Somat DH-100 Installation and operating instructions

Operation/Service Manual

DH-100 Waste Dehydration System

165 Independence Ct, Lancaster Pa 17601 (Ph:800-237-6628) (Fax:717-291-0878)

To better serve your needs in the future, please record your equipments information

below.

Model Number: DH-100

Serial Number:

Service Company:

Service Phone Number:

Rep/ Dealer:

Rep/Dealer Phone Number:

Somat Service Dept: 800-237-6628

Somat Parts Dept: 800-237-6628

parts@somatcompany.com

To expedite service or parts, please have the above information available before you call.

The serial number of your machine is located inside of the main electrical control panel

for your Somat equipment.

SOMAT COMPANY

LIMITED WARRANTY

SOMAT COMPANY warrants each new product manufactured by it to be free from defects in

material and workmanship under normal use and service, which does not include normal wear

of parts, ("normal use and service", with respect to Pulpers, Presses, water Hydra-Extractors,

Waste Handling and Processing Systems, shall mean the handling only of waste items of the

types listed in the SOMAT®Quotation or Sales Order therefore and within the LIMITATIONS

THEREIN set forth), its obligation under this warranty being limited to repairing or replacing any

part or parts thereof, free of charge INCLUSIVE of labor to remove and replace, f.o.b. factory from

which shipped, which shall, within one year from initial start-up of the SOMAT®System or from

date of original installation of the product if not a system be returned to SOMAT®at the factory

from which shipped, with transportation charges prepaid, and which SOMAT's examination shall

disclose to its satisfaction to have been thus defective. This warranty shall not apply to any

product or part which shall have been repaired or altered by any person not employed or

retained by SOMAT®, so as in the judgment of SOMAT®to affect its operation and reliability, nor

which has been installed, operated, or maintained contrary to SOMAT®OPERATION or

PREVENTIVE MAINTENANCE INSTRUCTION MANUALS or to other written instructions or

drawings approved by SOMAT®, nor which has been subject to misuse, negligence, or accident.

This warranty shall not apply should the SOMAT®System be initially started up without a duly

authorized SOMAT®representative present.

EXCEPT AS HEREIN EXPRESSLY STATED, NO WARRANTY, EXPRESS, IMPLIED OR BY LAW,

(INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE), IS MADE BY SOMAT; AND IN ANY EVENT SOMAT’S

LIABILITY, WHETHER IN CONTRACT, TORT, STRICT LIABILITY, OR UNDER ANY WARRANTY, OR

OTHERWISE, SHALL NOT EXCEED THE PURCHASE PRICE RECEIVED BY IT AND SHALL IN NO

EVENT INCLUDE ANY CONSEQUENTIAL, INCIDENTAL, PUNITIVE OR OTHER SPECIAL

DAMAGES.

NO CHANGE IN THIS WARRANTY AND LIMITATION OF LIABILITY AND NO SUBSTITUTE

THEREFORE (WHETHER INCORPORATED IN A PURCHASE ORDER OR OTHERWISE) SHALL BE

EFFECTIVE UNLESS SPECIFICALLY SET FORTH IN A WRITTEN INSTRUMENT SIGNED BY AN

OFFICER OF SOMAT®.

Rev. 02/10

!WARNING!

Customer action required!

All DH products require quarterly

bearing maintenance. Failure to

properly inspect the bearings and

automatic greaser may result in

premature failure and costly

downtime.

!WARNING!

Table of Contents:

DH-100

Introduction……………………………………………………………………………..

Safety Instructions

General Description & Definitions

Installation………………………………………………………………………………..

Quick Guide

Start-up……………………………………………………………………………………..

Forms & Lists

Warranty Validation

Operation…………………………………………………………………………………

Cleaning & Maintenance……………………………………………….

Maintenance

Troubleshooting

Replacement Parts………………………………………………………….

