Solartron 7091 User manual

7061

SYSTEMS VOLTMETER

OPERATING MANUAL

'ssueC: Nov 1986 Part No. 70610012

Solartron Instruments, Victoria Road, Farnborough

Hampshire, England GU 14 7PW Telephone: Farnborough (0252) 544433

Telex: 858245 Solfar GCables: Solartron Farnborough

solartron pursues apoi'cy of continuous development and product improvement

he specification mthis document may therefore be changed without notice 19©86

Contents

Chapter 1General Information Page

1.1

lIntroduction 1.2

2Accessories 1.2

3The Configuration Switch 1.3

4Options 1.4

5Safety 1.5

6Connecting the ac mains 1.6

Chapter 2Getting Started 2.1

Chapter 3Front Panel Controls 3.1

1Introduction 3.3

2Front/rear switching 3.6

3Measurement keys 3.7

4Range keys 3.7

5Filter key 3.8

6Null key 3.8

7Ratio key 3.8

8Channel key 3.9

9Digits key 3.10

10 Track and trigger keys 3.10

11 General operating keys 3.13

12 Interface keys 3.13

13 Reset +enter &Menu +reset keys 3.14

14 Timer key 3.15

15 Scan key 3.17

16 Delay key 3.18

17 Probe key 3.18

18 Progs key 3.20

19 History key 3.28

Chapter 4Connections &Measurements 4.1

1General 4.2

2Voltage 4.2

3Current 4.3

4Resistance 4.3

5Drift correction 4.4

BRS/7061/2

Chapter 5Remote Control 5.1

1Introduction 5.3

2Remote commands and program names 5.4

3Interface command language 5.6

4Command set- verbose 5.6

5Command set -cryptic 5.37

6Programs 5.40

7Error messages 5.45

8Using the 7061 from the GPIB 5.46

9GPIB functions 5.54

Chapter 6Interference -some causes and cures 6.1

1Introduction 6.2

2Series mode interference 6.3

3Remedial action 6.3

Chapter? Specification 7.1

Chapter 8Calibration 8.1

Appendix AAdopted settings on power-up &reset

Appendix BMeasurement delay &integration times

Appendix COverload indication; display &output

formats

Index

BRS/7061/3

[Chap. 1

1

Chapter 1

General Information

Para. Pa8e

1Introduction 1-2

2Accessories 1-2

3The Configuration Switch 1-3

4Options 1-4

4.1 Scanner option 1-4

4.2 Memory option 1-4

5Safety 1-5

5.1 General Safety Precautions 1-5

5.2 Earthing 1-5

6Connecting the ac mains 1-6

6.1 Voltage Selector 1-6

6.2 Mains Fuses 1-7

6.3 Mains Lead 1-7

6.4 Connection Procedure 1-8

BRS/7061/2 1.1

[Chap. 1|

INTRODUCTION

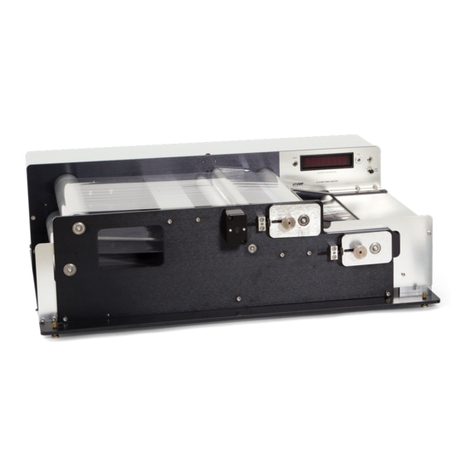

The 7061 combines high speed digital electronics with microprocessor control to provide

afast, accurate systems voltmeter. With channel scanning, timer control and

measurement processing, the 7061 is ideally suited to automated test requirements

using the built-in IEEE 488 interface (GPIB) to give remote control.

The 7061 is equally at home as abench instrument, with scanning, timing and

processing facilities all controllable from the front panel. And, of course, straightforward

voltage, current and resistance measurements are easily made with great reliability and

accuracy.

Chapter 1of the manual deals with details relevant to the installation of the voltmeter.

