SONOPAN LMC-10 User manual

November 2018

CONTACT LUMINANCE METER

LMC-10

INSTRUCTION MANUAL

PPUH SONOPAN sp. z o.o.

ul. Ciołkowskiego 2/2 15-950 Białystok Poland

phone /fax: +48 85 742 36 62

sonopan@sonopan.com.pl

http://www.sonopan.com.pl

TABLE OF CONTENTS

1. CHARACTERISTICS ...................................................................................................................... 1

1.1. Equipment.............................................................................................................................. 1

1.1.1. Basic accessories ........................................................................................................... 1

1.1.2. Additional accessories ................................................................................................. 1

1.2. CONFIGURATION ................................................................................................................. 1

1.2.1. Components of luminance meter .............................................................................2

1.2.2. Measurement module.................................................................................................. 3

1.3. Technical data ....................................................................................................................... 3

1.3.1. Spectral characteristics................................................................................................ 3

1.3.2. Directional characteristics .......................................................................................... 4

1.4. Temperature compensation.............................................................................................. 4

1.4.1. Compensation of zero indication .............................................................................. 5

1.4.2. Temperature compensation of the result...............................................................5

2. THE LMC-10 METER OPERATION............................................................................................5

2.1. Preparations .......................................................................................................................... 5

2.2. Measurement ........................................................................................................................ 5

3. BASIC FUNCTIONS OF CONTROL UNIT ................................................................................. 6

4. EXTENDED FUNCTIONS OF CONTROL UNIT........................................................................ 6

4.1. Access to extended functions of control unit............................................................... 6

4.2. Application: Medical monitors .......................................................................................... 7

4.3. Application: Measurements memory ..............................................................................7

4.4. Application: Advanced ........................................................................................................ 7

4.4.1. Relative measurement................................................................................................. 7

4.4.2. Integration ...................................................................................................................... 7

4.4.3. Statistics .......................................................................................................................... 7

5. CALIBRATION AND ADJUSTMENT..........................................................................................7

6. MAINTENANCE RECCOMENDATIONS ................................................................................... 8

7. FIRMWARE .................................................................................................................................... 8

8. CE MARKING AND WEE DIRECTIVE ........................................................................................ 9

- 1 -

1. CHARACTERISTICS

The SONOPAN LMC-10 contact luminance meter is designed for the luminance

measurement of the self-luminescent surfaces such as monitor matrices TV sets

negatoscopes reading panels etc. The meter ensures the accurate measurement

regardless of the spatial distribution of the measured luminance and the backlight

system of the surface being tested. It is indispensable f r the c ntr l f the medical

imaging m nit rs and negat sc pes. Its unique optical and measurement systems in

combination with the advanced algorithms of the measured signal processing guarantee

high accuracy and repeatability of measurements.

Owing to its technical parameters the LMC-10 meter is classified as a class A meter

according to DIN 5032-7 and TC-2.2 CIE.

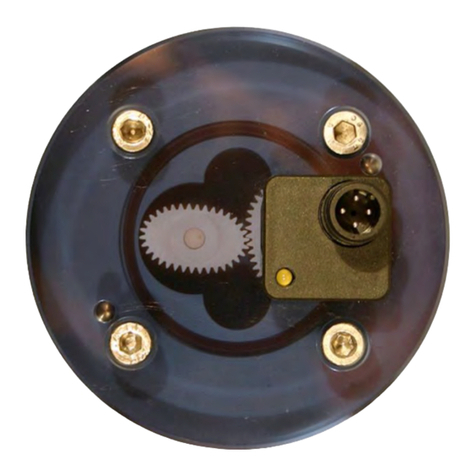

The meter consists of the measurement probe cooperating directly with the

SONOPAN P-200 control unit and with the SONOPAN RF-200C and the USB with a PC or

a tablet. The measurement probe is equipped with the multifunctional key that is used

to trigger a measurement save results and operate the chosen measurement procedure

e.g. to test the reproduction of the grayscale of monitors according to DICOM GSDF 1)

function. The function of the key can be dependent on the running application of the

control unit.

1.1. Equipment

1.1.1. Basic access ries

Components of set Set with

P-200 control unit Set with PC

LMC-10 measurement probe + +

Stabilizing cap Ø50mm + +

P-200 control unit + –

RF-200C interface – +

USB cable – +

RF200C software – +

Instruction manual + +

CE Declaration of Conformity + +

Warranty card + +

Carrying case + +

1.1.2. Additi nal access ries

Tablet 10" (concerning the set with a PC).

