Solartron Metrology OD4 User manual

PRODUCT NAME

user manual

Product Type

OD4

user manual

Conditioning Module

1.0 Index

Part No. 502621 Issue 10

2

Section Title Page

1.0 Index . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Safety Information . . . . . . . . . . . . 3

3.0 Introduction . . . . . . . . . . . . . . . . . 5

3.1 OD4 Mk2 Enhancements . . . . . . . 5

4.0 Installation . . . . . . . . . . . . . . . . . . 6

4.1 Mounting . . . . . . . . . . . . . . . . . . . 6

4.2 Operational Environment . . . . . . . 7

4.2.1 Residential, Commercial & Light

Industrial Environments . . . . . . . . 7

4.2.2 Industrial Environments . . . . . . . 7

4.3 Electrical Connections . . . . . . . . 8

4.4 Connecting the Transducer . . . . . 9

4.5 Connecting the Power Supply . . . 11

4.6 Connecting the Signal Out . . . . . . 11

Section Title Page

4.6.1 Voltage Connections . . . . . . . . . . 11

4.6.2 Current Connections . . . . . . . . . . 12

4.7 Using an EMC Cable Gland . . . . . 13

5.0 Setting up the Transducer and OD4 . 14

5.1 Option Links Explained . . . . . . . . . . . 15

5.2 Basic Procedure . . . . . . . . . . . . . . . . 17

5.3 Sensitivity and the X2, X4,DIV2 Links . 21

6.0 Half-Bridge Version . . . . . . . . . . . . . . 22

7.0 Specifications . . . . . . . . . . . . . . . . . . 22

7.1 Electrical . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Mechanical and Connections . . . . . . 25

7.3 Environmental . . . . . . . . . . . . . . . . . 25

7.4 Notes . . . . . . . . . . . . . . . . . . . . . . . 26

Return Of Goods

Solartron Sales Offices

1.0 Index

Part No. 502621 Issue 10

3

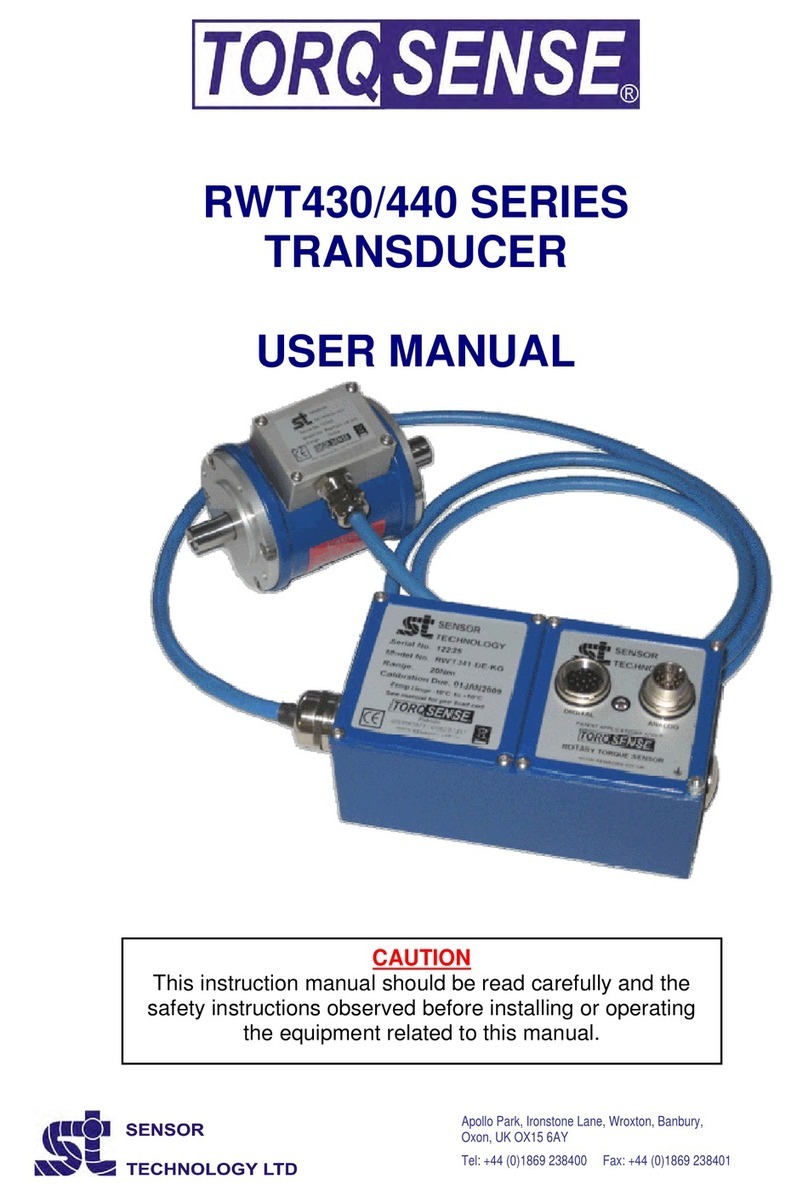

2.0: Safety Information

2.0: Safety Information

Terms in this Manual

WARNING statements identify conditions

or practices that could result in personal injury

or loss of life.

CAUTION statements identify conditions

or practices that could result in damage to the

equipment or other property.

Symbols in this manual

This symbol indicates where applicable

cautionary or other information is to be

found.

WARNINGS:

Do not operate in an explosive atmosphere

To avoid explosion, do not operate this

equipment in an explosive atmosphere.

Safety Critical Environments

This equipment is not intended for use

in a safety critical environment."

CAUTION:

Low Voltage

This equipment operates at below the SELV and

is therefore outside the scope of the Low Voltage

Directive.

This equipment is designed to work from

a low voltage DC supply. Do not operate this

equipment outside of specification.

Part No. 502621 Issue 10

4

2.0: Safety Information

2.0: Safety Information

CAUTION:

Electrostatic Discharge

This equipment is susceptible to ESD (Electrostatic

Discharge) when being installed or adjusted, or

whenever the case cover is removed. To prevent

ESD related damage, handle the conditioning

