– 2 –

TABLE OF CONTENTS

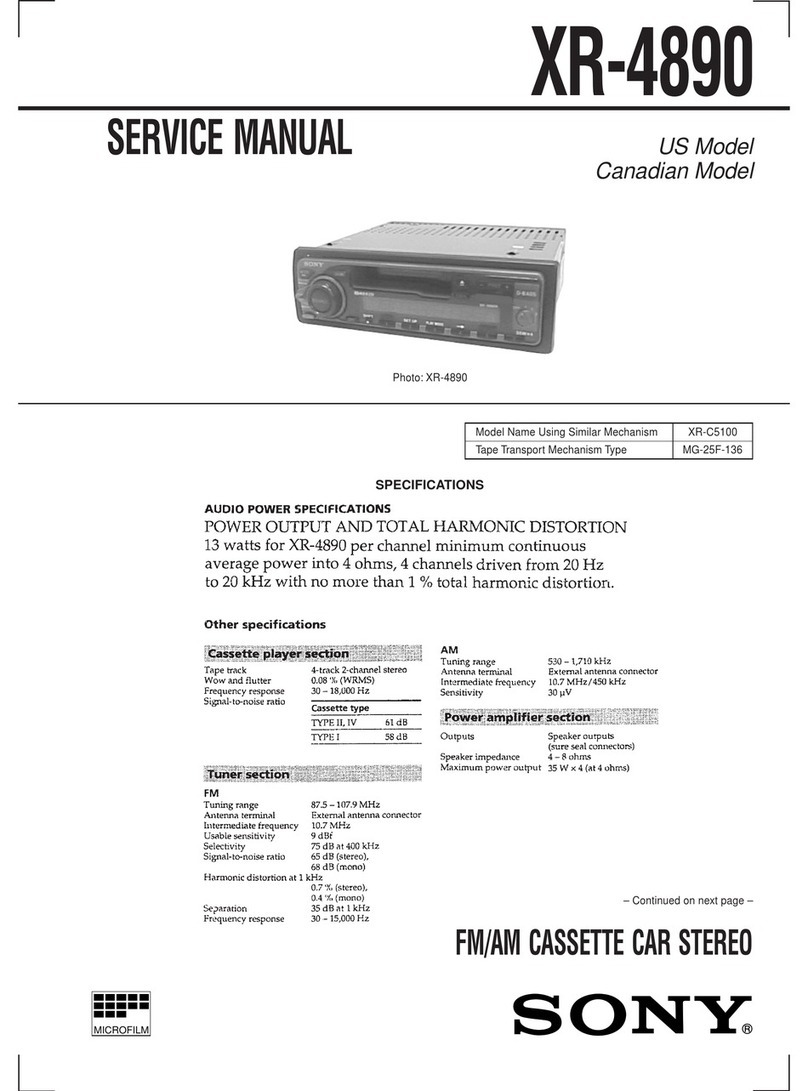

1. GENERAL

Location of Controls ....................................................... 3

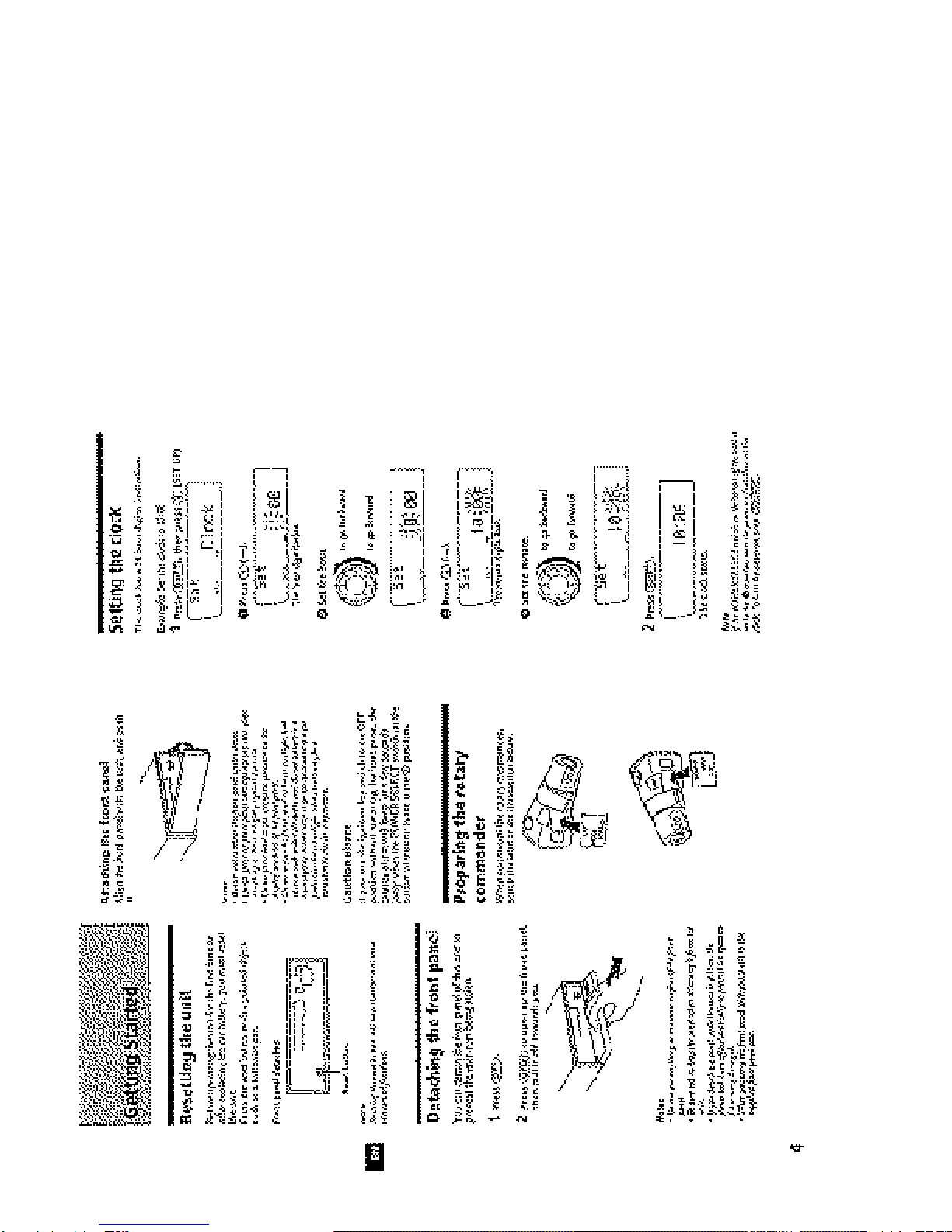

Resetting the Unit ........................................................... 4

Detaching the Front Panel............................................... 4

Setting the Clock ............................................................. 4

