Solid Apollo RGB NeonMini User manual

Other Solid Apollo Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Rime Lite

Rime Lite XB PRIME 3 user guide

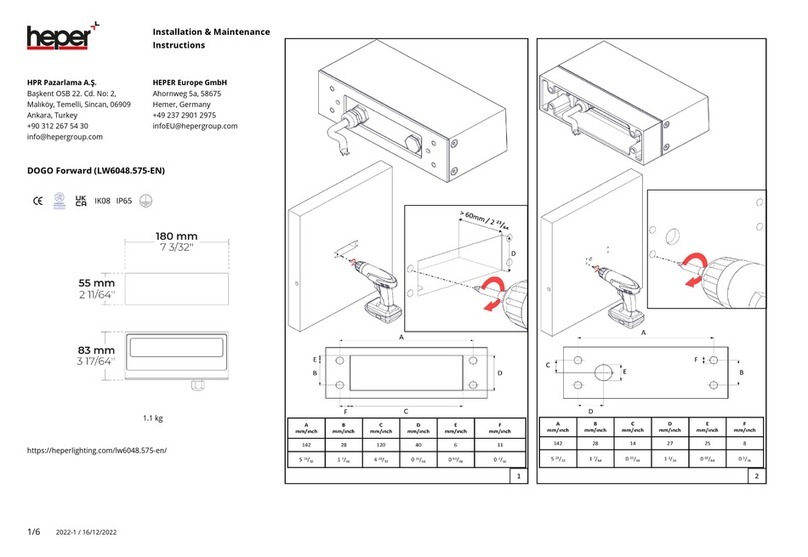

HEPER

HEPER LW6048.575-EN Installation & maintenance instructions

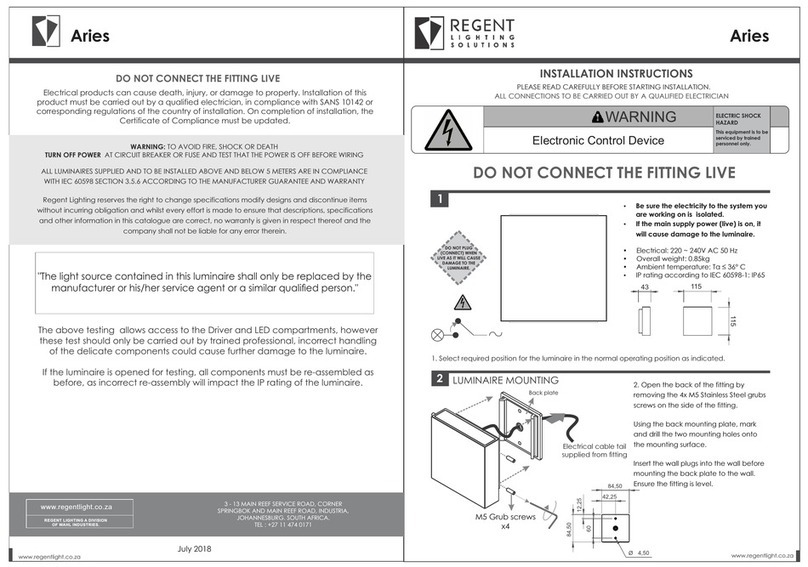

Regent Lighting Solutions

Regent Lighting Solutions Aries installation instructions

