to iSTAR Edge.

iSTAR Edge Components and Boards

Table 3 shows the power requirements of iSTAR Edge components and

attached boards.

aRM-4 board has only been evaluated by UL with RM Series readers (RM 1,2,3)

bRM-4E boards have only been evaluated by UL for use with RM-DCM-2 enclosure.

Depth 4.5" (11.4 cm)

TABLE 1. Cabinet Assembly Specifications

Item Specification

TABLE 2. Environmental Requirements

Status Range

Operation 32° F (0° C) to 120° F (48.9° C)

Storage 4° F (-20° C) to 158° F (70° C)

TABLE 3. Component and Board Power Requirements

Component/Board Current Draw at 12VDC

iSTAR Edge 400 mA with LCD - no load

RM-4 boarda80 mA without LCD - no load

180 mA with LCD - no load

RM-4E boardb125 mA - no load

I/8 board 125 mA - no load

R/8 board 150 mA - no active relays.

Add 20 mA for each active relay

Installation Requirements

9

Individual/Total Loads RS-485 Reader Power Outputs: 10.6-12.5 VDC, 1.5 A max each.

Wiegand Reader Power Outputs: 10.6-12.5 VDC, 350 mA max each.

Total of all Reader and AUX outputs combined (RS-485 & Wiegand) not to

exceed 1.5 A

Four (4) activated relay coils = 100 mA (25 mA/relay)

One I/8 module – 12 VDC, total= 125 mA

One R/8 module – 12 VDC, total= 325 mA (125 ma + 25 mA for each active

relay (max 4))

R/8 relay contact ratings – 30 VDC at 1 A (resistive)

iSTAR Edge Wiegand Reader Ports

Table 4 shows the maximum ratings for iSTAR Edge Wiegand direct reader

ports.

Table 5 shows maximum rating for RM Reader ports.

Ethernet Requirements The iSTAR Edge Ethernet connection is:

Onboard 1 Ethernet port – supports 10/100Base-T Ethernet connections.

TABLE 4. Wiegand Port Rating

Port Rating

Reader output control

(red, green, yellow, beeper)

Low = 0 v to 0.8 v

High = 4.0 v to 5.25 v

20 mA maximum

Reader input data lines

(D0, D1)

Low = 0 v to 0.8 v

High = 4.0 v to 5.25 v

Reader output voltage +12 VDC

Reader current 350 mA max per reader, not to exceed

1.5 A for Readers and AUXs

TABLE 5. RM Port Rating

Port Rating

Reader output voltage +12 VDC

Reader current 1.5 A max per port, not to exceed

1.5 A for Readers and AUXs

Installation Requirements

10

Wiring Requirements Table 6 shows general wiring requirements for an iSTAR Edge and its

components.

TABLE 6. Equipment Wiring Specifications

Signal From To

Belden #

or equiv. AWG

#

Prs Shield

Max

Length

Max. Wire

Resistance

RS-485 Comm,

two wire

iSTAR

Edge

RM & I/O

Modules

9841 24 1 Yes 4000 ft.

(1212 m)

103Ω

Power iSTAR

Edge

RM & I/O

Modules

8442/8461 22/18 1 No Range of

600 ft. to

1500 ft.

depends

on AWG

See Note b

RJ45-Ethernet iSTAR

Edge

Hub, Host N/A Cat 5 or

more

24

2 N/A 328 ft.

(100 m)

8.4 Ω

Supervised

Input

iSTAR

Edge or I8

Input 8442/8461 22/18 1 No 2000 ft.

(606 m)

32Ω

Request-to-exit

(REX or RTE)

iSTAR

Edge or

RM-4/4E

module

Switch 8442/8461 22/18 1 No 2000 ft.

(606 m)

32 Ω

Door contact

(DSM)

iSTAR

Edge or

RM-4/4E

module

Contact 8442/8461 22/18 1 No 2000 ft.

(606 m)

32Ω

Supervised

Input (UL)

Note a

iSTAR

Edge or I8

Input 9462 22 1 Yes 2000 ft.

(606 m)

32Ω

Relay Control RM-4

module

ARM-1 9462 22 1 Yes 25 ft.

(7.6 m)

.04Ω

Reader Data iSTAR

Edge or

RM-4/4E

module

Proximity/

Wiegand

signaling

read head

9942

9260

Alpha wire

5386C

22

20

18

3 Yes 200 ft.

(60.96 m)

300 ft.