Using the Rotary Commander ........................................ 5

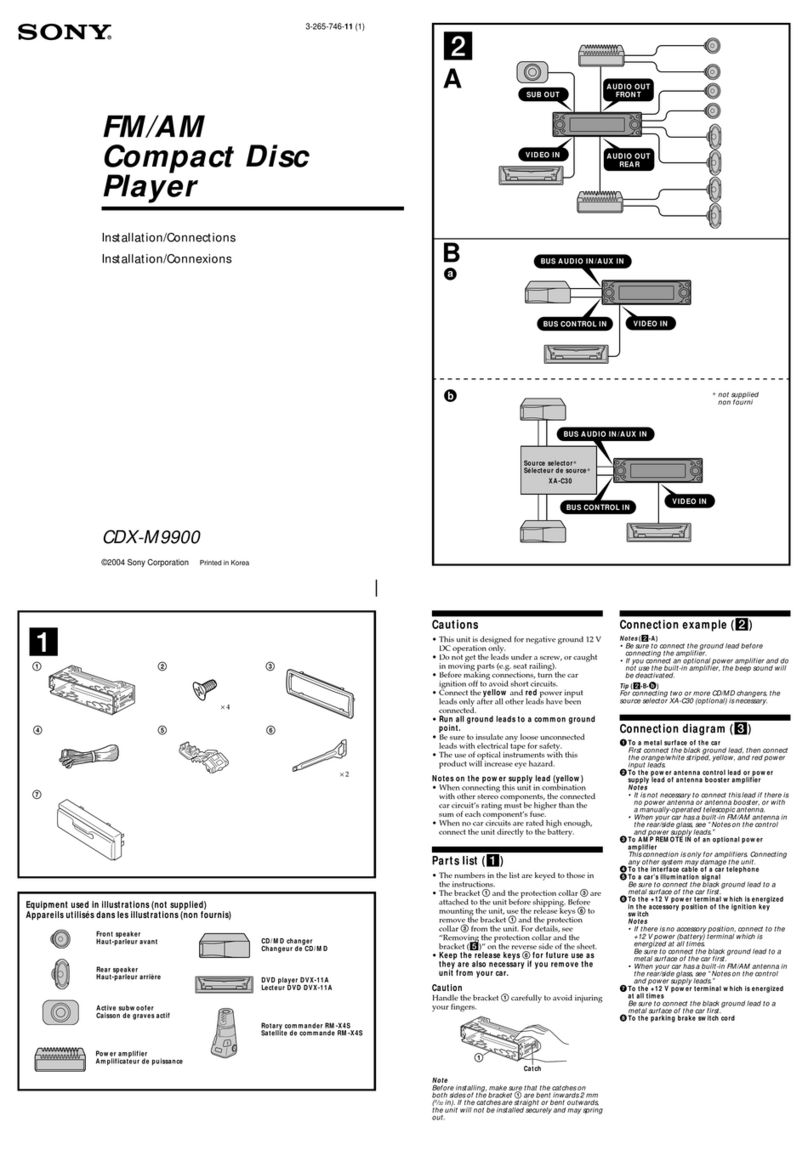

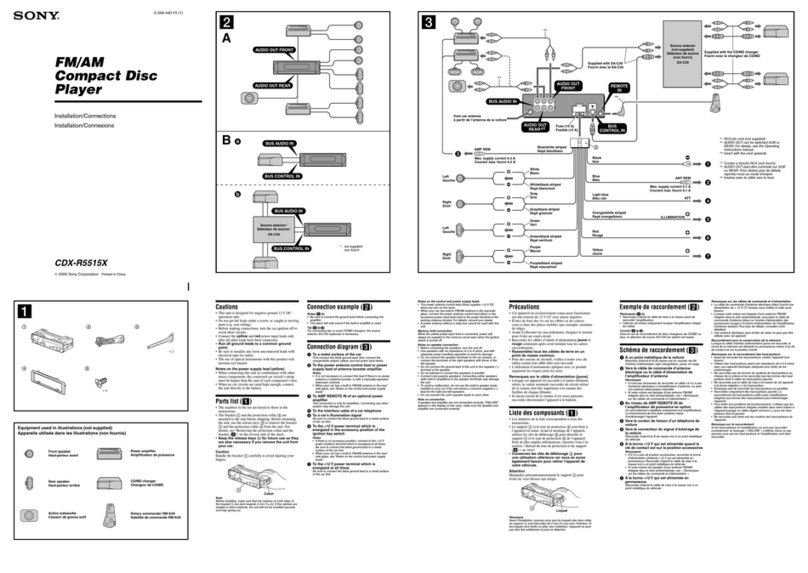

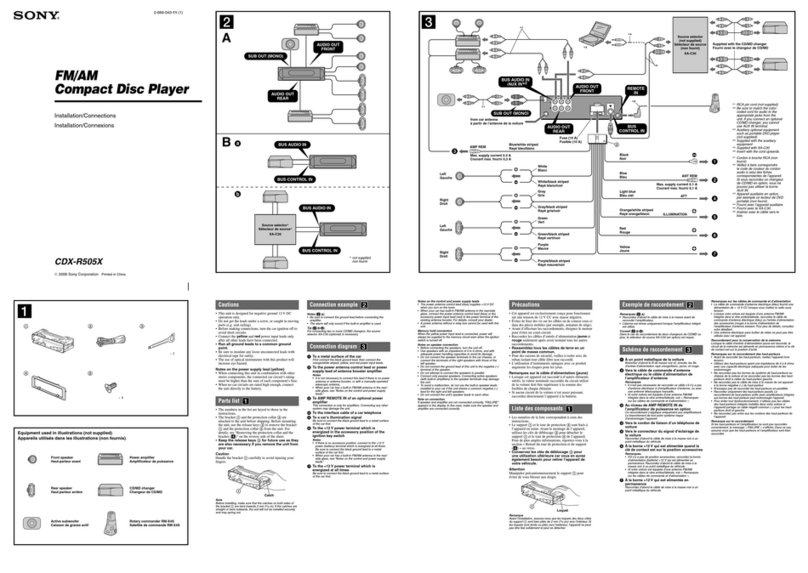

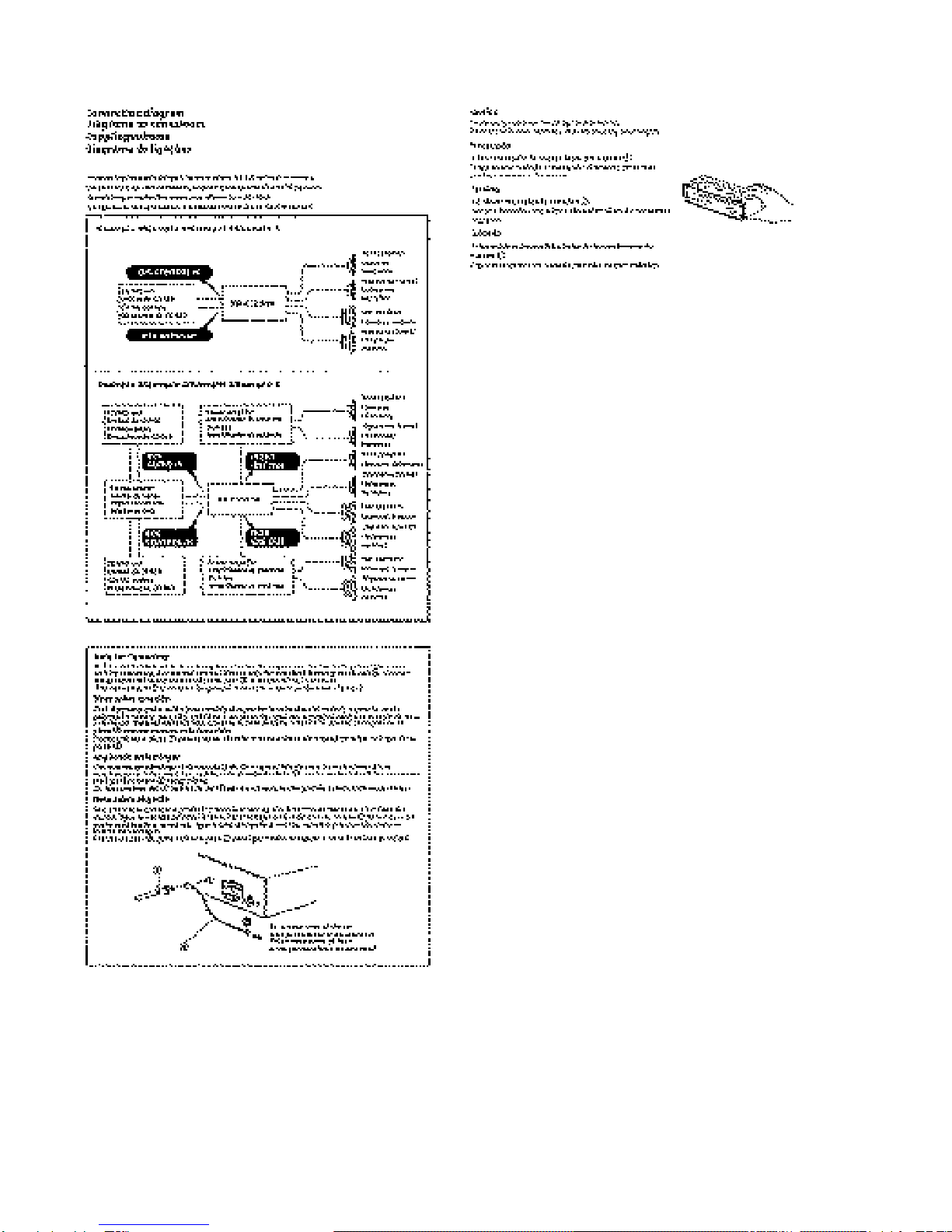

Installation....................................................................... 6

Connections ..................................................................... 7

2. DISASSEMBLY ......................................................... 10

3. ASSEMBLY OF MECHANISM DECK........... 13

4. MECHANICAL ADJUSTMENTS ....................... 16

5. ELECTRICAL ADJUSTMENTS

Test Mode ........................................................................ 16

Tape Deck Section .......................................................... 16

Tuner Section .................................................................. 17

6. DIAGRAMS

6-1. IC Pin Function Description ........................................... 21

6-2. Printed Wiring Board – MAIN Section – ....................... 25

6-3. Schematic Diagram – MAIN Section –.......................... 29

6-4. Printed Wiring Boards – PANEL Section –.................... 33

6-5. Schematic Diagram – PANEL Section – ........................ 35

7. EXPLODED VIEWS................................................ 41

8. ELECTRICAL PARTS LIST ............................... 44

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.