1.2. CONFIGURATION

The SONOPAN P-200 control unit or the RF200C software can be used to control the

LMC-10 contact luminance meter and read the measured values. In the former case the

probe is connected directly to the control panel while in the latter case it is attached to

the USB 2.0 port with the use of the RF-200C interface. As far as PCs are concerned it is

required to use Windows XP or higher. As for tablets they should be equipped with

Windows 10. The RF200C does not work yet with such systems as Windows CE Android

or iOS.

1) DICOM GSDF: Grayscale Standard Function according to PS 3.14-2011 Digital Imaging and

Communications in Medicine (DICOM) Part 14: Grayscale Standard Display Function.

- 2 -

The LMC-10 meter is powered with the use of the control unit.

Both configurations are shown in Fig. 1 and Fig. 2.

Fig. 1. Configuration of the LMC-10 measurement probe with the P-200 control panel.

Fig. 2. Configuration of the LMC-10 measurement probe with a PC.

1.2.1. C mp nents f luminance meter

configuration with P-200 control unit configuration with a PC / tablet

• LMC-10 measurement probe

• P-200 measurement module

• LMC-10 measurement probe

• RF-200C interface

• RF200C measurement module

Each of the above-mentioned components of the measurement system is identifiable

according to the requirements of ISO/IEC 17025 standard. The LMC-10 measurement

probe RF-200C converter and the P-200 control unit have unique serial numbers. The

measurement modules of the P-200 control unit and RF200C software are marked with

their own numbers of their software versions.

The P-200 control panel and the RF200C software are functionally corresponding to

each other.

- 3 -

1.2.2. Measurement m dule

The measurement module of the P-200 control unit and the RF200C software constitute

a distinct part of the software and contain the procedures that calculate the

measurement result on the basis of the data downloaded from the meter. These include

among others the averaging and rounding-off of the result.

1.3. Technical data

Spectral sensitivity: V(λ) CIE

Measurement field angle: 1º

Measurement field: Ø 10mm

Spectral matching: f1' 2) ≤ 3%

Directional response index: f2g 2) ≤ 3%

Effect of the surrounding field: f2u 2) ≤ 1 5%

Linearity: f3 2) ≤ 0 5%

Temperature coefficient: KT ≤ 0 02%/K

Measurement ranges 3): 500 cd/m2

50 000 cd/m2

Measurement resolution: 0.01 cd/m2 (range 500 cd/m2)

1 cd/m2 (range 50 000 cd/m2)

Total error 4): +10°C – +40°C 2.5%

-10°C – +50°C 3.0%

Power supply: with control unit (5V 25mA)

Environmental conditions

- temperature:

- relative humidity:

-10°C ÷ +50°C

≤90% (without condensation)

Dimensions

- measurement probe:

- interface:

Ø25 x 160mm

Ø15 x 42mm

Measurement probe weight: 150g

RF-200C interface weight: 15g

1.3.1. Spectral characteristics

Very good spectral matching of the detector to the spectral sensitivity V(λ) is realised

with the use of the set of glass absorption filters. Such a solution guarantees high long-

term and temperature stability especially in comparison with the cheaper realisations in

which interference filters are used. The quality of this kind of matching ensures the

accurate measurement regardless of the spectral distributions of the measured

luminous flux which in the used systems of matrix backlights vary to a great extent from

the spectral efficiency of the calibration illuminant and are the main source of errors.

2) ISO/CIE 19476 Characterization of the performance of illuminance meters and luminance meters (this standard

replaces CIE publication 69/1987).

DIN 5032-7 Photometry; Classification of illuminance meters and luminance meters

3) The specified measuring ranges are the minimum values guaranteed by the manufacturer. The actual

values depend on the sensitivity of the detector and the calibration factor and can be even twice as

high.

4) The percentage deviation of the measured value for white light sources with any spectral distribution in

the given operating temperature range. It takes into account all the factors affecting the accuracy of

the measurement (spectral and directional mismatch temperature influence and others). It does not

include the uncertainty of calibration.

- 4 -

Fig. 3. Typical spectral sensitivity of the L 200 probe.

1.3.2. Directi nal characteristics

The unique optical system of the measurement probe ensures an identical assessment

of every point of the tested surface. The special attention should be paid to the fact that

the countersink angle for the cone of rays reaching the detector from every point of the

tested object is identical with the measurement field angle which is unachievable for

standard luminance meters and can become the source of serious measurement errors

for them. Such shape of the beam of rays is the main attribute for the LMC-10

measurement probe and its enormous advantage over other meters available on the

market. Therefore the influence of luminance irregularity of the monitor matrix for

various directions of observations is negligible in the case of the LMC-10 meter.

Fig. 4. Directional response of the LMC 10 probe.

