SOGEDIS Y Series User manual

SERVICE MANUAL

YSERIES

1

YSERIES (WITHOUT ON-OFF

BUTTON AND KNOB) WITH

AND WITHOUT DISPLAY

PRODUCTS

SERVICE MANUAL

YSERIES

2

PROGRAM CANCELLATION OF YSERIES

1) The machine must be open position to do the cancellation process.

2) Push the Start/Pause button for 3 sec. while the machine is operating.

3) After 3 sec, the drying light lights up and then it starts draining by the drain pump operates.

(Approximately 30 sec)

4) After the end of draining operation, the draining pump stops and the End light lights up.

On-off

SERVICE MANUAL

YSERIES

3

ON-OFF OPERATION FOR YSERIES

1) The machine is closed while the on/off button is on the closed position. All of the buttons don’t operate.

The lights don’t light up. Only the electronic card has energy.

2) The machine will be opened when the on/off button is on.On/Off light lights up. If machine has no

display, also Start/Stop and Eco program lights turn on.

THE SERVICE TEST OF YSERIES

1) Power OFF; press Start/Stop button.

2) Power ON by pressing On/Off button and continue to press Start/Stop button at least for 6”.

SERVICE MANUAL

YSERIES

4

3) When “Service test” is recognized

• For models w/o display: All leds are ON. Next, Start/Stop led blinks and service test starts.

4) During the first 6” of test, if a failure code is stored in memory, its codification blinks. Also at the end

of the test if an error occurs its error code blinks.

Note: Service program can be cancelled with cancellation operation.

SALT SETTING OF YSERIES

1) Power OFF; press program button.

2) Power ON and continue to press program button at least for 3”.

3) If “Hardness set” is recognized all leds blink for 2”.

5)Press program button to set the desired level.

• For models w/ display: All leds are ON, SP is visualized on display and service test starts.

At any pressure of program button hardness level is incremented. Hardness level 1 returns after

hardness level 6.

* If it is the first hardness set, hardness level is level 3.

Release program button. The last setting level is viewed*.

4)

For models w/o display;

SERVICE MANUAL

YSERIES

5

For models w/ display;

Power OFF; press program button.

1)

2)

3)

4)

5)

Power ON and continue to press program button at least for 3”.

If “Hardness set” is recognized “SL” is shown for 2”.

Release program button. The last setting level is viewed*.

Press program button to set the desired level. At any pressure of program button hardness

level is incremented. Hardness level 1 returns after hardness level 6.

* If it is the first hardness set, hardness level is L3.

Note:The machine is came to the closed position to exit from

the water hardness setting and to get in memory the last

setting.

