Software House iSTAR Ultra SE Manual

1

iSTAR Ultra SE Controller

Hardware Installation

Version D0

Part Number UM-311

October 2017

OVERVIEW

The iSTAR Ultra SE can be configured as an iSTAR Pro (in Pro Mode) or as an

iSTAR Ultra (in Ultra Mode for use with C•CURE 9000). The configuration is

based upon the GCM S1-4 switch setting.

The iSTAR Ultra consists of the following hardware components:

General Controller Module (GCM)

Access Control Module (ACM) - 2 maximum

or IP-ACM Ethernet Door Modules (supported in Ultra Mode only) - 32

maximum (IP-ACM installation and configuration is not included in this

document, see the IP-ACM Ethernet Door Module Quick Start Guide)

General Control

Module

The GCM is a General Purpose Module running the Linux®operating system.

The GCM provides the following features:

Two network Gigabit Ethernet ports.

An LCD panel that displays the current status, and provides built-in

diagnostics.

NOTE The iSTAR Ultra SE in Pro Mode is supported by C•CURE 9000 and C•CURE 800/8000. Refer to

the iSTAR Pro Controller software configuration information when using the C•CURE 9000 or the

C•CURE 800/8000.

Pro Mode does not support the optional RC4 network encryption setting in either C•CURE 800 or

C•CURE 9000 systems. Check the Message Encryption system variable to ensure RC4 is not being

used.

The iSTAR Ultra SE in Ultra Mode is only supported on C•CURE 9000 v2.50 and higher. Refer

to the iSTAR Ultra Controller software configuration information when using the C•CURE 9000.

The iSTAR Ultra SE in Ultra Mode has a reduced feature set when compared to the iSTAR Ultra.

There are 16 Inputs instead of 24 and 8 Relays instead of 16, per ACM and no embedded lock

power management.

Overview

2

Two RS-485 Ports for Aperio™hubs and wireless locks, or Schlage®PIMs

and wireless locks.

Up to 30 eight-port Aperio hubs (15 per RS485 port) up to 32 Aperio

locks.

Or,

Up to 32 16-port Schlage PIMs (16 per RS485 port) up to 32 Schlage

locks.

Tamper switch for security.

Four USB ports to communicate with the ACM and import encryption keys.

(USB Ports have only evaluated by UL for connection to ACMs)

External Power Fail and Battery Monitoring Inputs.

Access Control

Module

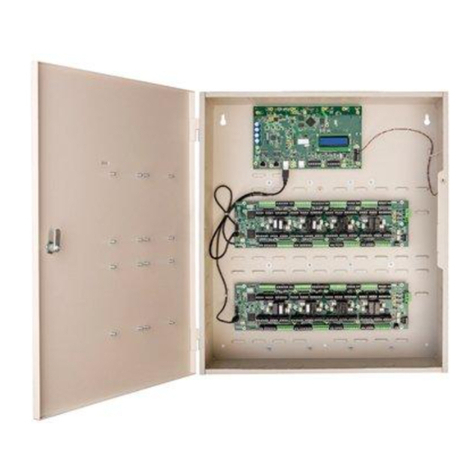

The ACM is a special purpose Access Control Module that interfaces with the

GCM and provides inputs, outputs, and reader interfaces. An iSTAR Ultra SE

can contain up to two ACMs that interface directly with Wiegand signaling

devices and RM reader busses. The RM reader busses can interface with

Wiegand signaling devices and ABA (magnetic) signaling devices. FAI (Fire

Alarm Interface) is also supported along with the ability to selectively energize

the relays and optionally latch them until released by a Key switch. The

maximum number of readers per ACM is 8.

IP-ACM Ethernet Door

Module

The IP-ACM module provides connection and management of the access

control for two readers. The GCM supports a maximum of 32 IP-ACM modules

with 1 reader per IP-ACM or a maximum 16 IP-ACMs with 2 readers per IP-

ACM. The limiting factor is a maximum of 32 readers.

For the iSTAR Ultra SE to operate with the IP-ACM v1 modules, the GCM

must be running firmware version 6.4.1 or higher and C•CURE 9000 must be

version 2.50 SP1 or higher.

For the iSTAR Ultra SE to operate with the IP-ACM v2 modules, the GCM

must be running firmware version 6.5.4 or higher and C•CURE 9000 must be

version 2.60 or higher.

For more information regarding the features and installation of the IP-ACM,

refer to the IP-ACM Ethernet Door Module Quick Start Guide.

NOTE Aperio hubs and readers have not been evaluated by UL.

NOTE Only two ACMs are supported.

NOTE FAI/Key inputs are not supported on the iSTAR Ultra SE in Pro Mode.