1.4. Temperature c mpensati n

The change in the temperature of the probe influences the measurement result. Due to

the temperature change the other parameters also change and they are as follows :

●detector dark current - shift of zero indication

●offset voltage of the measuring circuit - shift of zero indication

●responsivity of a detector - change of measured quantity value

- 5 -

●gain of the measuring circuit - change of measured quantity value.

Measuring probes are equipped with the temperature sensor and functions that

minimise the influence of the above-mentioned factors on the measured value.

1.4.1. C mpensati n f zer indicati n

Compensation of zero indication occurs after zeroing of the detector or the measuring

circuit. It is realised with the aid of the functions which the LMC-10 probe is equipped

with. For compensation of zero indication it is necessary to use the following commands

of the control device:

• Zeroing of detector. The zeroing procedure of the detector consists in the

measurement of the dark current of the measurement probe detector and its

corresponding temperature. It can be conducted only with the covered reception

field of the probe. The value of the dark current and the temperature of the zeroing

are saved to the memory of the measurement probe.

• Zeroing of measurement system. The zeroing procedure of the measurement system

consists in the direct measurement of the correction that results from the measuring

circuit offset voltage which is deducted from the result. It is automatically conducted

after the probe is connected to the control unit and whenever the detector is zeroed.

The value of the correction and the temperature of the zeroing are saved to the

memory of the probe.

1.4.2. Temperature c mpensati n f the result

Alongside the use of the high-class elements in the design of the meter the LMC-10

probe is equipped with the automatic compensation system of the influence of the

environmental temperature on the measurement value. The temperature in which the

calibration is conducted is the reference to the correction factor being then calculated

for the current temperature. The influence of the ambient temperature on the

measurement value is virtually possible to be omitted for typical usage.

2. THE LMC-10 METER OPERATION

2.1. Preparati ns

• Connect the LMC-10 probe to the control unit according to its instruction manual.

• Start the measurement.

• Check the zero indication with the covered reception field of the probe and

alternatively conduct zeroing of the detector.

• Remove the cap from the probe. The instrument is ready to operate.

2.2. Measurement

• The stabilising cap should be put on the probe when larger surfaces are tested.

• Set the result averaging time in the control unit. The more unstable in time the value

of the measured quantity is the longer the time should be. In most applications the

sufficient averaging time amounts to 1s

• Choose the automatic or manual change of the measurement range. It is

recommended by the manufacturer to turn on the automatic change of the range.

The manual control is intended for the procedures of checking linearity during

calibration or in specific conditions of measurement when the value of the measured

quantity changes in time to such an extent that the control unit cannot determine

the proper measurement range.

• Place the measurement probe perpendicular to the measured surface.

- 6 -

• Trigger the measurement with the key on the probe or with the certain key on the

control unit.

In the case of the tested medical imaging monitors it is necessary to use the application

of the control unit intended for this kind of measurement.

3. BASIC FUNCTIONS OF CONTROL UNIT

The basic functions of the P-200 control unit and the RF200C software are the following

ones:

• Choice of the measurement probe which concerns the RF200C software.

• Zeroing of the detector.

• Zeroing of the measurement system.

• Manual or automatic choice of the measurement range.

• Choice of the single or continuous measurement mode.

• Choice of the averaging time in range from at least 1-10s 5). The measurement result

is the moving average that is refreshed every 1s.

• Triggering and stopping the measurement.

• Presentation of the measurement result.

• Calibration and adjustment of the meter.

All the detailed information is included in the instruction manuals for the control units.

4. EXTENDED FUNCTIONS OF CONTROL UNIT

The control devices are equipped with applications or functions that extend the range of

the probe usage. All the applications have the possibility of archiving of the

measurements results to an external drive. In the case of the P-200 it is a microSD card

while in the case of the RF200C software it is a PC disc. The data is saved in text files

where tabs are separation signs. Such a file format enables the User to open it directly

with the help of the spreadsheet. The access rights to the certain application depend on

the type of the attached measurement probe.

4.1. Access t extended functi ns f c ntr l unit

The access of the LMC-10 probe to applications and functions of the P-200 control unit

and RF200C software:

Application Access to application

Medical monitors YES

Measurements memory

YES

Advanced

- relative measurement

- integration

- statistics

YES

The applications specified in the above-placed table concern the RF200C software. In the

P-200 unit advanced applications such as measurement storage relative measurement

integration and statistics are the extended functions of the control unit.

5) The range of values of the result averaging time depends on the control unit.

- 7 -

4.2. Applicati n: Medical m nit rs

The correct assessment of medical imaging monitors in a diagnostic station requires the

use of the luminance meter whose technical solutions and metrological parameters

comprise all aspects related to various designs of monitor matrices. The meter of this

kind is the SONOPAN LMC-10 which is above all intended for this type of tests as it

guarantees very high measurement accuracy. The LMC-10 contact luminance meter

meets the guidelines of the American Association of Physicists in Medicine (AAPM) as

well as the users’ expectations.