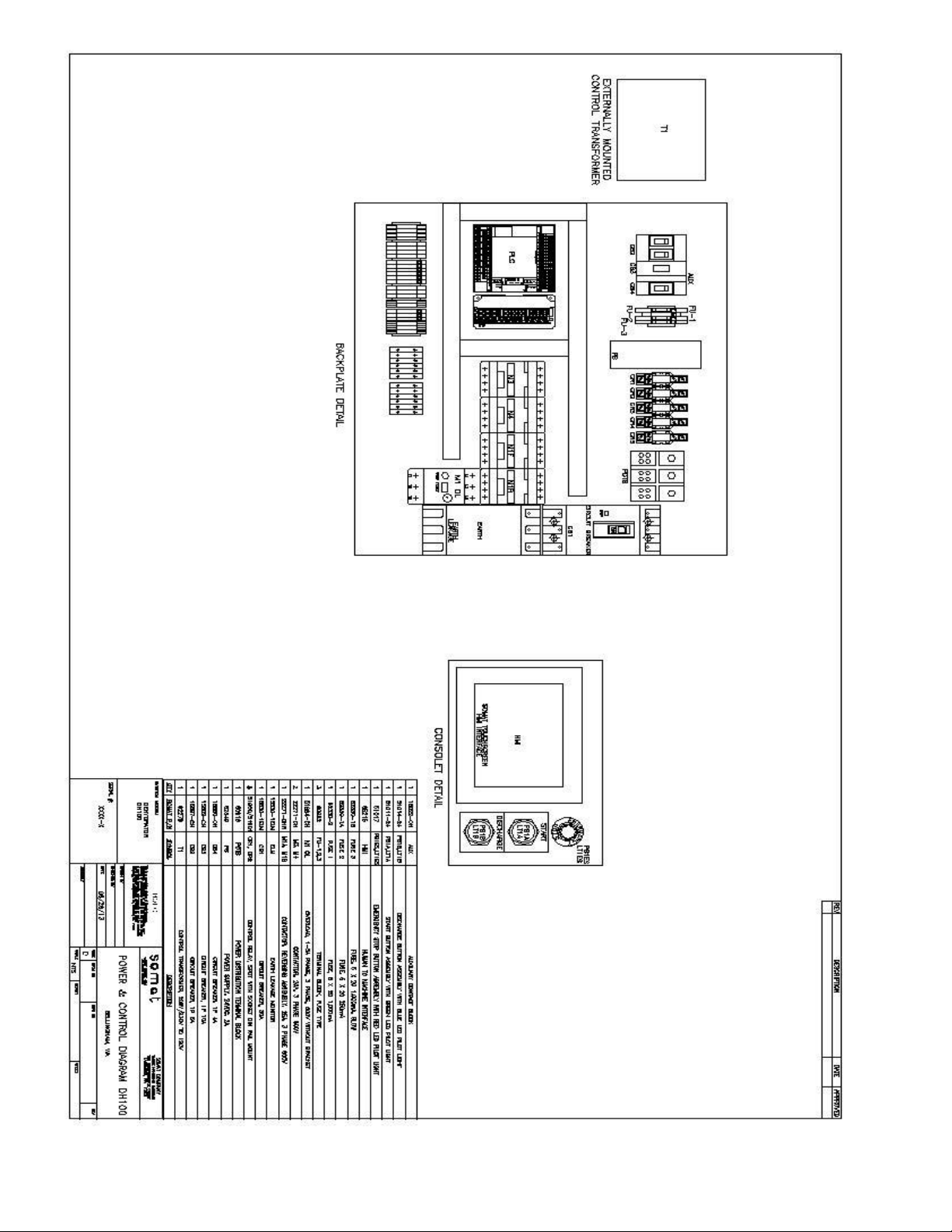

Electrical Panel

Safety Precautions and Warnings

READ THE MANUAL

COMPLETELY BEFORE ATTEMPTING TO OPERATE THE UNIT.

HIGH VOLTAGE!

DO NOT PERFORM ANY REPAIRS TO MOTORS OR CONTROL SYSTEMS

WITHOUT TURNING OFF THE MAIN POWER.

ALWAYS

TURN THE MAIN POWER OFF

AND LET ALL MOTORS COME TO A STANDSTILL

BEFORE DOING ANY MAINTENANCE ADJUSTMENTS OR CLEANING OF THE UNIT.

BEFORE STARTING, BE SURE

ALL PERSONNEL ARE CLEAR

OF MOVING PARTS.

KNOW LOCATION AND FUNCTIONS OF ALL

START/STOP BUTTONS

AND SAFETY

SWITCHES.

DURING PERIODIC MAINTENANCE,

CHECK ALL SAFETY SWITCHES

TO BE SURE THEY

ARE OPERATING PROPERLY.

DO NOT REMOVE

OR ALTER GUARDS.