Requirements

3

Types of Mounting The iSTAR Ultra SE, and its components, can be installed in a wall mount

enclosure or in a separate rack mount enclosure.

REQUIREMENTS

Site Requirements Ensure that the site is ready:

The iSTAR Ultra SE installation must be performed by a certified installer.

All Control Units of the iSTAR Ultra SE must be installed in a restricted

access protected area.

Non-limited power supply lines, lines capable of sourcing 5A or more, must

maintain (1/2 inch (1.3 cm)) spacing from limited power supply lines and

other signaling lines. Secure lines must be installed in accordance to local

and national electric codes.

The site must be approved and all wiring must comply with UL requirements

and other codes, as appropriate. Installation shall be in accordance with the

National Electric Code, ANSI/NFPA 70-1993.

Wall Mount Dimensions Table 1 on page 3 lists the iSTAR Ultra SE Cabinet Wall Mount Dimensions

Environmental

Requirements

Table 2 on page 3 lists the iSTAR Ultra SE environmental requirements.

Table 1. Cabinet (Wall Mount Dimensions)

Item Dimension/Location

Weight 26.5 lb (12.02 kg)

Height 24.25 in. (61.6 cm)

Width 16.5 in. (41.9 cm)

Depth 4 in. (10.3 cm)

Upper Mounting

Holes

There are 2 upper keyhole type mounting holes that are spaced 14.25 in.

(36.2 cm) from each other. These two mounting holes are 7.125 in. (18.1

cm) from the enclosure center line.

Two Bottom

Mounting Holes

Directly below the upper mounting holes.

Table 2. Environmental Requirements

Status Range

Operation 32°F (0°C) to 120°F (49°C)

Storage 4° F (-20°C) to 158°F (70°C)

Altitude 6600 ft. (2000 m) maximum

Humidity 0 to 85%RH (Non-condensing)

Installation

4

INSTALLATION

This section assumes that the site meets the requirements.

Wall Mount Installation The most common installation is the wall mount. In this installation, the

enclosure is mounted directly to a wall or uni-strut using suitable user-supplied

hardware.

Requirements

The anchoring system must be capable of sustaining 75 lb (34 kg). This

weight does not include the cables.

The cables are protected by use of conduit, which is metal, plastic, or flexible

cable grip strain relief.

An external power supply provides 12 Vdc to power the iSTAR Ultra SE.

If an ACM is powered by a different Power Supply Unit (PSU), the ACM Fail

trigger must be configured to alarm on failure.

For a UL installation the Power must be approved to UL-294 and/or UL-603.

To Wall Mount the Controller:

1. Carefully unpack the components. Software House recommends removing

the GCM and the ACM(s) from the enclosure before mounting. Use ESD

procedures while handling the boards.

2. Open the enclosure door and disconnect the grounding wire on the door.

3. Carefully lift the door off the hinges and place it on a padded surface.

4. Verify that the upper mounting screws (or equivalent) are in place on the

mounting site for the keyhole locations.

ELECTROSTATIC SENSITIVE DEVICES: Observe precautions for handling.

Before handling any internal components, discharge static electricity by holding a

grounding lug or non-painted grounded surface for three seconds.

Wear a grounding wrist strap and stand on a grounded static mat.

Reduce movement during installation to reduce static buildup.

Make sure work area is safeguarded.

Transport components in static-shielded containers.

Note: The outside of the ESD bags are not ESD protective.

Verify that all components, materials, and the installer are referenced to a common

ground.