The manufacturer still has assigned for the L-200 probe the rights to the application of

medical monitors because its metrological parameters conform to the requirements of

this type of tests. Another condition for luminance measurement is the use of the

suitable adapter.

All the detailed information is included in the instruction manuals for the control units.

4.3. Applicati n: Measurements mem ry

The control units are used to archive the measurements conducted with the use of the

LMC-10 probe. It is possible to save one single measurement or chosen measurements as

well as to create the measurement history log within any time interval.

All the detailed information is included in the instruction manuals for the control units.

4.4. Applicati n: Advanced

4.4.1. Relative measurement

The control units enable to conduct and archive the measurements whose results are

expressed as a percentage of any reference. It is possible to save one single

measurement or chosen measurements as well as to create the measurement history log

within any time interval.

All the detailed information is included in the instruction manuals for the control units.

4.4.2. Integrati n

The control units are used to conduct and archive the measurements which are the time

integral of the partial results. The last result or the whole measurement history log can

be saved to the memory.

All the detailed information is included in the instruction manuals for the control units.

4.4.3. Statistics

The control units enable to conduct and archive the measurements as well as to make

simple statistical operations on the results. The last result or the whole measurement

history log can be saved to the memory.

All the detailed information is included in the instruction manuals for the control units.

5. CALIBRATION AND ADJUSTMENT

Calibration is the comparison of the measured values with those of a calibration

standard of known accuracy. On the basis of this comparison the calibration factor is

calculated and saved to the measuring probe. The control units allow the User to

conduct the adjustment procedure of the LMC-10 measurement probe. The procedure

should be conducted by a competent laboratory equipped with the suitable instruments

- 8 -

and the proper photometric standards that are indispensable for setting the reference

illuminance in the reception field of the probe. It is necessary to take into account the

fact that adjustment is related to all the components of the meter specified in Sec. 1.2.1.

All the detailed information is included in the instruction manuals for the control units.

6. MAINTENANCE RECCOMENDATIONS

• The LMC-10 measurement probe must be connected only to the devices described in

the instruction manual.

• The device should not be exposed to falls shocks or any other factors which can cause

mechanical damage.

• It is necessary to protect the optical element of the reception field from dirt.

• The lens can be dusted with a clean soft brush or with the airstream of the

compressed dry air after unscrewing the element of the probe with an entry hole:

. It is recommended to rely on the latter method. Spray preparations that act

as compressed air should be applied gently and very carefully. The container with such

spray should be held in a vertical position.

• The probe cap should be removed only during the measurement.

• The probe should be removed and put on while turning it right clockwise which

prevents it from being untwisted by accident.

• The instrument should be kept and transported only in the carrying case provided by

the manufacturer.

• All repairs of the instrument are performed by the manufacturer.

7. FIRMWARE

The User can deal with the firmware update by oneself. The number of the currently-

installed version is displayed on the splash screen of the control unit:

• in the case of the P-200 panel: Menu→Head info

• in the case of the RF200C software: View→About meter.

To update the instrument firmware you need to have a RF-200C converter and to follow

the below-placed instructions:

• Download from the manufacturer’s website the SonBoot application.

• Download from the manufacturer’s website the firmware file for the LMC-10 meter.

• Connect the probe to the RF-200C interface and the latter to the USB port of the PC.

• Wait until the drivers are installed in the system.

• Run the SonBoot.exe application.

• Choose the LMC-10 from the Device Type drop-down list.

• Choose the RF-200C from the USB device drop-down list.

• Open the firmware data file.

• Press the Program key.

- 9 -

8. CE MARKING AND WEE DIRECTIVE

The product described in the instruction conforms to the following EU Council

Directives:

2014/30/EC Electromagnetic compatibility

The conformance of the above-mentioned requirements is confirmed by CE mark.

This product cannot be thrown away with household waste. Deposit the product in

an authorized electrical and electronic waste collection area for recycling. Contact

the local authorities or the nearest waste disposal company to get more detailed

information.

Table of contents

Other SONOPAN Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Proline Promag L 800 Brief operating instructions

Worldcast Systems

Worldcast Systems audemat GOLDENEAGLE ATSC user manual

Spectro-UV

Spectro-UV Spectroline AccuMAX Series Operator's manual

VOH

VOH VISIOTEST user guide

Test Equipment Depot

Test Equipment Depot RXW-GP Series manual

Agilent Technologies

Agilent Technologies N4373A user guide