Software House RM2L-NH Instruction Manual

1

RM2L-NH-Keypad Arming Station

Quick Start

Installation Guide

Version A5

Document Part Number UM-235

July 2009

OVERVIEW This guide provides quick start installation and connection information for the

RM2L-NH Keypad Arming Station. The device has a keypad and LCD but no read

head.

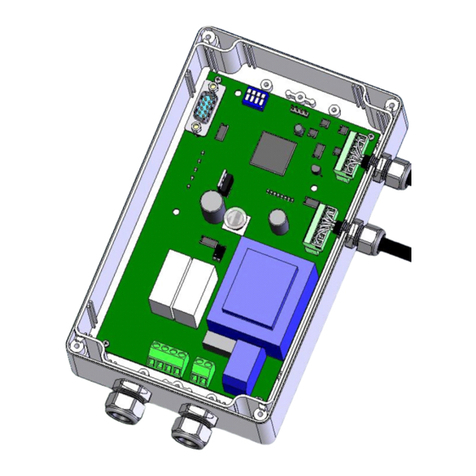

Figure 1 illustrates the RM2L-NH Keypad Arming Station.

FIGURE 1. RM2L-NH Keypad Arming Station

RM2L-NH

Overview

2

Specifications

The following specifications apply to the RM2L-NH Keypad Arming Station:

Data Cable: Recommended data cable is Belden #9841or equivalent. The maximum

length is 4000 feet (1212 meters) between the apC/iSTAR and the RM2L-NH

device.

Power Wiring: Recommended power wiring is Belden #8461 (18 AWG) or #8442

(22 AWG) twisted pair. Maximum length depends on the wire gauge. RM2L-NH

devices can be powered from a local power supply.

Temperature

Indoor: 32° F to 120° F (0° C to 49° C)

Outdoor: -31° F to 151 ° F (-35 ° C to 66° C)

RM 2L-NH Keypad

Arming Station

Table 1 shows the power requirements for RM2L-NH devices

NOTE The power source can be from a power limited output on an apC or iSTAR.

The local power supply must be a UL Listed Access Control (or Burglar Alarm),

power-limited, Class 2, power source.

TABLE 1. RM2L-NH Power Supply Requirements

RM2L-NH Device Model # Power Requirements:

12 VDC

With Keypad and LCD RM2L-NH 235 mA nominal

300 mA Peak

Installation

3

Standards RM2L-NH Keypad Arming Stations are Underwriters Laboratories Inc. (UL), Listed to

Standard UL 294, Access Control System Units, Fifth Edition.

RM2L-NH Keypad Arming Stations are Underwriters Laboratories Inc. (UL), Listed to

Standard UL 1076.

RM2L-NH Keypad Arming Stations must be wired in accordance with the National

Electrical Code (ANSI/NFPA 70), local codes, and the authorities having jurisdiction.

INSTALLATION To install an RM2L-NH Keypad Arming Station, perform these steps:

1. Install the RM mount plate.

2. Wire the components.

3. Connect and ground the cable shields on the reader bus

4. Set the RM-4 device address

5. Install the ARM-1 relay boards (optional)

6. Install the heater kit. (optional)

7. Mount the RM standard housing on the RM mount plate using the Software House

security screwdriver (Part number 132-183).

Install the RM Mount

Plate

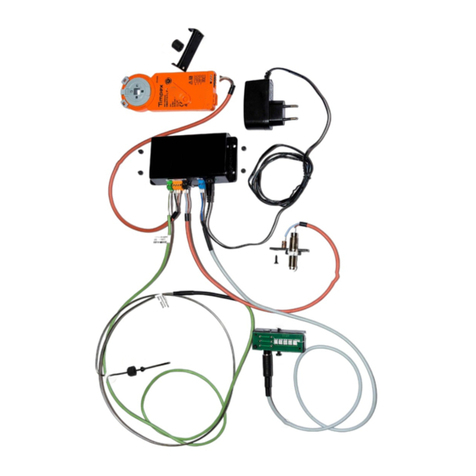

Figure 2 shows the RM standard housing, mount plate, and gasket. All RM2L-NH

Keypad Arming Stations conform to the same housing, mount plate, and gasket

dimensions.

