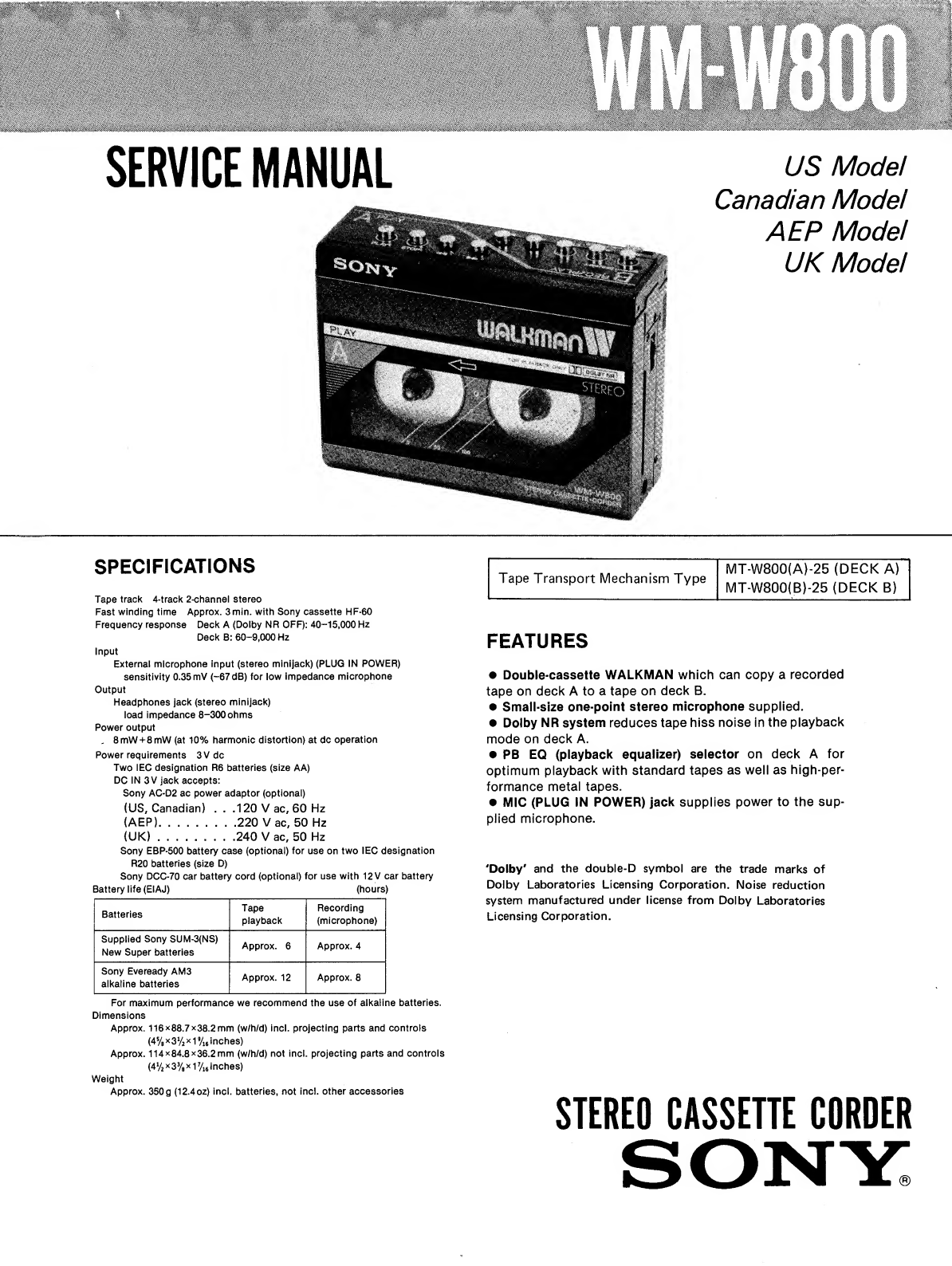

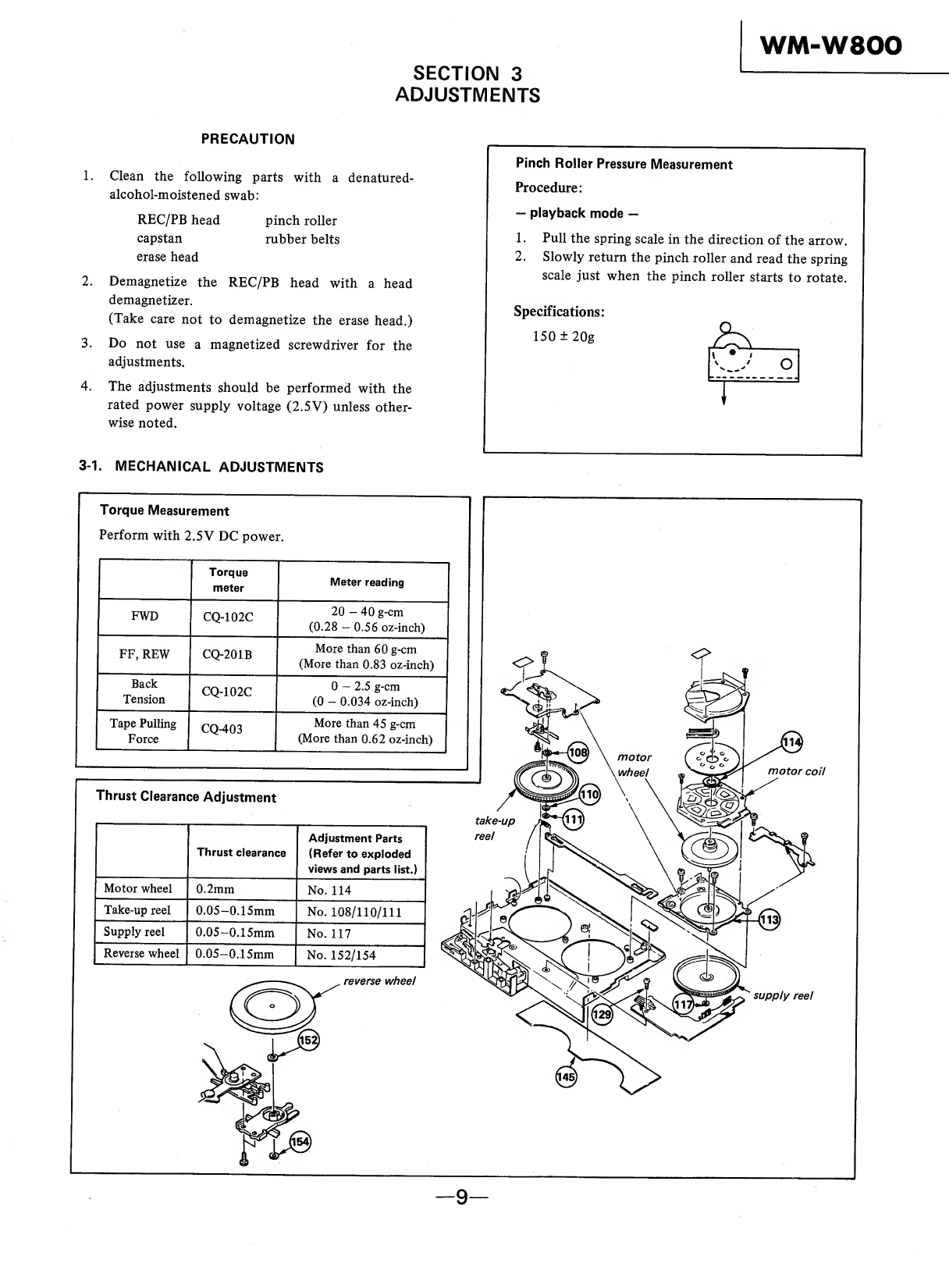

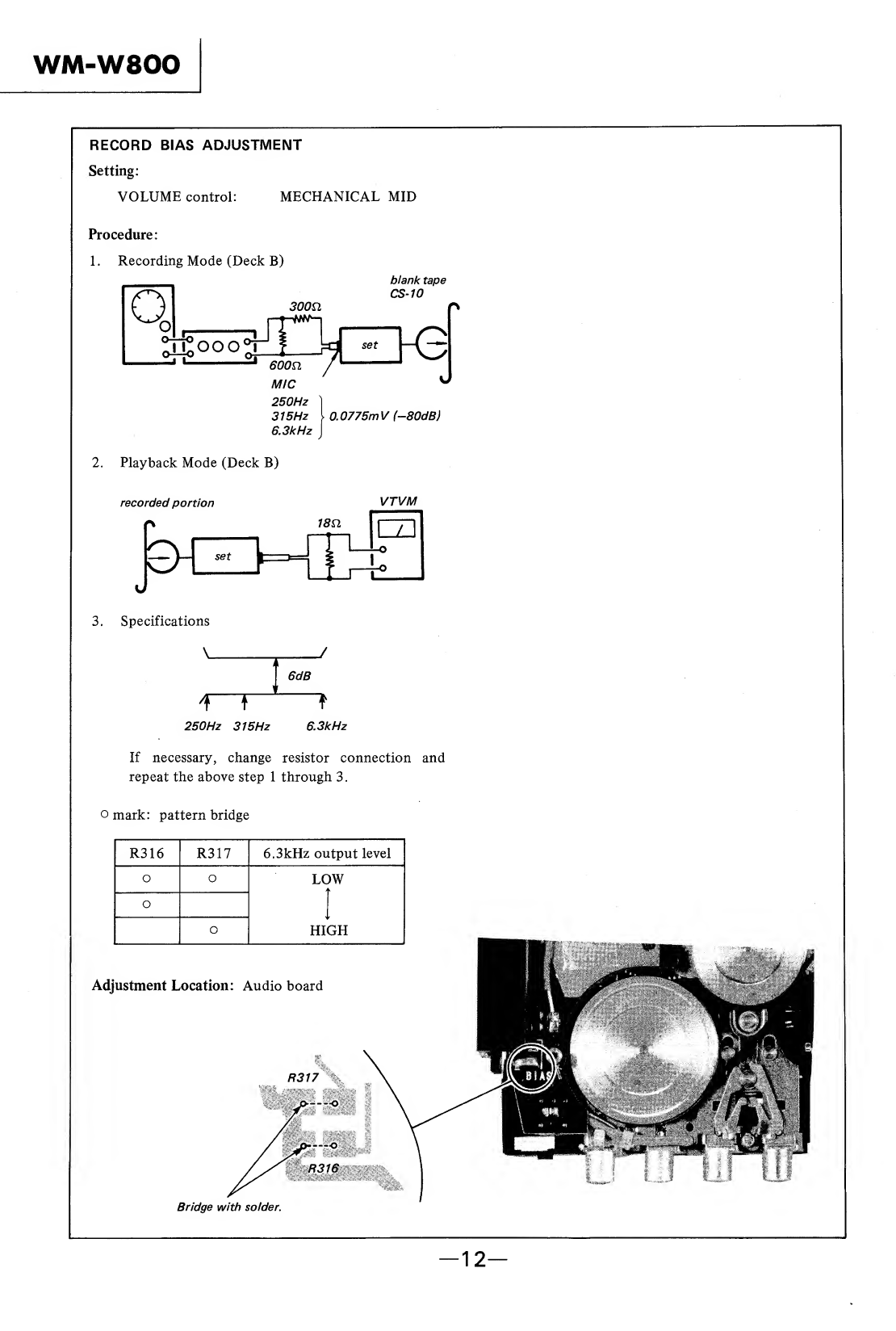

Sony WM-W800 User manual

Other Sony Cassette Player manuals

Sony

Sony TC-K750ES User manual

Sony

