Sony SAL-35F14G - 35mm f/1.4 Aspherical G Series Standard Zoom... User manual

Other Sony Camera Lens manuals

Sony

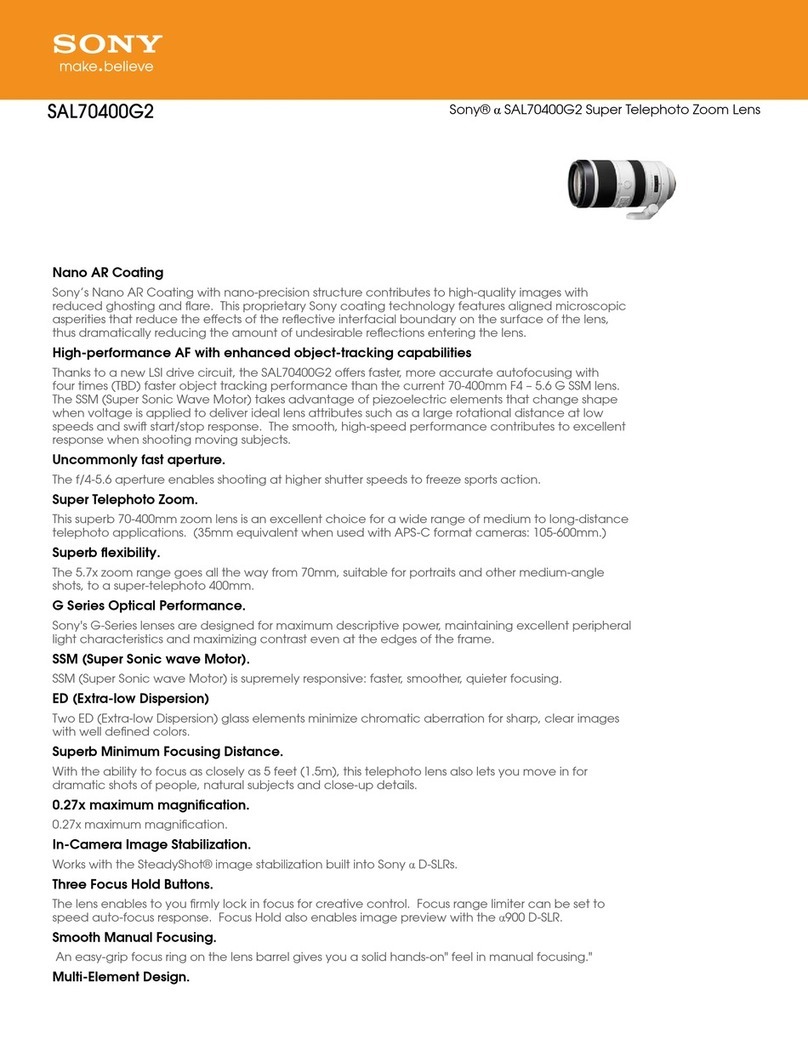

Sony SAL70400G2 User manual

Sony

Sony VCL-HA06 User manual

Sony

Sony SAL1118 - DT 11-18mm f/4.5-5.6 Aspherical ED Super Wide Angle Zoom... User manual