Rollei

Rollei Lumen Flex S manual

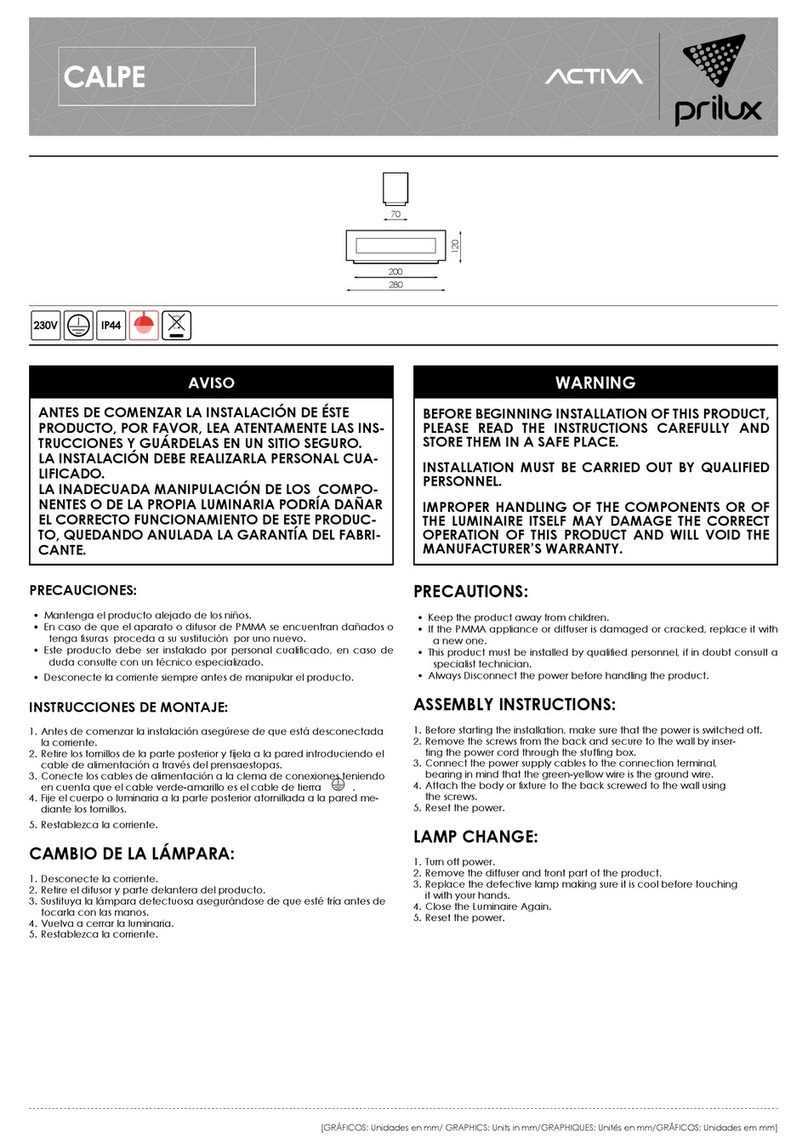

Prilux

Prilux ACTIVA CALPE quick start guide

B-K lighting

B-K lighting PS installation instructions

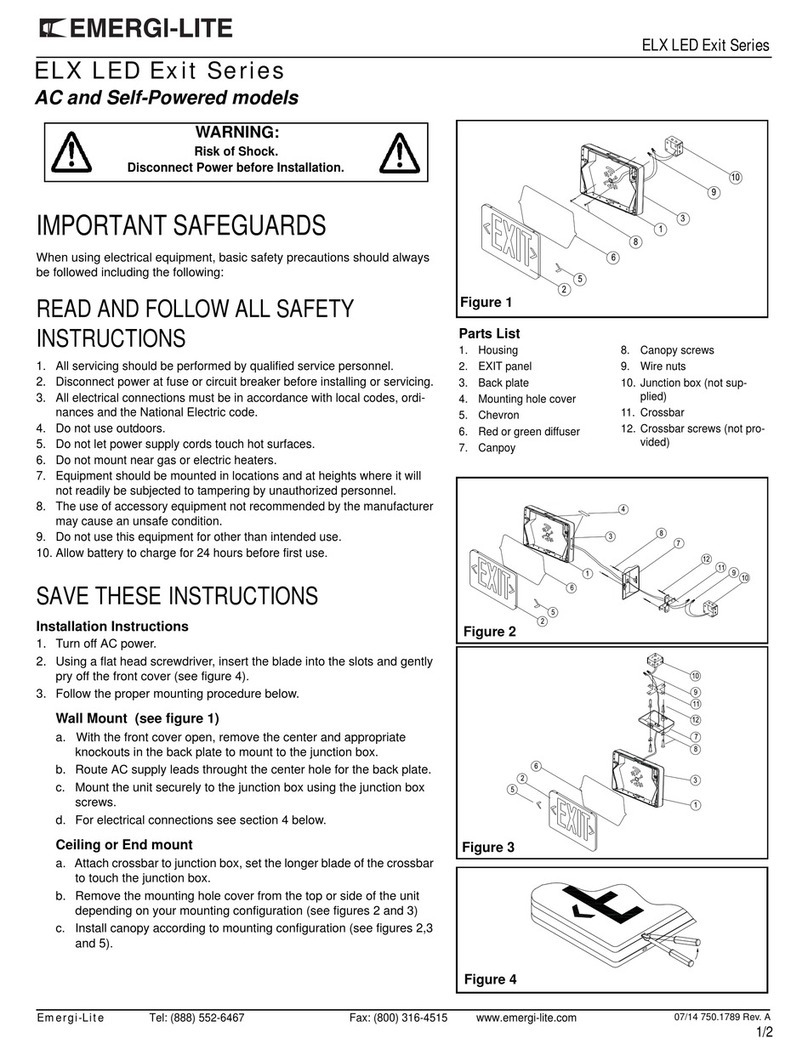

Emergi-Lite

Emergi-Lite ELX LED Exit Series installation instructions

Life

Life 39.9TS042620N user manual

Blizzard Lighting