DO NOT REMOVE

SAFETY LABELS. IF LABELS ARE MISSING OR DESTROYED, CONTACT

FACTORY FOR REPLACEMENT.

DO NOT OBSTRUCT

ELECTRICAL PANELS OR PUSH BUTTONS.

GOOD HOUSEKEEPING

IS THE MOST IMPORTANT SAFETY PROCEDURE.

The unit shall be installed in accordance with national and local wiring regulations and all

applicable codes.

The unit MUST be placed at least 8” from the wall

DO NOT pull or alter power cord. Pulling and misuse of the power supply cord can result in

damage to the unit and cause electrical shock.

Ensure the electrical cord is properly grounded.

DO NOT place any materials on top of unit

DO NOT use water to clean the unit, use an approved stainless equivalent.

DO NOT alter the pre-programmed settings or disassemble the unit without first contacting

Somat Company. Failure to do so may result in a voided warranty.

Turn off incoming power to unit and lockout breaker to perform any kind of maintenance or

cleaning.

DO NOT open the input door during operation, it can cause odor issues and errors in the

automated control and operation.

Ensure the unit and the area around the unit is clean. Proper maintenance of the unit is also

highly recommended.

Please have ALL operators read this manual to ensure proper understanding of the unit and

its operation.

Safety Precautions and Warnings

This equipment has locations which are hazardous and cause severe injury or death if

warnings are not followed. Always turn off power before reaching into any unit!

Maintenance to be performed by trained and authorized personnel.

This equipment has moveable lids

protecting you from moving parts. Do not

alter safety devices or guards. Do not reach

into any part of the unit with the power

turned on.

This equipment uses High Voltage! Only

trained and authorized personnel should

perform maintenance on the electrical

components of this machine.

This equipment has moving parts that can

crush and cut. Do not alter safety devices or

guards. Do not reach into any part of the

unit with the power turned on.

Caution: Damage will occur to this equipment if unsafe objects are fed into the

machine(s). Keep these items out of the machine(s) to avoid component failure and

unwanted downtime. When in doubt, keep it out of the machine(s)!

Glass, Bottles, Jars

Cans Silverware

Metal of any kind !

China Pans Wood

Towels / Rags Scrub-Pads

Always turn the power off before servicing the pulper!

GENERAL DESCRIPTION

The DH-100 is an automated on-site compostable waste dehydration

system that dehydrates compostable waste using an energy-efficient

and automated control process. The system requires no enzyme,

additives or fresh water during the entirety of the dehydration process.

The system is equipped with water recycling technology that uses the

condensate runoff to control the humidity in the processing chamber

during the process. The system also recycles the heat energy reducing

overall energy consumption. The dehydration processing time will vary

depending on the waste input but will be no longer than 24 hours. The

system is equipped with an odor management device to control odors

associated with the dehydration process. The one-touch control is fully

automatic, sensing the status and providing feedback and control of the

operation without pre-setting the timer.