Sony

Sony VCL SW04 User manual

Sony

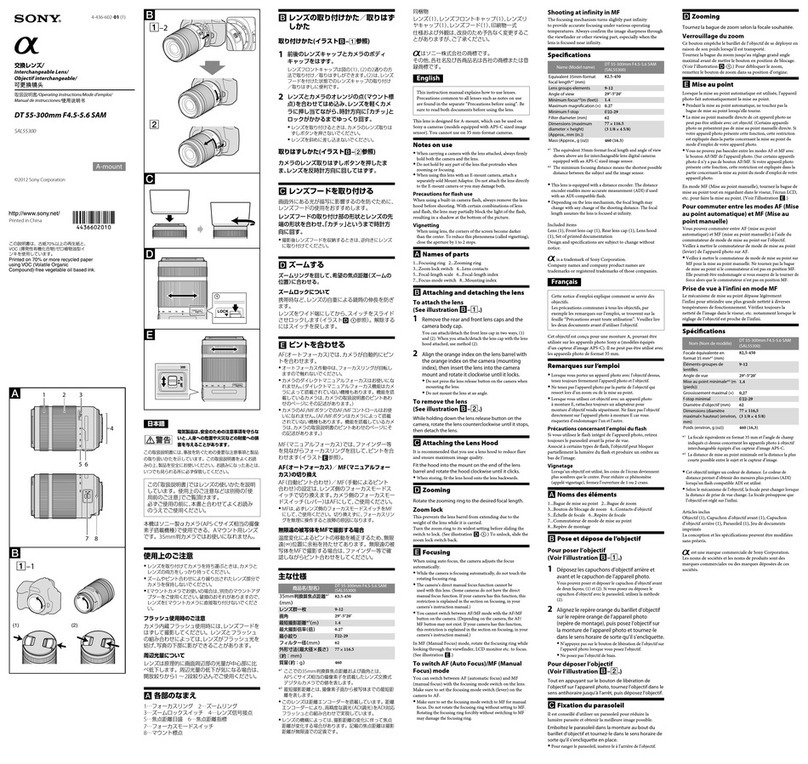

Sony Alpha SAL55300 User manual

Sony

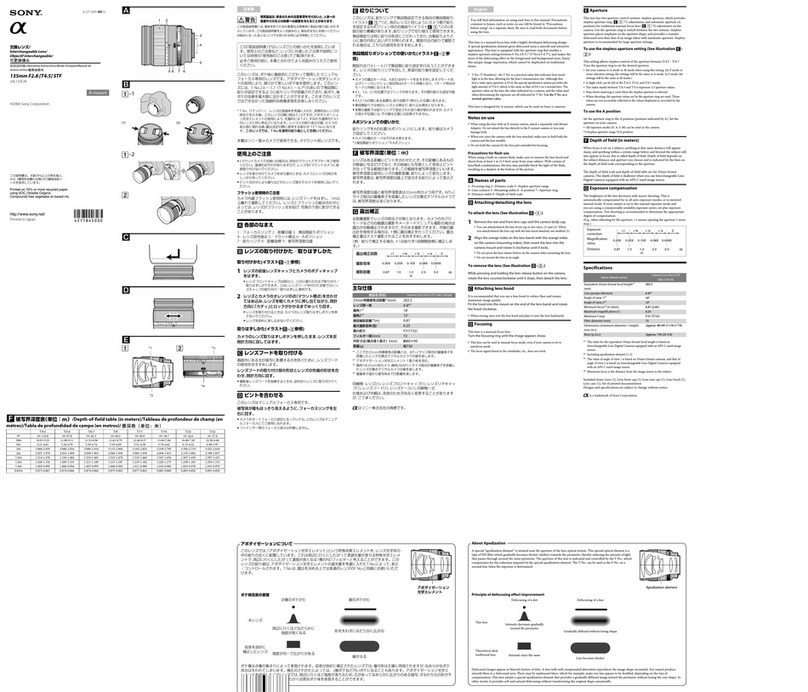

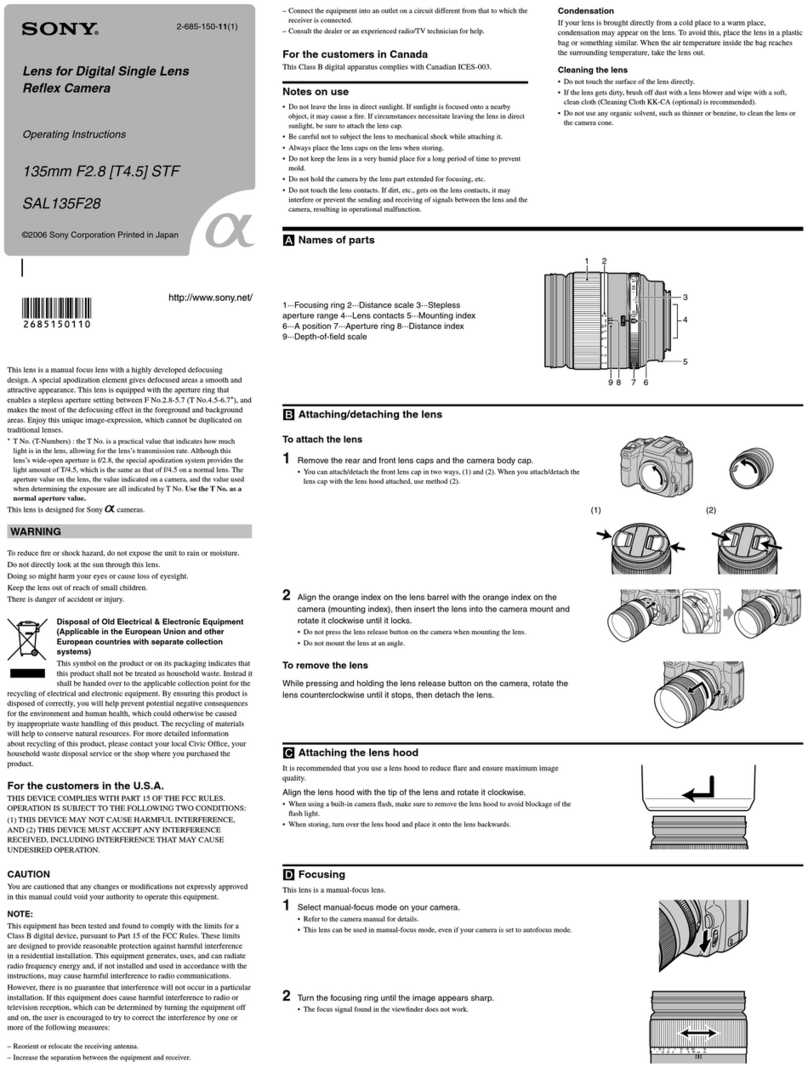

Sony SAL-135F28 - 135mm f/2.8 STF Telephoto Lens User manual

Sony

Sony SELP1020G User manual

Sony

Sony NEX-3D - alpha; Nex-3 With Sel-16f28 User manual

Sony

Sony SAL-300F28G User manual

Sony

Sony SEL55F18Z User manual

Sony

Sony SEL1224G User manual