Rack mounting is dealt with in Appendix D.

To make simple measurements, refer to Chapter 2, 'Getting Started'.

For more advanced measurements using processing facilities, but still under front panel

control, refer to Chapter 3, 'Front Panel Controls'.

To use the 7061 as aremotely controlled instrument via the GPIB, refer to Chapter 5,

'Remote Control'.

For information on making measurements, see Chapter 4.

Chapter 6contains the full specification and chapter 7gives calibration information.

ACCESSORIES

Supplied:

2-terminal input lead

Power lead

Copper crocodile clip (2)

Rack mounting brackets (2)

Operating manual

2-terminal reference lead

Spare fuses

Calibration key

Optional:

High voltage probe 70757

2-

terminal input lead 3187

3-

terminal input lead 3193

5-terminal input lead 3183

Kelvin input lead (4-terminal ohms) 70758 E

Low thermal input lead kit 70758 D

2-terminal reference lead 70617 B

4-

terminal reference lead 70617 D

Temperature probe, insertion PRT 70617 E

Telescopic rack slides (pair) 70759

Technical manual 70610011

1.2 BRS/7061/2

[Chap. 1|

3THE CONFIGURATION SWITCH

The configuration switch is adual in-line switch inside the instrument. Its settings are

shown in Fig. 1.1, with the example showing 50 Hz line frequency and 8channel

operation selected.

(5) SPARE

(4) SPARE

(3) 16/8 CHANNEL

(2) SPARE

(1) LINE FREQUENCY..

(0) LINE FREQUENCY..

1

—

Inn imt=m

M“=I i=*i

50 Hz 400 Hz 60 Hz 50 Hz

Fig. 1.1 Configuration switch settings

To reach the switch, disconnect the instrument from signal inputs and from the mams

supply before removing the top panel. This is held in place by four screws. The switch is

just behind the front panel, to the left of centre, as shown in Fig. 1.2. If the memory

expansion board is Fitted, this will have to be removed in order to reach the switch. It is

held in place by three screws.

Fig. 1.2 Plan view showing position of configuration switch

BRS/7061/2 1.3

[Chap. 1]