Installation

UNPACKING

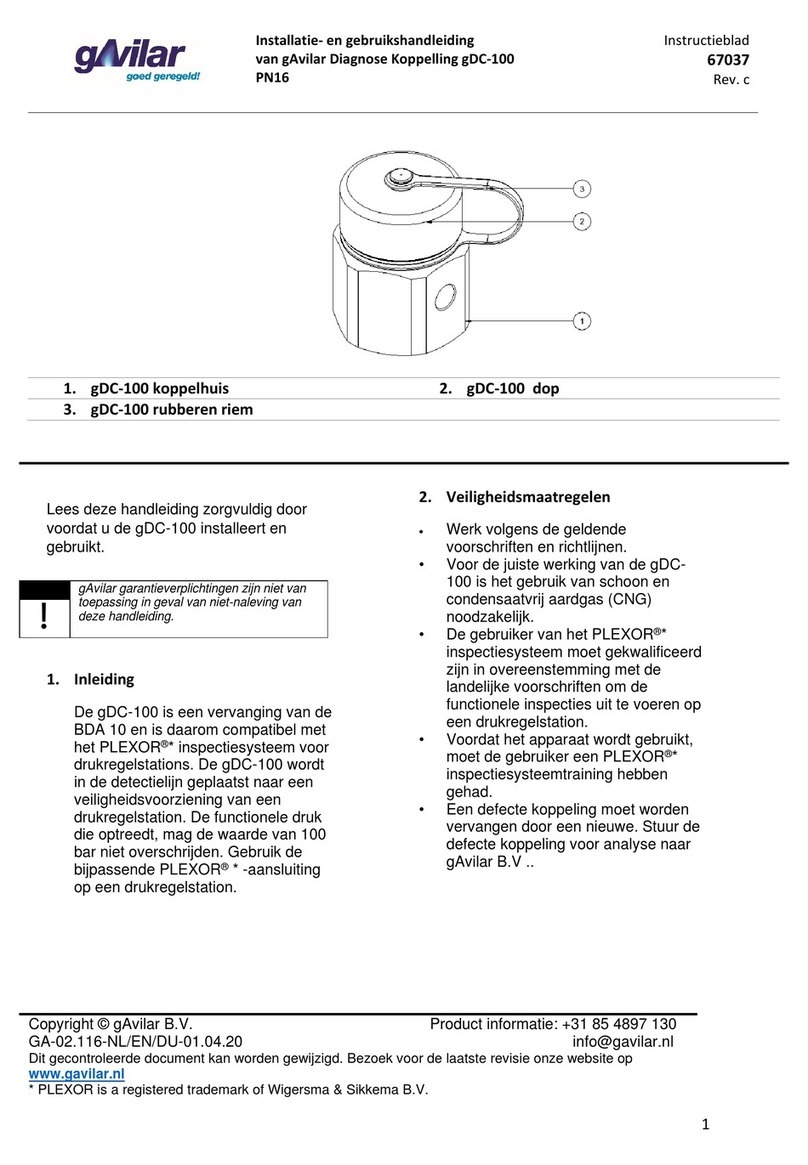

The crate containing your SOMAT®DH-100 will contain the following items:

DH-100

Condensate Hose

10’ of 10/4 SO Power Cord

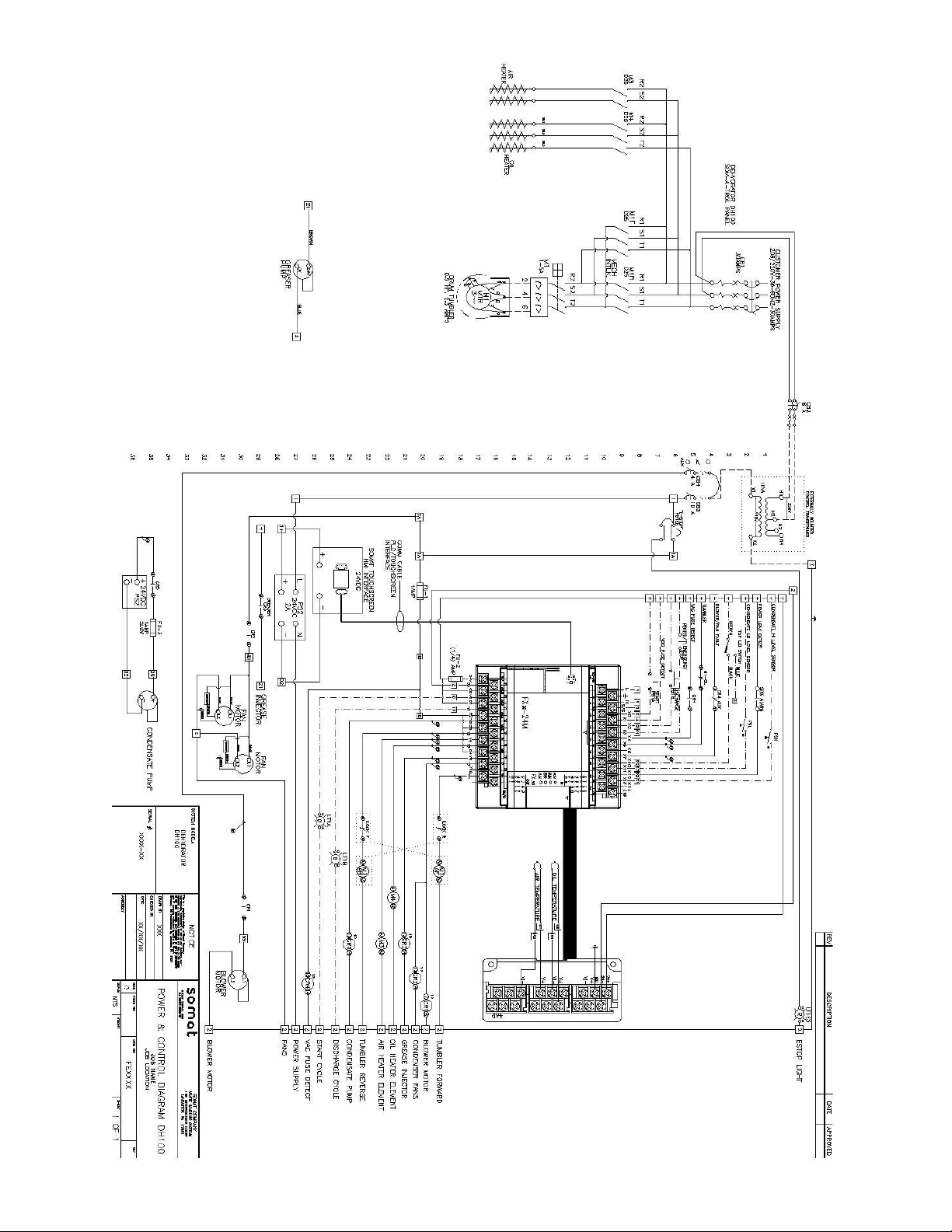

ELECTRICAL INSTALLATION

SUPPLYING THE SOM-A-TROL®WITH POWER

Use the supplied power cord to attach your own 3 phase plug or hardwire to a

location of your choice.

Improper connection of the equipment grounding conductor can result in a risk of

electrical shock. An equipment grounding conductor must be run with the circuit

conductors and connected to the pulper/extractor grounding terminal.

DH QUICKLIST

CHECK SHAFT ROTATION:

*Looking at side electrical panel*

Counter-clockwise rotation for NORMAL operation

Clockwise rotation for EMPTY

CHECK DRAIN LINE:

Make sure drain line is not kinked, damaged, or obstructed in any way.

Condensate is pumped out of the system, if line is blocked backups will

occur.

CHECK ELECTRICS:

Use the touch screen for all controls. Pushbuttons are for emergency

backup. All set-points are preset at the factory. Call Somat if these set-

points need to be adjusted.

CHECK CLEARANCE:

Make sure unit is placed NO CLOSER than 8” from a wall. Proper air

circulation is required.

CLEAN AIR FILTER:

EVERY CYCLE!!

CLEAN GASKET AREA:

EVERY CYCLE!!

Start Up

After installation is complete, your equipment will be started up by a qualified

Somat service representative. This start up will get your unit running in

accordance with Somat guidelines. The equipment may be demonstrated to you

by the service company or the equipment rep themselves.

The Somat equipment carries a 1 year warranty from date of start up. To

accurately track this information, we ask that you fill out the Warranty Registration

Sheet below and fax back to us. This will ensure your equipment is registered

with Somat’s Service Department and will allow Somat’s Service Department to

efficiently process a warranty claim if one should arise.

You will also find copies of instructions for the equipment operators if the

originally packaged laminated sheets are lost or damaged.

WARRANTY REGISTRATION FORM

Serial # :

Model # : DH-100

Date of Start Up: ________/_________/__________

Customer Name:___________________________________________________________

Address:__________________________________________________________________

City:_____________________________ State:____________ Zip:______________

Contact Name:_____________________________________________________________

Contact Number:________________________ Fax:______________________________

Service Company:__________________________________________________________

City:______________________________ State:_____________ Zip:_____________

Please fax to:

Somat Company Service Department

717-291-0878

OR send with startup paperwork.

WARRANTY REGISTRATION FORM

Operation

OPERATING INSTRUCTIONS

After the unit has been connected to the proper power source, the proper rotation of the

augers has been verified and the drain line has been routed its desired drain location,

you are ready to process.

Please use the touch screen for all operation commands described below. The

push buttons should only be used if the touch screen becomes inoperable.

Open the top lid, clean the screen filter and make sure the front discharge door is

closed. Load the product to be processed into the dehydrator. The maximum fill

level would be to the top of the paddles attached to the auger.

Close the top lid.

On the touch screen you will have access to the Batch Control screen. Simply press

the Batch Start button, confirm that you have cleaned the filter and the unit will run

until the cycle is complete. The green light on the start button will show a steady

green light.