electronics by its case and do not touch the

connector pins. During installation, follow the

guidelines below.

• Ensure all power supplies are turned off

• If possible, wear an ESD strap connected to

ground. If this is not possible, discharge yourself

by touching a metal part of the equipment into

which the conditioning electronics is being

installed.

• Connect the transducer and power supplies

with the power switched off.

• Ensure any tools used are discharged by

contacting them against a metal part of the

equipment into which the conditioning electronics

is being installed.

• During setting up of the conditioning electronics,

make link configuration changes with the power

supply turned off. Avoid touching any other

components.

• Make the final gain and offset potentiometer

adjustments, with power applied, using an

appropriate potentiometer adjustment tool

or a small insulated screwdriver.

Part No. 502621 Issue 10

5

3.0: Introduction

3.0: Introduction

The OD4 MK2 is a development of the original OD4.

It is a compact conditioning module powered from

a single DC supply. Adjustable gain and zero

controls are provided for use with the complete

range of Solartron LVDT and half-bridge

transducers.* The unit is of robust construction,

housed in a die cast aluminium box providing

a substantial degree of mechanical protection.

The OD4 MK2 incorporates its own voltage

regulation for operation from 10-30 VDC and

can provide outputs of up to ±10 V together

with ±20 mA.

3.1: OD4 MK2 Enhancements

The OD4 MK2 has been designed as a form, fit and

function replacement for the original OD4, but with

several enhancements.

• Wider gain range, allowing ALL Solartron

transducers to be connected without the need

for attenuation resistors.

• Up to ±10 V dc and ±20 mA are available

for all gain settings.

• Fixed and variable offsets make setting of uni-

polar output easier.

• Gain and offset adjustment are fully

independent.

• Selectable transducer excitation frequency.

• Selectable transducer load resistances.

• Selection between forward and reverse

connection.

• Fully CE Compliant.

• Half-Bridge transducers can now be

accommodated with simple plug wiring

changes.*

* For half-bridge only variant see section 6.0.

Part No. 502621 Issue 10

6

4.0: Installation

4.0: Installation

4.1: Mounting

The OD4 may be mounted in a variety of ways and

in any attitude. Ensure that there is enough space

for the cover to be removed to allow for internal

adjustments. Space should also be allowed for the

transducer connector, EMC glands (if fitted) and

cabling. It is recommended that the OD4 case

be connected to earth or chassis.

Underside Mounting

Top-Side Mounting

Note: If replacing OD4

MKI a retrofit mounting kit

is available if repositioning

holes is not possible.