Sony WALKMAN WM-EQ7WP User manual

Sony

Sony Pressman TCM-400DV User manual

Sony

Sony CFM-A50 User manual

Sony

Sony Walkman WM-EX631 User manual

Sony

Sony CFM-10 Operating Instructions (primary... User manual

Sony

Sony FLEXICART User manual

Sony

Sony PVW-2650 User manual

Sony

Sony TC-K222ESL User manual

Sony

Sony TC-FX211 User manual

Sony

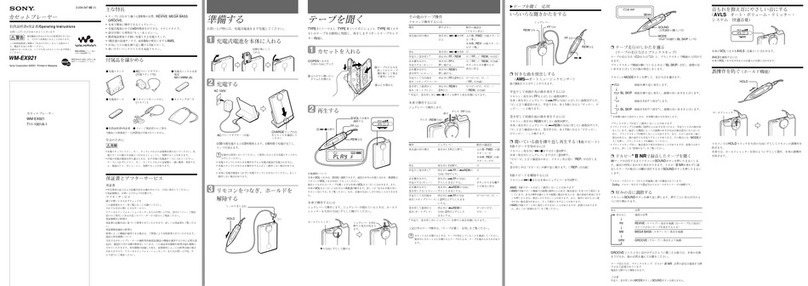

Sony Walkman WM-EX921 User manual

Sony

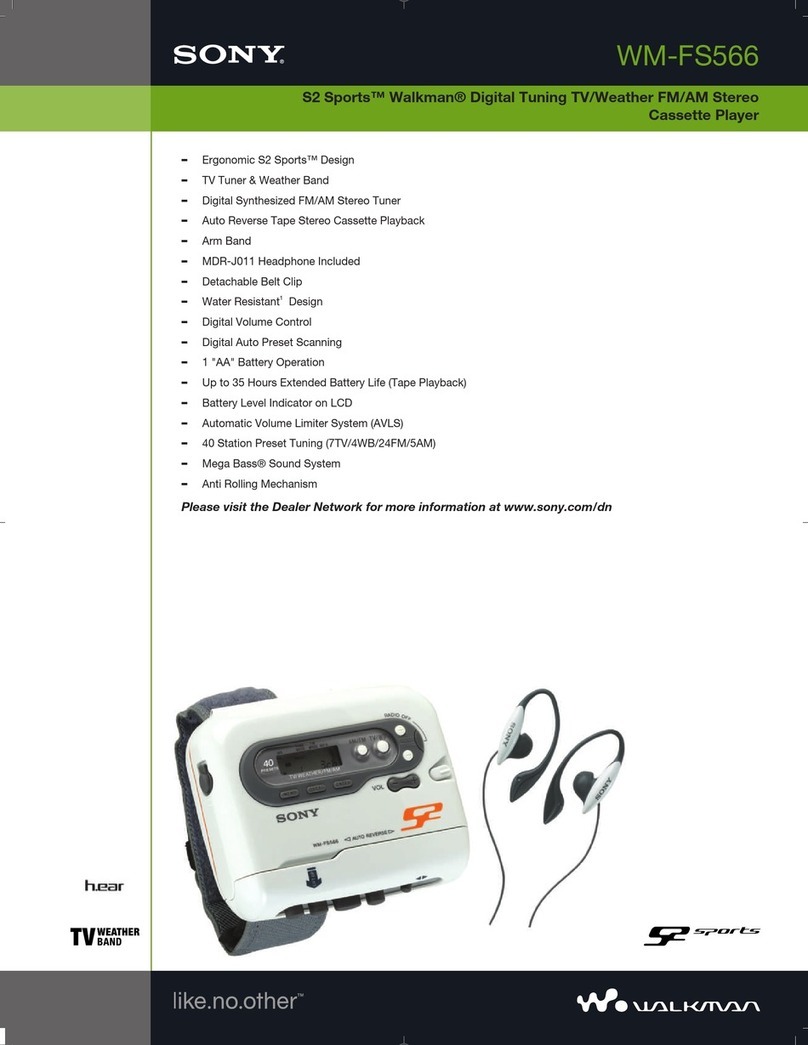