SERVICE MANUAL

YSERIES

6

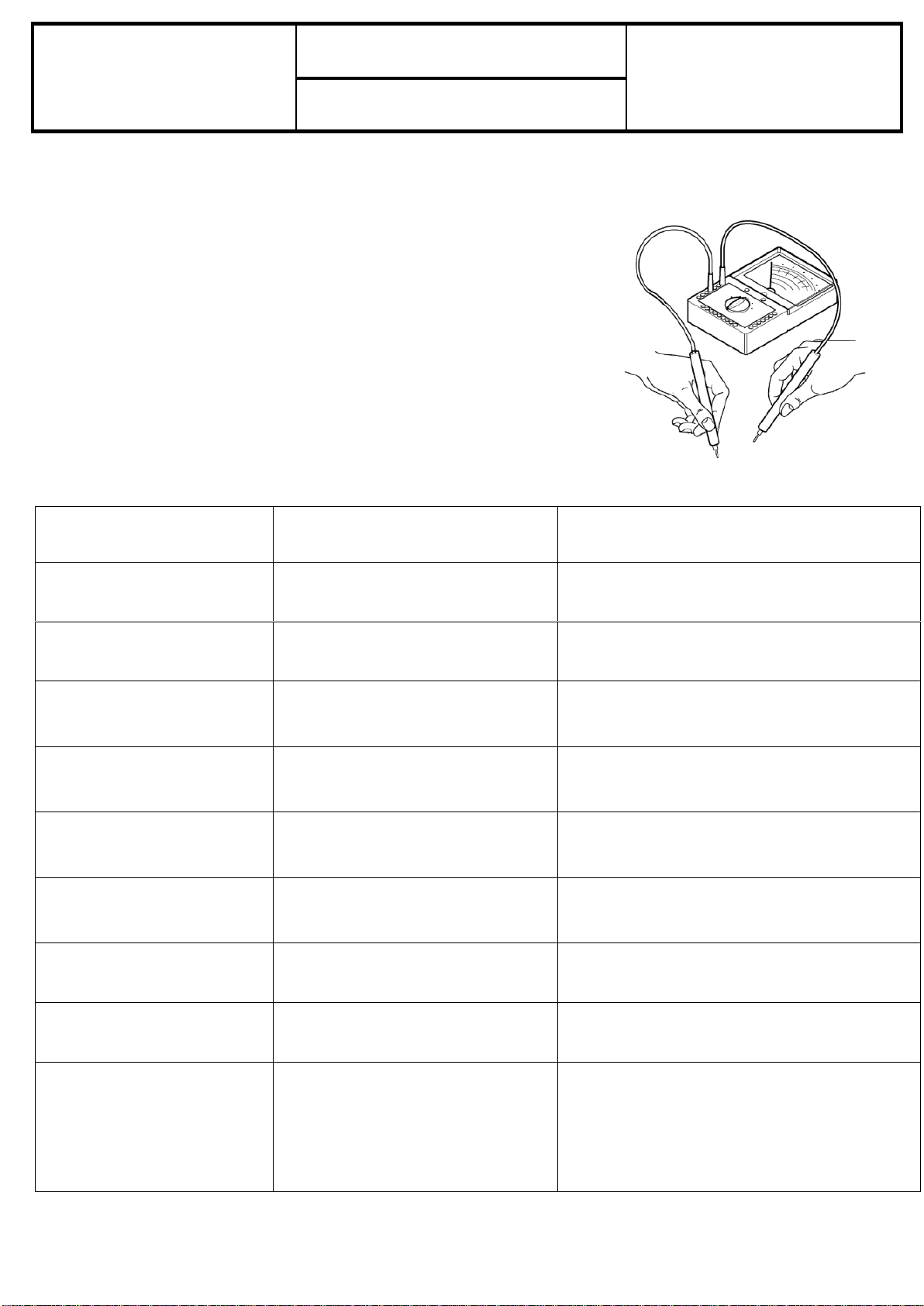

REPAIR TECHNIQUES

A simpler and special control procedure is obtained to test the

components efficiency.

In this control procedure, you can measure the resistance of the

components and compare with the normal resistance values. Then

you can understand that if the components are faulty or not.

You can measure the components directly or you can measure

from the connectors with the probes of the measurement gauge.

COMPONENTS

REAL VALUES

NOTES

ON / OFF BUTTON

0 Ω on component

ON/OFF button is pressed

DOOR SWITCH

CN2.9 –CN2.2 0 Ω

Door is closed

PRESSURE SWITCH

CN2.10 –CN2.2 0 Ω

∞ Ω

FULL FILL WATER

NO WATER

DRAIN PUMP

CN2.2 –CN2.4

141± %10MΩ

WATER INLET VALVE

CN2.6 –CN 2.9

4200 ±٪10 Ω

REGENERATION VALVE

CN2.10 –CN2.7

4130±٪10 Ω

HEATER

27.6-30.6 Ω

MEASURE JUST ON THE COMPONENT

DETERGENT

DISPENSER

1660 Ω ± %10 (25 C º)

MEASURE JUST ON THE COMPONENT

CIRCULATION PUMP

CN2.3 –CN2.9 118.2 - 135.9

117.9 - 135.6

Primary winding

Secondary winding (FROM THE

COMPONENT)

SERVICE MANUAL

YSERIES

7

SET NTC SENSOR

CN 3.2 25°- 5000Ω

%±5.0

CN 3.1 35°- 3300Ω

%±5.5

55°- 1520Ω

%±6.5

63°- 1174Ω

%±7.5

80°- 670Ω

%±8.0

90°- 488Ω

%±8.5

FLOATER

(MICROSWITCH )

CN2.1 –CN 2.5 0 Ω

CN2.1 –CN 2.4 ∞ Ω

MICROSWITICH IS INACT VE (NO

WATER)

MICROSWITCH IS ACTIVE (THERE IS

WATER )