This earth connection is not a safety earth, but

is part of the overall electrical screening scheme.

Part No. 502621 Issue 10

7

4.0: Installation (continued)

4.0: Installation (continued)

4.2: Operational Environment

This section discusses the type of installation

required depending on the electrical environment.

4.2.1: Residential, Commercial and Light

Industrial Environments

Typically, this will be an office, laboratory

or industrial environment where there is no

equipment likely to produce high levels of electrical

interference, such as welders or machine tools.

Connections may be made using twisted,

unscreened wire. This is a cost effective option and

will give good performance in this environment.

Standard equipment wire such as 7/0.2 (24 AWG)

can be twisted together as required. Standard data

cable such as generic CAT5 UTP will also give good

performance.

4.2.2: Industrial Environments

Typically, this will be an industrial environment

where there is equipment likely to produce high

levels of electrical interference, such as welders,

machine tools, cutting and stamping machines.

Connections should be made using screened cable.

Braided or foil screened cables may be used. The

cable screen should be connected to the OD4 case

at cable entry point. The case of the OD4 should be

connected to a local ground. An EMC cable gland is

recommended.

This is supplied with the OD4.

When selecting the type of wire or cable to be used,

consider the following parameters:

• Screening.

Conductor size (resistance).

Mechanical aspects such as flexibility

and robustness.

This is not a complete list. Installations may require

other special cable characteristics.

Part No. 502621 Issue 10

8

4.0: Installation (continued)

4.0: Installation (continued)

4.3: Electrical Connections

The OD4 requires three connections.

1. Transducer.

2. Power Supply.

3. Output Signal, Voltage or Current.

A small hole should be made in the grommet prior

to passing the wires through. If a screened cable

is to be used, an EMC cable gland is recommended

(see section 4.7).

For best performance in electrically noisy

environments, the case of the OD4 should be

connected to a local earth. This can be achieved

via the mounting bracket. This earth connection is

not a safety earth, but is part of the overall electrical

screening scheme.

The wiring layout arrangements are similar for OD4

fitted with EMC glands and screened cable.

Separate Power Supply and Signal Out wires

Power Supply and Signal Out wires from

one end only

Connections to the power supply should be

routed to one side as shown. This helps to reduce

interference between power supply wires and the

more sensitive parts of the circuitry.

A technical note explaining good practice

for cable installation and routing can be

downloaded from www.solartronmetrology.com

Tran sdu cer

0V +V E

V O UT 0V I O U T

CO A R S E G A IN

1 2 3 4 5 6 (7)

FI N E G A IN

CO A R S E

OF F S E T

-V E

+V E

5V

2.5 V

FI N E O F F S E T

10 K

2K

- -

¦

R

¦

|F |

- -

DI V 2

X2

(X 4 )

G B K W B R

LO

HI

S ig n a l O u t

P o w e r S u pp ly

Transd u cer

0V +V E

V O U T 0V I O U T

CO A R S E G A IN

1 2 3 4 5 6 (7 )

FI N E G A IN

CO A R S E

OF F S E T

-V E

+V E

5V

2.5 V

FI N E O F F S E T

10 K

2K

- -

¦

R

¦

|F |

- -

DI V 2

X2

(X 4 )

G BK W B R

LO

HI

S ig n a l O u t

P o w e r S u p ply

Part No. 502621 Issue 10

9

4.0: Installation (continued)

4.0: Installation (continued)

4.4: Connecting the Transducer

Transducers fitted with a 5-pin DIN plug are simply

screwed into the case mounted socket. Transducers

not fitted with a plug should be wired to the plug

supplied.

C O R E

P rim a ry

R e d

Blue

Ve

G re en

Yellow

W hite

V

V

A

B

C e ntre T a p

V

O

M e asu re d

O u tp ut

R e d

B lu e

Yello w

+

-

C a se

L V D T

C a b le S cre e n

B la c k

C a se

P lu g vie w

in to p ins

S ta n da rd L V D T G a u g in g P ro b e P l ug C o n n ec tio n s

N o te 1 : + indic a te s inw ard m ove m ent o f the tip.