4OPTIONS

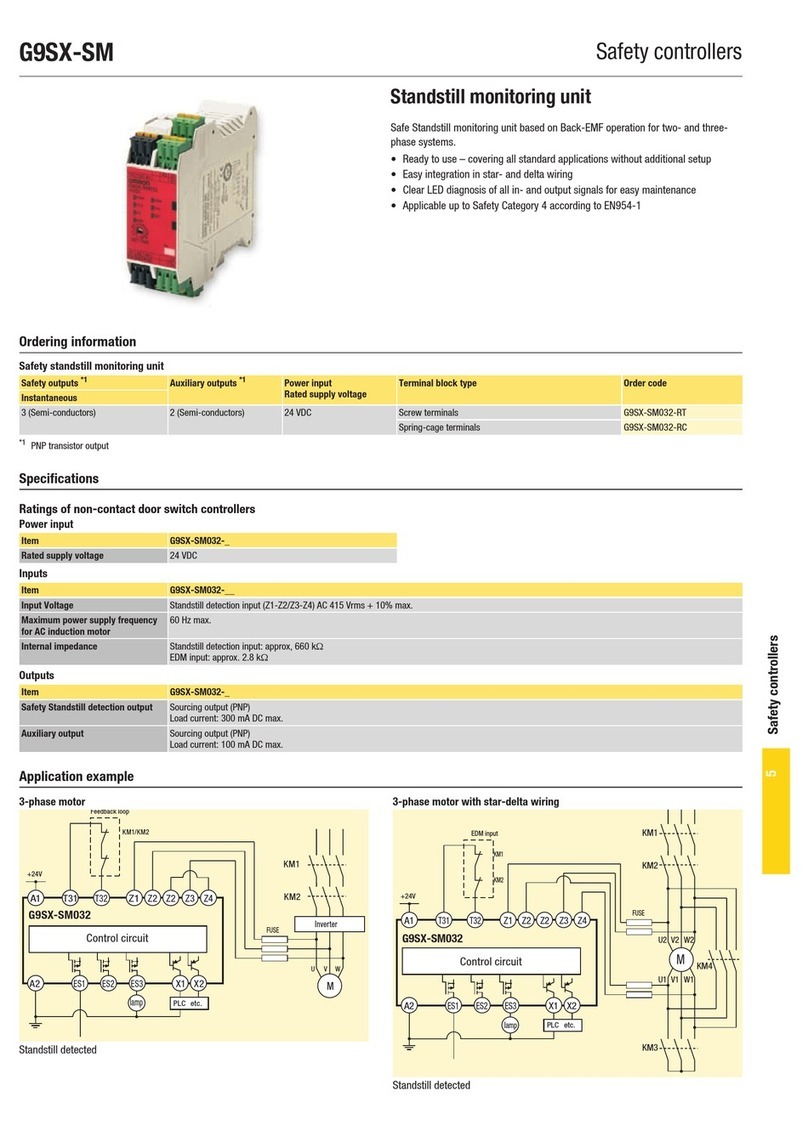

4.1 70612A SCANNER OPTION

The scanner option increases the number of physical input connectors on the instrument

from 2to 10 (plus current input). There are then 8, 4-pole or 16, 2-pole extra channels

available, depending on the selection made using the configuration switch.

1) HI ohms source

2) LO

3) LO ohms source

4) HI

5) Not used

Fig. 1.3 Rear panel view ofconnector socket, 8channels selected

1) HI (channels 10-» 17)

2) LO (channels 2-* 9)

3) LO (channels 10 17)

4) HI (channels 2-» 9)

5) Not used

Fig. 1.4 Rear panel view ofconnector socket, 16 channels selected

Input plug :

SwitchcraftTA5FL

(Solartron no. 351505030)

More details are given in the sections on the CHANNEL and SCAN keys and the

CHannel and SCan commands.

4.2 70613A MEMORY EXPANSION OPTION

The memory expansion option increases the measurement buffer from 1000 to 8000

memory locations.

1.4 BRS/7061/2

[Chap. 1

1

5SAFETY

The 7061 has been designed in accordance with the IEC publication 348 (Class 1), 'Safety

Requirement for Electronic Measurement Apparatus', and has been supplied in asafe

condition. This operating manual contains information and warnings which must be

followed in order to ensure safe operation and to keep the equipment in asafe condition.

The operating instructions include safety precautions where appropriate, but the

principal ones are also listed below.

5.1 GENERAL SAFETY PRECAUTIONS

1. Before switching on, ensure that the mains lead is connected to the ac supply in

accordance with the colour code.

2. Ensure that the mains voltage selector is correctly set.

3. Ensure that the mains plug is connected only to amains outlet which has a

protective earth contact. This applies equally if an extension lead is used: the lead

must contain an earth conductor.

4. For earthing, the mains plug must be inserted before connections are made to

measuring and control circuits. The mains plug or external earth (as appropriate)

must remain connected until all measuring and control circuits have been

disconnected.

5. Any interruption of the earth connection (inside or outside the 7061) is prohibited.

6. When the 7061 is connected to its supply the opening of covers or removal of parts

couid expose live conductors. The 7061 should be disconnected from all voltage

sources before it is opened for any adjustment, replacement, maintenance or repair.

Adjustments, maintenance or repair of the 7061 when it is powered should not be

attempted. Consult aSolartron Service Centre if repairs are necessary.

7. Ensure that fuses of the correct rating and of-the specified type are Fitted. Makeshift

fuses, and short-circuiting of fuse holders, is prohibited.

8. Whenever it is likely that the safety of the 7061 has been impaired, it should be

switched off and not used again until repaired. Safety could be impaired if the 7061:

a. shows visible damage

b. fails to perform intended measurements

c. has been subjected to prolonged storage under unfavourable conditions

d. has been subjected to severe transport stress.

9. The 'A' and Tsymbols on the 7061 mean 'Refer to Operating Manual' for detailed

instructions or safety precautions.

