www.velocitydetection.com Doc: GLT-295-7-1 Issue: 003 Date: 29 4 2022

General

The VL-ZMB is a six zone monitor module that is designed to be DIN mounted inside of a Velocity control panel. It’s

powered and interfaced to the Velocity MMP via a RJ45 connection. The module has six class B zone monitor’s which

can be typically used for conventional devices and or for special detectors that are not available in addressable form

such as UV detectors, aspiration and beam detectors etc. The module monitors and transmits the status (normal,

open, short, or alarm) of a zone with the detectors to a control panel. Each zone input can be programmed to either

give a supervisory or alarm signal when active.

Installation

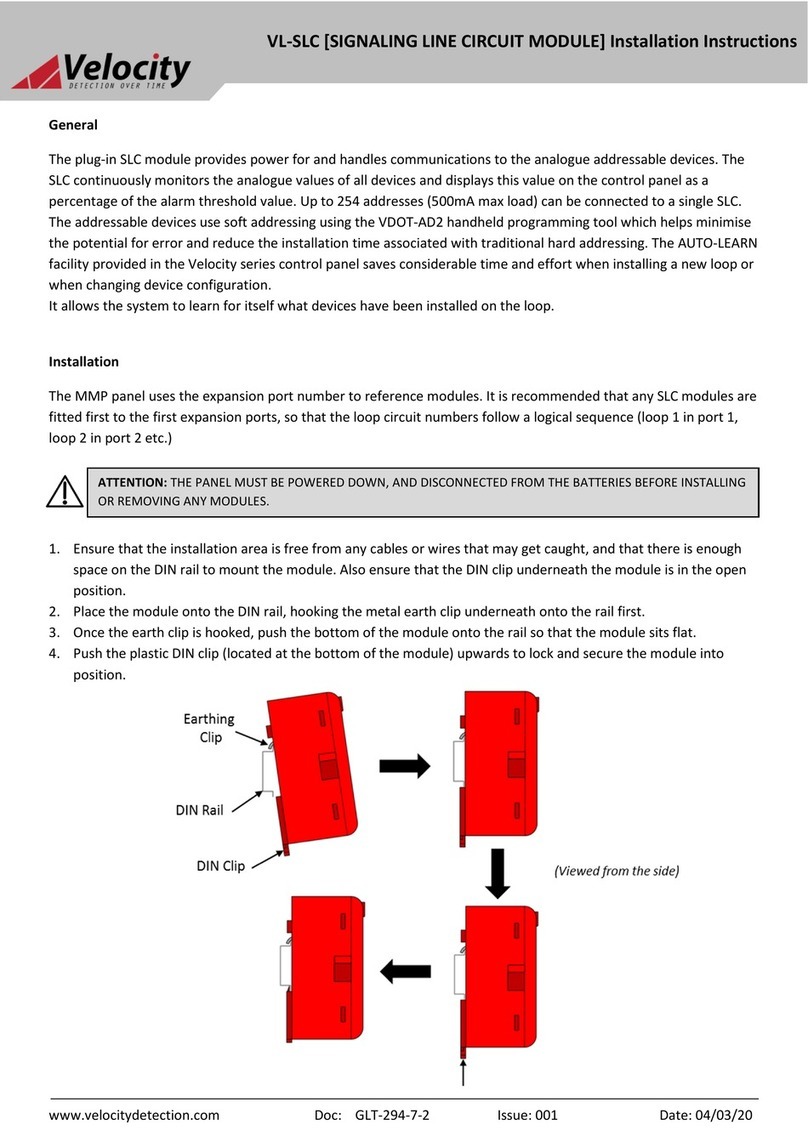

1. Ensure that the installation area is free from any cables or wires that may get caught, and that there is enough

space on the DIN rail to mount the module. Also ensure that the DIN clip underneath the module is in the open

position.

2. Place the module onto the DIN rail, hooking the metal earth clip underneath onto the rail first.

3. Once the earth clip is hooked, push the bottom of the module onto the rail so that the module sits flat.

4. Push the plastic DIN clip (located at the bottom of the module) upwards to lock and secure the module into

position.

5. Once the module is secured to the DIN rail, simply connect the supplied CAT5E cable to the module’s RJ45 port.

6. Connect the other end of CAT5E cable to the nearest unoccupied RJ45 port on the termination PCB.

VL-ZMB [ZONE MONITOR] Installation Instructions

ATTENTION: THE PANEL MUST BE POWERED DOWN, AND DISCONNECTED FROM THE BATTERIES BEFORE

INSTALLING OR REMOVING ANY MODULES.