N o te 2 : Th e tra n sducer body m a y be dis connected from th e c a b le sc re e n b y

cu tting the b la ck wire in side th e c o n n e ctor

3

4

5

2

1

G re en

W hite

LVDT Electrical Connections

Red and Blue Energising

Green and White Signal

Yellow Secondary Centre Tap

Red and White In Phase for Inward

Displacement

Black Transducer Body Ground

Part No. 502621 Issue 10

10

4.0: Installation (continued)

4.0: Installation (continued)

C O R E

Blue

Yellow

R e d

V

V

A

B

C e ntre T a p

V

O

R e d

B lu e

Yello w

+

-

C a se

H a lf- B rid ge

C a b le S c re e n

B la c k

C a se

P lu g v ie w

in to pin s

S ta n da rd H a lf-B r id g e G a u g in g P r ob e P lu g C o n n ec tio n s

N o te 1 : + in d icates in w ard m o vem e n t of the tip .

N o te 2 : The transducer bod y m ay be d is co n n e c te d fro m th e cab le sc re e n by

cu ttin g the black wire in s ide the conne ctor

4 2

1

3

5

L IN K

Half-Bridge Electrical Connections

Red and Blue Energising

Green and White Signal

Yellow In Phase for Inward

Displacement

Red and Yellow In Phase for Inward

Displacement

Black Transducer Body Ground

Part No. 502621 Issue 10

11

4.0: Installation (continued)

4.0: Installation (continued)

4.5: Connecting the Power Supply

The OD4 requires a dc power supply in the range

10-30 V. A fully regulated supply is not required,

but the voltage at the input to the OD4 must remain

within specification. Ideally, the 0 V at the power

supply should not be connected to earth or the

chassis, as this would result in ground loops being

formed. The 0V supply, 0V signal and case are all

internally connected together at the OD4.

4.6: Connecting the Signal Out

The output signal may be voltage or current.

4.6.1: Voltage Connections

Voltage can easily be monitored using a variety of

instrumentation such as voltmeters. Voltage drops

along wires contribute to measurement errors, so

care must be taken when using long cable lengths

(100 m for example). High impedance instruments

are more prone to interference.

The signal 0V should always be used as reference.

If power supply 0V is used, then error voltages may

be introduced.

P o w er S u p pl y

0V

+ 10 -3 0 V 0V

+ V E

0V

V o u t

Io ut

P ro c e s s M o n it or

+

-

V o lta g e

Section 0

Part No. 502621 Issue 10

12

4.0: Installation (continued)

4.6.2: Current Connections

Current output requires the use of purposely

designed current input instrumentation. Current

output is more suitable for transmitting over longer

distances because current is not lost due to wiring

resistance. Additionally, with a low impedance, a

current loop is less likely to pick up noise.

The total loop resistance (resistance of measuring

equipment and wiring)

must not exceed specification.

Note: The OD4 is not loop-powered, so a power

supply must not be used in-line with the current

output.

4.0: Installation (continued)

Part No. 502621 Issue 10

13

Screen

125 mm

30 mm 10-15 mm

4.0: Installation (continued)

4.0: Installation (continued)

4.7: Using an EMC Cable Gland

To ensure the cable screen is properly connected to

the OD4 case, an EMC cable gland should be used.

This is supplied as an optional extra. The diagrams

below assume a single 4-way cable is being used.

Remove the grommet and fit the cable gland as

shown below.

- Prepare cable as shown.

- Slide the Dome nut, sealing ring and plastic

insert over cable.

- Fold and roll the screen back over itself

to form a lump.

Rolled Back

Screen

Dome Nut

Sealing

Ring

Plastic Insert Gland Body

Case Wall

Rotate Gland Body to

Tighten

- Push cable into gland body, followed by the plastic

insert (ensure anti-rotation slots engage), sealing

ring and dome nut.

- Ensure all components are properly seated before

tightening the dome nut.

Part No. 502621 Issue 10

14

5.0: Setting up the Transducer

and OD4

5.0: Setting up the Transducer and OD4

The OD4 may be set-up with output signals

anywhere within a ±10 VDC or ±20 mA range.

Typical outputs are ±10 VDC, ±5 VDC, 0-10 VDC

and 4-20 mA. These procedures apply to voltage

and current output.

Voltage and current output are available at the same

time, although they cannot be individually adjusted.

Either voltage or current should be chosen as the

calibration reference.

All outputs use 0V signal as the signal reference.

A list of standard link settings is available,

see section 5.2.

