– 7 –

SECTION 3

MECHANICAL ADJUSTMENTS SECTION 4

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab:record/playback/earth head pinch roller

rubber belts capstan

idlers

2. Demagnetize the record/playback head with a head demagne-

tizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

PRECAUTION

1. The adjustment should be performed in the publication.

(Be sure to male playback adjustment at first.)

2. The adjustments and measurement should be performed for

both L-CH and R-CH.

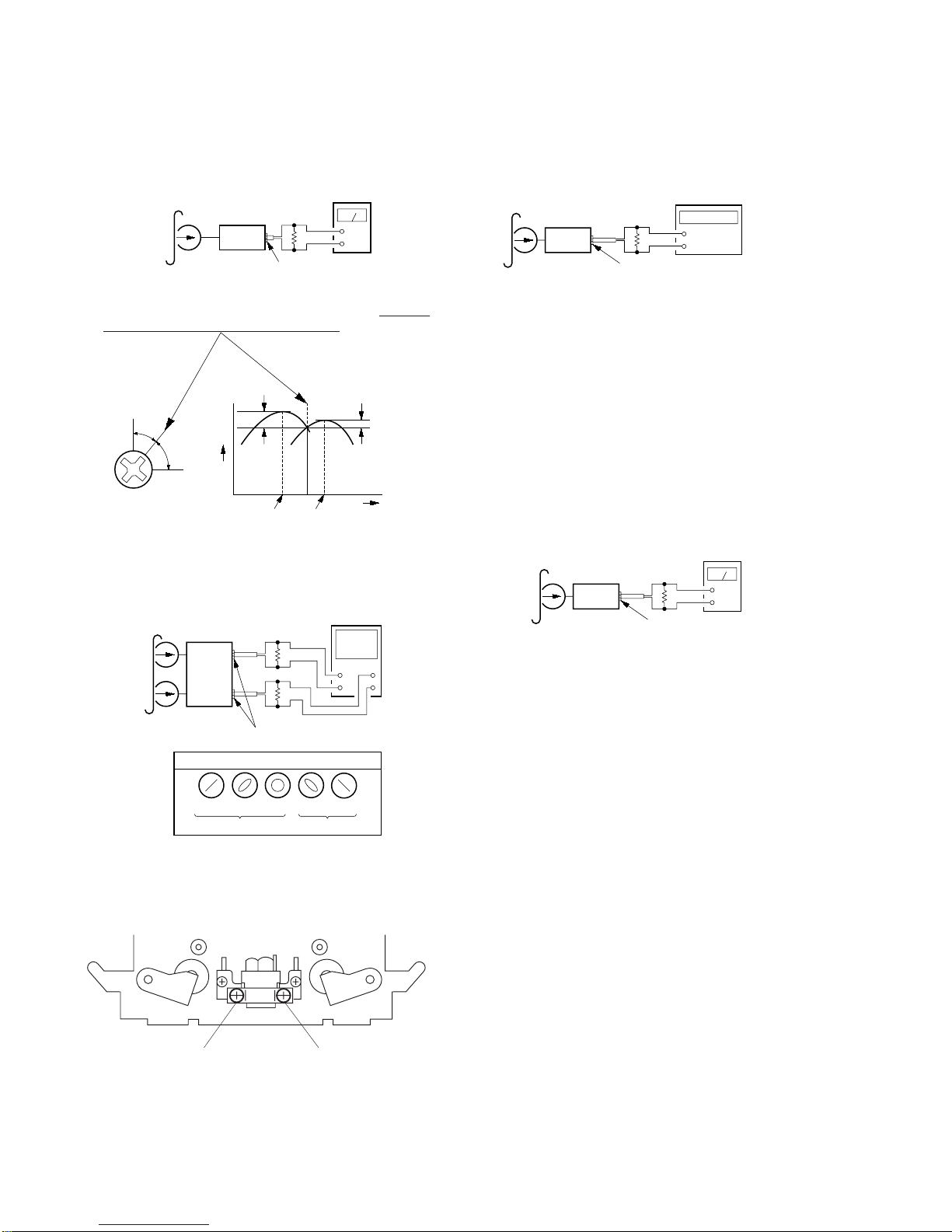

•Switch position

DOLBY NR switch : OFF

DIRECTION switch : A

•Standard record position

Deliver the standard input signal level to input jack and set

the REC LEVEL (RV301) control to obtain the standard

output signal level as follows.