FIGURE 2. Standard Housing and Mount Plate

Standard Housing

Standard mount plate

Housing

screws

Gasket

Requires a security screwdriver

Installation

4

Figure 3 shows RM mount plate dimensions.

FIGURE 3. RM Mount Plate Dimensions

This device has been approved for outdoor use when properly installed with RM

Heater Kit Installation (P.N. 130-915) and the supplied gasket material. Position

the gasket with the RM mount plate so that the mounting holes are properly

aligned. Ensure that the gasket is placed between the mounting surface and

mating surface of the RM mount plate. Fasten the RM mount plate to the

mounting surface with the gasket material in between. Install the gasket so that

no gaps or wrinkles are present.

The RM mount plate contains eight mounting holes. However, you do not have to

use all eight holes; usually any four of the eight holes are adequate. The

mounting holes are 0.156” and provide clearance for 6-32 flat head counter sunk

bolts or screws.

Wiring

access

1.29"

.83"

2.47"

3.66"

2.73"

1.54"

5.45"

4.94"

4.11"

1.82"

3.92"

3.64"

8 mounting holes

.0.156" Thru, 0.280” Countersink

Installation

6

Wiring the Inputs,

Outputs, Reader Bus

Figure 5 shows RM-4 P1 and P5 wiring.

FIGURE 5. RM-4 Wiring Requirements

NOTE: Set SW3-2 to OFF for UL installations.

TABLE 2. P5 Input and Output Wiring

P5 Function

1 +12 VDC relay power

2 Relay 1 drive (GND) for first ARM-1 Module

3 Relay 2 drive (GND) for second ARM-1 Module

4 Supervised Input1

5 Supervised Input1

6 Supervised Input2

7 Supervised Input2

RM2L-NH Setup

7

RM2L-NH SETUP To set up an RM2L-NH Keypad Arming Station:

1. Set the Device Address Switch, SW1 (a 16 position rotary switch, see Figure 5), to a

number from one to eight. Each Device along the bus must have a unique address.

2. The SW3-2, SW3-3, and SW3-6 Configuration Switches are factory preset to OFF

for the RM2L-NH Device.

3. SW3-1, SW3-7, and SW3-8 are not used.

Note that you can set SW3-4 and SW3-5 as required.

Caution: To properly terminate an RS-485 line, only the last unit on the bus

should have SW3-5 in the On (closed) position.

NOTE: Set SW3-2 to OFF for UL installations.

4. Connect P5 input and output wiring, as shown in Table 2 and Figure 8 on page 11.

TABLE 3. SW3 Configuration Switch Settings

SW3 # Function Off (Open) On (Closed)

SW3-1 Device type (N/A) Magnetic (N/A) Wiegand (N/A)

SW3-2 LCD LCD Present No LCD

SW3-3 LED Option Normal N/A

SW3-4 Tamper Normal Bypass

SW3-5 (see

caution below)

EOL-Termination Not last unit Last unit in bus

SW3-6 LED Option Normal N/A

SW3-7 Beeper Control (NA) Enable RM-4

Beeper (NA)

Disable RM-4 Beeper

(NA)

SW3-8 Beep on Read Control

(N/A)

No Beep on Read

(N/A)

Enable Beep on Read

(N/A)

RM2L-NH Setup

9

Table 4 shows the P3 Keypad device signals.

TABLE 4. P3 Keypad Device Signals

Table 5 indicates the wiring for units with keypads.

P3 Keypad Device Signals

1N/A

2 N/A

3N/A

4 +5 V (red)

5 N/A

6N/A

7RedLED

8YellowLED

9 Green LED

10 N/A

11 N/A

12 N/A

TABLE 5. Wiring for Units with Keypads

J2 Pin Function

1 Col 3

2 Col 2

3 Col 1

4 Col 0

5 Row 3

6 Row 2

7 Row 1

8 Row 0

123

456

789

0CE

CMD

ENT

C3 C2 C1

R3

R2

R1

R0

Note: On a 3 x 4

matrix keypad,

Pin 4 (C0) is not

used.