CAUTION:

During installation and adjustment, the

top of the enclosure has to be removed

for access to user adjustments. At this time,

standard ESD handling precautions for

electronic equipment should be followed.

15 Part No. 502621 Issue 10

5.0: Setting up the Transducer

and OD4 (continued)

5.0: Setting up the Transducer and OD4 (continued)

5.1: Option Links - Explained

The table below and subsequent diagrams explain the link functions and show the factory setting.

Link Description Options Standard Setting

Course Gain Sets the basic gain 1 link on Positron 1 to 6 Link ON Position 1

Fine Gain Adjustment between course gain ranges Potentiometer Adjustment Mid Position

Course Offset Shifts the output by a fixed amount Link ON -VE or +VE and Link ON 5 V or 10 V No

offset - Link Parked

No offset - Links Parked

Fine Offset Fine trim around any fixed offset Potentiometer Adjustment Mid Position

(7) Null Used during set-up to null output ON, OFF OFF

Freq. Selects transducer primary frequency Lo - ON, Hi - Parked Hi Freq. - Link Parked

Input Resistance Sets transducer secondary load 100 KΩParked, 10 KΩ- ON, 2 KΩ- ON 100 KΩ- Link Parked

Polarity (FR) Enables output signal direction change 2 Links across Forward or Reverse F Position

- 2 Link ON

Input Gain Input Gain of x1, x2, x4 or divide 2 X1 - Parked, X2 - ON, X4 - ON, DIV2 - ON Link parked on X2

L in k O N L in k P A R K E D Lin k O F F

0 V + V E

V O U T 0 V I O U T

C O A R S E G A IN

F IN E G A IN

C O A R S E

O F FS E T

-V E

+VE

5V

10V

F IN E O F F S E T

10K

2K

- -

¦

R

¦

|F |

- -

D IV 2

X2

X4

G B K W R B

O U T P U T

P O W E R

1 2 3 4 5 6 (7 )

F R E Q

LO

(O N )

H I

(O F F )

N U L L

Part No. 502621 Issue 10

16

5.0: Setting up the Transducer

and OD4 (continued)

5.0: Setting up the Transducer and OD4 (continued)

5.2: Basic Procedure

To set-up the OD4, some basic steps should

be followed.

The following steps describe a typical setting

procedure and applies to most applications.

Other procedures may be used as appropriate.

For a bi-polar output i.e. ±10 VDC or ±20 mA,

follow steps 1 to 3. For a uni-polar output i.e.

0-10 V, 0-20 mA or 4-20 mA, follow steps 1 to 4.

In either case, step 5 (final checks) should be

followed on the completion of the set-up.

Ze ro

-5V + 5 V

N u ll

elec tro n ic s

transd u cer

N u ll

Ze ro

transd u cer

elec tro n ic s

N u ll

+5 V0V + 1 0V

elec tro n ic s

transd u cer

S h ift

zero

V/V

±V

Hz

KΩ

Step 1

Set-up OD4

links

Step 2

Align OD4 and

Transducer Null

Step 3

Set OD4 and

Transducer Range

Step 5

Final Checks

Step 4

Add Offset

if Required

Part No. 502621 Issue 10

17

5.0: Setting up the Transducer

and OD4 (continued)

5.0: Setting up the Transducer and OD4 (continued)

5.2: Basic Procedure (continued)

STEP 1 - Set-up OD4 Links

If the transducer characteristics are known,

set the frequency and input resistance links

as required. A list of standard settings for all

Solartron transducers is available from www.

solartronmetrology.com. If the transducer

characteristics are not known, the standard link

settings should be used.

If your transducer is known to be outside of the

standard sensitivity range, the X2 or DIV2 links will

have to be used. See section 5.3.

STEP 2 - Align OD4 Null and Transducer Null

Any electrical offset in the OD4 is removed. The

transducer position is adjusted so that transducer

and OD4 nulls are aligned.

Null the OD4.

1. Put the Gain link on position (7) as shown.

This allows any electronics offset in the output

stage to be removed.

2 Adjust the Fine Offset control to give as near

to zero output as practical.

1 2 3 4 5 6 (7)

F R E Q

LO

(O N )

H I

(O F F)

N U L L

Part No. 502621 Issue 10

18

5.0: Setting up the Transducer

and OD4 (continued)

5.0: Setting up the Transducer and OD4 (continued)

5.2: Basic Procedure (continued)

Null the transducer.

