SOLANO HORIZONTE RD75 User manual

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 1

FRONT HARVESTERS

DRY FUITS

RD75 & RD90 / P

FROM SERIE Nº 16.001 ON

Update review 07 -13.10.2020

MANUEL OF INSTRUCTIONS

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 2

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 3

mado cliente:

Dear customer:

SOLANO HORIZTE S.L. has written this manual of instructions for you,

so that you can get the maximum yield of your new HARVESTER.

Your new machine has gone through a very comprehensive and

exhaustive process of control of quality of its structure and working, which

makes it very reliable. However, should you see any misfunctioning, do not

hesitate to contact SOLANO HORIZONTE S.L. or our dealer to solve quickly

your problem.

SOLANO HORIZTE S.L. is fully aware that the best advertising

is the quality and efficiency of its products and, above all, customers’

satisfaction. So, quality, seriousness and giving a good service are very

important to us.

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 4

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 5

INDEX

1. 1.CONSIDERATIONS BEFORE TO START. ....................................................................... 8

1.1. Integration of safety............................................................................................................. 8

1.2. Exemption of responsibility. ................................................................................................ 9

2. INTRODUCTION. ................................................................................................................ 11

3. SAFETY MEASURES. ......................................................................................................... 12

3.1. Road circulation. ............................................................................................................... 15

4. SAFETY PICTOGRAMS. ..................................................................................................... 16

5. IDENTIFICATION. ............................................................................................................... 22

6. TECHNICAL SPECIFICATIONS.......................................................................................... 23

7. CONNECTIONS AND START UP. ...................................................................................... 25

7.1. Whenyou receive your machine....................................................................................... 25

7.2. Identification of main parts ................................................................................................ 26

7.3. General Indications ........................................................................................................... 29

7.4. Hitching to / unhitching from the tractor............................................................................. 30

A) Hitching points of the rear part (hydraulic central)............................................................... 33

B) Top link arms........................................................................................................................ 34

C) Hitching the harvester. ........................................................................................................ 35

D) Hydraulic and electrical connections. .................................................................................. 36

E) Cardan shaft (rear part)....................................................................................................... 38

8. IDENTIFICATION OF THE FUNCTIONS OF THE CONTROL BOX. ................................. 40

8.1. Joystick control (option)..................................................................................................... 42

9. ELECTRONIC CONNECTIONS BOX. ................................................................................ 44

10. HYDRAULIC SYSTEM....................................................................................................... 46

10.1. Components of the hydraulic system in the harvest box................................................. 46

10.2. Components of the rear hydraulic central ....................................................................... 48

11. UMBRELLA. ....................................................................................................................... 51

11.1. Regulation of the closing/opening speed of the umbrella................................................ 52

11.2. Misalignment of the canvas of the umbrella.................................................................... 53

11.3. Extension kit to increase the diametre of the umbrella (Option). ................................... 55

12.Shaking head....................................................................................................................... 56

12.1. Additional bulks................................................................................................................ 58

INDEX

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 6

13. PEELERS ........................................................................................................................... 60

13.1. Regulation of peelers....................................................................................................... 60

13.2. Maintainance and replacement of rubber "stars" of peelers............................................ 62

14. WORM SCREWS............................................................................................................... 67

15. RUBBER PARTS................................................................................................................ 68

15.1. Rubber "trunk-closing" piece. .......................................................................................... 68

15.2. Rubber arms of the head................................................................................................. 70

15.3. Head elevation................................................................................................................. 71

16. OIL TANK. .......................................................................................................................... 72

16.1. System of oil filters. ......................................................................................................... 73

17. AUTOMATIC WORKING SEQUENCES (Option). ........................................................... 75

17.1. Programmation................................................................................................................ 76

18. KIT FOR YOUNG TREES (Option). .................................................................................. 80

19. GUIDELINES ON ALMOND HARVESTERS. ................................................................... 84

20. UNLOADING FRUITS. ...................................................................................................... 95

ANNEXE CONVERTING TO PISTACHIOS & DRY FRUITS HARVESTING.......................... 99

21. INTRODUCTION................................................................................................................ 99

22. DISMOUNTING THE PEELERS. ..................................................................................... 100

23. DISMOUNTING THE FRUIT-DRIVING WORM SCREWS.......................................... 99103

24. CONSIDERATIONS WHILE WORKING.......................................................................... 106

ANNEXE MAINTAINACE OF THE HARVESTER.................................................................. 107

25. LEVELS. .......................................................................................................................... 108

25.1. Level of the oil tank........................................................................................................ 108

