– 2 –

TABLE OF CONTENTS

1. GENERAL

Location of Controls ....................................................... 3

Resetting the Unit ........................................................... 4

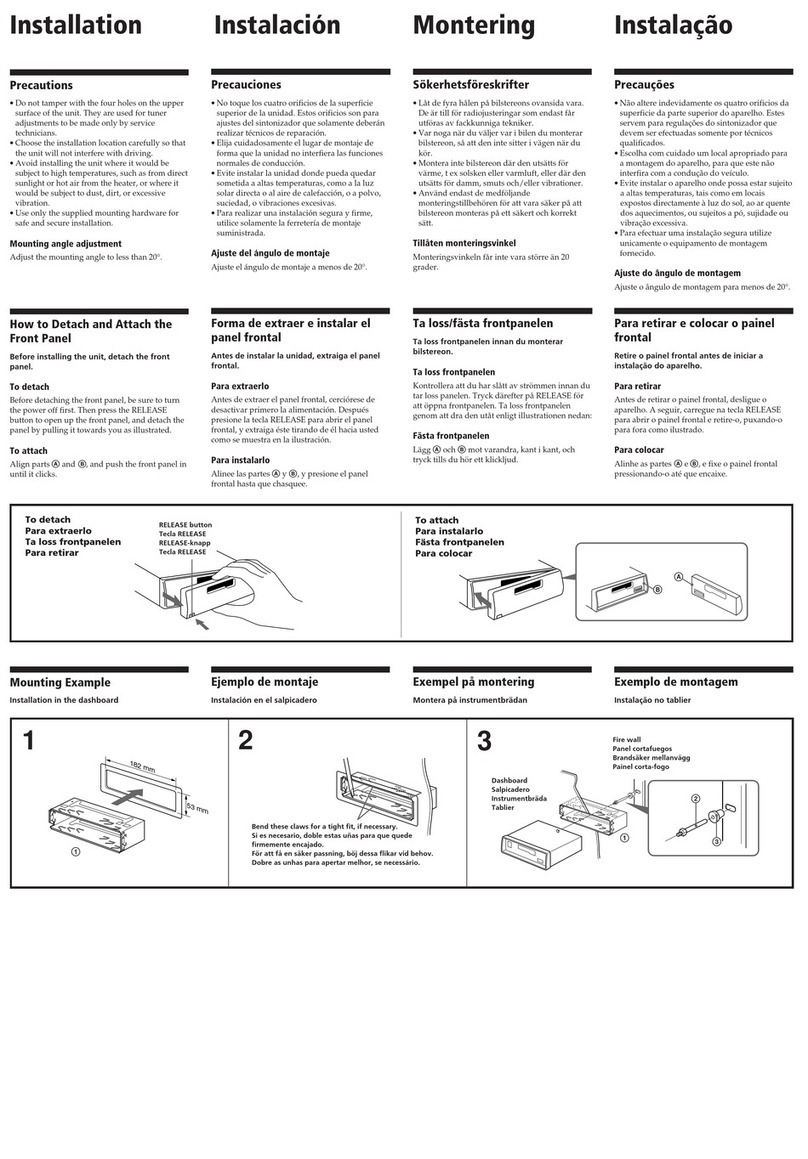

Detaching the Font Panel ................................................ 4

Preparing the Rotary Commander .................................. 4

Setting the Clock ............................................................. 4