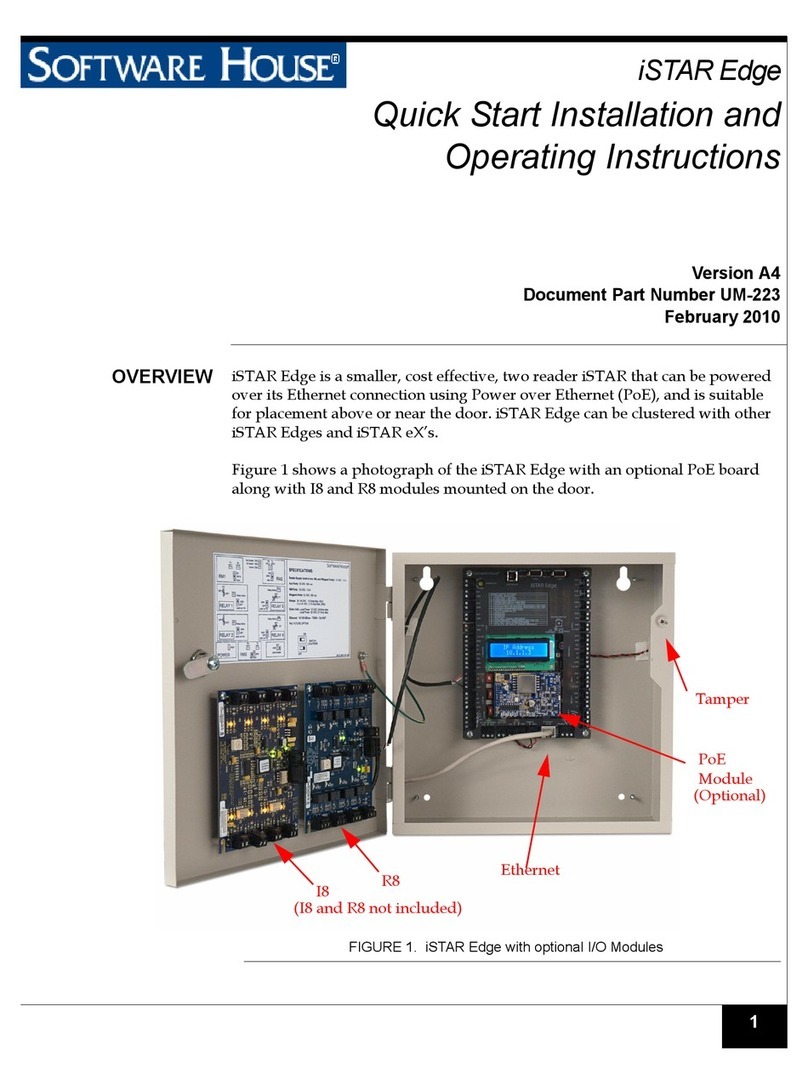

NOTE See Figure 1 on page 5 for the location of the keyhole slots, screws, and knockouts.

Installation

5

Figure 1. iSTAR Ultra SE Controller with Door Removed (Two ACMs Mounted)

LCD

5. Align the mounting keyhole slots at the upper back of the enclosure with the

two upper mounting screws, and lower the enclosure into position.

6. After the enclosure is mounted tighten the mounting screws.

7. Install the two lower mounting screws.

8. Attach the conduit couplings to the knockout openings as needed to comply

with local code requirements.

9. Reattach the grounding wire between the door and the enclosure.

10.Connect to a grounding lug with a low impedance cable going to Earth

Ground.

11. When routing signal cables from the ACM to accessory boards on the door,

ensure that the cables are not pinched by the door and cables are routed in

accordance with NEC Codes or the applicable Local codes.

Ground Stud

(6-32)

For Shield Wire,

1 By Each Knockout

Assorted Knockouts

Cabinet/Enclosure

General Controller

Module (GCM)

Access

Control

Module

(ACM)

Assorted

Knockouts

Keyhole

Mounting

Slot (2)

Lower Mounting

Hole (2)

Tamper Switch

Assorted

Knockouts

USB Cables

ACM 1

ACM 2

GCM

E-Net

Tamper

LCD

LCD

Reader & Logic Power

Reader & Logic Power

Installation

6

12.Use the appropriate conduit or strain relief with proper spacing according to

local and national codes. Building power shall be routed and connection will

be made at the terminal block inside the enclosure.

Wall Mount Door Components

The wall mounted iSTAR Ultra SE has stand-off’s on the enclosure door that

can support up to two RM Bus components.

The I/8, I/8-CSI, R/8, and RM-4E boards are supported. There can be any

combination of these boards.

Board Configuration Examples:

Two I/8’s, two I/8-CSI’s, two R/8’s or two RM-4E’s

One I/8 and one R/8, etc.

Wiring: Route the RM bus from each RM device to the next. Connect the end to

one of the RM connectors on the ACM (for example, STAR1 through STAR8).

See Figure 2 on page 6. Terminate the last unit but not the middle unit.

Figure 2. Wiring Wall Mount Door Components

NOTE During configuration, be sure to note the values of the pins on the boards for correct wiring.

Pin 1

Use Care not to pinch

wiring at this location

Installation

7

Rack Mount Installation The GCM and ACMs are mounted separately in standard 19-inch racks. The

cables will be inside the cable management system of the rack. The

components must remain secure, be clearly labeled, and be easily accessible

when using the correct tools.

Rack Mount Considerations

Be aware of the following considerations when mounting the iSTAR Ultra SE as

a Rack Mount:

Rack Mount ACM's need to located close enough so that the 3 foot USB

supplied cable can be routed and still have a proper service loop.

Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Verify that 0to 49is maintained.

Reduced Air Flow - Installation of the equipment in a rack should be

such that the amount of air flow required for safe operation of the

equipment is not compromised. Verify that 0to 49is maintained.