Blizzard Lighting G-Max 150 user manual

Home Decorators Collection

Home Decorators Collection HD19565TL Use and care guide

Commercial Electric

Commercial Electric PWRW28-4K-BZ Use and care guide

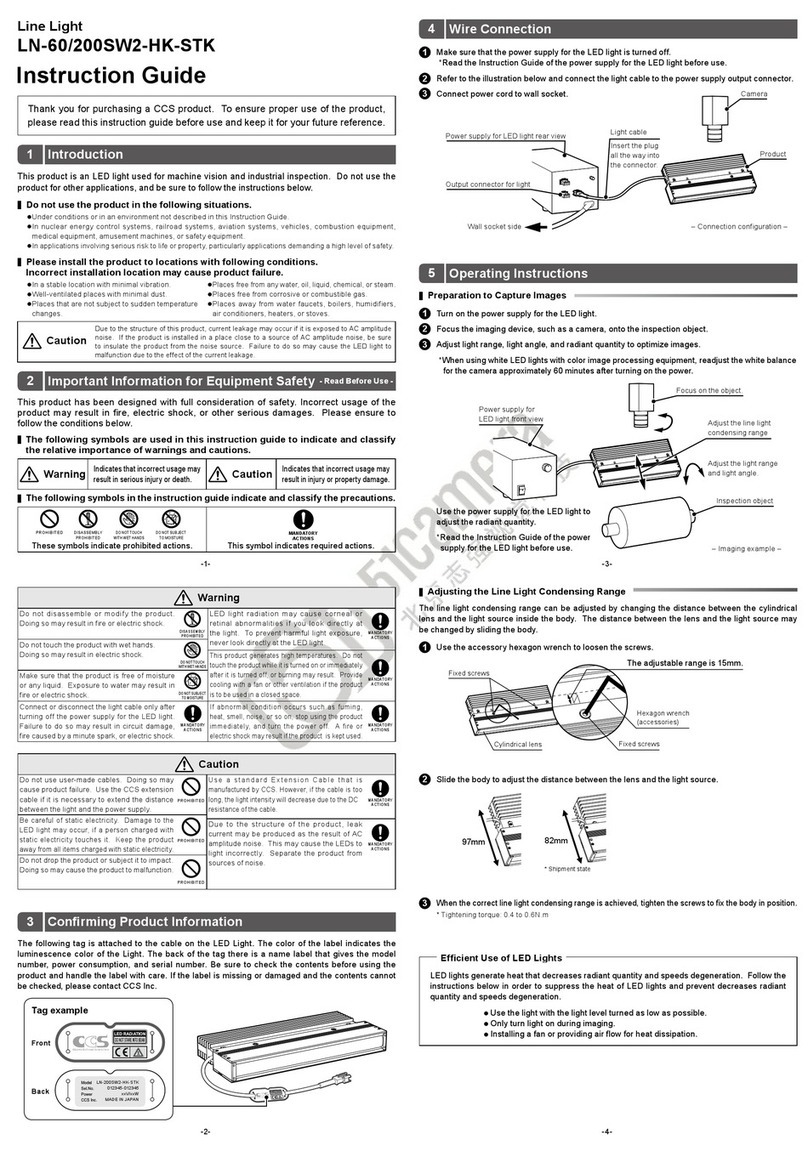

CCS

CCS LN-60/200SW2-HK-STK Instruction guide

Gewa

Gewa PL-78 instruction manual

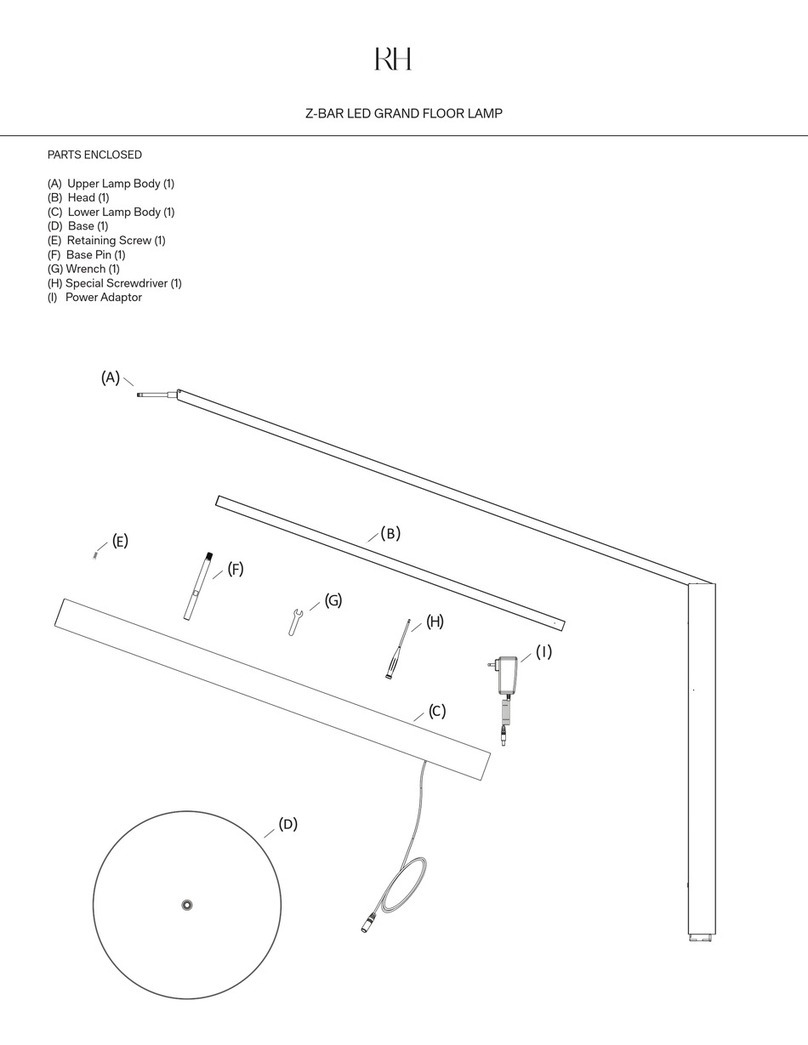

RH

RH Z-BAR quick start guide