5.2 EARTHING

For safety, an earth connection is essential whenever measurement and control circuits

are connected, even if the 7061 is switched off. The instrument is earthed by connecting it

to amains outlet or other suitable earthing point. This earth should be capable of

carrying 25 Aand conform to the regulation in 'British Standard Code of Practice CP10 13

1965, Earthing'.

BRS/7061/2 1.5

(Chap. 1|

CONNECTING THE AC MAINS

lever flap open

from here

The 7061 is fitted with amains unit (Fig. 1.5) containing two mains fuses, and avoltage

selector. These items cannot be accessed until the mains connector has been unplugged

from the unit.

VOLTAGE SELECTOR

The following table gives the correct selector setting for different mains voltage ranges

(nominal 50Hz or 60Hz):

Mains Voltage

Variation Range

90-110V

108- 132V

198 -242V

216 -264V

Voltage Selector

Setting Required

100V

120V

220V

240V

In cases of doubt, set the voltage selector to the lower of the two possible values to ensure

that all 7061 internal voltage levels are fully attained.

To change the selected voltage:

1. Unplug the mains connector from the unit.

1.6 BRS/7061/2

[Chap. 1]

2. Lever open the hinged flap with ascrewdriver and lift out the voltage selector roller

block.

3. Refit the block with the chosen voltage value facing outwards.

4. Close the flap securely, checking that the correct value shows through the aperture.

5. Plug in the mains connector again.

6.2 MAINS FUSES

Live and Neutral are both fused in the 7061. Fig. 1.5 shows how these fuses are accessed,

after the mains connector has been unplugged. The arrowheads marked on each

fuseholder must align with those on the flap when the fuesholders are refitted.

The fuse values are:

200 mA, SLO-BLO for 220V or 240V operation

400 mA, SLO-BLO for 100V to 120V operation

Relacement fuses must be 20mm x5mm cartridge type.

6.3 MAINS LEAD

An appropriate ac mains connector lead, complete with amating socket for the IEC plug

on the 7061 mains input unit, is supplied according to the destination country.

This lead should be connected to the ac supply according to the following colour code:

BROWN =LIVE

BLUE =NEUTRAL

GREEN/YELLOW =EARTH

An IEC socket and lead other than the one supplied may be used, but it must be correctly

wired as shown in Fig 1.6.

Fig. 1.6 IECpower socket connections

BRS/7061/2 1.7

IChap. II

CONNECTION PROCEDURE

1. Before connecting the supply, ensure that the mains voltage selector on the rear

panel is correctly set, and that the correct fuses are fitted in the mains input unit. If

necessary, the mains power frequency selection can be checked by looking at the

configuration switch (see para. 3).

2. Ensure that the power- on/off switch on the rear panel, next to the mains input unit,

is 'off.

3. Connect the mains lead.

4. Switch the 7061 'on' at the rear panel.

1.8 BRS/7061/2

IChap. 2|

Chapter 2

Getting Started

Getting Started

Page

2.2

BRS/7061/2 2.1

[Chap. 2

1

GETTING STARTED

At first sight, the front panel may appear to be rather complex, but to make simple

measurements of voltage, current and resistance, only afew of the keys are required.

These are some of the keys to the right of the display and the two orange keys near the

bottom left hand corner of the display.

After plugging in to the mains supply, connect atwo-terminal test lead to the input

socket and switch on the machine (rear panel mains switch).

DC VOLTAGE

To measure dc voltage, connect the test leads to the voltage source and make the

following sequence of key pushes, using the keys shaded black on the diagram :

2.2 BRS/7061/2

[Chap. 2|

AC VOLTAGE

To measure ac voltage, the keys used and the sequence of key pushes are as follows :

TRACK

s/

t

Press if TRACK

LED not lit.

Notice that in both of the above measurements, AUTORANGE and TRACK were used.

Using AUTORANGE means that there is no need to worry about selecting the correct

range to match the level of the input signal -this is done automatically.

TRACK gives acontinuous sequence of readings, so the display is continually being

updated.

To get asingle measurement, press TRIG instead of TRACK and the single reading

remains in the display until another one is made.