25.2. Rotation multiplyer box of pumps. ................................................................................ 109

26. MEASURING WORKING PRESSURES. ........................................................................ 112

27. GREASING POINTS. ...................................................................................................... 113

28. UNCOUPLING THE MACHINE. ...................................................................................... 115

29. STORING GUIDELINES. ................................................................................................ 117

30. IMPORTANT RECOMMENDATION. .............................................................................. 118

31. POSSIBLE PROBLEMS AND POTENTIAL CAUSES. ................................................... 120

32. CONTROL BOX SAFETY. .............................................................................................. 123

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 7

CONDITIONS OF WARRANTY ............................................................................................. 125

A. INTRODUCTION. ................................................................................................... 126

B. VALIDITY PERIOD OF THE WARRANTY.............................................................. 126

C. HYDRAULIC AND MECHANICAL PARTS & COMPONENTS............................... 127

D. HYDRAULIC COMPONENTS & PARTS EXCLUDED FROM WARRANTY. ......... 128

E. STRUCTURAL ELEMENTS.................................................................................... 129

F. LABOUR, DISPLACEMENT AND TRANSPORT COSTS. ..................................... 129

G. ELEMENTS NOT COVERED BY WARRANTY...................................................... 129

H. ADMINISTRATIVE PROCEDURE .......................................................................... 131

NOTES.................................................................................................................................... 133

DECLARATION OF CONFORMITY....................................................................................... 135

CERTIFICATE OF DELIVERY OF THE MANUAL OF INSTRUCTIONS............................... 137

CERTIFICATE OF DELIVERY OF THE MANUAL OF INSTRUCTIONS (copy).................... 139

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 8

1. CONSIDERATIONS BEFORE TO START.

Before to handle the machine, you have to read the following indications:

1.1. Integration of safety.

According to what is stated in the point “ESSENTIAL REQUIREMENTS OF

SAFETY AND HEALTH” of section 1.1.2 “Principles of integration of the safety” of

ANNEX I of the Directive 2006/42/CE regarding the convergence of the legislations

of Member States about machinery.

And that is applied to machinery, interchangeable equipment, safety

components, lifting accessories, chains, ropes and webbing, removable mechanical

transmission devices and partly completed machinery.

THE MACHINES DESCRIBED IN THIS MANUAL OF INSTRUCTIONS HAVE

BEEN DESIGNED AND CONSTRUCTED SO THAT IT IS FITTED FOR ITS

FUNCTION, AND CAN BE OPERATED, ADJUSTED AND MAINTAINED WITHOUT

PUTTING ANYBODY AT RISK WHEN THESE OPERATIONS ARE CARRIED OUT

UNDER THE CONDITIONS FORESEEN BY THE MANUFACTURER IN THIS

MANUAL OF INSTRUCTIONS.

BEFORE TO START

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 9

1.2. Exemption of responsibility.

SOLANO HORIZONTE S.L.U., as manufacturer of the machines described in

this manual, will disclaim any responsibility for damages that occur to people,

animals or objects as a result of not complying with the rules and recommendations

that are established in this manual.

You will find this symbol throughout the manual to indicate and stress a

WARNING or a HAZARD.

Not respecting the indicatations that are underlined by this symbol may

involve serious damages to operators or elements of your machine.

You will find this symbol throughout the manual to indicate and stress

SOMETHING THAT IT IS WORTH KNOWING.

Not respecting the indications that are underlined by this symbol may

involve damages to operators or elements of your machine.

This symbol means COMPLETE STOP OF THE MACHINE, by removing the

contact keys from the dashboard of the tractor.

THIS OPERATION IS COMPULSORY TO AVOID INJURIES AND HARMS.

When performing an operation on the machine, this symbol informs you

that you must follow the instructions to the letter in order to avoid

potential damages.

This symbol shows you that one element or component of the machine

will have to be recycled to respect and protect the environment.

BEFORE TO START

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 10

If you need more information about the working of your machine, or about any

issue related to it, do not hesitate to contact SOLANO HORIZONTE, S.L.U.

SOLANO HORIZONTE, S.L.U.

Carretera de Fuente Álamo, 1.

30153 Corvera, Murcia. Spain.

Telf: +34 968 38 01 13

Fax: +34 968 38 04 68

export@solano-horizonte.com

http://solano-horizonte.com

If you need more information about the working of your machine, or

about any issue related to it, do not hesitate to contact SOLANO

HORIZONTE, S.L.U.

BEFORE TO START

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 11

2. INTRODUCTION.

READ THIS MANUAL CAREFULLY, THINK ABOUT AND UNDERSTAND

EVERY POINT THAT IS DESCRIBED IN IT.