Reliable Grounding - Reliable earth ground of rack-mounted equipment

should be maintained.Grounding needs to follow NEC Codes or the

applicable Local code.

To Perform a Rack Mount Installation:

1. Pick a location for the rack, while observing the “Rack Mount

Considerations” on page 7.

2. Mount the unit with either 10/32 or 12/24 hardware.

3. Connect Ethernet, as required, to the Ethernet port(s).

4. Secure the power inputs with zip-ties to maintain minimum safe distance for

electrical safety. Install in accordance with local and national regulations.

Grounding

Requirements

Grounding requirements are as follows:

Grounding needs to follow NEC Codes or the applicable Local code.

Ensure that the iSTAR Ultra SE controller is properly connected to an earth

ground at the ground studs.

Shielded wires should have the shields grounded to the chassis enclosure

as close as possible where the respective cables are entering the enclosure.

NOTE Use a service loop when connecting the cables.

NOTE If you are mounting the iSTAR Ultra SE in Pro Mode as a rack mount, the ACM must be

tampered with a supervised input dedicated as a tamper.

NOTE The iSTAR Ultra SE must be installed in a UL-listed rack mount for UL compliant installations.

Power

8

When disconnecting wiring, disconnect ground wires last (to provide

maximum protection to the equipment and personnel).

POWER

This section provides the power requirements for the iSTAR Ultra SE and its

components. A limited power supply (LPS class 2) is required.

Electrical Electrical ratings are dependent upon the configuration.

GCM

Power Input (12 Vdc -15%, +10%)

• 12 Vdc , 1.5A minimum, 4.5A maximum (if fully loaded)

Power Output

• RS485:12 Vdc , nominal, 1.3A maximum each port.

ACM

Power Input (12 Vdc -15%, +10%)

Power Output

• RS485: 12 Vdc nominal, (11.14V measured) from external power

supply

▫1.3A maximum per port

▫11 Vdc with STAR-PS

• Wiegand: 12 Vdc nominal (11.4V measured) from external power

supply, (11.3V measured with STAR-PS)

▫800mA maximum per output, total not to exceed 5A

▫4.7 Vdc from an external power supply

▫0.8A maximum per output, total not to exceed 1.25A

▫5Vdc is 800mA maximum per output, total not to exceed 1.25A

• Dry Relay Out: 30 Vdc/Vac, 5A maximum each

• Total output from the STAR-PS not to exceed 5A

Disconnect all sourced power before modifying the wiring.

NOTE GCM RS485 outputs were evaluated by UL only for connection to Schlage PIM-400/AD-400

Readers and Locks.

NOTE The Wiegand, RS-485, and Aux ports are power limited on the ACM.

Power

9

IP-ACM (supported in Ultra Mode)

Power Input

• 12 or 24 Vdc 32W maximum

• IEEE 802.3af (PoE) and 802at (PoE Plus), 25.5W maximum. LLDP

supported for PoE Plus

UL tested with PHIHONG PoE injector model POE36U-1AT-R

Power Output

RS485/Wiegand: 12 Vdc; The aggregate load of each pair of RS-485 and

Wiegand connections together must not exceed 750mA. Each set of

RS-485 and Wiegand can support 750mA. Maximum combined output

limit for readers and locks is 17W.

Wet Relay: 12 or 24 Vdc (jumper selectable)

– 0.5A (per lock) IP-ACM v1 (P/N 0312-7166-01)

– 0.75 (per lock) IP-ACM v2 (P/N 0312-7239-01)

Dry Relay: 0 to 30 Vdc, 5A maximum. NO, 3A maximum. NC

AC Power

100-240 VAC~1.7A, 50-60Hz

The iSTAR Ultra SE comes with the power supply installed. There is an optional

powers supply that can be purchased (STAR-PS or USTAR-PS) for Access

Control only, not standby-power.

Additional Power

Requirements

An external over-current protection device (i.e. circuit breaker) must be

installed in a secure location readily accessible to a service person.

Circuit Breakers need to be sized so that its normal sourced current does not

exceed 80% of the circuit breaker rating.

The system power circuit breaker must only be assessable by Authorized

Personal.

NOTE Compliance with IEEE 802.3 (AT or AF) specifications was not verified as

part of UL294/B.

NOTE USTAR-PS has not been evaluated by UL.

RISK OF ELECTRICAL SHOCK:

Installation and maintenance must only be performed by qualified persons.

Disconnect from branch-circuit supply before installation.

Ensure that the iSTAR Ultra SE enclosure (STAR-CAN, P/N 0505-2020-01) is properly

connected to an earth ground at the ground stud near the AC input wiring.