1. Replace the Gain link to the original position.

2. Adjust the position of the transducer to give as

near

to zero output as practical.

This is the centre of the mechanical range.

If the transducer cannot be centered for practical

reasons an offset will remain within the system.

There may be noticeable interaction between Gain

and Offset adjustment. This does not prevent the

OD4 being set-up. However several iterations

may be required when adjusting Gain and Offset.

Please contact your supplier if guidance is

required.

STEP 3 - Setting Bi-Polar Full-scale Output

1. Move the transducer to the position where

maximum OD4 output is required.

2. If the polarity of the output is wrong, move the

Polarity (FR) links to the R position (see link

diagram).

Move the transducer back and re-check the zero

position. Adjust transducer position as required.

3. Move the RANGE link between 1 and 6 until the

OD4 output is near the required value.

4. Adjust the Fine Gain control to give the required

output.

5. A bi-polar output has now been set, proceed to

step 5. If a uni-polar output is required, proceed

to step 4.

10K

2K

- -

¦

R

¦

|F |

- -

D IV 2

X2

X4

Normal Output Polarity

10K

2K

- -

¦R¦

|F |

- -

D IV 2

X2

X4

Reverse Output Polarity

19 Part No. 502621 Issue 10

5.0: Setting up the Transducer and OD4 (continued)

5.2: Basic Procedure (continued)

Example: ±10 VDC is required from a ±1 mm

transducer. Set the transducer to +1 mm and set

the output to 10 V.

If your transducer is known to be outside of the

standard sensitivity range, the X2 or DIV2 links will

have to be used. See section 5.3.

STEP 4 - Setting Uni-polar Full-Scale Output

(adding an offset)

1. Move the transducer to the null position.

OD4 output will be 0 V or 0 mA.

2. Apply offset using the +VE, -VE, 5 V and 10 V

links and then adjust the Fine Offset control to

set the offset precisely.

3. Perform final checks, step 5.

Example: 0-10 V is required for a ±1 mm

transducer. Set the transducer to give ±5 V over

the full range and then, with the transducer at null,

add +5 V offset. Adjust the Fine Offset control to

give 5 V. When the transducer is moved to the +1

mm position, the output will be +10 V.

Example: 4-20 mA is required for a ±1 mm

transducer. Set the transducer to give ±8 mA

over the full range and then, with the transducer

at null, add +5 V (approx. 10 mA) offset. Adjust

the Fine Offset control to give +12 mA. When the

transducer is moved to the +1 mm position, the

output will be +20 mA.

STEP 5 - Final Checks

Ensure that the calibration is correct by moving the

transducer across the required mechanical range,

checking calibration points. Fine adjustment can

be made if required.

It may only be possible to set the output accurately

at the two calibration points. This is due to non-

linearity within the transducer.

5.0: Setting up the Transducer

and OD4 (continued)

20 Part No. 502621 Issue 10

5.3: Transducer Sensitivity and the X2, X4,

DIV2 Link

The OD4 compensates for changes in primary

signal amplitude by producing an internal error

signal that is the ratio between the primary and

secondary signals. If the transducer output signal

is too high or too low, errors may occur that can

degrade the performance of the OD4 / transducer

combination. For these transducers, the X2, X4 or

DIV2 input gain link must be used.

For Solartron transducers, consult the list of

standard settings available from the downloads

section of www.solartronmetrology.com.

Transducer Full Range Output

In general, transducer sensitivity is quoted as

mV/V/mm

Where: mV is the output of the transducer

Vis the primary voltage

mm is the mechanical position

of the transducer

from null (usually mid mechanical range).

To get the transducer Full Range Output, multiply

all three together.

Example: AX/1.0 sensitivity is 210 mV/V/mm

AX/1.0 range is ±1 mm

OD4 primary voltage 3 V

Transducer Full Range Output

= 210 x 3 x 1 = 630 mV (0.63 V)

Set the X2, X4, DIV2 link as shown

in the table below.