(91.4 m)

500 ft.

(152.4 m)

3.2 Ω (22)

3.2 Ω (20)

3.2 Ω (18)

a. To comply with UL requirements, use shielded, minimum 22 AWG stranded, twisted pair cable for monitor points,

DSMs, and REXs. Use Belden 9462 or equivalent.

b. Calculations are based on a single RM-4 reader with keypad and LCD (250 mA):

Using 22 AWG, distance = 600 ft. (.0165 Ω /ft.)

Using 18 AWG, distance = 1500 ft. (.0065 Ω /ft.)

Installation Requirements

11

Grounding

Requirements

Grounding requirements are as follows:

Ensure that the iSTAR Edge controller is properly connected to an earth

ground at the ground stud in the cabinet. (Identified by symbol.)

Use 16 AWG or larger wire.

Ensure that the shield wires for the readers, inputs, outputs, and AUX

cables are grounded to the nearest earth/ground connection at one end only

of the cable.

Disconnect the ground wire last to provide maximum protection to the

equipment and personnel.

NOTE All cabling must be shielded. See Table 6 for Belden types.

NOTE iSTAR Edge has not been evaluated by UL for operation over WAN

topologies.

Specifications

12

SPECIFICATIONS As indicated on the door map shown below, the following are power

specifications for the iSTAR Edge:

Entire Unit

• Local Power 12 VDC, 3.8 Amp Max.

• Local Power 24 VDC, 3.1 Amp Max.

Reader and I/O Module Supply (Total of AUX, RM, and Wiegand Ports)

• 12 VDC, 1.5 Amp

– AUX Ports 12 VDC 350 mA each

– RM Ports 12 VDC, 1.5 Amp each (but the max. is also 1.5 Amp for all)

– Wiegand Ports, 12 VDC, 350 mA each

Relays

• 30 VAC/DC 1.0 Amp Max. (Dry) each

• 12 or 24 VDC 0.75 Amp Max. (Wet) each

FIGURE 4. Specifications

PoE Plus

PoE

NOTE If using Power Over Ethernet (PoE), be sure that the jumper on the PoE

board is set correctly. As shown in Figure 4, there is a jumper position

for PoE and another for PoE Plus (+).

Specifications

13

Power General The iSTAR Edge can be powered by PoE, PoE Plus, or traditional 12V or 24V

DC power supplies. PoE and PoE Plus provide a method to significantly reduce

installation costs using 100 meters of ethernet cable for both power and data to

the controller.

PoE (IEEE 802.3af) installation is limited to 12.95W of power consumption

including the controller.

PoE Plus (IEEE 802.3at) installation is limited to 25.5W of power

consumption including the controller.

Careful selection of components allows a 1-door system to operate from PoE

and a 2-door system to operate from PoE Plus.

Traditional power supplies include:

An apS

Any external UPS (12/24 VDC)

Alternate Power

For those systems that exceed these limits, alternate DC supplies can be

deployed including external PoE splitters.

Alternate DC supplies are installed by the customer per the requirements of the

particular installation. When alternate DC supplies are deployed for devices on

the relay circuits, the relays circuits are configured as dry. The devices/loads do

not source power from the iSTAR Edge and are removed from the power

budget calculation.

If spare PoE/Poe Plus ports are not available in the system, PoE injectors can be

used at the source of the CAT5/6 cable.

Batteries

When onboard batteries are installed they must be fresh (they must produce

more than 5V), otherwise a too low battery-cut circuit will disconnect them. The

LCD will display information about the state of the batteries.

AC / Main Fail input:

Indicates whether the external power source has reported loss of its main

power.

Shares connector and Ground pin with Low Battery.

Normally closed dry relay contacts are required.

Configured on host as an unsupervised input, as with iSTAR eX, iSTAR Pro.

Low Battery input

Indicates whether external power source, has reported its battery is low.

Specifications

14

Wired in from external power source.

Shares connector and Ground pin with AC / Main Fail.

Normally closed dry relay contacts are required.

Configured on host as an unsupervised input, as with iSTAR eX, iSTAR Pro.

Onboard Battery Low input

Internal measurement (no connections necessary) of onboard AA alkaline

batteries.

Active if their voltage is below 4.6 volts.

Active if they are not present or one or more of them is not making full

connection.