UNDERSTANDING HOW THE MACHINE WORKS IS A WAY TO FORECAST

ANY ABNORMAL SITUATION, AND WILL HELP YOU TO COPE WITH THESE

SITUATIONS.

You will find in this book all the information about your new machine: how to

use it, how to regulate it, how to do maintainance operations, how to deal with

potential problems.

READ CAREFULLY ALL THE INSTRUCTIONS AND SAFETY MEASURES

BEFORE YOU START WORKING WITH YOUR MACHINE!

Make sure that all the staff members that work with the machine (using,

maintainance, repairing, etc.) have read and understood perfectly the manual of

instructions, and that it is kept in an easy-to-reach place known by all the staff

members that work with the machine

KEEP IT WELL.

THE HARVESTER HAS BEEN DESIGNED TO WORK IN A SAFE AND RELIABLE

WAY IF IT IS USED ACCORDING TO THE GIVEN INSTRUCTIONS.

SOLANO Horizonte S.L.U. reserves the right at any time and without

previous notice to modify the machine as it considers appropriate and

without having to update this manual.

INTRODUCTION

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 12

3. SAFETY MEASURES.

The design of our machines has taken into account and been very careful with

those parts that are likely to cause accidents during working and maintainance

operations.

So, we have adequately protected all the in-motion elements (mobile, rotating,

etc.) that, according to the task they have to perform, can be protected.

Apart from these safety measures and the exhaustive information shown by

stickers on the machine according to current safety rules and located in well-visible

places, you must follow scrupulously the following norms.

You must use safety equipment and devices when we mention it, as it will

be done all long this manual.

It is important to rigorously respect and follow these norms in order to prevent

accidents that could be very serious:

§Any operator of the machine will have to be qualified and have the required

knowledge to work and handle the machine according to the instructions of

this manual.

§If you remove any protection element (like a cover, grid…), do not forget to put

it back into its place before to start working.

§When the machine is working, never handle under any circumstances one or

more in-motion parts (moving, rotating, etc.).

§If you have to perform any repair or maintainance operation, the machine must

be perfectly wedged. You can use metallic or wood wedges that must be

strong enough to support the weight of the machine.

§When the machine is working, never put your hands inside it because you

could get seriously injured.

SAFETY MEASURES

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 13

NEVER HANDLE THE MACHINE IF THE ENGINE IS RUNNING AND ONE OR

MORE PROTECTION COVERS (OR GRIDS) HAVE BEEN REMOVED OR DO

NOT STAND WHERE THEY SHOULD.

§No one can stand upon the machine under any circumstances when it is

working or being transported.

§Before to start working and while working, the operator of the machine must

keep on paying attention to any action that could put at risk its physical

integrity and the physical integrity of people near the machine.

§NO ONE can stand near the machine when it is handled. Its moving parts

could catch a limb from any person close to the machine and cause

her/him serious injuries.

§Very important: while an operator is handling the machine (starting, working,

maintaince, etc.), any person that has nothing to do with him must keep a

sufficiently cautious safety distance. Your machine has a big volume and

some of its movements can be abrupt and could injure anyone who does not

respect safety distance.

Safety distance: it is measured from the most salient point of the

machine up to any person or object that could get injured or damaged,

the machine being in transport or in working position.

§Before to unplug a hydraulic pipe, make that there is no pressure left inside it.

If there remains some pressure, you could not only get stained, but also be

seriously injured if you are hit by pressurized liquid in vital parts such as skin

or eyes.

§Pumps: never go beyond 75% of the maximum pressure during the first 50

hours of work, and change oil change every 500 hours or according to the

instructions of the manual of the pumps.

§Check that valves work properly and are in the right position.

SAFETY MEASURES

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 14

§Never stand under the machine when it is in suspension, even though the

tractor is stopped.

§Do not allow anyone to use the machine if she/he has not read and

understood this Manual of Instructions before. People under the age of

majority are forbidden to use the machine.

§During the transport of the machine, all its mobile parts will have to be folded

or in transport position, and their safety sysem (if they have one) will have to

be fastened. Check minimum and maximum dimensions of the transport

vehicle as well as road circulation rules.

§NEVER STOP WATCHING THE MACHINE, NOT EVEN FOR A SHORT

WHILE, WHEN IT IS RUNNING.

§In addition to all the above mentioned points, it is very important that all the

operators wear the necessary indivudual protection equipments as well as the

adequately tight clothes that will prevent them from being caught by some

element of the machine.