5.0: Setting up the Transducer and OD4 (continued)

5.0: Setting up the Transducer

and OD4 (continued)

Transducer Full

Range Output

Input Gain

Link Setting

400 mV FR

to 2500 mV FR

Standard Range

- Link Parked on X2

2500 mV FR

to 5000 mV FR

High Transducer Output

- Link ON DIV2

150 mV FR

to 400 mV FR

Low Transducer Output

- Link ON X2

55 mV FR

to 150 mV FR

Very Low Transducer

Output - Link ON X4

Table of contents

Other Solartron Metrology Transducer manuals

Popular Transducer manuals by other brands

FuehlerSysteme

FuehlerSysteme FS1580 operating manual

Sensor Technology

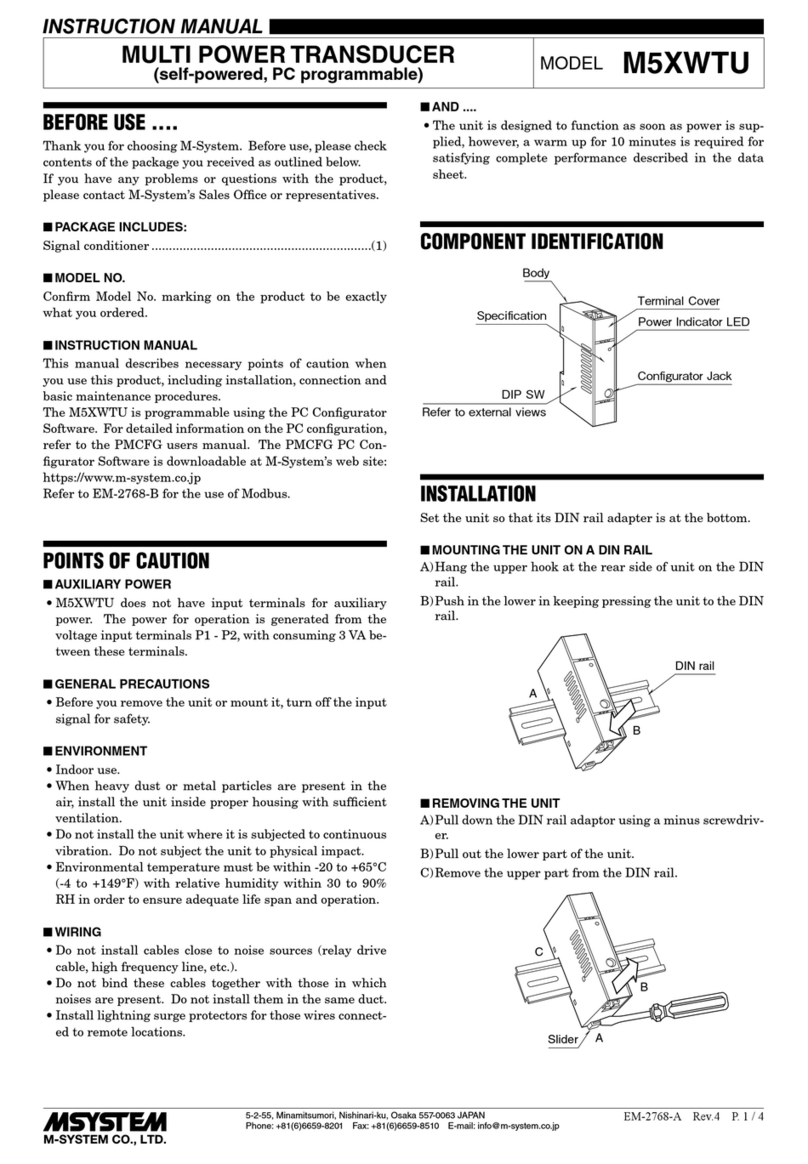