– Record Mode –

set

AF OSC

attenuator

600

Ω

10 k

Ω

LINE IN

+

–

LINE OUT

47 k

Ω

level meter

Standard Input Level

Input terminal LINE IN

source impedance 10 kΩ

input signal level 0.5 V (– 3.8 dB)

Standard Output Level

Output terminal LINE OUT (L-CH)

load impedance 47 kΩ

output signal level 0.5 V (– 3.8 dB)

TestTape

Type Signal Used for

P-4-A100 10 kHz, – 10 dB Azimuth Adjustment

P-4-L300 315 Hz, 0 dB PB Level Adjustment

WS-48B 3 kHz, 0 dB Tape Speed Adjustment

0 dB = 0.775 V

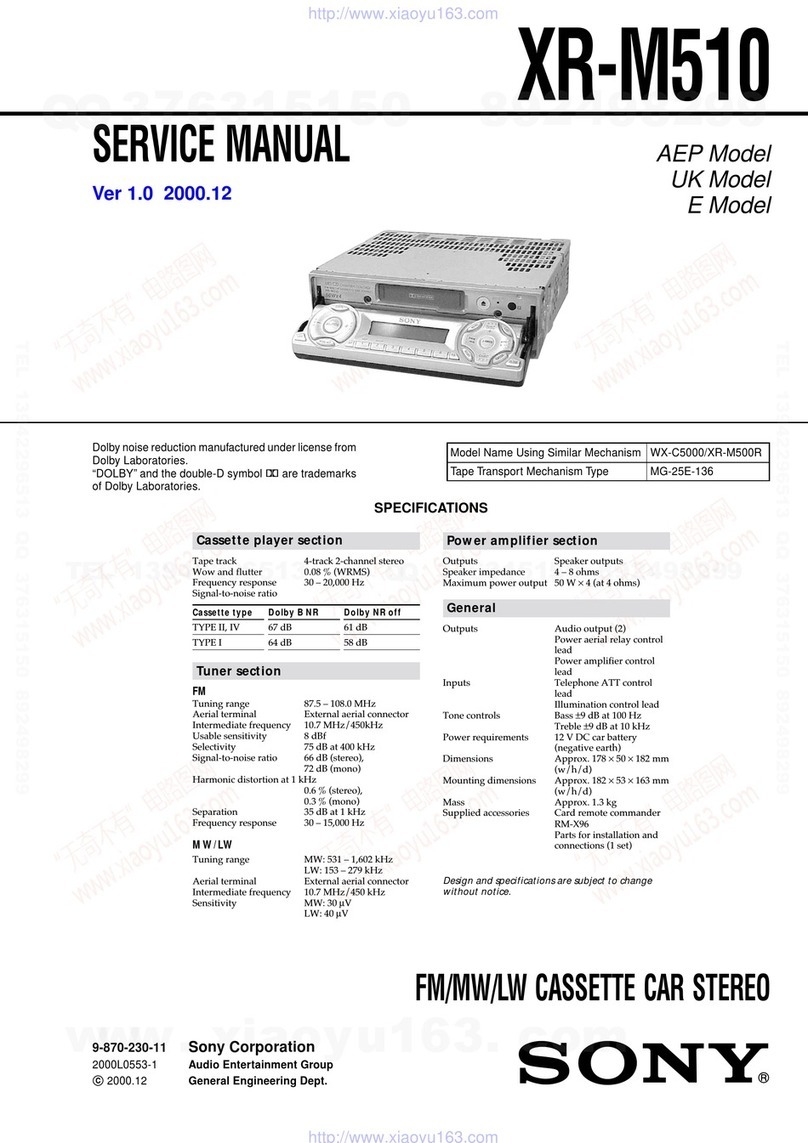

Mode Torque Meter Meter Reading

CQ-102C

30 – 65 g•cm

FWD (0.42 – 0.90 oz•inch)

FWD 1.5 – 6 g•cm

Back tension (0.021 – 0.083 oz•inch)

CQ-102RC

30 – 65 g•cm

REV (0.42 – 0.90 oz•inch)

REV 1.5 – 6 g•cm

Back tension (0.021 – 0.083 oz•inch)

