1-1 (E)

BDX-M1000

Section 1

Installation

1-1. Installation Environment

Operating temperature : 5dC to 40dC

Storage temperature : _20dC to +60dC

Operating humidity : 20%to 90%(non-condensing)

Do not install the BDX-M1000 in the following locations:

.Areas where the unit will be exposed to direct sun light

or any other strong lights.

.Areas near heat sources.

.Dusty areas or areas where it is subject to vibration.

.Areas with strong electric or magnetic fields.

.Areas where is subjected to electricity noise.

.Areas where is subjected to static electricity noise.

To prevent the temperature rise inside the BDX-M1000,

pay careful attention to circulation of air in the place where

the BDX-M1000 is installed.

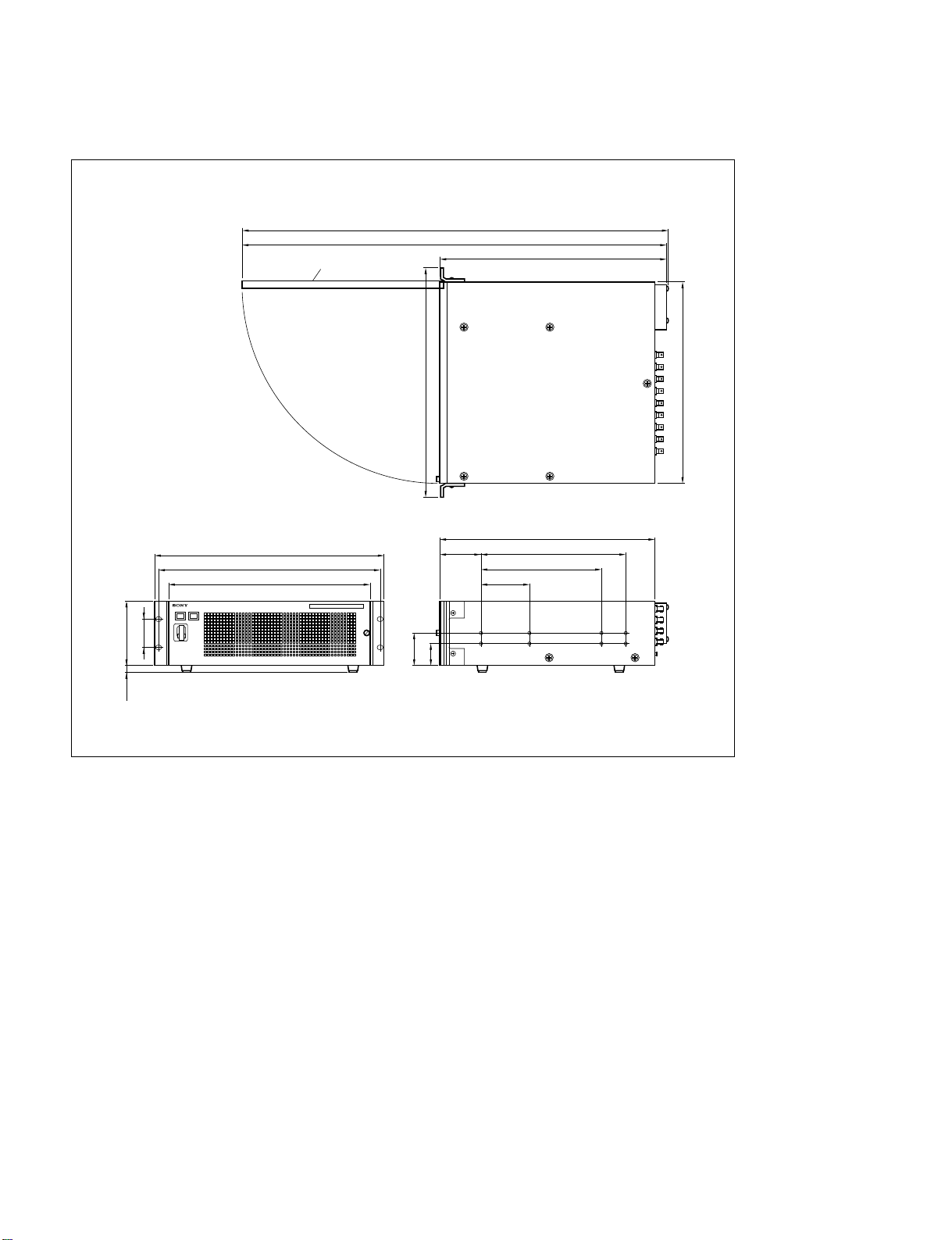

The rear side of the BDX-M1000 should be at least 20 cm

(8 inches) away from walls for ventilation and

maintenance.

c

Do not block the ventilation holes.

If the ventilation holes are blocked, overheating inside the

unit may cause fire.

1-2. Power Supply

1-2-1. Power Specifications

Power requirements : AC 100 to 240 V

50/60 Hz

Current consumption: maximum 2.0 A (at 100 V)

maximum 1.0 A (at 240 V)

A switching regulator is used for the power supply of the

BDX-M1000. The voltage within the range of 100 V to

240 V can be used without changing the supply voltage.

n

As the inrush current at turn-on is maximum 20 A (at

100 V)/maximum 40 A (at 240 V), the capacity of the AC

power must be adequate with the inrush current of maxi-

mum 20 A (at 100 V)/maximum 40 A (at 240 V).

If the capacity of the AC power is not the adequately large,

the breaker of the AC power at the supply side will operate

or the BDX-M1000 will abnormal operate.

1-2-2. Power Cord

w

To avoid a fire or an electric shock, be sure to use the

designated power cord. And do not damage to the power

cord.

n

For the customer outside of the area as shown above or in a

part of Europe, the above-mentioned power cords can not

be used.

Use the power cord that is applicable to the places in the

world.

1 2

2

2

Power cord for the customer in the U.S.A. and Canada.

1Power cord set !1-557-377-11

2Plug holder (Black) 2-990-242-01

Power cord for the customer in the United Kingdom.

1DK-2401 (UK) (approx. 2.4 m)

2Plug holder (Black) 2-990-242-01

Plug holder is included in DK-2401 (UK).

Power cord for the customer in Europe except the

United Kingdom.

1DK-2401 (AE) (approx. 2.4 m)

2Plug holder (Brown) 3-613-640-01

Plug holder is included in DK-2401 (AE).

AC inlet

AC inlet

1

AC inlet

1