Solar Stik PDM 3000 Installation instructions

|1April 2020 |Solar Stik®, Inc.

OPERATOR AND MAINTENANCE MANUAL

FOR THE

POWER DISTRIBUTION MODULE (PDM)

3000

Updated:20200428

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

Revision: A

Item #: 20-0002510

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.2 |

Contents

GENERAL INFORMATION, THEORY OF OPERATION, AND EQUIPMENT DESCRIPTION

PDM 3000 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Theory of Operation

Important Product Safety Information and Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Information Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fire Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Recommended Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electric Shock Hazard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Environmental and Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Impact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Dust/Foreign Object Intrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Equipment Description

The Inter-Connect System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PDM 3000 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Regulated Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PDM 3000 Information Plate (I-Plate) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OPERATOR INSTRUCTIONS

Integrating the PDM 3000 into a System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MAINTENANCE INSTRUCTIONS

Preventive Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Foreign Object Debris (FOD) and Water Intrusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Water Intrusion Remediation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PDM 3000 PMCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transporting Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SUPPORTING INFORMATION

PDM 3000 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Warranty and Returns

Return Material Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

ABOUT SOLAR STIK, INC.

Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

|3April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Section Page(s) Description Date

First published March 2020

List of Tables

Table 1. PDM 3000 PMCS.............................................................................................................................................. 18

Revision History

List of Figures

Figure 1. PDM 3000 circuits ............................................................................................................................................. 4

Figure 2. PDM 3000.......................................................................................................................................................... 5

Figure 3. Inter-Connect plug........................................................................................................................................... 10

Figure 4. PDM 3000 front ............................................................................................................................................... 11

Figure 5. PDM 3000 left side .......................................................................................................................................... 11

Figure 6. PDM 3000 right side........................................................................................................................................ 12

Figure 7. PDM 3000 bottom ........................................................................................................................................... 12

Figure 8. PDM 3000 top, Faceplate, specs, and cautions ............................................................................................. 13

Figure 9. PDM 3000 output breakers ............................................................................................................................. 14

Figure 10. Connecting 24 VDC power source to the PDM 3000.................................................................................... 14

Figure 11. Connecting a voltage-sensitive 28.0 VDC load to the PDM 3000................................................................. 15

Figure 12. Connecting a 24 VDC load to the PDM 3000................................................................................................ 15

Figure 13. Location of drain plug screws in the PDM 3000 ........................................................................................... 17

Figure 14. PDM 3000 bottom cutouts ............................................................................................................................ 18

Figure 15. PDM 3000 transportation .............................................................................................................................. 19

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.4 |

GENERAL INFORMATION, THEORY OF OPERATION,

AND EQUIPMENT DESCRIPTION

PDM 3000 Introduction

The primary function of a Power Distribution Module (PDM) 3000 is to provide 28.0 VDC power in a

stable, regulated manner to DC loads that are sensitive to the quality of power.

The PDM 3000 “boosts” the DC bus voltage (typically < 30.0 VDC), up to 36 VDC then “bucks” it

down to a stable, regulated 28.0 VDC. Power sources (24 VDC nominal) may be connected to the

Inter-Connect port or to the NATO port.

The PDM 3000 is Plug & Play–compatible with the Solar Stik Inter-Connect circuit, and can be

used in concert with other Solar Stik components. The modular design allows the operator to use it

with other technologies/capabilities that collectively meet the specic mission requirements for an

application.

Cables for the PDM 3000 are sold separately; load cables are customized for the application with

the proper connector(s), wire gauge, and length.

Theory of Operation

Figure 1. PDM 3000 circuits

Voltage-sensitive

28.0 VDC Loads

24 VDC Loads

24 VDC

System power source

(Power Hub or PRO-Verter)

The PDM 3000 provides stable, regulated 28.0 VDC power to support voltage-sensitive loads.