IT IS MANDATORY TO FOLLOW ALL THE SAFETY RULES

SAFETY MEASURES

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 15

3.1. Road circulation.

Our harvesters have been designed to be transported on public roads in

accordance the rules of the “Reglamento General de Circulación vigente” in

Spain. For other countries, check the rules that are in-force.

Before to start circulating, you will have to check that all the

parts of the machine are locked, and that all the safety devices

are in their place and fastened. If your machine has a road light

kit, you will have to check that they work correctly.

If some elements are stuck to the machine (due to the use of

the machine, due to the storage, etc.), you will have to remove

them to prevent them from flying away as it could cause a

dangerous situation on the public road.

Check that the weight of the machine does no exceed the authorized

maximum mass on all or one of the axles of the tractor. Otherwise, do

not circulate on public roads until you have solved the problem.

WHEN CIRCULATING ON PUBLIC ROADS, THE MACHINE MUST BE

DISCONNECTED; ANY PART THAT COULD PULL AWAY FROM THE

MACHINE MUST BE FOLDED AND SECURED FOR TRANSPORT; YOU

MUST FASTEN ALL THE SAFETY DEVICES OF THE MACHINE, AFTER

HAVING CHECKED THEY WORK WELL.

Check that your tractor has enough mechanical power and capacity to

run the machine. Check that the hitching system of your tractor has

enough lifting capacity. To do so, compare them to the technical

specifications of your machine.