This informs user that they should replace the onboard backup batteries for

this controller as soon as possible.

The user does not need to power down the controller to remove/replace the

batteries

Configured on host as an unsupervised input. This is a new input not

present in iSTAR eX or iSTAR Pro.

PoE Present

Internal sensing of whether PoE module is attached.

Is visible to user in the Status Tab of the iSTAR Edge Controller editor in the

C•CURE 9000 Application program. The PoE module should only be

installed or removed when board is entirely powered off.

Power in 12 / 24 VDC

iSTAR Edge can run off either 12VDC or 24 VDC power applied to the PWR

connector. Normal operating ranges include:

12V operation: 10.2 V to 14.4 V (-15/+20%)

24V operation: 20.4 to 30.0 V (-15/+25%)

Configuration for either 12V or 24V operation is stored in flash. During boot up

the iSTAR Edge detects an input power voltage as either 12 or 24 VDC and

automatically sets operation accordingly.

The iSTAR Edge will not automatically re-adjust back from 24V to 12V. This is

because a measurement of 12V input power could indicate a 12V supply or a

24V supply with a very low battery. To set the board back to 12V from 24V,

manual intervention is required:

1. Remove external power from the iSTAR Edge.

2. Select position 9on the rotary switch.

Specifications

15

3. Connect a power supply of the desired voltage (12V or 24V) to the iSTAR

Edge.

4. Watch the LCD for the message to reset the board.

5. Select position 0(or other desired position other than 9).

6. Press RESET button.

The iSTAR Edge Wiegand reader power, RS-485 serial port power and AUX

power are always configured at 12 VDC.

The Relay Wetted power is either 12 VDC or 24 VDC, depending on the input

power source.

Onboard backup

batteries

iSTAR Edge uses four onboard AA batteries to power backup to flash on loss of

main input power. These batteries must be non-rechargeable Alkaline batteries,

specifically:

AA

Alkaline

2.5 Amp hour

Button top

In order to prevent voltages that partially run the processor, the iSTAR Edge has

a battery-cut circuit. When the batteries fall below 4V, they are disconnected

from rest of the board.

The user has an onboard battery low input, configured in the host, that will

indicate when the onboard batteries need to be changed. This input will be

active when batteries are not present, not making contact, or too low to

guarantee a backup and three days of power for the clock. The user should

replace the batteries immediately when this input is active.

Backup iSTAR Edge handles backup in essentially the same way as iSTAR Classic and

iSTAR eX. When power (input voltage) drops too low to support full operation,

power usage is reduced as much as possible, processes are stopped and data is

written into flash. Processes remain stopped until the input voltage returns to a

normal operating range. At that point, iSTAR Edge reboots and reloads data

from flash to RAM and starts processing again.

The only input that controls the initiation of iSTAR Edge’s power-fail backup

process is iSTAR Edge's own onboard measurement of incoming power

voltage. iSTAR Edge measures external power voltage every 1/10 of a second.

When external power voltage moves outside of normal operating voltage (10.2

V to 14.4 V for nominal 12 V operation, or below 20.4 V for nominal 24 V

operation), iSTAR Edge will initiate the backup process.

Specifications

16

Power Out iSTAR Edge has various ways to provide power to external devices:

The following power outputs combined can provide a total of 1.5A at 12V.

• each of three serial ports

• each of two Wiegand ports

• each of two aux ports, suitable, for example, for motion sensor power.

The relays can be configured by jumper to provide power.

• Each relay is limited to 0.75A by an individual resettable fuse.

• If one load is shorted the individual fuse limits the shutdown to the

shorted load

• Power fed to wetted relay contacts is 12V for PoE or PoE plus and

otherwise is the DC input voltage.

USB provides 500mA at 5V for each device port. Each port has a resettable

fuse, this meets the USB standard and should not be exceeded by a well

functioning device.

If powered by an external DC supply the amount of power available will

depend on that supply, subject to the limits stated above.

PoE and PoE Plus have the following power limits

PoE provides 12.95W with 100 meters of cable between PSE (Power

Sourcing Equipment) and iSTAR Edge

PoE Plus provides 25.5W with 100 meters of cable between PSE and iSTAR

Edge

Cable length is part of the power budget, i.e. a shorter cable increases

available power, e.g. PoE Plus provides about 10% more power with 50

meters of cable between PSE and iSTAR Edge

Specifications

17

Door Map The Door Map shows the location of the Switches, Jumpers, and LEDs.