Power

10

Battery The GCM contains a rechargeable 3V CR2032 lithium coin cell battery that is

used to retain the real-time clock for at least three weeks. After three weeks of

accumulated power outage, the battery should be replaced.

Detaching the Pull-Tab from the Battery Holder

You need to detach the pull-tab from the battery holder before you put the board

online. After the tab is pulled out, and the board is configured, the battery can

only maintain the Real Time Clock (RTC) for 30 days without power supplied to

the board.

The iSTAR Ultra SE must be supplied by a 15A circuit breaker protected branch-circuit.

FOR BURGLAR ALARM INSTALLATIONS:

The iSTAR Ultra SE is not provided with backup power. An external power supply

must be provided with the following characteristics:

UL 603 and/or UL 294 Listed

Minimum four hours of standby power.

The iSTAR Ultra SE is not UL1076 approved when used with internal STAR-PS.

Tyco / Software House Advanced Power Supply (apS) used in-conjunction with the

iSTAR Ultra SE will be sufficient in meeting the requirements of UL-1076.

When using external power supply, the supply shall be Class 2, and compliant with EN/

IEC 60950-1 or IEC 62368.

All Burglar Alarm and Intrusion Zone inputs must be supervised and have Triggers

configured to Alarm upon Tamper.

At least one RM2L Series reader must be in each area/partition for signal

acknowledgement.

There are multiple power inputs to the unit. To completely de-energize the unit,

disconnect ALL power sources.

NOTE For UL Listed products, a UL 603 and UL 294 listed power supply must be used.

NOTE In the absence of power failures, the expected coin cell battery life is five years.

The replacement battery must be UL approved.

The battery on the GCM shall be checked and replaced only by a trained

technician.

Power

11

Wiring Requirements The iSTAR Ultra SE Ethernet connections are two GCM Inboard Ethernet ports

which support up to 1 Gbps each (auto-sense 10, 100, 1000 Mbps).

Table 3 on page 11 lists the general wiring requirements for an iSTAR Ultra SE

and its components.

.

NOTE J5 and J6 Ethernet are supported on C•CURE 9000 (Pro Mode and Ultra Mode).

J6 Ethernet is used instead of a PCMCIA NIC card for the iSTAR Ultra in Pro Mode when

configured in C•CURE 9000 or C• 800.

Ethernet cabling must be CAT-5E or better.

The Power Input terminals on the iSTAR Ultra SE accept conductor size up to 2mm2(12

AWG).

Table 3. Equipment Wiring Specifications

Signal From To AWG Shield Maximum Length

RS-485 Comm, Data Half-

duplex 2 wire

ACM RM & I/O

Modules

22 Yes 4000 ft.(1212 m)

RS-485 Power ACM RM & I/O

Modules

22/18 Yes Range of 600 ft. to 1500 ft. depends on

AWGb

RJ45-Ethernet GCM Level 3

Switch,

Hub, Host

Cat 5E or better No 328 ft. (100 m)

Supervised Input ACM, I8, RM-

4/4E module

Input 22/18 No 2000 ft. (606 m)

Request-to-exit

(REX or RTE)

ACM, I8, RM-

4/4E module

Switch

contact

22/18 No 2000 ft.(606 m)

Door State Monitor

(DSM)

ACM, I8, RM-

4/4E module

Switch

contact

22/18 No 2000 ft.(606 m)

Relay Output ACM or RM-

4E

Locking

Device

14, 18 No 2000 ft.(606 m)

Relay Control RM-4 ARM-1 or

equivalent

22 Yes 25 ft. (7.6 m)

Supervised Input (UL)

Notea

ACM, I8, RM-

4/4E module

Input 22 Yes 2000 ft.(606 m)

Reader Data (Direct

Wiegand Connection)

ACM or RM-

4/4E module

Proximity/

Wiegand

signaling

read head

22

20

18

Yes 200 ft.(60.96 m)

300 ft. (91.4 m)

500 ft. (152.4 m)

a. To comply with UL requirements, use shielded, minimum 22 AWG stranded, twisted pair cable for monitor points, DSMs, and REXs.

Use Belden 9462 or equivalent.

b. Check wire lengths to verify that voltage drops are acceptable.

Calculations are based on a single RM-4 reader with keypad and LCD (250 mA):

Using 22 AWG, distance = 600 ft. (.0165 ohms /ft.)

Using 18 AWG, distance = 1500 ft. (.0065 ohms /ft.)