SAFETY MEASURES

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 16

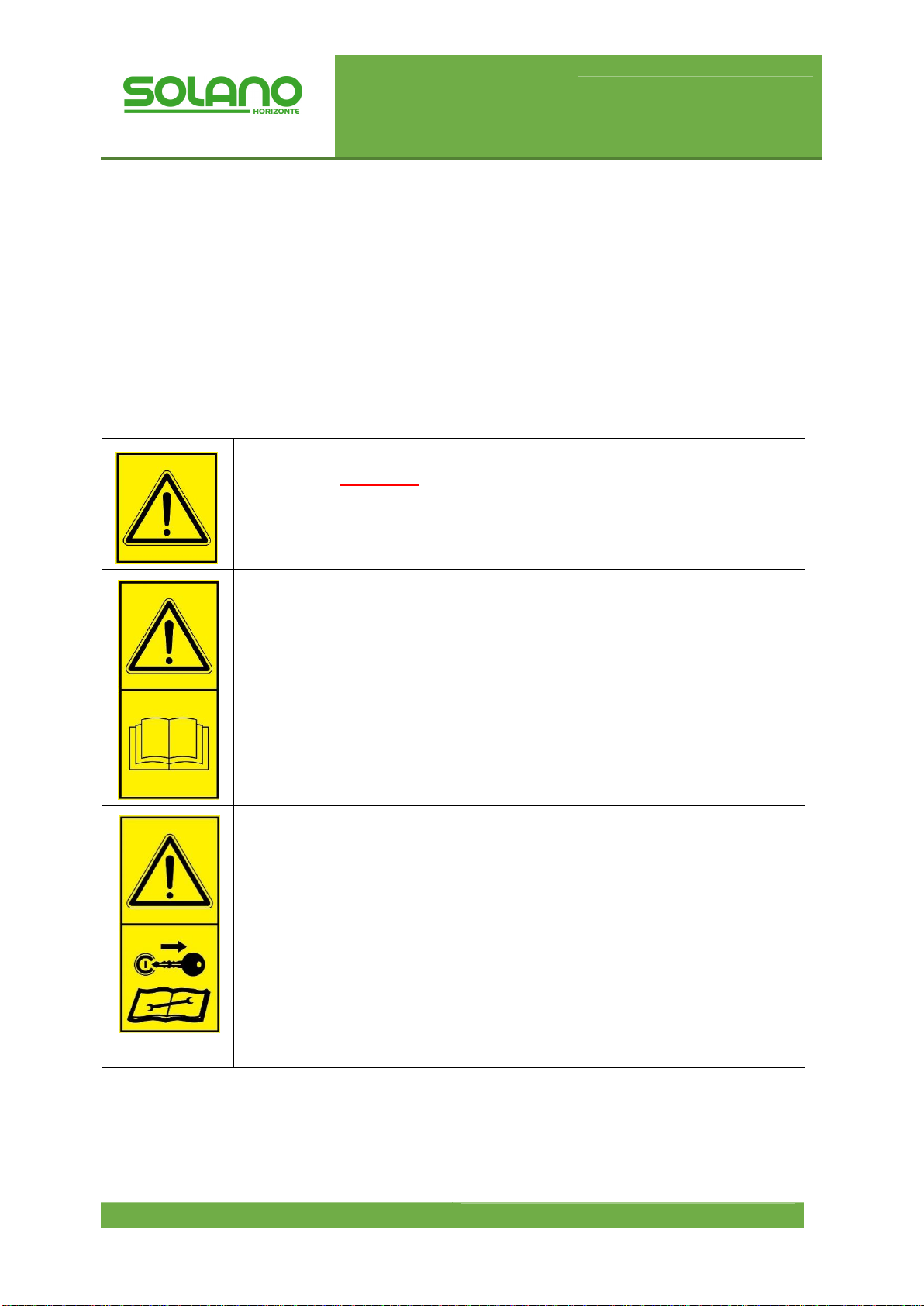

4. SAFETY PICTOGRAMS.

Yellow safety stickers are stuck on the harvesters. They are located in the areas

of the machine where there are potential risks of accidents, and they feature

pictograms intuitive enough to warn operators and persons against these risks.

Nonetheless, and for a better safety of the operators of the machine, we explain

you below the meaning of each pictogram.

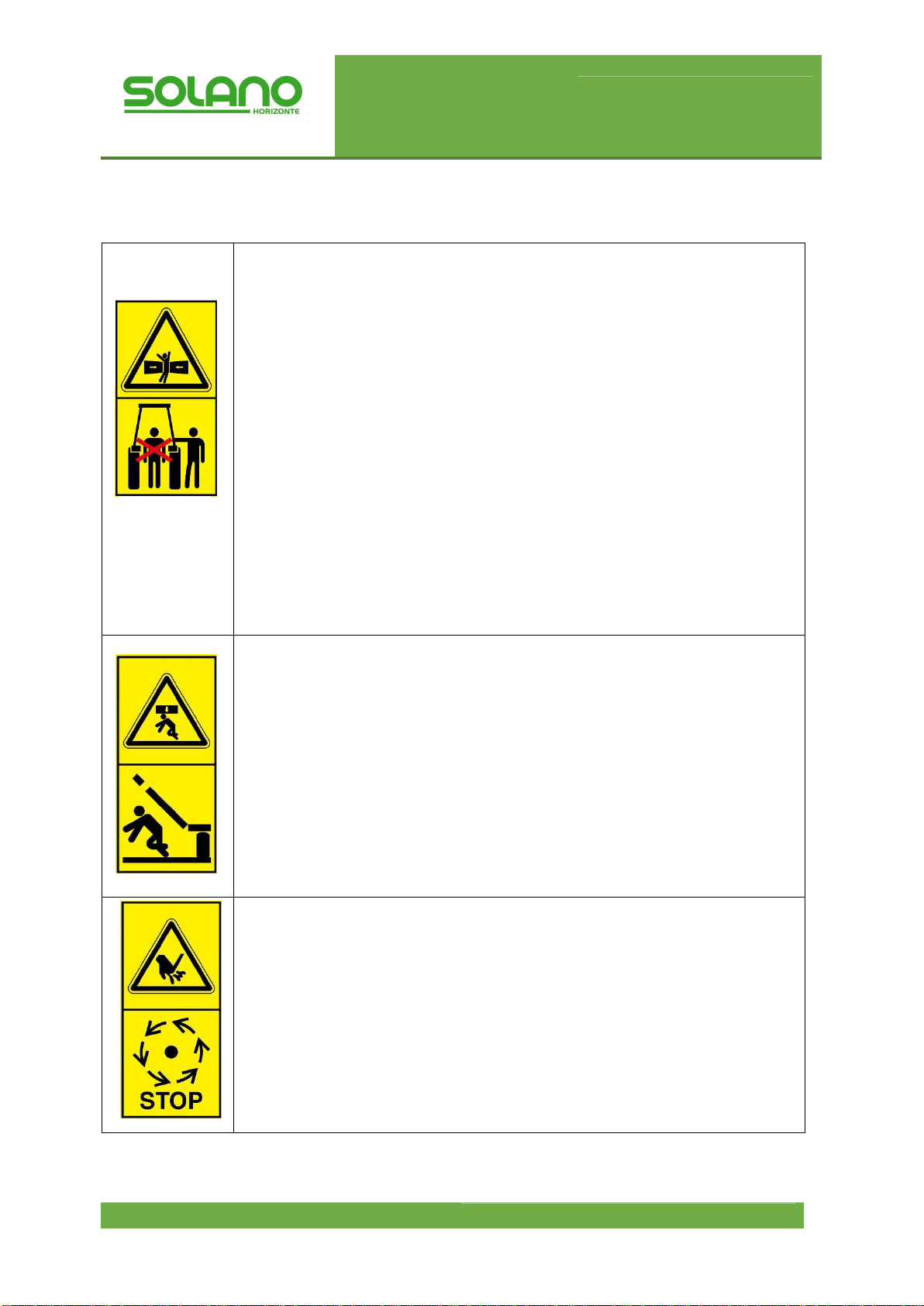

This icon is WARNING you against one or more hazards for personal

safety. When you see it on the machine, you must pay attention because

there is a potential risk of accident.