70 – 130 g•cm

FF, REW CQ-201B (0.98 – 1.80 oz•inch)

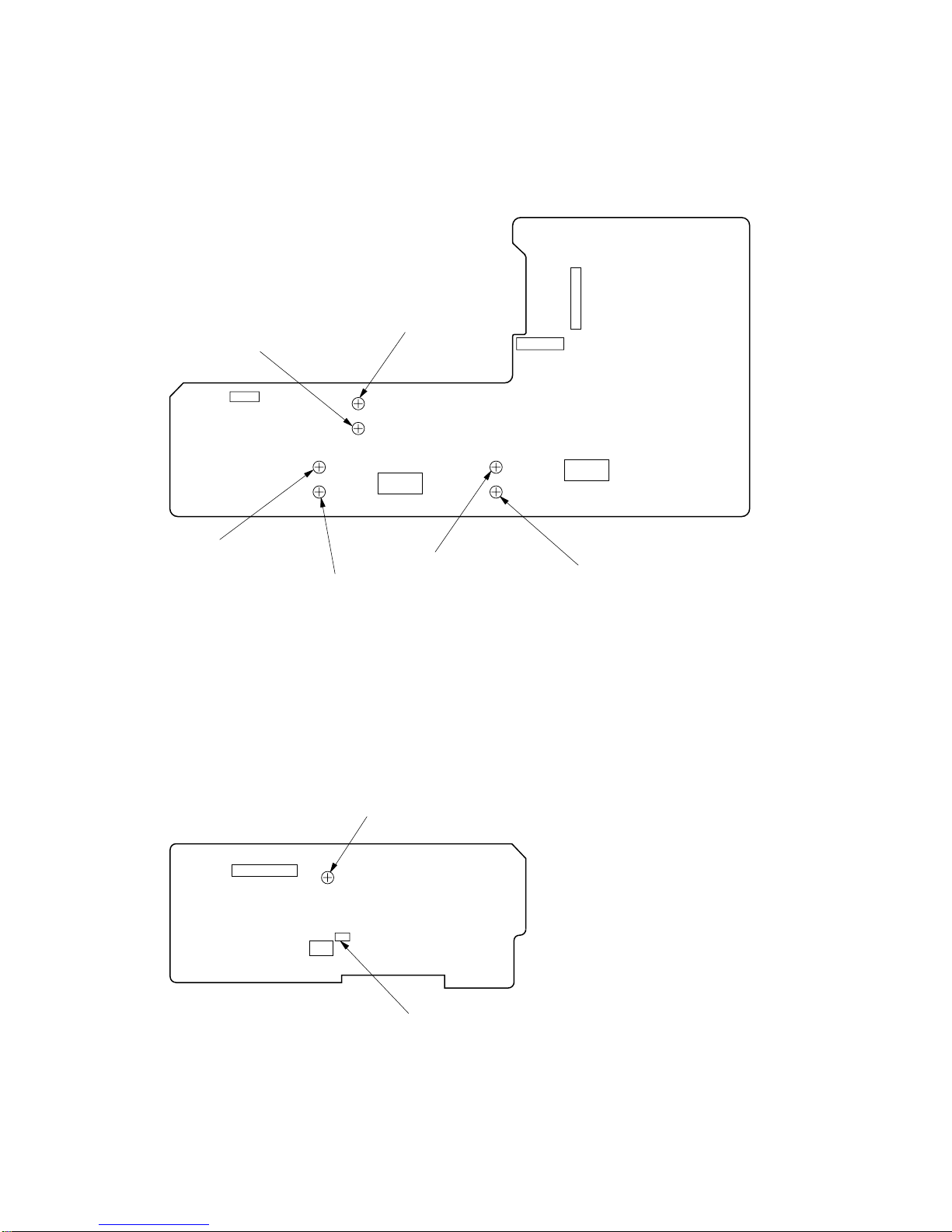

Test Mode

With the POWER turned OFF, short the test point CN801 (2P) on

the SYSTEM CONTROL board (making IC801 pin !º “L”) and

turn the POWER ON. Thus, the TEST mode will be activated.

If a recording is done in the TEST mode, the REC MEMORY

mode becomes active where the tape is rewound by the amount of

recording when a rewinding is executed after recording.

After adjustment, make the CN801 (2P) open to release the TEST

mode.