The Inter-Connect and NATO input ports are functionally equivalent, allowing the PDM 3000 to be

integrated into a Solar Stik Hybrid Power System (HPS) or to obtain power from a source such as a

military vehicle or genset with the common 24 VDC NATO connector.

|5April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Important Product Safety Information and Instructions

This manual contains important safety instructions that must be followed during the installation and

operation of the PDM 3000. Read all instructions and safety information contained in this manual.

While the PDM 3000 is designed for indoor/outdoor operation, the cutouts on the bottom must

remain clean with access the environment for proper cooling.

The PDM 3000 is not eld serviceable. If repair is needed, contact Solar Stik Technical Support for

assistance in diagnosis and identication of the proper repair and parts.

Exercise caution when handling or operating equipment. Live power may be present.

Figure 2. PDM 3000

Safety Information Labels

Your safety and the safety of others is very important.

Always read and obey all safety messages.

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill you or

hurt you and others. All safety messages will follow the safety alert symbol and the word

“DANGER”, “WARNING”, or “CAUTION”. These words are dened as:

DANGER Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of

injury, and tell you what can happen if the instructions are not followed.

WARNING

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.6 |

Fire Hazard

Fire Types

Class A fire - Fires in ordinary combustibles such as wood, paper, cloth, trash, and plastics.

Class B fire - Fires in ammable liquids such as gasoline, petroleum, oil, and paint.

Class C fire - Fires involving energized electrical equipment such as motors, transformers, and

appliances. Remove the power source and the class C re becomes a class A or B re.

Recommended Fire Extinguisher

NSN 4210-00-288-7219 Fire Extinguisher, Carbon Dioxide, 10 lb

Carbon dioxide is a liqueed gas, which is highly effective ghting class B and C res. These

extinguishers are ideal for areas where contamination and/or cleanup are a concern, such as data

processing centers, labs, and telecommunication rooms.

Using the Fire Extinguisher

When using the extinguisher on a re, remember PASS:

Pull the pin.

Aim the nozzle or hose at the base of the re from a safe distance.

Squeeze the operating lever to discharge the re extinguishing agent.

Sweep the nozzle or hose from side to side until the re is out. Move forward or around the re as

the re diminishes.

Watch the area for reignition until the cause has been xed.

Use Sweeping Motion

WARNING

Only CO2(carbon dioxide) re extinguishers should

be used with this equipment.

These additional cautionary steps will ensure

your safety:

• System components should not be operated in

standing water.

• Close and latch the component lids if it is

precipitating.

• System cables should not be routed through

standing water.

• Cable connections should remain dry.

• Unused ports on System components should

be covered when not in use to reduce the

possibility of water intrusion.

|7April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Electric Shock Hazard

DON’T LET THIS BE YOU!

HIGH VOLTAGE: System components,

photovoltaic (PV) arrays, and generators may

have lethal line voltages. Extreme care should be

taken to protect against electrocution.

Always:

• Work with another person in case an

emergency occurs.

• Disconnect power before performing

maintenance.

• Wear safety glasses whenever working on any

part of a System that requires exposure to

mechanical or direct electrical contacts.

WARNING

The PDM 3000 is NOT GFCI protected.

WARNING

Standing water around the electrical equipment and/or intrusion of water into the

System components can increase the risk of electrical shock.

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.8 |

Environmental and Handling Precautions

All Solar Stik components are ruggedized, yet there are a few things the operator can do to prevent

failures and prolong the operational life of the product.

Water

If outdoor operation is necessary, cases

should be placed upright, especially during

inclement weather.

Impact

Equipment should not be dropped onto hard

surfaces at a height greater than one foot

when transporting or during operation.

Dust/Foreign Object Intrusion

As a general rule, minimize exposure to

high levels of particulates and foreign

object debris by exercising common-sense

placement and protection during both

operation and storage.