BEFORE TO USE THE MACHINE, READ CAREFULLY THE MANUAL OF

INSTRUCTIONS!

By doing so, you will prevent your machine from being deteriorated

and/or suffering accidents. You will also use it in an adequate way and

get a better yield from itAvant d’utiliser votre machine, lisez

attentivement le manuel d’instructions.

Stop the engine and remove the contact keys from the dashboard of the

tractor in order to eliminate any risk of unexpected starting of the engine

of the tractor. You will prevent operators from getting into very

dangerous situations while they handle the machine.

Think about the risks of unexpected and unintended connections and

working of the machine if the engine of the tractor is running.

STOP THE ENGINE OF THE TRACTOR TO DO MAINTAINANCE

SAFETY

PICTOGRAMS

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 17

ALWAYS KEEP OUTSIDE THE DANGEROUS AREA WHILE YOU HANDLE

THE ELEVATION SYSTEM OF THE TRACTOR!

The area between the hitching 3 points of the tractor and the machine is

a dangerous area. Inside it, you can be caught by the elevation system of

the tractor.

So, when you have to handle elements of the machine within this area,

make sure that the tractor’s engine is stopped.

If it is not possible, do the manipulations remaining always outside the

dangerous area.

ALWAYS REMAIN OUT OF REACH OF THE WORKING RANGE OF THE

MACHINE!

The machine is lifted above the ground, thus creating a risk of very

serious and dangerous accidents.

So, you must always be and remain outside this dangerous area.

NEVER GO NEAR THE MACHINE IF IT HAS NOT TOTALLY STOPPED!

While the machine is working, it is very difficult, or impossible, to see its

moving and rotating parts. Do not forget that your body is fragile.

KEEP FAR FROM THE MACHINE UNTIL IT HAS TOTALLY STOPPED!