SERVICE MANUAL

YSERIES

8

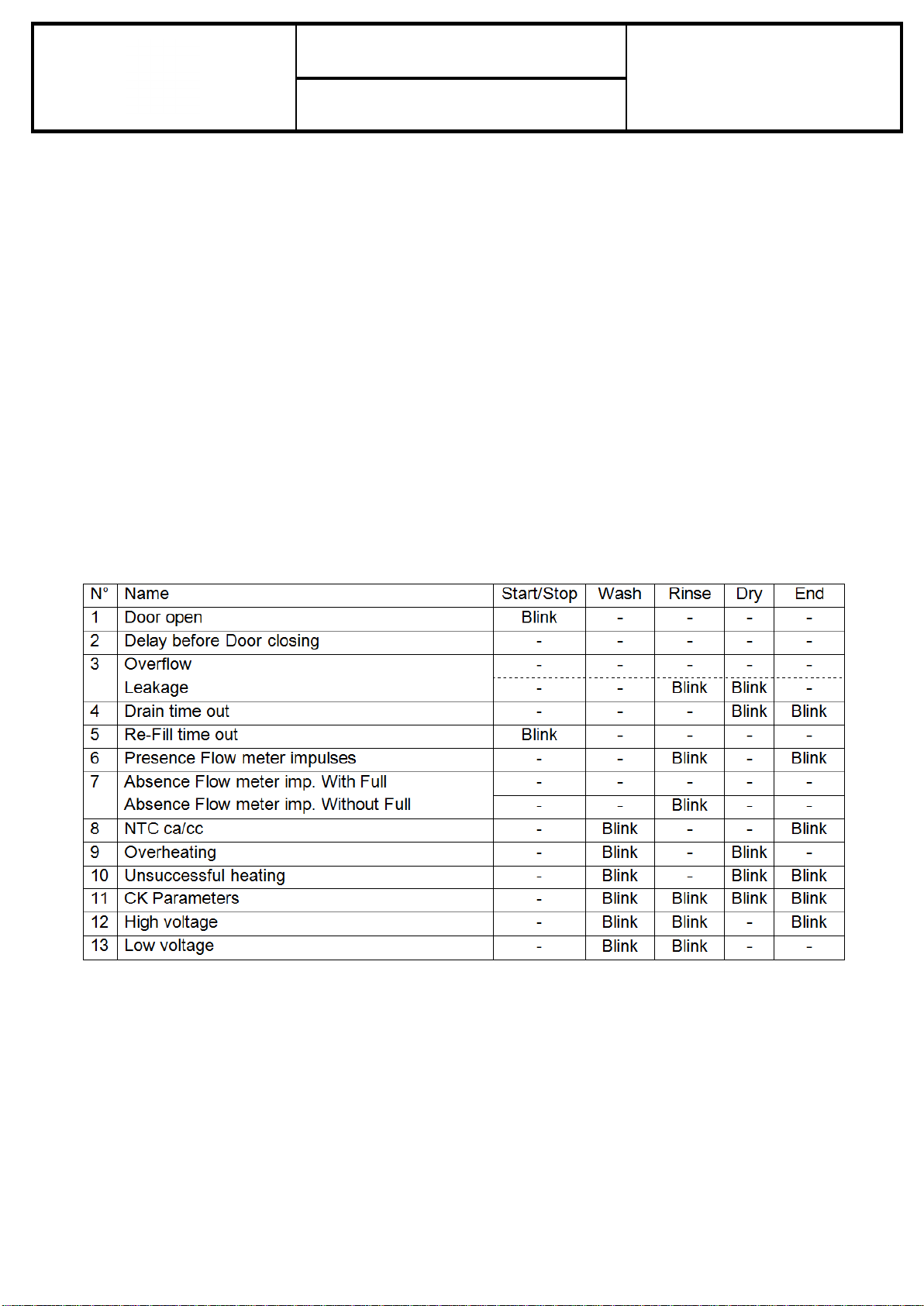

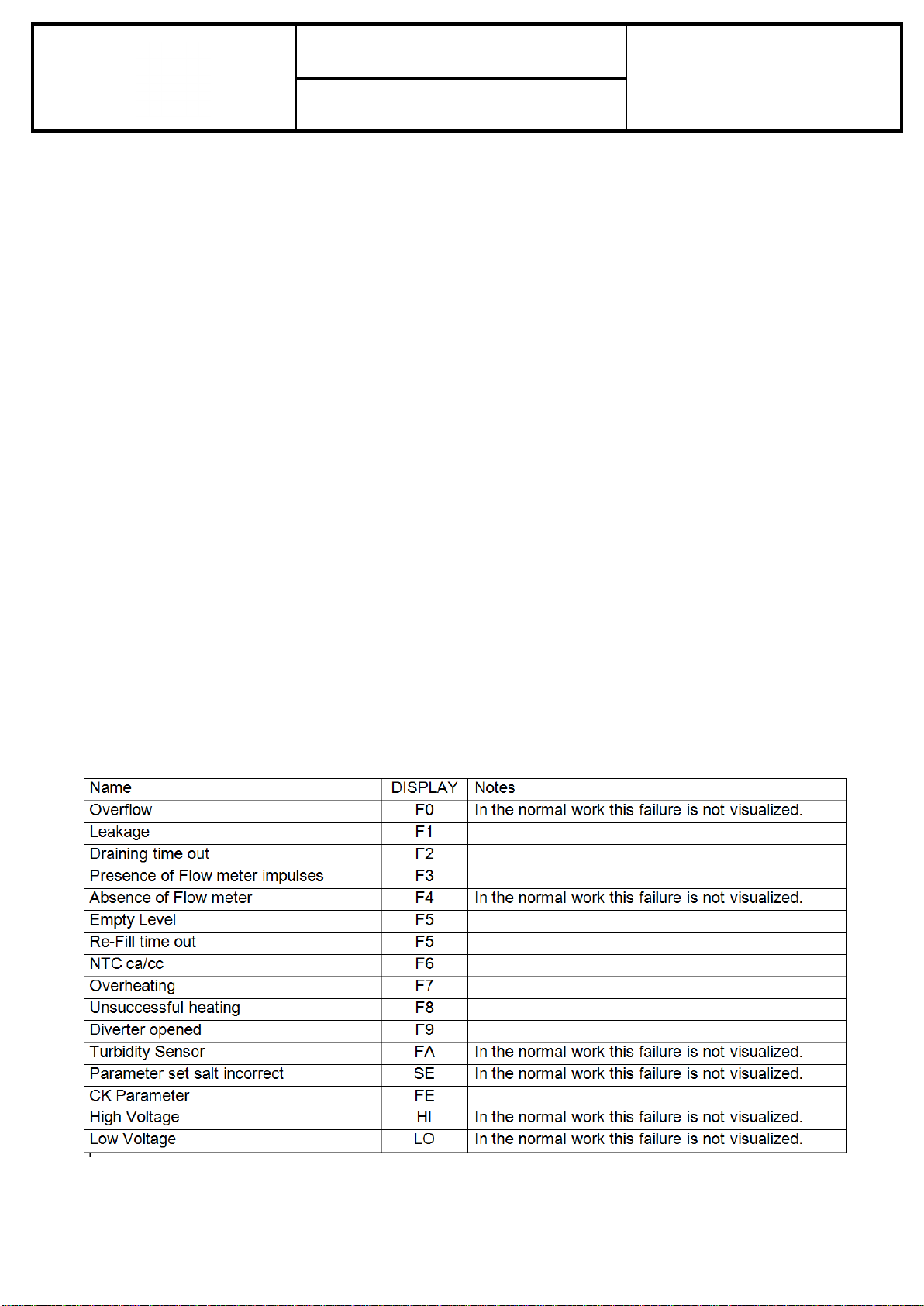

FAILURE CODES

PRODUCTS WITHOUT DISPLAY

SERVICE MANUAL

YSERIES

9

W/O DIVERTER(Y1A, Y1B, Y1C,Y1D, Y1E, Y1F)

PRODUCTS WITHOUT DISPLAY

W/ DIVERTER(Y21, Y22, Y23,Y24)