Sony

Sony SAL-1680Z User manual

Sony

Sony ILCE-QX1 User manual

Sony

Sony SAL70200G - 70-200mm f/2.8 SSM Lens Installation instructions manual

Sony

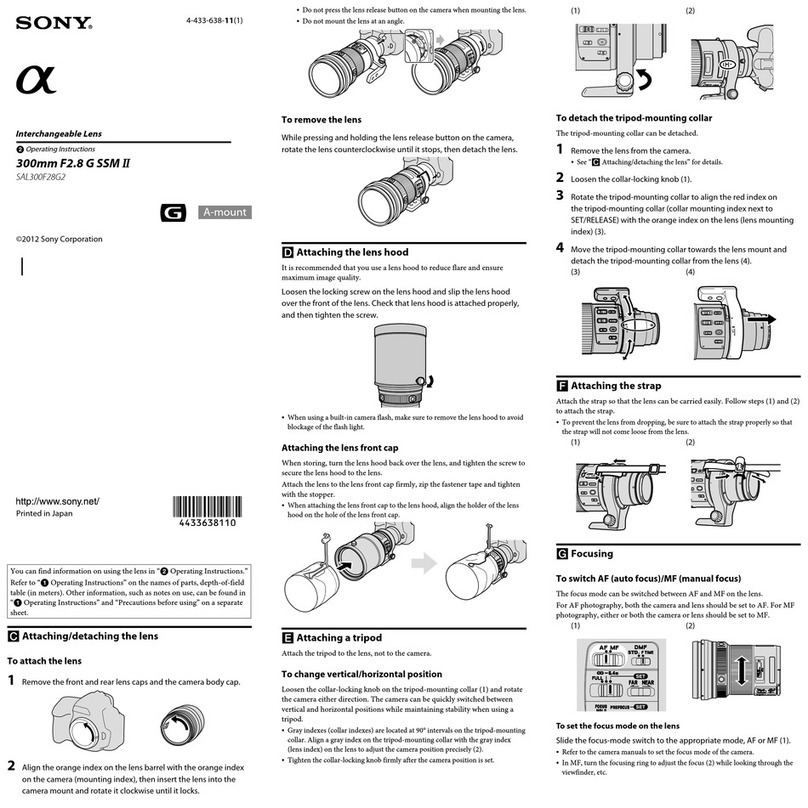

Sony SAL-300F28G2 User manual

Sony

Sony VCL-HG0730 User manual

Sony

Sony SAL55200-2 User manual

Sony

Sony ALC-SH111 User manual

Sony

Sony SAL-135F28 - 135mm f/2.8 STF Telephoto Lens User manual

Sony

Sony SAL20F28 - Wide-angle Lens - 20 mm User manual