Sony S2 Sports Walkman WM-FS566 User manual

Sony

Sony TC-WE675 - Dual A/r Cassette Deck Guide

Sony

Sony Walkman WM-FX405 User manual

Sony

Sony Walkman WM-GX677 User manual

Sony

Sony Walkman WM-GX788 User manual

Sony

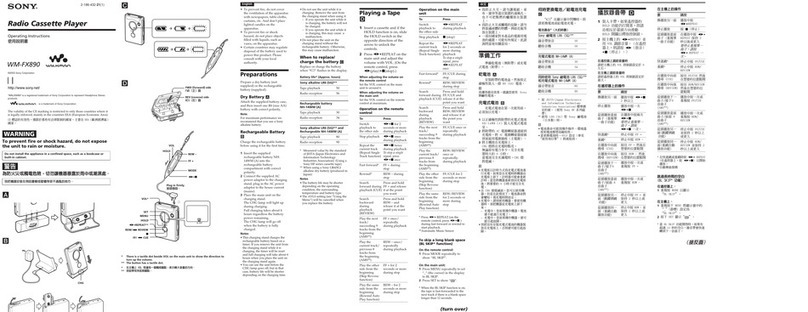

Sony WM-FX890 - Walkman User manual

Sony

Sony TCM-27 User manual

Sony

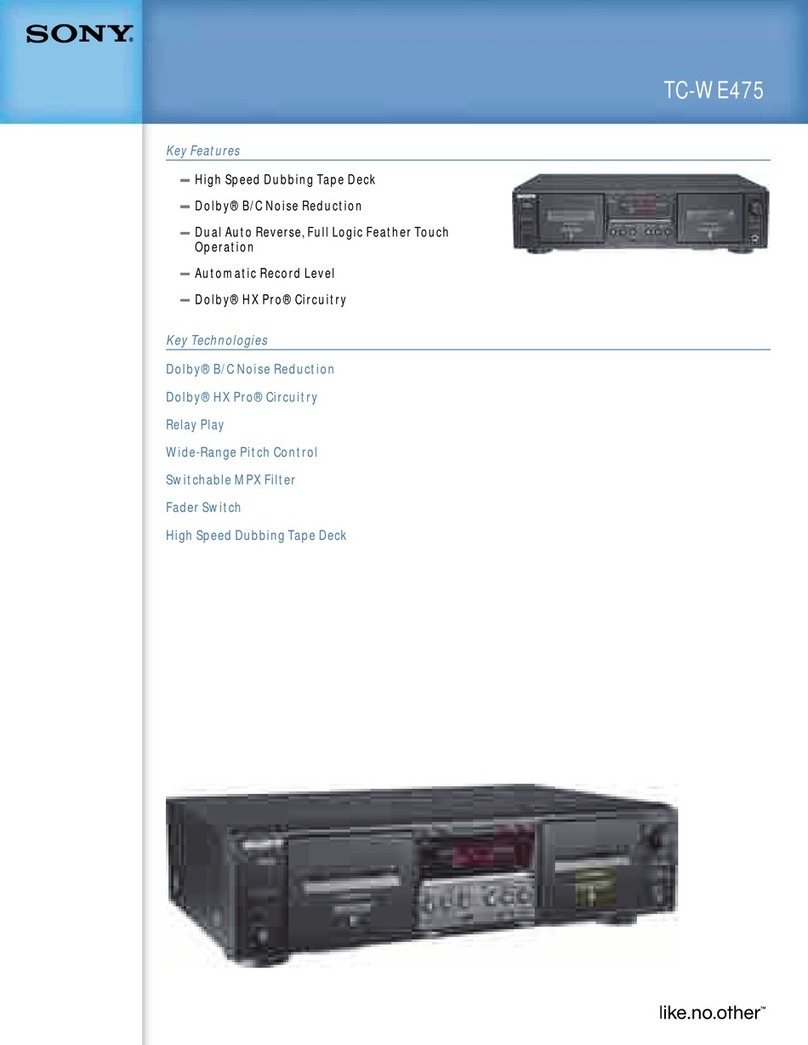

Sony TCW-E475 User manual

Sony

Sony Sports Walkman WM-FS495 User manual