Heat

Heat and solar loading reduces efciency and

life expectancy. Shade components (except

PV panels) to prevent the negative effects of

heat.

|9April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Equipment Description

The Inter-Connect System

The System is comprised of three (3) distinct types of technologies:

• Energy storage

• Power management

• Power generation

All of the individual components that operate in these categories utilize a unique connection

architecture known as the Inter-Connect Circuit.

The Inter-Connect Circuit is the connection framework of the System’s DC power network. It uses

a simple, polarized, locking connection that is common throughout the architecture. All power

management, energy storage, and power generation components are compatible with the Inter-

Connect Circuit.

Using a common, polarized connector allows rapid “Plug & Play” scaling of components, adaptation

of capabilities within the architecture, technology refreshment, and swapping of components when

conditions warrant. It also ensures that there is no unsafe way to make connections.

Circuit Breaker Protections

The Inter-Connect network is protected from overloads and short circuits through a network of circuit

breakers strategically placed throughout the circuit. It ensures the potential for a reverse polarity

connection within the circuit is minimized. If a problem occurs in a leg of the Inter-Connect Circuit,

the affected leg will disconnect from the primary network, leaving the other circuits functioning. If a

major failure occurs in the circuit, then the entire network will shut down for System and Operator

protection.

Operate with Voltage

The Inter-Connect Circuit communicates simple battery voltage to all components on the network,

allowing them to independently coordinate their respective functions. Battery voltage is used to

trigger actions such as Automatic Generator Start/Stop (AGS) function, power distribution timing,

and more. Therefore, the proper setup of the Inter-Connect Circuit is critical to properly communicate

voltage to all points in the System and to ensure all of the components operate together to provide

seamless power to the load.

Optimize with Data

Data collection for a System occurs through the Inter-Connect network. Power management devices

such as Power Hubs and PRO-Verters meter voltage, current and time through the circuit, providing

critical real-time data the operator can use to troubleshoot and verify System performance. Data

collection enables programming/architectural changes to optimize performance based on evolving

conditions.

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.10 |

Figure 3. Inter-Connect plug

The Inter-Connect Plug

• Polarized

• 200 A maximum current

• 24 VDC connection only

• Mechanically “locks” into place

• Rotate knob clockwise to lock,

counterclockwise to release

• Can be repaired or modied in the eld

|11April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Power Output

The 24VDC NATO port provides unregulated 24 VDC power to a load.

Note: This port may also be used for 24 VDC power input if required.

Figure 4. PDM 3000 front

Figure 5. PDM 3000 left side

The 24VDC Input Only Inter-Connect port allows the PDM 3000 to use the Solar Stik HPS Inter-

Connect circuit as a power source.

PDM 3000 Connections

Description Connector Voltage Amps

ABattery Connection Inter-Connect Port 24 VDC 100

A

Description Connector Voltage Amps

A24 VDC NATO Slave (unmetered) NATO Slave 24 VDC 100

A

Power Input

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.12 |

The bottom of the PDM 3000 case is cut away to facilitate heat dissipation. The internal components

are sealed from exposure to the environment by a gasket.

Output Breakers

Regulated 28 VDC

to PDU

Figure 6. PDM 3000 right side

Regulated Power Output

The 2-pin connector in the right side of the PDM 3000 provides regulated 28.0 VDC power to a load.

The 100 A breakers on the right side also serve as power switches for engaging and disengaging

power circuits to the 24 VDC NATO and 28.0 VDC Amphenol ports.

Note: Both output connectors are customizable per application/customer requirements.

CAUTION

Do NOT connect a battery directly to the regulated 28 VDC output port because this

will damage the PDM 3000.

Description Connector Voltage Amps

A28.0 VDC regulated output Amphenol 28.0 VDC 75

BRegulated 28 VDC output to PDU N/A N/A 100

C24 VDC output to Tower N/A N/A 100

A

B C

Figure 7. PDM 3000 bottom

|13April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

PDM 3000 Information Plate (I-Plate)

Figure 8. PDM 3000 top, Faceplate, specs, and cautions

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.14 |

OPERATOR INSTRUCTIONS

A

Output Breakers

2. Use an Inter-Connect cable to connect the PDM 3000 to a 24 VDC power source (e.g., Solar Stik

HPS PRO-Verter or Power Hub DC bus). The choice of HPS Inter-Connect port will depend on

the HPS conguration. Contact Solar Stik Technical Support.