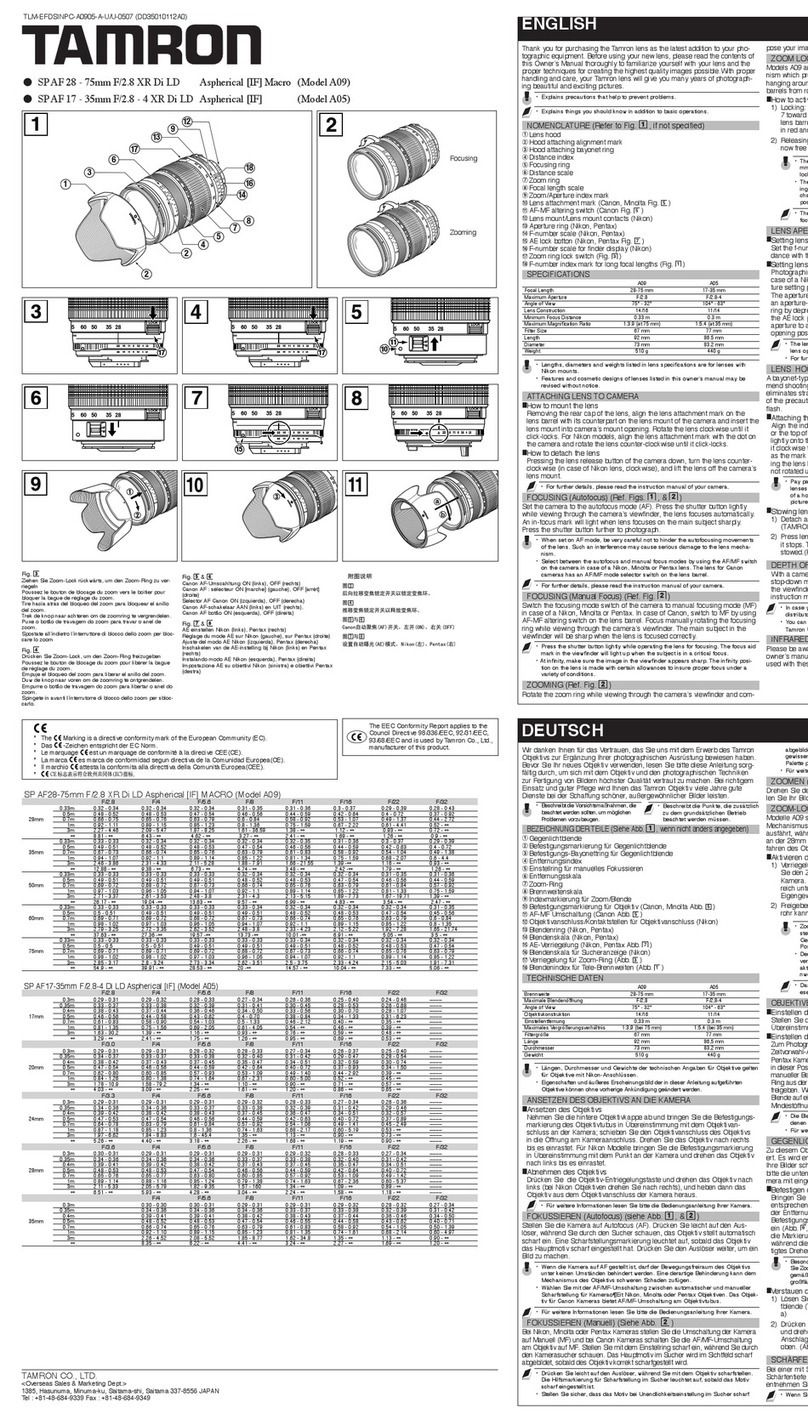

Popular Camera Lens manuals by other brands

Rokinon

Rokinon SP 85mm F1.2 instruction manual

Nikon

Nikon AF-S Zoom-Nikkor 17-35mm f/2.8D IF-ED manual

Samsung

Samsung Samsung 18-55mm user manual

FujiFilm

FujiFilm XF56mm F1.2 R APD owner's manual

FujiFilm

FujiFilm FUJINON XK6x20 SAF Operation manual

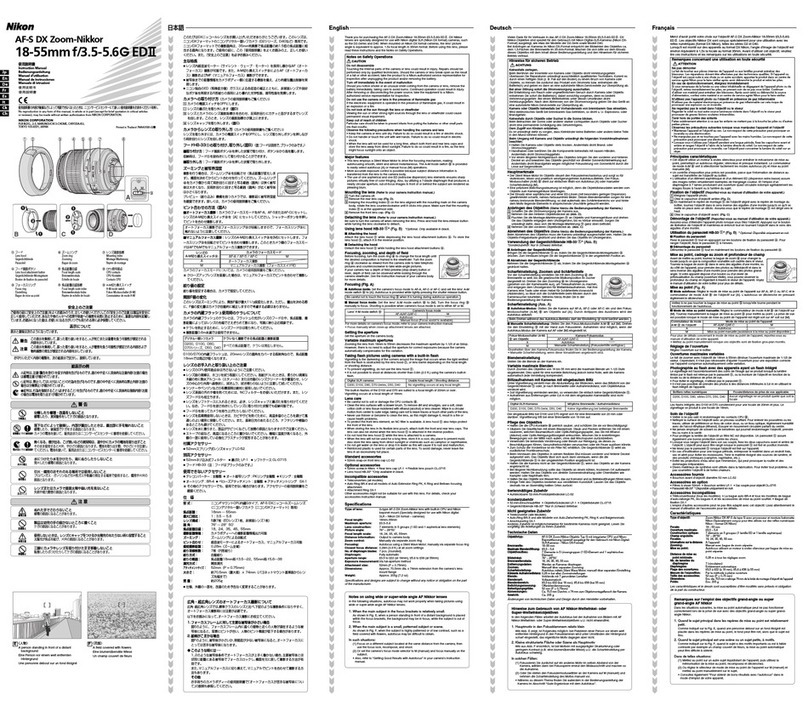

Nikon

Nikon AF-S DX Zoom-Nikkor 18-55mm f/3.5-5.6G ED II instruction manual