FIGURE 5. Door Map

Visual Indicators LCD

LCD will display diagnostic messages in a similar way to the iSTAR eX.

Diagnostics are controlled by the rotary switch, SW1.

Contrast controlled by potentiometer, RV1.

Backlight is ON when door is open, OFF when door is closed, and during

power-fail backups.

LEDs

The super-bright white Power LED is illuminated when the enclosure door is

closed, i.e. when the tamper switch closes. The power LED normally runs at

12VDC and extinguishes at about 8VDC.

The relay activation LEDs remain active regardless of the state of the enclosure

door.

The balance of the indicators are illuminated when the enclosure door is

opened. The LCD backlight and all LEDs other than the power LED and the

relay LEDs are under firmware control and are extinguished when the unit

detects input power failure and enters sleep mode to minimize power

consumption.

Specifications

18

Users have the ability, via the host, to configure LCD backlight and LEDs other

than Power LED, the Bright White external view Power LED, and the relay

activation LEDs to be always be off, regardless of tamper state.

The table below summarizes the operation of the LEDs.

TABLE 7. LED Operation

Indicator

Input

power

good,

door

closed

Input

power

good,

door

open

Input power

lost, backing

up/sleeping

Input

power

< 8V Controlled by

Power LED On On n/a Off Hardware

Bright White LED On Off Off n/a Firmware

Relay Activation LEDs On On Off Off Firmware

All other indicators, and

LCD backlight

Off On Off n/a Firmware

All other indicators, and

LCD backlight if

configured OFF in host

Off Off Off n/a Firmware

Specifications

19

The following table summarizes the function and designation of each LED

Onboard controls Reset button

The reset button performs a hard reset of the processor and as many peripherals

as possible. It causes all RAM to be erased. The Flash, including backups and

ICU configuration information, is not erased. As with iSTAR eX, use Rotary

switch position D to clear the flash and restore factory defaults.

TABLE 8. Functions of LEDs

LED Function Comment

DS21 Main Power - Internal View Always on if Voltage in > 8V

DS20 Main Power - External View Super bright White LED, visible

from outside of the enclosure

when the door is closed. Off when

the door is open.

Relay Outputs

DS15 Output 1 NO Closed Always on if Voltage in > 8V

DS14 Output 2 NO Closed Always on if Voltage in > 8V

DS13 Output 3 NO Closed Always on if Voltage in > 8V

DS8 Output 4 NO Closed Always on if Voltage in > 8V

Ethernet

DS4 Ethernet Activity Off when door is closed

DS2 Ethernet Full Duplex Off when door is closed

DS3 Ethernet 100 Mbps Off when door is closed

Serial

DS17 RS-485-1 Tx Off when door is closed

DS19 RS-485-1 Rx Off when door is closed

DS12 RS-485-2 Tx Off when door is closed

DS11 RS-485-2 Rx Off when door is closed

DS10 RS-485-3 Tx Off when door is closed

DS9 RS-485-3 Rx Off when door is closed

Specifications

20

Switches and Jumpers

Rotary switch There is an onboard 16 position rotary switch, SW1. Most of the positions are

used to control LCD diagnostics, and is similar to iSTAR eX.

Following is a reference table for iSTAR Edge rotary switch functions:

TABLE 10. iSTAR Edge Rotary Switch Functions

TABLE 9. Switches and Jumpers

Ref Type Description

SW1 Rotary Diagnostics, restore factory default and

other options.

SW7 Dual DIP Slide RS485-3 Termination

SW8 Dual DIP Slide RS485-2 Termination

SW9 Dual DIP Slide RS485-1 Termination

SW10 Push button Reset

J10 Jumper Relay Output 1 Source/Dry

J5 Jumper Relay Output 2 Source/Dry

J11 Jumper Relay Output 3 Source/Dry

J23 jumper Relay Output 4 Source/Dry

PoE Board - J2 Jumper Select PoE or PoE+

Position Description

0 ICU Block Off (Read/Write/Update) Display General Messages

1 Display card data from last card read, 7 second LCD display (slow mode)

2 Display card data from last card read, 2 second LCD display (fast mode)

3 Display supervised input changes, 2 second LCD display (slow mode)

4 Display supervised input changes, 1 second LCD display (fast mode)

5 Display manual output changes (include readers and R/8 boards), 2 second LCD display

(slow mode)