1. Turn off both breakers during System setup.

Figure 9. PDM 3000 output breakers

Hybrid Power

System

PRO-Verter

Power Hub

OR

Figure 10. Connecting 24 VDC power source to the PDM 3000

Integrating the PDM 3000 into a System

|15April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

3. Connect load (PDU) to Regulated 28 VDC Output port.

Note: This connector is custom. Contact Solar Stik for information about connector/cable

options.

4. Use a NATO slave cable to connect load to 24 NATO port to a load (tower).

28.0 VDC

Load

24.0 VDC

Load

Figure 11. Connecting a voltage-sensitive 28.0 VDC load to the PDM 3000

Figure 12. Connecting a 24 VDC load to the PDM 3000

CAUTION

Do NOT connect a battery directly to the regulated 28 VDC output port.

Connecting a battery directly to the regulated 28 VDC output port will damage the PDM 3000.

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.16 |

Preventive Care and Maintenance

The PDM 3000 case is sealed. No maintenance to internal parts is required or advised.

The function and efciency of all electronic equipment is related to and dependent upon the

temperature at which it is operating. It performs optimally within a narrow temperature range and

less so as the temperature falls outside of that range. Heat will cause the PDM 3000 to derate.

Please use the following measures to mitigate against heat and other environmental effects:

• Shade the PDM 3000 from direct sun exposure and shelter it from the elements as much as

possible.

• Keep unused connector covers closed to prevent water/dust intrusion.

• Check the integrity of electrical connectors on a monthly basis.

• Turn off loads when they are not in use. This will save power and allow more power to be

available when it is needed.

MAINTENANCE INSTRUCTIONS

Foreign Object Debris (FOD) and Water Intrusion

All Solar Stik equipment is designed for operation in adverse environmental conditions; however,

certain rules apply:

1. If operating in wet environments, use common-sense placement to avoid water intrusion by

either ooding or precipitation.

2. If operating in dusty environments, place unit in a location that minimizes exposure to

particulates.

Consult the Preventive Maintenance Checks and Services (PMCS) section of this manual for

additional details.

Output Breakers

5. Turn on the breakers required to support the load(s).

|17April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Figure 13. Location of drain plug screws in the PDM 3000

• Remove the screw from the drain hole at the bottom edge of the component case. If water ows

out of the drain hole after removal of the plug, let it ow until it stops. Then slightly and slowly tilt

the case toward the drain hole to remove any remaining water. Continue to increase the angle of

the component slowly until no more water drains from the hole. After the water has been drained,

move the component to a safe, dry location. Place the component in the most dry environment

possible for a time long enough that any remaining moisture inside will dry. When it is dry,

reintegrate the component to the System and test it to determine if it is still functional.

WARNING

Standing water around the electrical equipment or intrusion of water into the System

components can increase the risk of electrical shock.

Water Intrusion Remediation

• If water intrusion is suspected and the System is still functional, disconnect power sources

entering that component from the most distant location possible, power down the System (turn off

the power switches on all of the System components), then disconnect the component from the

System. Do not to try to remove what may be a ooded component while it is still powered up.

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.18 |

Item #

Item to be

Inspected Interval Procedures Non-mission Capable

1

Visual

inspection of

PDM 3000

M

1. Inspect case for visible damage

and missing items.

2. Clean excessive dust or dirt

accumulation from the exterior,

interior, and connectors and from

the cutouts on the bottom.

3. Close all unused port covers.

~If the case is broken or split or

if connectors are damaged, do

not place into service.