SAFETY

PICTOGRAMS

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 18

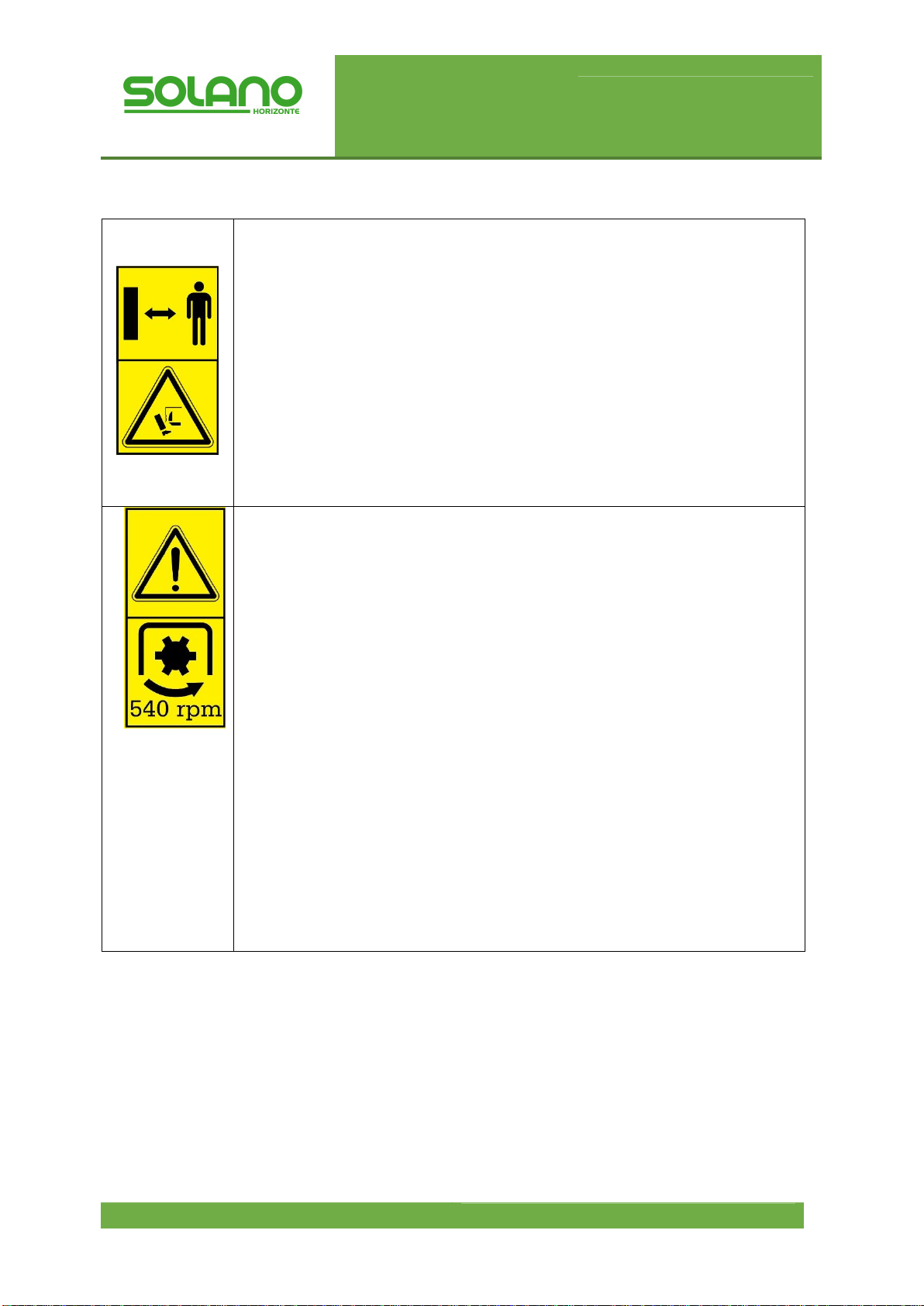

DO NOT GET TOO CLOSE TO THE MACHINE IF IT DOES NOT REST

PERFECTLY ON THE GROUND!

No matter if it is working or not, your feet could be flattened by the

machine if you are too near.

To avoid any risk before to go near the machine, make sure that it stands

perfectly on its lowest support points and that there is no risk to put your

feet under it unintendedly.

DO NOT CONNECT THE MACHINE TO A PTO SPLINE THAT TURNS MORE

THAN 540 R.P.M.!

As you are likely to know, most tractors feature PTO spline that can turn

at 540 and 1.000 r.p.m., and sometimes even at 750 r.p.m.

Nearly all our machines work at 540 r.p.m. If you connect the machine by

mistake at more than 540 r.p.m., you could damage it.

For our machines which works in a different rpm position, a pictogram

will warn you when the machine needs the tractor to be in 750 or 1.000

rpm position

RD75 HARVESTERS NEED THE TRACTOR TO BE IN 540 RPM POSITION.

THE OPTIMUM WORKING POINT IS BETWEEN 380 AND 400 R.P.M.

SAFETY

PICTOGRAMS

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 19

The pincer-head get closed at a very high pressure. If you put your hand

or any other part of your body into it, you will be flattened and seriously

injured. If your head or trunk be caught, you would die. So:

KEEP FAR FROM THE PINCER-HEAD WHILE IT IS BEING USED AND

HANDLED!

Even when you are doing maintainance operations.

RISK OF FLUID PROJECTION AT HIGH PRESSURE.

Check the installations of the machine and, if you see parts in poor

conditions, chage them because a breakdown or a misfunctioning may

provoke accidents and injuries. The machine must be fully stopped when

you check and/or service it. If necessary, have it done by a qualified

tecnhician.

Inside the harvesting box, there are “endless” screws (worm screws) and

other elements that are rotating as soon as the tractor is working and

the PTO shaft is connected.

These elements could catch you and you could be seriously injured.

So, when the tractor is running, NEVER try to handle any of these

elements even though you use a bar, or a tool or anything similar.

The fruit intercepting inverted umbrella can reach a diametre superior to

7 metres when opening.

It is important to make sure that you stay outside its reach when it

close/open beacause your head or other part of your body could be hit!