Readers and Accessory Boards

12

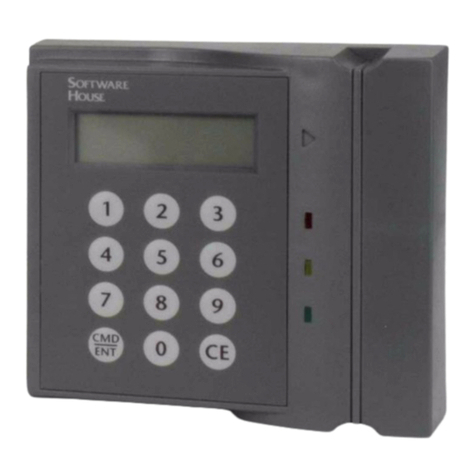

READERS AND ACCESSORY BOARDS

The following readers and accessory boards are UL supported:

Wiegand Signaling Readers:

SWH-4000, SWH-4100, SWH-4200

SWH-2100

SWH-5100

P345MTR, P345KPMTR

HID 5365 series

HID RP40 multiCLASS

HID RPK40 multiCLASS

HID RP15 multiCLASS

RS-485 RM Bus:

RM1 series (SWH)

RM2 series (SWH)

RM3 series (SWH)

RM2L series (SWH), RM2L-PI, RM2L-4000, RM2L-NH

RM1-SE

RM2-SE

RM2L-SE

SWH-TST-100 Touchscreen Terminal

SWT-TST-100-V Touchscreen Terminal

Accessory boards:

I/8, I/8-CSI

R/8

RM-4, RM-4E, RM-DCM-2

iSTAR Ultra SE also supports the following wireless reader combinations:

16 Schlage PIMs and 16 Readers - only one GCM RS-485 Port (Pro Mode)

32 Schlage PIMs and 32 Readers (Ultra Mode)

NOTES UL Requirements

For UL compliance, the Tamper, Low Battery, and AC power fail inputs must be enabled and

connected to the iSTAR Ultra SE.

For UL listed products, burglar alarm inputs must be supervised.

UL Listed panic hardware shall be used to allow emergency exit from a protected area.

All inputs and outputs, except FAI, FAI Key, and Ethernet must be shielded.

Part Numbers

13

30 ASSA ABLOY Aperio Hubs and 32 Readers (Ultra Mode only)

PART NUMBERS

NOTE ASSA ABLOY Aperio hubs and readers have not been evaluated by UL.

Table 4. Part Numbers

Part Number Description

USTAR008-SE iSTAR Ultra SE with one GCM, one ACM, one wall mount enclosure, and

a power supply. Supports up to eight readers.

USTAR016-SE iSTAR Ultra SE with one GCM, two ACM’s, one wall mount enclosure,

and a power supply. Supports up to 16 readers.

USTAR008-SE-NPS iSTAR Ultra SE with one GCM, one ACM, and one wall mount enclosure.

Supports up to eight readers.

NOTE: The Power Supply is not included.

USTAR016-SE-NPS iSTAR Ultra SE with one GCM, two ACM’s, and one wall mount

enclosure. Supports up to 16 readers.

NOTE: The Power Supply is not included.

USTAR-ACM-SE-4U iSTAR Ultra SE Rack Mount ACM

Subassemblies

USTAR-ACM-SE iSTAR Ultra SE Access Control Module, board only, supports up to 8

readers.

USTAR-ACM-4USCAN iSTAR Ultra SE 4U Rack Enclosure, no ACM.

USTAR-SE-CAN Wall Mount Enclosure.

Adapter Plates

Note: adapter plates have not been evaluated by UL.

USTAR-AP-ISC ISC adapter plate for Ultra SE GCM and ACMs.

USTAR-AP-ISC-1 ISC adapter plate including one Ultra GCM and one ACM, supports up to

8 readers.

USTAR-AP-ISC-2 ISC adapter plate including one Ultra GCM and two ACM, supports up to

16 readers.

USTAR-AP-GCM iSTAR Pro GCM adapter plate for iSTAR Ultra GCM.

USTAR-AP-APC apC/8X enclosure adapter for Ultra SE GCM and ACMs.

General Control Module

14

GENERAL CONTROL MODULE

General Control Module

15

Network Connections Connect a CAT-5E, or better, RJ45 cable to J5.

J5 Ethernet up to 1 Gbps (10, 100, 1000)

J6 Ethernet up to 1 Gbps (10, 100, 1000)

• When in Pro Mode, this port is configured at the Host as PCMCIA NIC for

second network connect in C•CURE 9000 and C•CURE 800/8000.

There are built in LEDs in the connectors that indicate the Ethernet Link and

Receive Data signals.

Switches SW7 - Soft Reset (Reboot)

The SW7 push button saves all data in non-volatile memory and then reboots

the unit. It may take several minutes for the formatting and saving of the data.

The iSTAR Ultra SE is fully capable of operating without contact with the Host

after the reboot.