Table 1. PDM 3000 PMCS

PDM 3000 PMCS

Figure 14. PDM 3000 bottom cutouts

The PDM 3000 case is sealed. No maintenance of internal parts is required or advised.

cutouts

|19April 2020 |Solar Stik®, Inc.

Operator and Maintenance Manual for the PDM 3000

Transporting Components

The PDM 3000 carries like a briefcase using the case handles (arrow). There are no transport

restrictions. It is safe for all modes of transportation, including land, sea, and air.

Figure 15. PDM 3000 transportation

Operator and Maintenance Manual for the PDM 3000

April 2020 |Solar Stik®, Inc.20 |

SUPPORTING INFORMATION

PDM 3000 Technical Specifications

General

Nominal Operating Voltage 24 VDC

Battery Voltage Range 24–30 VDC

Internal cooling Passive cooling

Case 1560 Pelican case

Warranty 1-year materials and

workmanship

Efciency 95%

Safety

Breaker(s) • (1) 100 A unregulated DC output breaker

• (1) 100 A regulated DC output breaker

Fuse(s) (1) 200 A catastrophic fuse

Reverse Polarity Polarized connectors

Ground Fault Grounding lug

Weights and Dimensions (L x W x H)

Weight 50 lb (22.6 kg)

Dimensions 23.5 x 18.25 x 10.375 in (59.7 x 46.4 x 26.4 cm)

Connections

Input(s) (1) 24 VDC Inter-Connect*

Output(s) (1) AIB2-32-5SC (regulated 28 VDC)

Input/Output(s) (1) NATO port

Environmental

Operating Temperature -40 °F to 140 °F (-40 °C to 60 °C)

*Deltran 224-0061-BK

Table of contents

Popular Control Unit manuals by other brands

Texas Instruments

Texas Instruments TPA3255EVM user guide

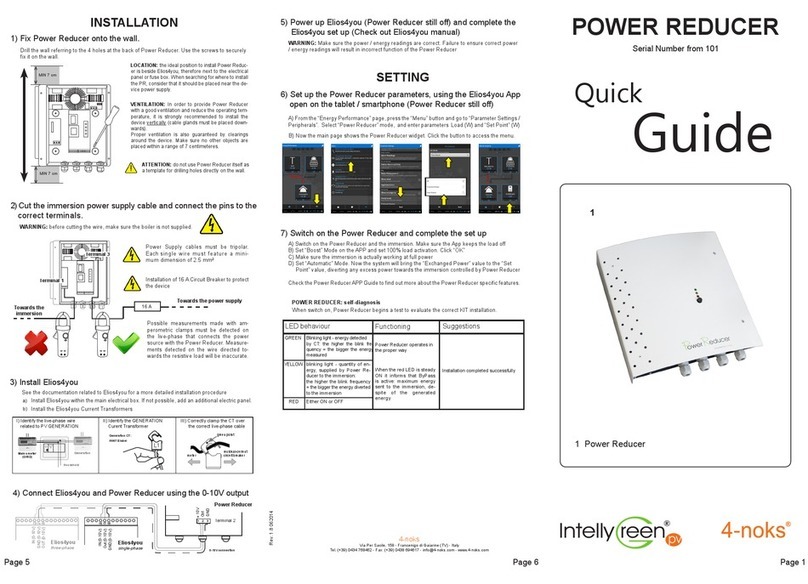

Elios4you

Elios4you Power Reducer quick guide

Neles

Neles XG Series Installation maintenance and operating instructions

American

American TIM-48 quick start guide

M-system

M-system R7G4HH-A-YVF4 instruction manual

Phoenix Contact

Phoenix Contact FL WLAN 1100 user manual

Savant

Savant SAV-LMP-0300 Quick reference guide

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS FluidControl FCU 8111 Operating and maintenance instructions

Vag

Vag 991-D Installation, operation and maintenance manual

Toshiba

Toshiba V Series user manual

Inner Range

Inner Range SkyGuard IGM Installation & operation manual

Watts

Watts 2300 Series installation instructions