EDER Maschinenbau ESG1 Guide

EDER bark - stripper

ESG1

for fitting to power saws

Operating Instructions and Spare Parts List

EDER Maschinenbau GmbH

Schweigerstraße 6

DE-3830 Wolfenbüttel

Tel. +49-5331-76046

Fax +49-5331–76048

www.eder-maschinenbau.de

Technical Data

Weight without power saw .5 kg

Drive capacity from 1. kW

Working width 1 0 mm

Knife width 30 mm

Number of knives 4 units

Areas o Application

The bark-stripper is apt for peeling trunks of any strength. The thicker and

harder the bark, the more economical is its application. The constructive

formation of the peeling barrel causes a high chipping performance at minimal

effort. Hard metal pins arranged directly behind the knives are formed in such

a way that the distance of the peeling knives from the trunk wood is observed

automatically, and regardless of the bark strength, on the entire trunk length.

Branch departures and thin branches are easily and cleanly bevelled. The

barrel is straight and moulds a plane area similar to the parer. So, in working

at the side of the trunk and in peeling root departures, the device can be

applied in an angular or diagonal manner. The device may only be used as

intended for the listed operations.

Mounting the bark - stripper to the Chain Saw

The stripper can be assembled to ordinary power saws from 1. kW. The

fitting attached parts for the saws mentioned in the accompanying documents

and bills of delivery are included in delivery. The peeling head carrier is to be

assembled instead of the sword. For assembly, the chain folding plate, sword

and chain pinion must be removed. The chain pinion is replaced by the

coupling barrel with V-belt pulley (0 06). The peeling head carrier (0 01) is

fastened instead of the sword in connection with the chain wheel cap. The

peeling head (0 0 ) is slided onto the peeling head carrier (0 01). The V-belt

is laid onto the V-belt pulley (0 06) of the coupling barrel and the V-belt pulley

(0 04) of the peeling head. The V-belt is prestressed and the peeling head

(0 0 ) is fastened by tightening the clamping screw (0 07). Subsequent

clamping, as with the normal chain, is done with the chain adjuster of the

power saw. Sharp metal edges at the power saw – in the V-belt area – should

be rounded. The supply of chain oil must be prevented by shutting down the

oil pump or by emptying the oil tank.

Starting Operation o the bark - stripper

In this version, the device may only be operated in agriculture and forestry by

instructed persons. The relevant regulations for the prevention of accidents

are to be observed. Apply the bark stripper to the trunk surface at running saw

engine only at full revolution, and lead the bark stripper over the trunk

continuously and without pressure. Should the stripper cut too deep or even

chip, the knives are to be set back by around 0. mm. If the cutting depth is

too short, the knives are to be set forward by around 0. mm. The required

knife adjustment is based on the type of wood to be peeled and must be newly

adjusted as the case arises. It is to be observed that the hard metal pins on

the knife disc (0 11) always stand right to the knife edge. All 4 knives must

have the same adjustment and the same measure to the hard metal pins. Dull

knives can be reground by hand at normal grinding wheels. The edge angle is

40°.

Instructions or Use

Before every application, the trunks to be peeled are to be checked. Nails,

sticky sand and other foreign material must be removed before planing, as

otherwise the peeling knives will be damaged. On actuation, the machine is to

be safely supported and held tight, at which the peeling barrel must stand free.

Apply the peeling device to the plane trunk surface only with the saw engine

running at full revolution. For the use of the saw, read the operating

instructions of the saw manufacturer.

Adjusting the Knives on the EDER bark - stripper

For optimal performance of the bark - stripper, sharp, correctly adjusted knives

are required.

For adjusting, you need the provided hexagonal wrench and proceed as

follows:

1. Lay wrench onto the device as in illustration below.

. Make wrench and hard metal pin touch each other.

3. Hold wrench in this position, now turn back the peeling barrel, until the

knives stand in front of the wrench (viz. illustration)

4. Adjust distance to 0.5 to 1.5 mm.

5. All 4 knives are adjusted in the same way.

6. The clamping bolts for the knives are to be tightened at a torque of at least

35 Nm. A corresponding torque wrench can be obtained from EDER-

Maschinenbau as optional accessory or from the specialized tool trade.

7. The knives may never be positioned beyond the hard metal pins, as the

hard metal pins serve as depth limitation.

8. It’s absolutely necessary, that the hard metal pins show forward in direction

to the knife edge.

Protection rom Accidents

The safe state of the machine is to be checked each time before beginning to

work. This applies, above all, for the condition and the safe fit of the knives

and the fixing elements.