SW7 should be used to Reset to Factory Default by changing the Rotary

Switch (SW3) to ‘D’ and pressing SW7. See Table 5 on page 16 for Rotary

Switch descriptions.

To Clear Memory and Reboot the Unit:

1. Set rotary SW3 to D.

2. Press and release switch SW7.

Instructions appear on the LCD in approximately ten seconds.

3. Follow the instructions.

4. Set rotary SW3 back to 0 or F.

5. Press and release SW7. The controller restarts.

6. After the controller restarts, use the iSTAR Configuration Utility (ICU) to

configure the controller.

SW2 - Hard Processor Reset

Press and release SW2.

• The panel reboots immediately with no database backup.

• During reboot, the panel restores database from the SD card. This occurs

only if there has already been a previous backup.

SW2 Hard Processor Reset should only be used by a Certified Integrator.

General Control Module

16

SW3 Rotary Switch

SW3 is an onboard 16-position rotary switch. Most of the positions are used to

control LCD diagnostics.

Table 5 on page 16 provides descriptions of the iSTAR Ultra SE rotary switch

functions.

Encryption - S1-1 (Ultra Mode only - ON by default)

The Encryption switch enables FIPS 197 AES 256-bit encryption. The switch

setting must match the software configuration of the cluster and the controller.

When S1-1 is turned ON, followed by a factory reset, the iSTAR Ultra SE

controller in Ultra Mode becomes encrypted and can cluster with the following

encrypted iSTARs:

iSTAR Ultra LT

Table 5. iSTAR Ultra SE Rotary Switch Functions

Position Description

0 ICU Block Off (Read/Write/Update) Display General Messages

1 Display card data from last card read, 7 second LCD display (slow mode)

2 Display card data from last card read, 2 second LCD display (fast mode)

3 Display supervised input changes, 2 second LCD display (slow mode)

4 Display supervised input changes, 1 second LCD display (fast mode)

5Display manual output changes (include readers and R/8 boards), 2 second LCD

display (slow mode)

6Display manual output changes (include readers and R/8 boards), 1 second LCD

display (fast mode)

7 Not used

8 Hardware Test (On board Ethernet 1 and 2, USB ports). For internal use.

9 Not used

A Not used

B MFG - ATE (Automated Test Equipment) (Software House only)

C Disable watchdog (Software House only)

D Restore Factory Default. Erase DB files and Communication Parameters from

flash. (Press SW7 Soft GCM reset, wait for LCD instructions, set rotary switch

back to 0 or F, press reset again.)

E Boot to backup image (Activate on Software House instruction only)

F ICU Block On (Read only) - Display General Messages

General Control Module

17

iSTAR Ultra

iSTAR Edge

iSTAR eX

Other iSTAR Ultra SE in Ultra Mode with the Encryption Switch set to ON

If non-encrypted, the iSTAR Ultra SE controller in Ultra Mode can cluster with

the un-encrypted iSTARs:

iSTAR Ultra LT with the Encryption Switch set to OFF

iSTAR Ultra with the Encryption Switch set to OFF

Other iSTAR Ultra SE running in Pro Mode

iSTAR Pro and Classic

CPNI - S1-2

When this switch is set to ON, the iSTAR Ultra SE runs in CPNI (Centre for the

Protection of National Infrastructure) mode and all database and transactions

are stored in RAM. The database and transactions are not backed up on the

SD. The default setting is OFF.

Pro Mode - S1- 4 (Ensure that S1-1 is set to OFF)

Puts the iSTAR into iSTAR Pro Mode. Changing SW1-4 either way requires a

reset to Factory defaults, and all data is lost.

RS-485 Terminators - SW5 and SW6

These switches provide termination at the end of the two RS-485 Ports.

LCD Contrast Potentiometer - RV1

Used to adjust the contrast of the LCD. Requires a 2 mm screwdriver.

USB Ports Four Host Ports (Two Dual Ports) J8 and J9

The ACM communications cables connect to these Ports. It does not matter

which Port is used as the ACMs are uniquely addressed using the USB 2.0

protocol.

AC Fail - Low Battery - J2

Figure 3 on page 18 shows AC Fail and Low Battery wiring. They are NC

(Normally Closed) non-supervised connections, and share a common ground

pin.

NOTE CPNI has not been evaluated by UL.

General Control Module

18

Figure 3. AC Fail - Low Battery J2

AC Fail Input

Indicates whether the external power source has reported loss of its main

power.

Shares the connector and Ground pin with Low Battery.

Normally closed dry relay contacts are required. This signal is usually wired

to the energized NO (Normally Open) output on the apS or UPS.