DC CURRENT

To make asingle reading of dc current, connect the current source to the two 4mm input

sockets on the rear panel and make the following key pushes :

BRS/7061/2 2.3

[Chap. 21

RESISTANCE

Measuring resistance is just as easy. Connect the two terminal test lead across the

unknown resistance then

:

The more straightforward measurements have now been described, but note that there is

akey labelled 'True Q'. This may be used instead of Qwhen thermally induced voltages

and currents could beaproblem, for example, when measuring low resistances in relay

circuits.

There are other keys, 'NULL' and 'FILTER', which also allow more accurate

measurements under certain circumstances. See the chapter on 'Front Panel Controls'

for details of their use. The same chapter describes the functions of all the remaining

keys. Use of these allows great flexibility of measurement and processing of results.

Some of the front panel keys call up menus. In other words, on pressing the key, achoice

of functions is given. Menu keys are shown shaded in the following diagram:

rf=27061 SYSTEMS VOLTMETER

1.234567 KOHM “1 '

Jnj ]iii

i

vone oo

J

As an example, the darker shaded key, the RATIO key, allows the multiplication or

division of the measured value from any channel by the value from any other channel.

2.4 BRS/7061/2

[Chap. 2|

RATIO

Apossible application for RATIO is the direct measurement of power, for example, dc

power:

Connect the current source to the 4mm rear panel input sockets (channel 0current

input). Connect the reference lead (channel 1) so as to measure voltage across the

relevant component. Then

Select channel 0

:

Set up channel 0to read dc current

:

Press either skip key

until 'RATIO CHAN =shows

in the display.

Set channel 1to read dc voltage, autorange

:

Go back to channel 0:

BRS/7061/3 2.5

fChap. 2

1

Now set the ratio function to give the product of channel 0with channel l

:

Press either skip key until

'PRODUCT' shows in the display.

(Note that the vertical arrows to the right of the display mean that 'SKIP' (T i )then

'ENTER' are the next keys to be pressed.)

The display now shows the product of the two channels -in this case, adirect reading of

power. The 'PRD' in the display indicates aproduct reading.

SCANNING

The usefulness of the instrument is increased by its ability to measure more than one

channel on receipt of atrigger. This is achieved using the scan key. Details are

described later in the manual, but asimple scan sequence using channels 0and 1 is

shown here.

First initialise the instrument, then turn track off

:

then ’7061 INITIALISED’

2.6 BRS/7061/2

[Chap. 2

1

Ensure that the GPIB is set to OUTPUT OFF using the following key sequence

Press either skip key

until 'GPIB' shows in

the display.

Then:

t

LA

r-i

ENTER

<>

ENTER

k

1

r1'

'^

1

vJ

Press either skip key The last part of the menu

until 'OUTPUT OFF 'shows is irrelevant to front panel operation

in the display. -simply press ENTER again

Suppose we want to measure ohms both on the main input (channel 0), and on

reference input (channel 1).

Set up channel 0to read ohms

:

Select channel land set it to read ohms

:

BRS/7061/2 2.7

[Chap. 2]

Set up the scan sequence from channel 0to channel 1

:

The display now reads *CHANNEL =0This is the default setting, which in this case

is wanted.

’ENTER' the default setting, then put channel 1into the scan sequence

:

’CHANNEL =END '’CHANNEL =END

'

The scan sequence has now been set up, and it starts each time atrigger is sent or runs

continuously when TRACK is on. The display shows first the reading from channel 0,

then the reading from channel 1.

Before preceding to the next example, turn off the scan sequence by pressing SCAN:

PROGRAMS

The 7061 contains seven programs for processing data. They are described in detail in

chapter 3(Front panel controls) and chapter 5(Remote control). For example, the

OFFSET program adds apre-defined constant to the measured value. For instance, add

10 to each measurement

:

2.8 BRS/7061/3

Table of contents

Other Solartron Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCB Piezotronics

PCB Piezotronics 355B02 Installation and operating manual

Neptune Technology

Neptune Technology TRICON SmartTrol Installation and maintenance guide

Fluidwell

Fluidwell E126-P-EL manual

Veris

Veris E50B1 installation guide

LI-COR

LI-COR LI-3100C instruction manual

PureAire

PureAire 99062 instruction manual