The machine may not be used if damage is noted.

If the machine is not used temporarily or transported, the engine is to be shut

down, or the chain brake to be activated, so that unintentional actuation of the

peeling barrel is avoided.

During operation, no person may stay within the working area of the device.

Splinters flying around are to be anticipated. A safety distance of at least 10 m

to other persons is to be observed.

The machine is to be held tight with both hands at work. A safe stand is to be

ensured at work.

It is to be operated in such a way that emissions are not inhaled as far as

possible. Devices with a combustion engine may not be used in closed rooms.

The machine is to be operated with as little noise and emissions as possible.

For checking the V-belt, subsequent clamping, changing the knives and

removing disturbances, the motor must be shut down.

On fueling the machine, the motor must be shut down, it must not be smoked,

and there must be some distance to open fires.

On working on the slope, it is to be observed that the person operating the

device is standing above or aside the trunk to be worked on.

Instructions or maintenance

Operations of maintenance and repair may only be executed by persons who

possess the necessary knowledge and abilities (e. g. professional workshop).

Before correcting disturbances and on interruptions of work, the entire engine

is to be shut down and its standstill is to be awaited. Apt measures are to be

taken against erroneous actuation and involuntary moves (e. g. pull the plug).

Foreign substance or material parts may not be removed from near moving

parts. Defective connections, or connections no longer valid, may not be

used. Apt tools are to be used for maintenance and installation. Only original

EDER spare parts are to be used or replacement!

Instructions or the Use o Personal Protective Equipment

On operating the bark - stripper, all regulations and security provisions as for

the operation of power saws are applicable. The service personnel must wear

equipment for the protection of the body, especially including eye and face

protection, ear protection, protective gloves and protective shoes. Leg

protection is recommended.

Protective Devices

The machine may only be used with the protective and security devices (e. g.

protective plate) provided for the purpose. Protective and security devices

may not be invalidated and must be cleaned if necessary.

We, the company

EDER Maschinenbau GmbH

Schweigerstraße 6

3830 Wolfenbüttel

declare in sole responsibility that the product

EDER bark - stripper

Type: ESG1

to which this declaration refers, is in accordance with the following standards and normative

documents:

1. EC Directive Machines, Appendix I in connection with DIN EN

9 , Principal security and health requirements at conceiving and constructing

machines

. Check of the centrifugal force according to DIN EN 847 Part 1, Machine

Tools for Woodworking

Attention: The accessory equipment to which this manufacturer’s declaration

refers may only be operated with machines / engines which are in accordance

with the EC Directive for achines and are thus marked CE.

The mount may only be executed to machines / engines which are expressly

named in the accompanying documents / bill of delivery.

Wolfenbüttel, 01/0 / 009

Ulrich Schrader

managing director

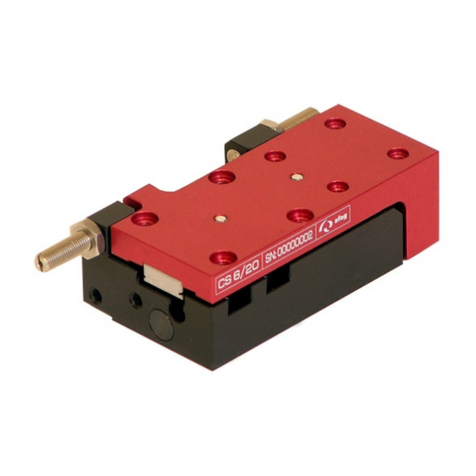

Spare parts list

EDER Bark Stripper for assembly to power saws

including adaptor kit (peeling head carrier + coupling barrel)

06 14 17 15 16 02 07 01 12 13

04 03 18 05 11 10 09

No. ARTICLE NAME No. ARTICLE NAME

01 0201 Peeling head carrier 10 0210 Knife disc

02 0202 Body 11 0211 Knife screw M8 12

03 0203 Peeling barrel 12 0212 Hexagonal wrench DIN

911

04 0204 V-belt pulley 13 0213 Bolt short

05 0205 Protective plate 14 0214 Bolt long

06 0206 Coupling barrel 15 0215 Grooved ball bearing

DIN 625

Washer 17 0217 Retaining ring

07 0207 Clamping screw with 16 0216 Sealing ring/Nilos ring

08 0208 V-belt SPZ 987 lw 18 0218 Protective plate

09 0209 Knife clamping bolt M5x12

With the spare parts marke by * please in icate your type of power saw.

Table of contents

Other EDER Maschinenbau Industrial Equipment manuals