Configurable on the host as an unsupervised input.

Low Battery Input

Indicates whether the external power source has reported its battery as low.

Wired in from the external power source.

Shares the connector and Ground pin with AC Fail.

Normally closed dry relay contacts are required.

Configured on the host as unsupervised input.

Tamper - J1

Figure 4 on page 18 shows Tamper - J1 NC (Normally Closed). It is connected

to the Tamper switch on the enclosure. If there is no standard enclosure, be

sure that there is a jumper across the two pins.

Figure 4. Tamper -J1

Visual Indicators

19

The super bright LED turns ON or OFF depending upon the tamper condition.

The super bright LED turns OFF when the door is open.

GCM Power - J4

12 Vdc @ 4.5A maximum (Note: pin 1 on the left is +12 Vdc, pin 2 is GND.)

J14 SD Card

Located on the back of the GCM to the left of the SOM, near the Hard Reset

switch. This non-volatile memory is where backups are stored.

The following ports are used for wireless readers and have not been evaluated

by UL:

RS-485 1 and 2 (J12 and J13)

These two ports can be used exclusively for Assa Abloy Aperio or Schlage

wireless readers.

• Aperio - Up to 15 Hubs and 16 Readers per port. (Ultra Mode only)

• Schlage - Up to 16 PIMs and 16 Readers per port. (Ultra Mode only)

• Schlage - Up to 16 PIMs and 16 Readers on J12 only. (Pro Mode)

USB Micro Type AB - J7

Not supported. Possible future option.

RS-232 Diagnostic Port (P4)

Software House Tech Support and Engineering use for troubleshooting.

COMM Board Connector - J15

Not supported.

VISUAL INDICATORS

Power - DS1 and DS2 Indicates that power is supplied to the unit.

LCD The LCD displays status and diagnostics messages.

Diagnostics are controlled by the rotary switch, SW3. See “SW3 Rotary

Switch” on page 16.

Contrast is controlled by potentiometer, RV1.

LEDs The super-bright white Power LED (DS1) is illuminated when the enclosure

door is closed and the tamper switch closes. Table 6 on page 20 provides

descriptions of the GCM LEDs.

NOTES The Tamper, Low Battery, and AC power fail inputs must be enabled and connected to

report for compliance with UL requirements.

Shielded cable must be used for AC Fail and Low Battery Input connections.

Access Control Module

20

ACCESS CONTROL MODULE

The ACM provides Readers, Inputs, and Outputs used in access control. An

iSTAR Ultra SE contains one or two ACMs.

8 RS-485 Reader Ports for RM Bus Devices.

• Terminator switch for the RS-485 Port

8 Direct Connect Wiegand Port with LED drives. This is for ‘Wiegand

signaling’ devices that communicate using data 1 and data 0.

Relays:

• Field replaceable - mounted in a socket

▫8 per ACM

▫Can be used for FAI (SE Ultra Mode only)

▫Dry Rating 5 Amps @ 30 Vdc or 30 Vac

▫Form C

• Switches for selection of relays for control by FAI (SE Ultra Mode only).

• Switch to enable the FAI pull-up resistor (SE Ultra Mode only).

Table 6. GCM LED Functions

LED Function Comment

DS2 Main Power - Internal View Always on if Voltage IN > 8 Vdc

DS1 Main Power - External View Super bright White LED, visible from outside of the enclosure

when the door is closed. Off when the door is open.

DS6 RS-485 Port 1 Enabled Used for Aperio Hubs or Schlage PIMs.

DS3 RS-485 Port 2 Enabled Used for Aperio Hubs or Schlage PIMs.

DS9 COMM board Enabled Not currently supported.

N/A Ethernet Carrier LEDs built in to J5 and J6 (Solid Green)

N/A Ethernet Activity LEDs built in to J5 and J6 (Blinks Yellow)

DS4 RS-485-1 Tx Port 1 Transmit Data

DS5 RS-485-1 Rx Port 1 Receive Data

DS7 RS-485-2 Tx Port 2 Transmit Data

DS8 RS-485-2 Rx Port 2 Receive Data

NOTE When you use FAI, set the FAI control inputs to true on only one ACM.

Table of contents

Other Software House Controllers manuals

Popular Controllers manuals by other brands

Advantek

Advantek PixLite E4-S Mk3 user manual

EUCHIPS

EUCHIPS DMX-E05 manual

Headsight

Headsight HORIZON Installation & operation manual

Technogamma

Technogamma tPell manual

PEAK COMMUNICATIONS

PEAK COMMUNICATIONS UPC7000 Series Installation and operating handbook

Hughes Network Systems

Hughes Network Systems GMH2000 Installation and maintenance manual