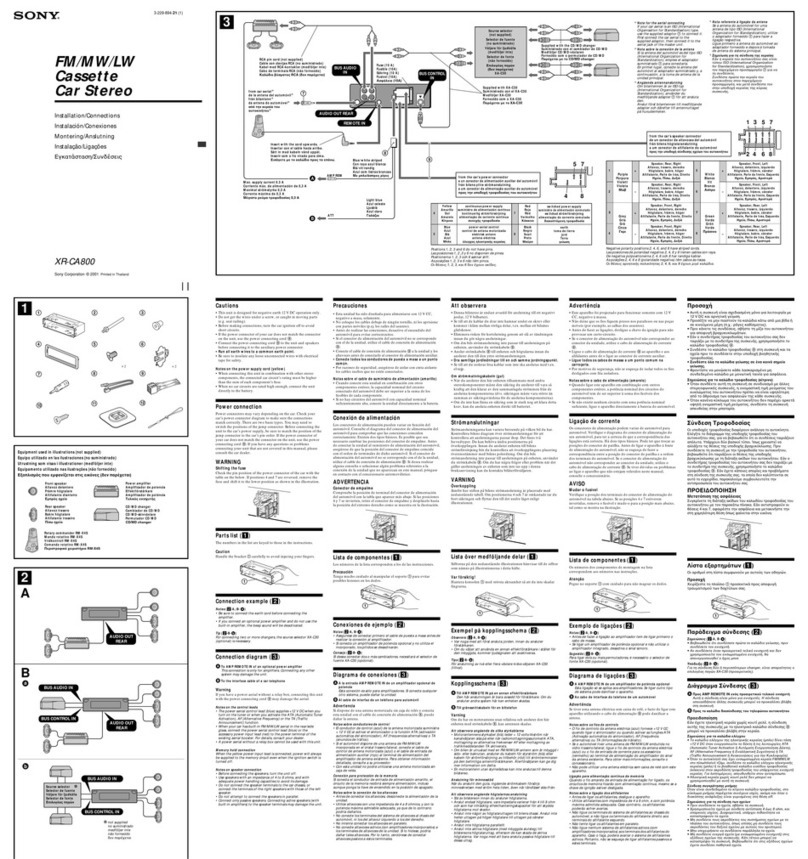

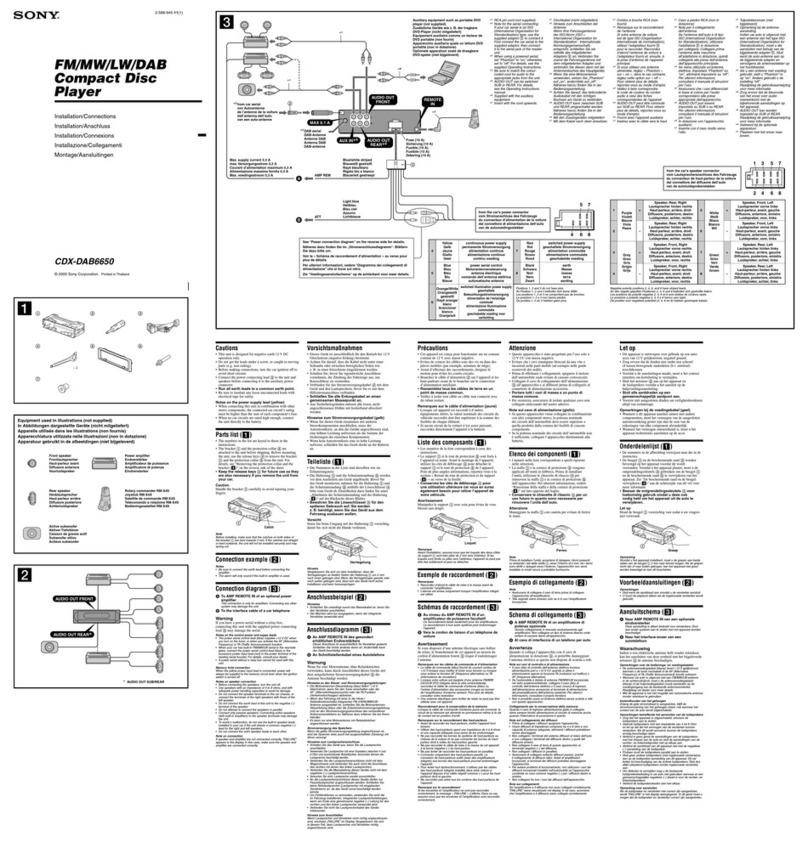

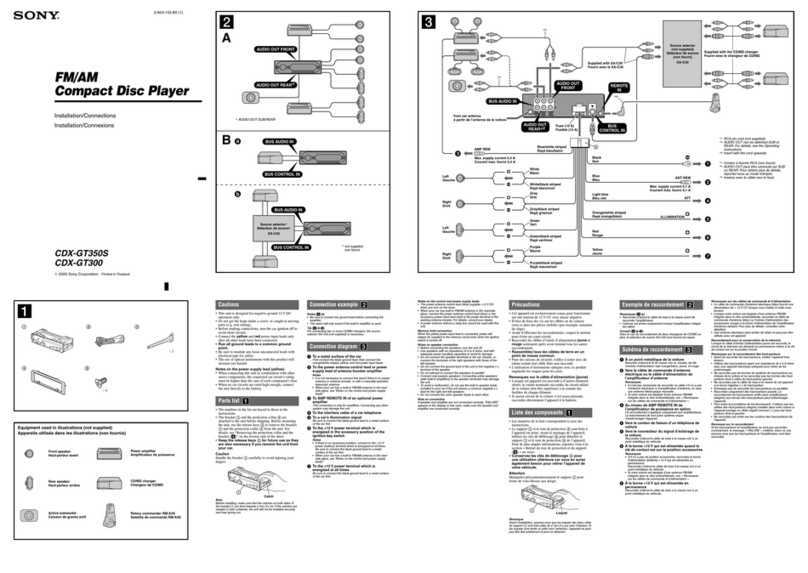

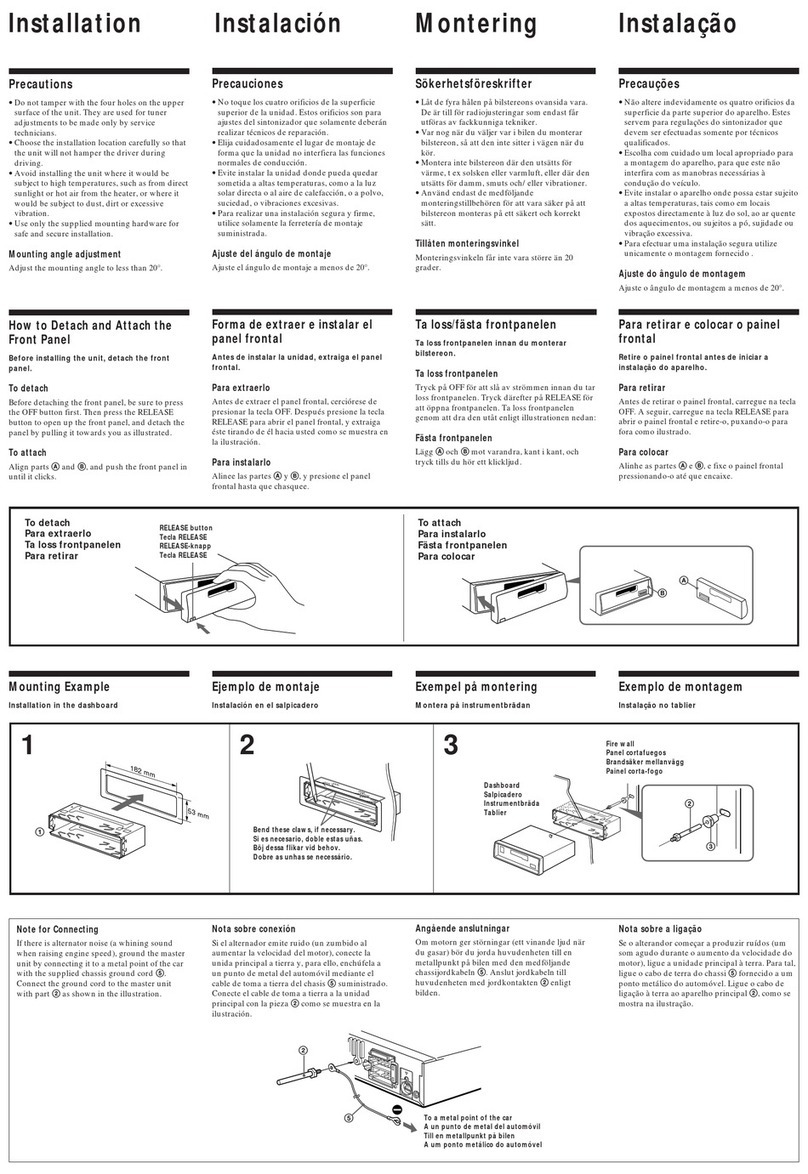

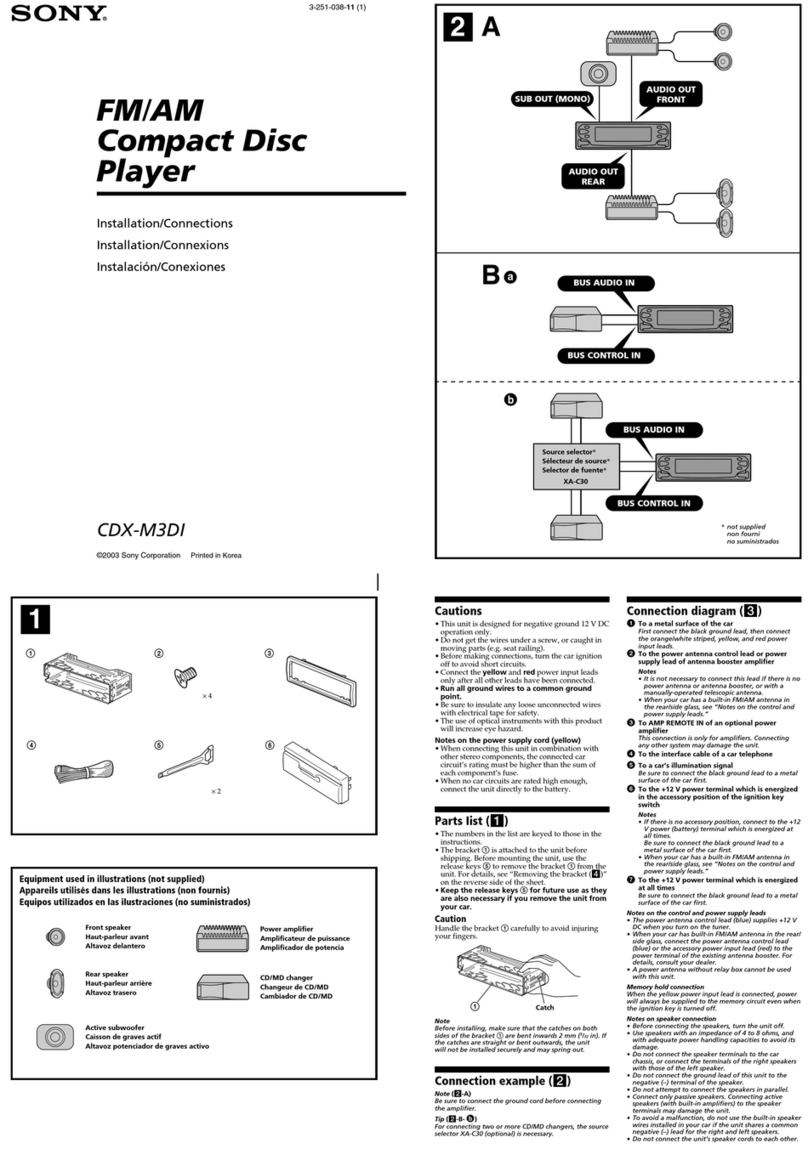

Installation....................................................................... 5

Connections ..................................................................... 6

2. DISASSEMBLY ......................................................... 8

3. ASSEMBLY OF MECHANISM DECK........... 11

4. MECHANICAL ADJUSTMENTS....................... 14

5. ELECTRICAL ADJUSTMENTS

Test Mode ........................................................................ 14

Tape Deck Section .......................................................... 14

Tuner Section .................................................................. 15

6. DIAGRAMS

6-1. IC Pin Function Description ........................................... 18

6-2. Printed Wiring Board – MAIN Section – ...................... 25

6-3. Schematic Diagram – MAIN Section –.......................... 29

6-4. Printed Wiring Boards – PANEL Section – .................. 33

6-5. Schematic Diagram – PANEL Section –....................... 35

7. EXPLODED VIEWS................................................ 41

8. ELECTRICAL PARTS LIST ............................... 44

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.