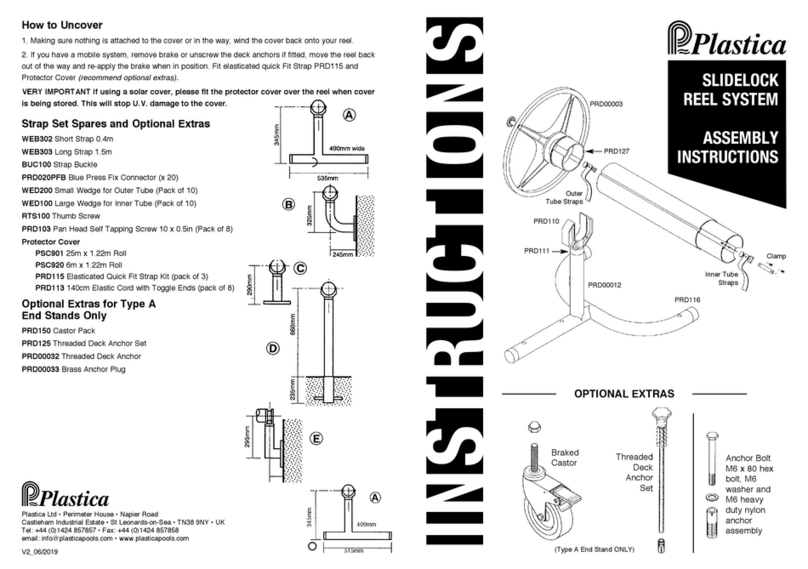

Plastica

Plastica SLIDELOCK REEL SYSTEM Assembly instructions

Larson Electronics

Larson Electronics IND-AHF-CD-UVC-R1-220V-50C instruction manual

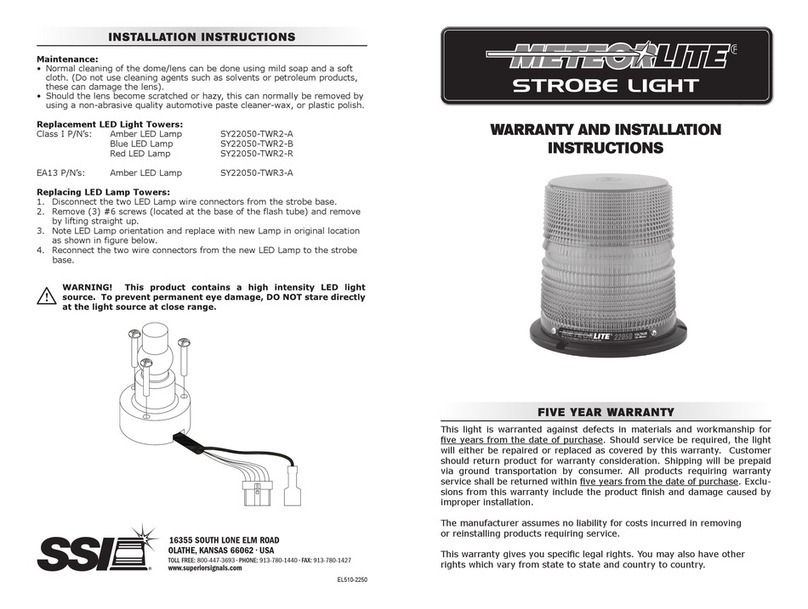

SSI

SSI METEORLITE installation instructions

GAME OF BRICKS

GAME OF BRICKS Real Madrid Santiago Bernabeu Stadium 10299 instruction manual