SERVICE MANUAL

YSERIES

10

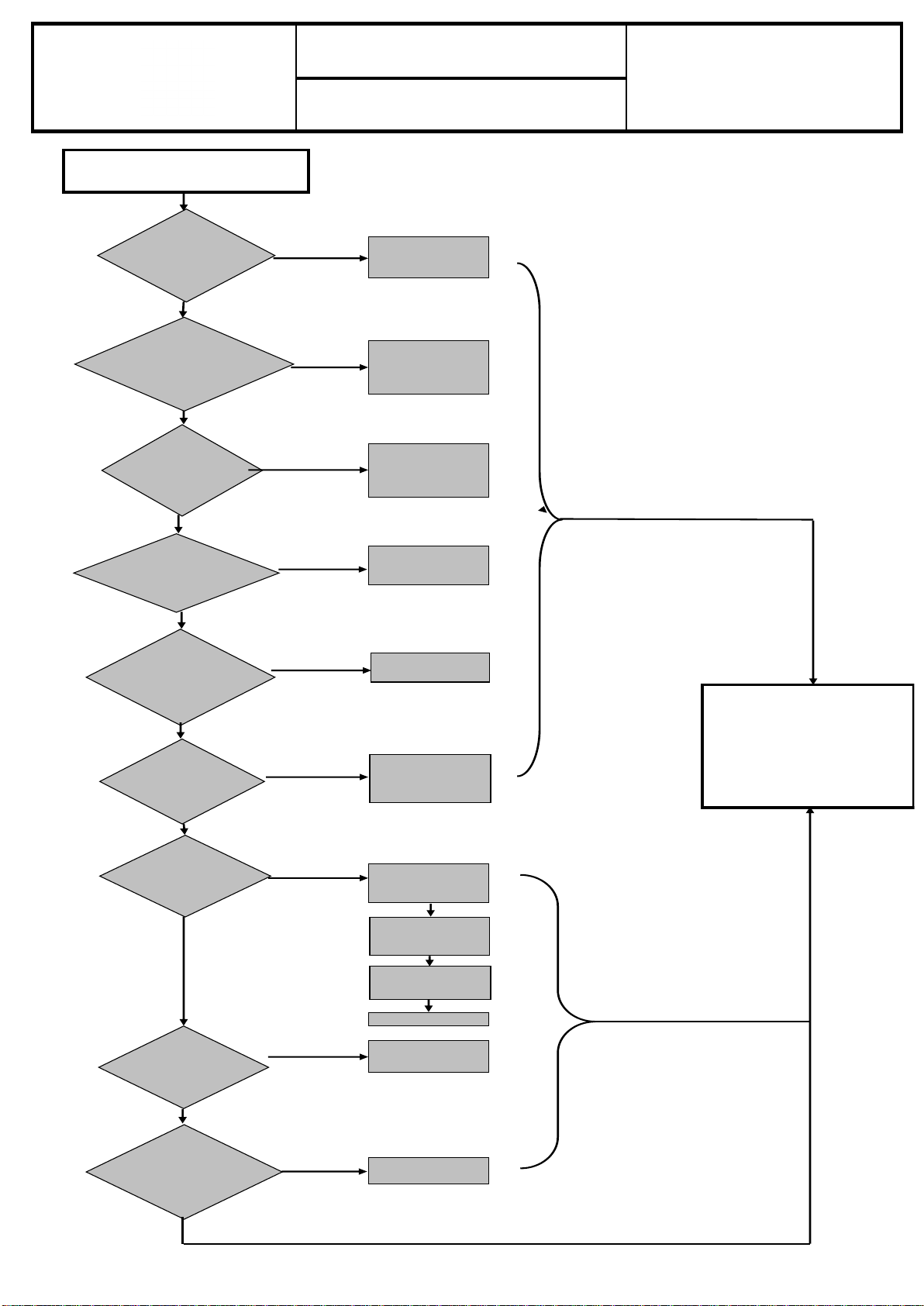

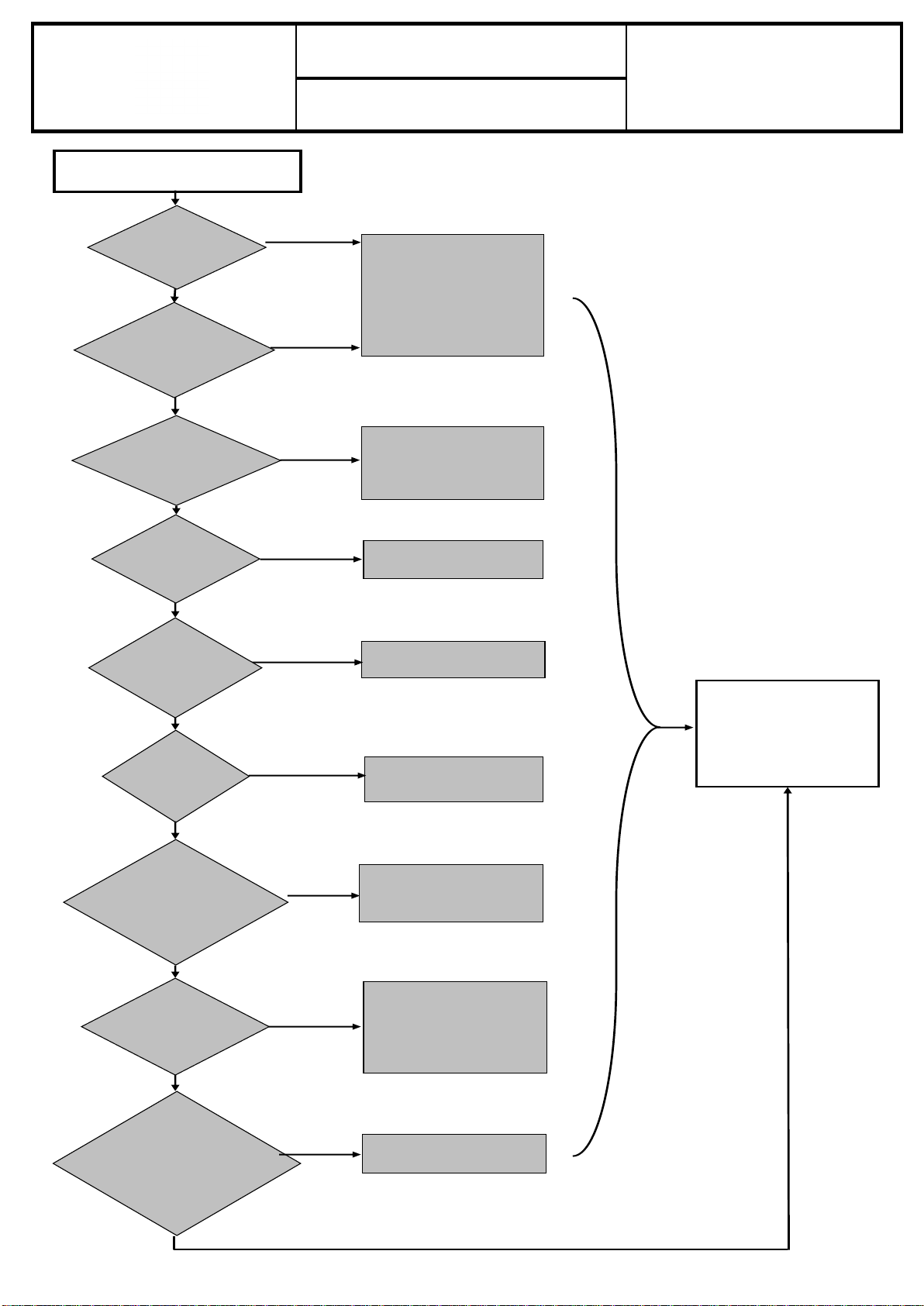

Water is not enough

☺

Are thefilters of

the w ater inlet

valveand water

inlet hose

Clean the valve

fil ters.

Is the connection

betweenwaterinlet

hose- valve

Fix the valve

connections of the

w ater inlethose.

Check the cablegroup

and cableconnections

of the w ater inlet valve.

Did you

operate

the service

program?

Operate theservice

program. Go on the

controlaccordingtothe

failurethat yousee.

Is the machine

taking w ater in

the normal

levels?

Check the w ater inlet

valveand givean

externalenergy.

Arethecirculation

pump socketand

the cablegroup

checked?

Check the PCB card.

Is the circulation

pump operating

whilethe

machine is

Check the pressure

switchandcable

connections.

Check the flow meter

and the cable

connections.

Yes

Yes

Yes

No

No

Is the w ater pressure

between1-10bar

and the supplying

voltagebetween

Make the

environmental

conditions appropriate.

Yes

No

Yes

No

Yes

No

No

No

Yes

Yes

Is it controlled

that if the water

is flowingfrom

the tap?

Yes

Tell the consumer that

the tap has a problem.

No

Is the draining

hoseposition

coorect?

The draining hose

altitude must be

minimum 50 cmand

maximum 110 cmfrom

the ground.

No

Check the PCB card.

SERVICE MANUAL

YSERIES

11

Not washing clean

☺

By using transparent

cover, Arethe

rotation speeds

under 44±5 RPM for

low er spray armand

32±5 for upper spray

Clean the plugged hole andgive

information aboutspray arm

cleaning to theconsumer.

Yes

No

Yes

Yes

No

Arethere any

soil or detergent

residueon the

dishes?

Yes

Give some informations about

detergentusageto the consumer.