Sensor Technology TorqSense RWT430 Series user manual

Camille Bauer

Camille Bauer SINEAX F 535 operating instructions

GE Oil & Gas

GE Oil & Gas 4411 instruction manual

Simrad

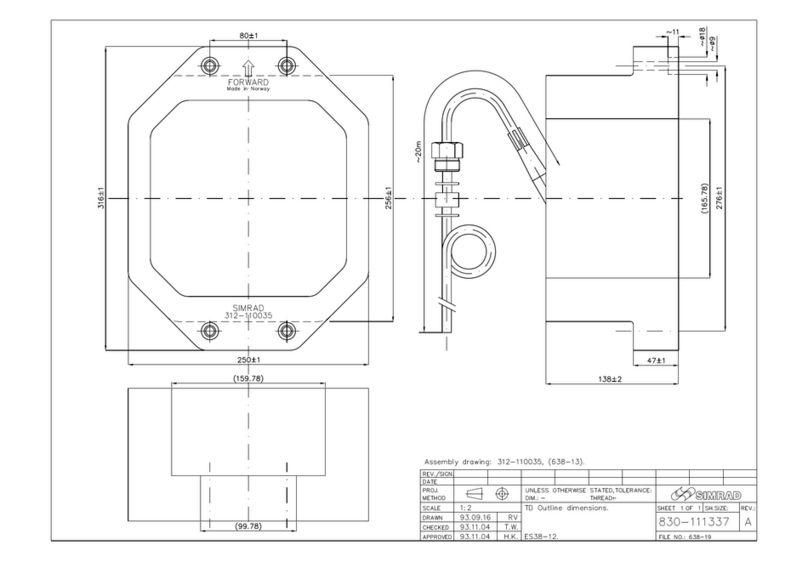

Simrad 710-36E - REV E datasheet

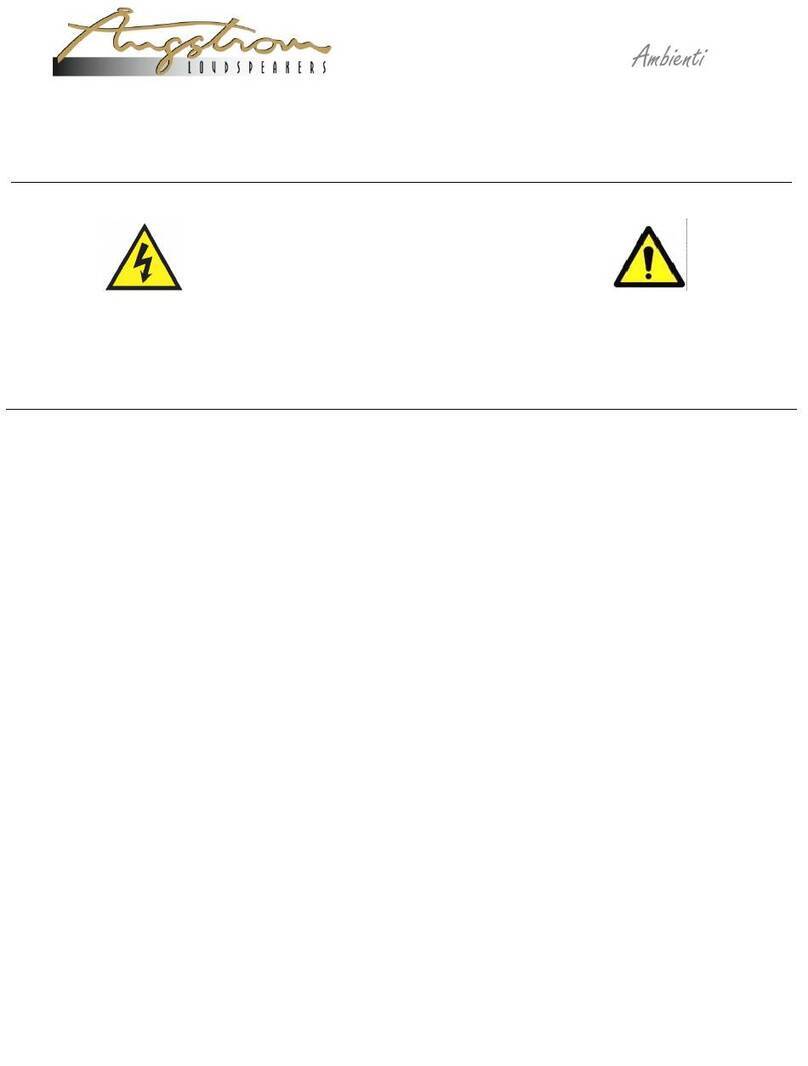

Angstrom

Angstrom ALFT10S-150 Ambienti quick start guide

Camille Bauer

Camille Bauer SINEAX G536 operating instructions

Ultrasound Technologies

Ultrasound Technologies Fetatrack 310 Service manual

Simrad

Simrad 50-200 COMBI C - REV D installation manual

Atlas Copco

Atlas Copco IRTT-B 1A-I06 user guide

Shinkawa

Shinkawa FK F Series instruction manual

Iskra

Iskra iMT440 user manual