Other miscellaneous monitoring information is displayed on this screen and is not

necessary for daily operation. These are explained in further detail in the Screens

section of the manual.

When the unit has completed the batch it will automatically enter the cooling mode.

The green light on the start button will begin to blink and the timer on the touch

screen will begin to count down the time left for the cooling cycle.

When the cooling cycle is complete a suitable container should be placed under

the discharge door on the front of the unit and the discharge door opened. Press

the End of Batch Discharge button to begin the discharge process. This process

will shut off automatically. Close the discharge door.

You are now ready to start a new batch.

If any troubles occur during the processing of a batch, the unit will shut down and

an alarm banner will be displayed on the touch screen indicating the issue and

the probable cause. Please refer to the Screens section of the manual for further

details.

Other manuals for DH-100

1

Table of contents

Other Somat Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Soosan

Soosan SB Series Operations manual & parts list

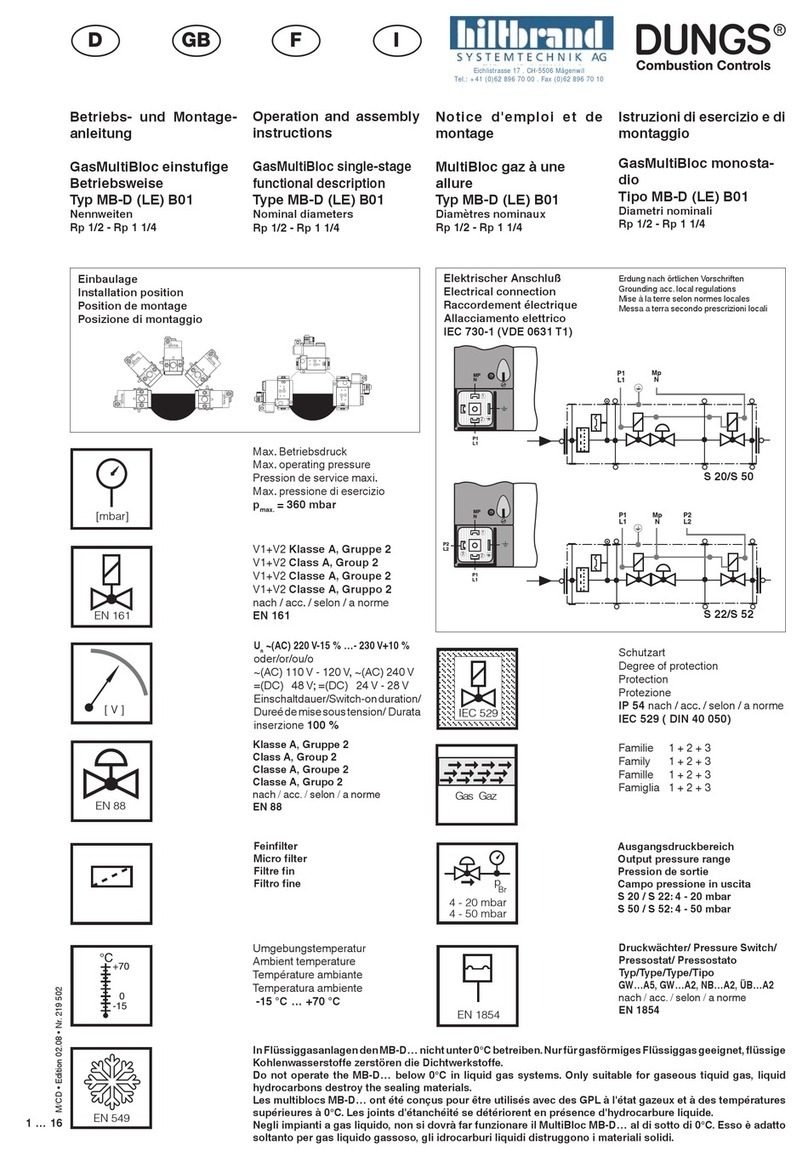

hiltbrand

hiltbrand DUNGS MB-D LE B01 Operation and assembly instructions

Formulatrix

Formulatrix MANTIS user guide

HAITAI

HAITAI HTW320 manual

ITEM

ITEM KLE 5 40x40 LR Notes on Use and Installation

Viessmann

Viessmann Vitodens 200-W System Replacement instructions