RM2L-NH Setup

10

Grounding and

Shielding

Single RM2L-NH Keypad

1. When connecting a single RM2L-NH Keypad to the bus, use twisted pair, shielded

minimum 24 AWG cable. Attach the shield at one end only, usually at the apC or

iSTAR end.

2. Attach a local earth ground (18 or 22 gauge) wire to the J5 component on the RM

module of the RM2L-4000 keypad.

Multiple RM Bus Devices

When wiring an RM2L-NH Keypad to a bus with multiple devices, such as other

RM readers, I/8s, or R/8s:

1. Attach the shields along the bus together (insulate each connection). Snip off the

shield wire at the end of the bus. See Figure 7

2. Attach the shield to the ground at only one point – at the ground stud inside the

iSTAR or apC cabinet adjacent to the knockout.

3. Attach a local earth ground (18 or 22 gauge) wire to the J5 component on the

RM2L-NH keypad.

FIGURE 7. RM Shield Wiring

Setting Module

Address and

EOL Termination

To set the module address, set SW1 (16 position rotary switch) to a number from one to

eight. Every RM2L-NH device on a bus must have a unique address.

To set RS-485 EOL (End of Line) termination, set SW3-5 to the On (closed) position if

the module is the last unit on the bus. If the module is not the last unit on the bus,

SW3-5 should be Off (open).

ACM module

RS-485 connector on a reader

Knockout

Twist shield wires together and insulate

(do not ground)

Ground stud

(bus configuration)

Shield wire

Enclosure/cabinet

Shield wire Snip off shield

wire at end of

bus

RM2L-NH Setup

11

Wiring Inputs and

Outputs

Figure 8 shows how to connect ARM-1 relay modules to the RM-4 outputs and how to

wire NO (Normally Open) and NC (Normally Closed) supervised inputs.

FIGURE 8. RM-4 Input/Output Connections

NOTE Maximum distance from P5 to the ARM-1 is 25 feet.

Maximum distance from P5 to the inputs is 2000 feet.

Locate the 1KΩ resistors for the NO and NC supervised inputs as close as possible

to the switch.

To comply with UL requirements, use shielded, minimum 22 AWG stranded,

twisted pair cable for monitor points, DSMs, and REXs. Use Belden9462 or

equivalent.

RM2L-NH Setup

12

Installing the ARM-1

Relay Module

Two ARM-1 relay components can be connected to the RM2L-NH device through the

P5 connector (Table 6 ).

RM P5-1 is the common (+12 VDC) pin for either ARM-1.

RM P5-2 is the output drive (GND) for the first relay.

RM P5-3 is the output drive (GND) for the second relay.

NOTE The ARM-1 has not been evaluated by UL.

Installing the Heater

(optional)

RM2L-NH devices require a heater kit (Model 130-915) when installed outdoors in an

environment and where temperatures may drop below 40° F (5° C).

The Model 130-915 heater kit contains the following parts:

Part # 130-915A is supplied without a transformer. A UL Listed Class 2 transformer

rated output 12 VAC, 40 VA is required for proper installation.

TABLE 6. ARM-1 Wiring

Module Wiring

ARM-1 Relay ARM P2-1 to RM P5-1

ARM P2-2 to RM P5-2

ARM-2 Relay ARM P2-1 to RM P5-1

ARM P2-2 to RM P5-3

TABLE 7. Heater Parts

Quantity Description

1 Transformer 12 VAC 40VA

2 Heater Strips

1 Thermostat (turns on at 40 ° F)

3 Wire nuts

2 6-32 x 1/4” screws to mount thermostat to RM plate.

RM2L-NH Setup

13

Figure 9 shows how to wire the RM heater kit.

FIGURE 9. RM Heater Kit Wiring

Figure 10 shows the location of the heater strips and thermostat on the RM mount plate.

.

FIGURE 10. RM Installation

Applying Heater Strips

To apply heater strips:

1. Clean the attachment surface of the RM mount plate with a solvent such as alcohol

(use all required precautions when handling solvents).