SAFETY

PICTOGRAMS

SAFETY

PICTOGRAMS

HARVESTERS

RD75/90/P

MANUAL OF INSTRUCTIONS 20

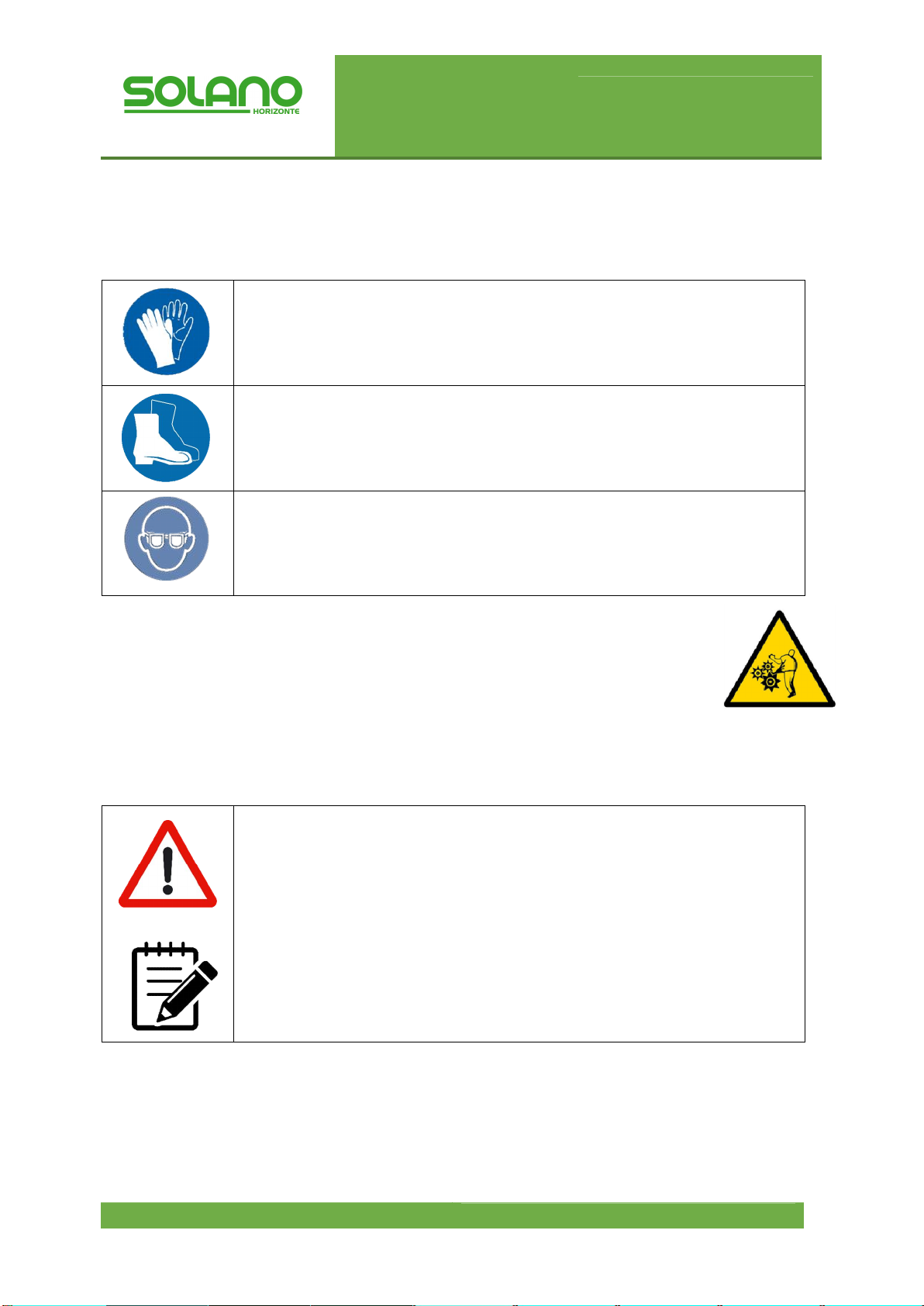

INDIVIDUAL PROTECTIVE EQUIPMENT, CLOTHES AND DEVICES:

The under explained pictograms placed on the machine informs you of the

individual protective equipement that you must wear in order to prevent risks.

You must wear safety gloves to handle the machine to prevent risk of

injuring hands.

Operators must wear safety boots/shoes to prevent risks of injuries

while handling/operating the machine.

It is compulsory to wear safety glasses while you are working with the

machine as there is a risk of projection of elements.

We also recommend you to wear working clothes as tight and

body-fit as possible while you are using or servicing the machine

to prevent risks of being caught by some of its parts.

Individual Protection Clothes and Accessories must have their respective

manual of instructions. Read them carefully and check that they are in accordance

with in force laws and rules in your country/region.

If a safety measure that has not been written by the manufacturer in this

manual of instructions is considered and/or is indicated on the machine,

operators will have to apply and respect it.

Non-compliance of safety measures and of the normal use of the

machines may have consequences.

This manual suits for next models

2

Table of contents

Other SOLANO HORIZONTE Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions