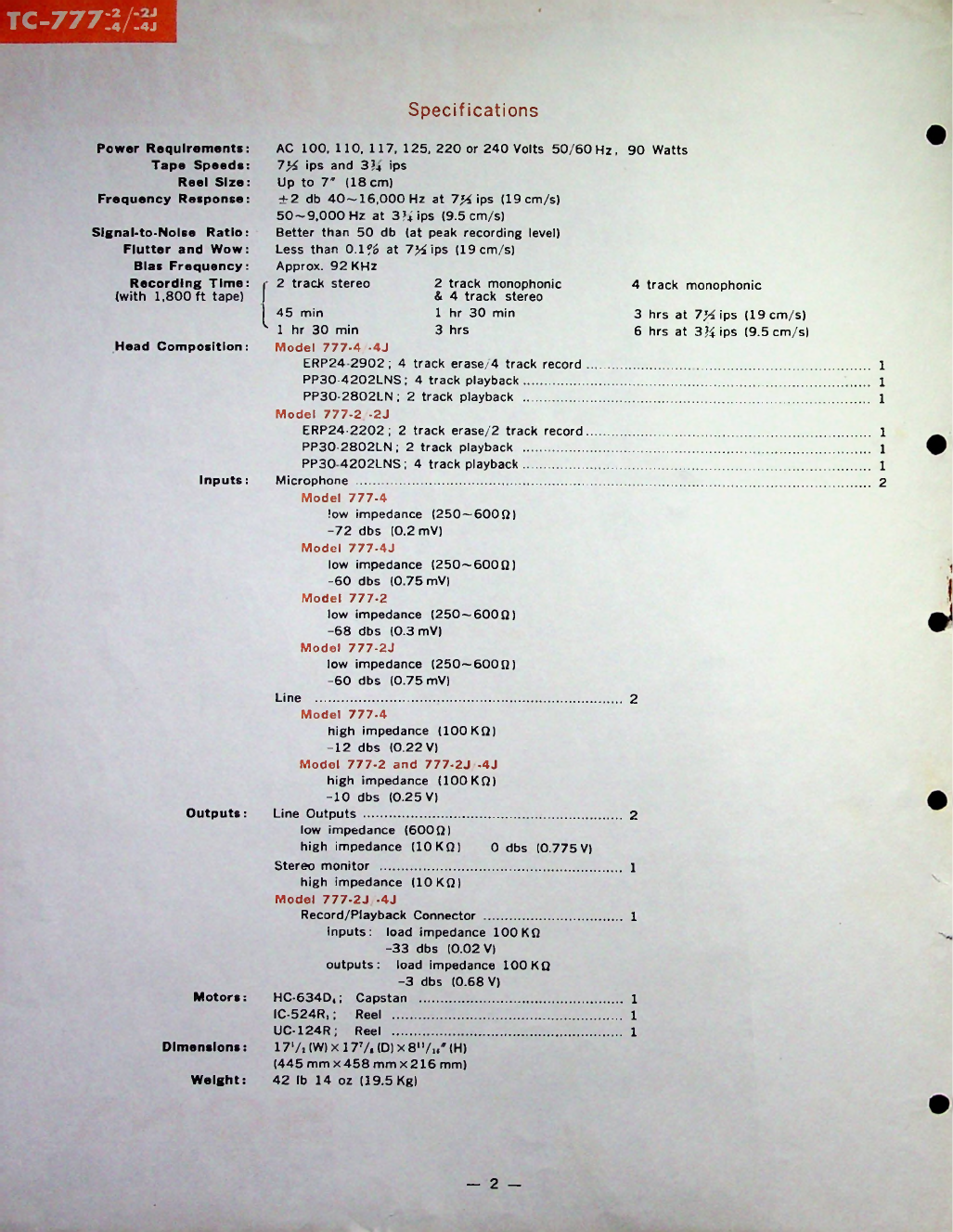

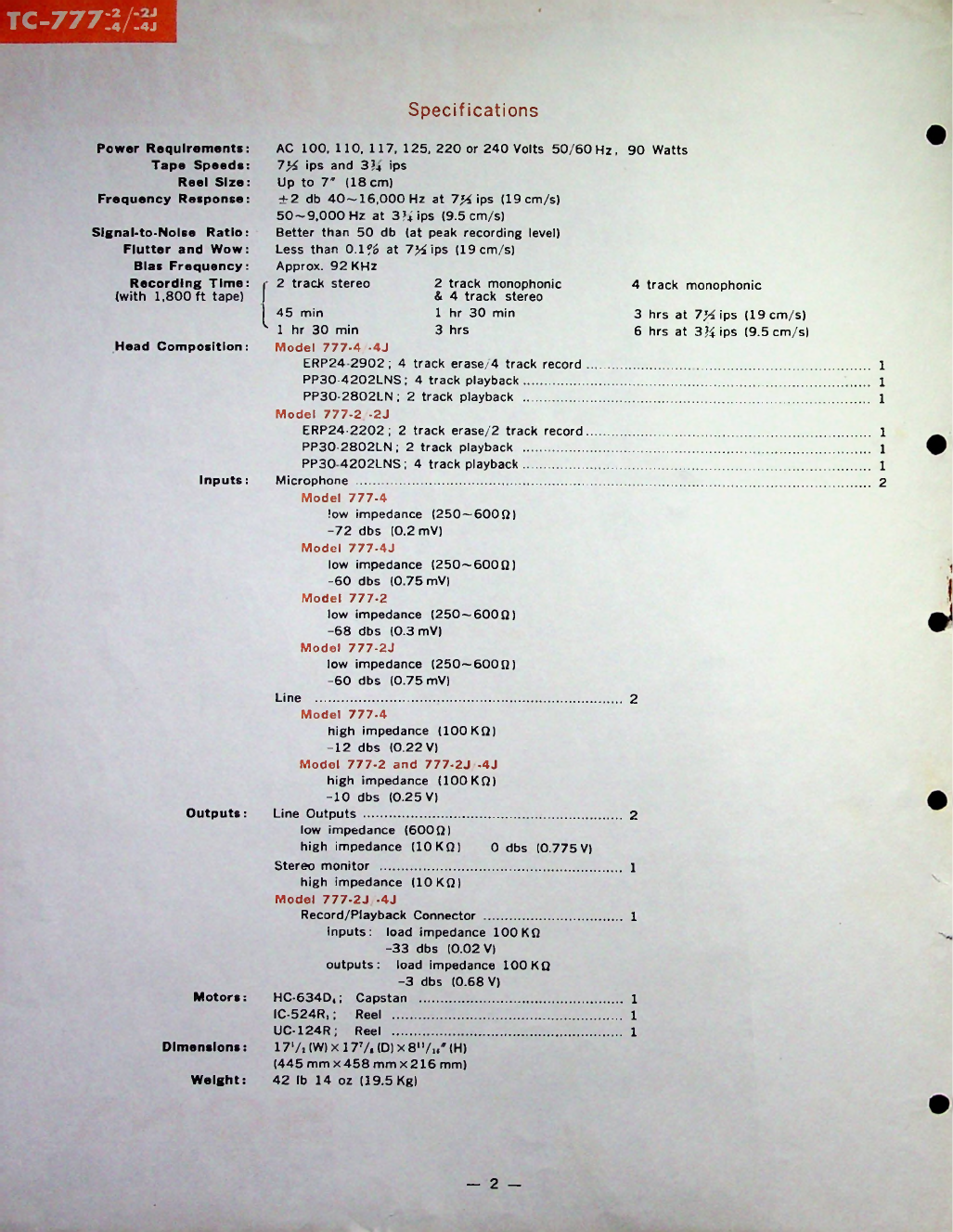

Specifications

4

track

monophonic

Head

Composition:

Inputs

:

2

Outputs

:

2

0

dbs

(0.77

V)

1

1

outputs

:

Motors

:

Dimensions

:

Weight:

2

-

1

1

1

Signal-to-Nolse

Ratio:

Flutter

and

Wow:

Blas

Frequency:

Recording

Time:

(with

1,800

ft

tape)

Power

Requirements:

Tape

Speeds:

Reel

Size:

Frequency

Response:

2

track

monophonic

&

4

track

stereo

1

hr

30

min

3

hrs

3

hrs

at

7'/i

ips

(19

cm/s)

6

hrs

at

3J4ips

(9.

cm/s)

1

1

1

1

1

1

2

IC- 24R,

;

UC-124R;

17*/,

(W)

x

177.

(0)

x

8'7..'

(H)

(44

mm

x

4 8

mm

x

216

mm)

42

lb

14

oz

(19.

Kg)

AC

100,

110,

117,

12 ,

220

or

240

Volts

0/60

Hz,

90

Watts

7%

ips

and

3?4

ips

Up

to

7*

(18

cm)

±2

db

40-16,000

Hz

at

7%

ips

(19

cm/s)

0-9,000

Hz

at

3?;

ips

(9.

cm/s)

Better

than

0

db

(at

peak

recording

level)

Less

than

0.1%

at

7>4ips

(19

cm/s)

Approx.

92

KHz

2

track

stereo

tc

-777:V:4

j

j

Line

...........................................................

Model

777-4

high

impedance

(100

KQ)

-12

dbs

(0.22

V)

Model

777-2

and

777-2J

-4J

high

impedance

(100

KQ)

-10

dbs

(0.2

V)

Line

Outputs

.....................................

low

impedance

(600

Q)

high

impedance

(10

KQ)

Stereo

monitor

...............................

high

impedance

(10

KQ)

Model

777-2J

-4J

Record/Playback

Connector

inputs:

load

impedance

100

KQ

-33

dbs

(0.02

V)

load

impedance

100

KQ

-3

dbs

(0.68

V)

HC-634D,

;

Capstan

..........................................

Reel

....................................................

Reel

....................................................

4

min

k

1

hr

30

min

Model

777-4

-4J

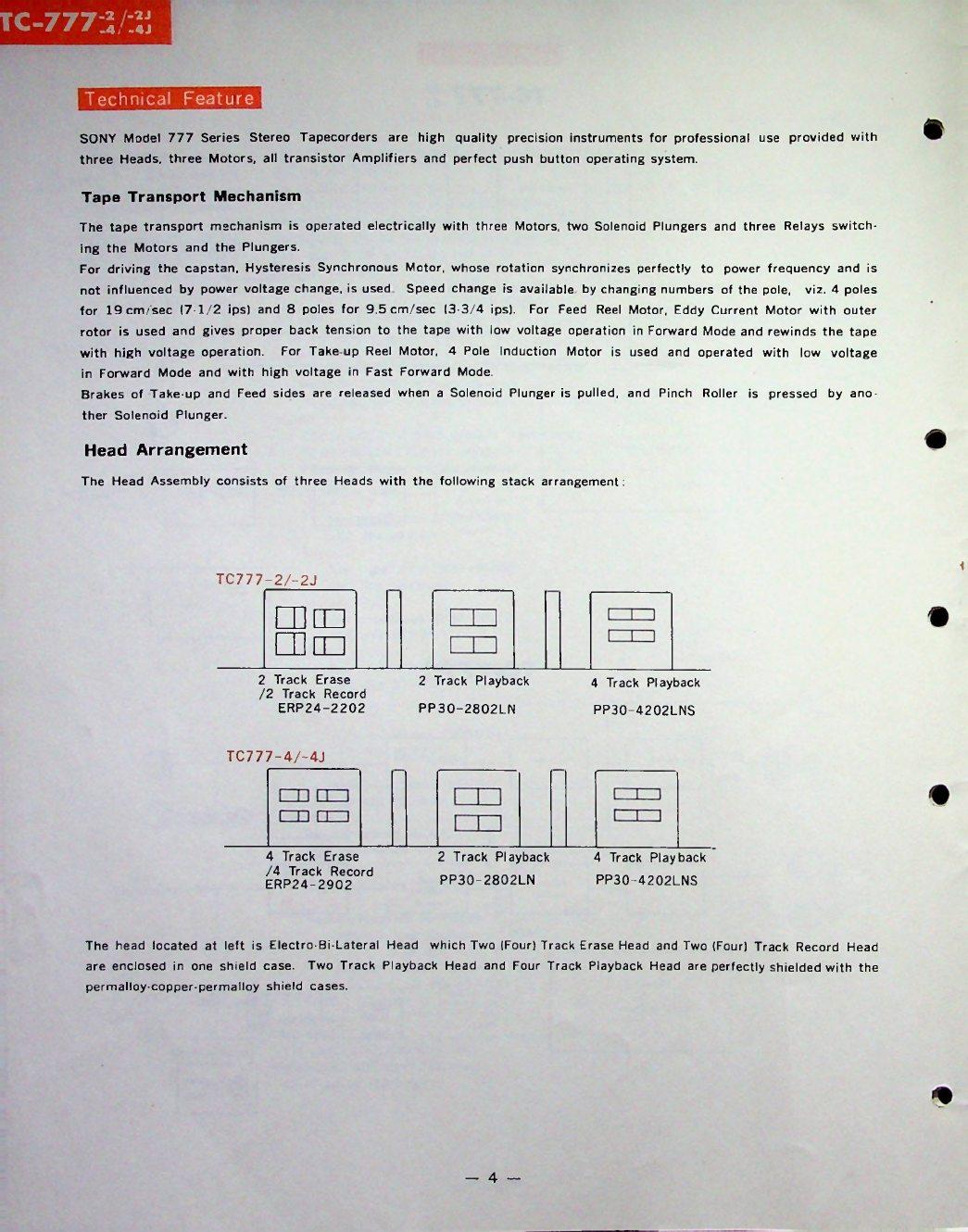

ERP24

2902;

4

track

erase/4

track

record

PP30-4202LNS

;

4

track

playback

...................

PP30-2802LN

;

2

track

playback

...................

Model

777-2

-2J

ERP24-2202

;

2

track

erase/2

track

record

PP30-2802LN

;

2

track

playback

...................

PP30

4202LNS

;

4

track

playback

...................

Microphone

..........................................................................

Model

777-4

low

impedance

(2 0

—

600Q)

-72

dbs

(0.2

mV)

Model

777-4J

low

impedance

(2 0

—

600Q)

-60

dbs

(0.7

mV)

Model

777-2

low

impedance

(2 0

—

600Q)

-68

dbs

(0.3

mV)

Model

777-2J

low

impedance

(2 0

—

600Q)

-60

dbs

(0.7

mV)