2. Carefully remove the release film from the adhesive.

3. Locate the heater on the clean surface of the RM mount plate exactly as shown in

Figure 10

RM2L-NH Setup

14

4. Gently roll the heater strip in place to remove air bubbles.

5. For maximum adhesion, do not apply pressure to the heater strips for 72 hours.

NOTE Air gaps or bubbles under the heater cause localized overheating and possible heater

burnout. Also, application of adhesives at temperatures below 50° F is not

recommended.

Installing the Thermostat

To install the thermostat:

1. Fasten the thermostat to the RM mount plate with the body of the device facing the

junction box and the face sitting flat against the RM mount plate surface.

2. With the back (or outside) surface facing up, align the thermostat such that the screw

holes of the thermostat allow for the 6-32 x 1/4” screws to secure the device to the

RM mount plate.

3. Use two (Quantity 2) 6-32 x 1/4” screws to mount the thermostat to the RM mount

Plate. Tighten the screws allowing the thermostat to be sufficiently secured to the

RM mount plate. Do not over tighten the screws.

Testing RM2L-NH Keypads

15

TESTING RM2L-NH

KEYPADS

To test RM2L-NH keypads:

1. Properly configure Devices, Inputs, and Outputs using the C•CURE Administration

application and put the device Online.

2. Measure the supply voltage to the RM-4.

The voltage can be measured between pin 1 (+12 VDC supply) and pin 4 (ground)

on the P4 connector. The voltage must be +12 VDC (+/-5%).

3. Check the RM2L-NH device address setting.

The RM2L-NH device must be set to an unused address, between 1 and 8, when

connected to the apC or iSTAR. Use rotary switch SW1 to set the device address.

4. Check the RM-4 for communications to the apC or iSTAR by observing LED2 and

LED3.

5. Check the supervised inputs. Configure the inputs on the apC or iSTAR using the

C•CURE Administration application.

With no switches or resistors connected to the supervised input 1 and 2 lines, the

C•CURE Monitoring application should report inputs as “Open Loop”. When you

connect the 1,000-ohm resistor to the input terminals, the C• CURE Monitoring

application should report that the input as “Deactivated”. Supervised inputs #1 is

found at pins 4 and 5 of P5. Supervised input #2 is found at pins 6 and 7 of P5.

6. Check the outputs.

The outputs can be functionally tested by using the “momentary activate” feature in

the C• CURE Monitoring application. When the outputs are momentarily activated,

the signal will change state for a few seconds.

Canadian Radio Emissions Requirements

16

CANADIAN RADIO

EMISSIONS

REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les

limites applicables aux appareils numeriques de la class A prescrites dans le Reglement

sur le brouillage radiolelectrique edicte par le ministere des Communications du

Canada.

FCC DIGITAL

DEVICE

LIMITATIONS

Radio and Television Interference

This equipment has been tested and found to comply with the limits for a digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense.

Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

In order to maintain compliance with FCC regulations, shielded cables must be

used with this equipment. Operation with non-approved equipment or unshielded

cables is likely to result in interference to radio and television reception.

Caution: Changes or modifications not expressly approved by the manufacturer

could void the user’s authority to operate this equipment.

FCC Digital Device Limitations

17

C•CURE® and Software House® are registered trademarks of Tyco

International Ltd. and its respective companies.

Certain Product names mentioned herein may be trade names and/or registered

trademarks of other companies. Information about other products furnished by

Software House is believed to be accurate. However, no responsibility is

assumed by Software House for the use of these products, or for an

infringement of rights of the other companies that may result from their use.

RM2L-NH Keypad Arming Station Quick Start Installation Guide

Document Number: UM-235

Revision: A5

Release Date: July 2009

This manual is proprietary information of Software House. Unauthorized

reproduction of any portion of this manual is prohibited. The material in this

manual is for information purposes only. It is subject to change without notice.

Software House assumes no responsibility for incorrect information this

manual may contain.

Copyright ©2009 Tyco International Ltd. and its respective companies.

All rights reserved.

FCC Digital Device Limitations

18

Table of contents

Other Software House Controllers manuals