1-The pow der detergentsmust be

presevedinclosedpackets.

2-The pow der detergentsmust not

be preservedinmoist rooms.

3-The pow der detergentsmust not

be usedextremelymuch or little

4-The pow der detergentsmust be

added into the machine justbefore

washing.Itmust not be fulledand

closed before for along time

No

Is the filter

groupsoiled or

plugged or not

fixedcorrectly?

Clean the filter groupand give

information aboutfilter cleaningto

the consumer.

No

Check the upperbasket to fitthe

backfeeding canal. Check the

lower spray armthatif it is fittedto

its nest.Change the spray armif it

is necessary.

Yes

Arethebaskets

full withdishes

extremely?

Yes

Give detailed informations about

basketplacement toconsumer.

1-The basketsmust notbe filled

much cramped.

2-The dishes must be placedas not

closedeachother.

3-The dishes must notpreventthe

rotation of theupperand lower

spray arms.

No

Which programis used

by the consumer? Can

it be possiblethat an

inappropriateprogram

is beeing usedby the

consumer?

Yes

Suggestto consumerto usehigh

temperatureprogramaccordingto

the impurity rateof the dishes.

Is the

draining hose

position

coorect?

The draining hosealtitude must be

minimum 50 cmand maximum 110

cmfromthe ground.

No

Yes

No

Is the water

hardness setting

done accordingto

waterhardness?

Measurethe hardness of the

supplyingwater. Thendothe water

hardness setting accordingto the

valuesin the servicebook.

(Suggestto theconsumerto use

w ater softener if thehardness is

under 5 dh.)

No

Yes

Yes

Is there any

plugged hole on

the upper and

lower spray

arms?

Are theglasses of

the consumer have

a lime or w ater

stainproblem?

SERVICE MANUAL

YSERIES

12

MACHINE IS NOT

WORKING

☺

Is the Start/Pause

button led flashing

whenyoupushthe

Start/Pause button?

If the Start/Pause

button led is going on

lighting, checkthe

programchooser

cable.

Yes

Is the washingled

lighting whilepushing

the Start/Pause

button onthe Cancel

condition?

Operate theservice

program. Go on

controllin accordingto

the failuredescription.

Is the start/pause

button lighting

whenyougive

energy tothe

machine?

Check the supplying

voltage,On/Off button

and cableconnections.

No

No

Check the PCB card.

Check the PCB card.

No

Yes

Check the door sw itch

and cableconnections.

The door canbe

unclosed.

Check the PCB card.

Yes

SERVICE MANUAL

YSERIES

13

Not taking the detergent /

Not dissolved

☺

Yes

Is the detergent

coveropenat the

end of the

program?

Yes

Operate the

machine withthe

serviceprogram.

Is the cable

connectionof

detergentcover

controlled?

Check the cable connection.If

thereis a problem, changethe

cablegroup.

Check the

PCB card.

Change if it is

faulty.

No

Is the detergent

cover activationcoil

operating?

Yes

The dishes canbe situatedas

preventingto openthe detergent

coveratthe endof the program.

Give informations to the consumer

about theissue.

Give external220 V energy tothe

detergentcover activation coil.If it

is notworking,changewithanew

one.

No

The detergentcovercanbeopen

very little becauseof friction.If

thereis burr,cleanit. If there is a

dimensionally problem, changethe

detergentcover.

No

Operate theserviceprogram.Go

on controllingaccordingto the

failuredescription.

SERVICE MANUAL

YSERIES

14

Water overflow/water

leakage

☺

Yes

Is the draining pump

operateand show

w ater overflow -

leakage failurewhen

yousupply energy to

Is there any

w ater onthe

baseof

machine?

Check the sytrofoam

height of the security

systemof water

overflow andswitch.

Change the component

if it thereis aproblem.

No

Yes

Operate the

machine withthe

serviceprogram.

Operate theservice

program. Go on

controlling accordingto

the failuredescription.

Yes

No

If the failurethatseen

in serviceprogramis

w ater leakage,check

the overflow hosesand

the areathat has

leakage. Change the

component that causes

the water leakageif it is

necessary.

No

If the failurethatseen

in serviceprogramis

w ater overflow,check

the flowmeter.Change

it if it is faulty.

Dischargethe wateronthe

baseof machine and operate

the serviceprogram.

Other manuals for Y Series

2

This manual suits for next models

10

Table of contents

Other SOGEDIS Dishwasher manuals