6 Display output changes (does not include readers and R/8 boards), 1 second LCD display

(fast mode)

7 Activate output test mode (include readers and R/8 boards_

8 Test Onboard Ethernet

9 Used to reset 24 V mode to 12 V mode (See Power chapter.)

A Not used

Other manuals for iSTAR Edge

1

Table of contents

Other Software House Controllers manuals

Popular Controllers manuals by other brands

EnOcean

EnOcean Omnio UPJ230/12 manual

Manning

Manning YB8 Operating and instruction manual

Magnetek

Magnetek SBN Series instruction manual

86Pixels

86Pixels PinVision for Twilight Zone installation manual

ABB

ABB PLUTO Safety-PLC operating instructions

Ametek

Ametek Magnetrol Tuffy Installation and operating manual

Bticino

Bticino AXOLUTE HD4657M3 quick start guide

Ltech

Ltech WiFi-102-CT operating instructions

Hytork Dossier

Hytork Dossier XL 45 Installation, operating and maintenance instructions

Ambient

Ambient Lockit Timecode manual

Davies Craig

Davies Craig EWP-FAN installation instructions

Danfoss

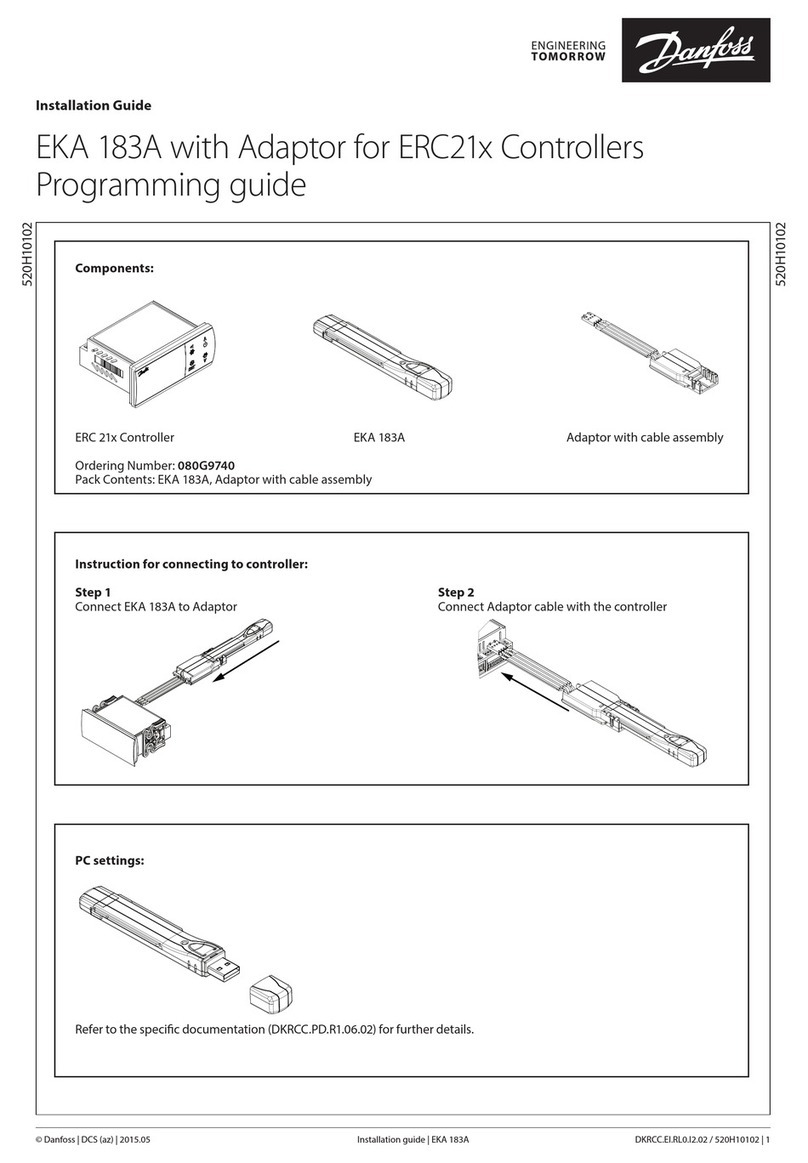

Danfoss EKA 183A installation guide