3

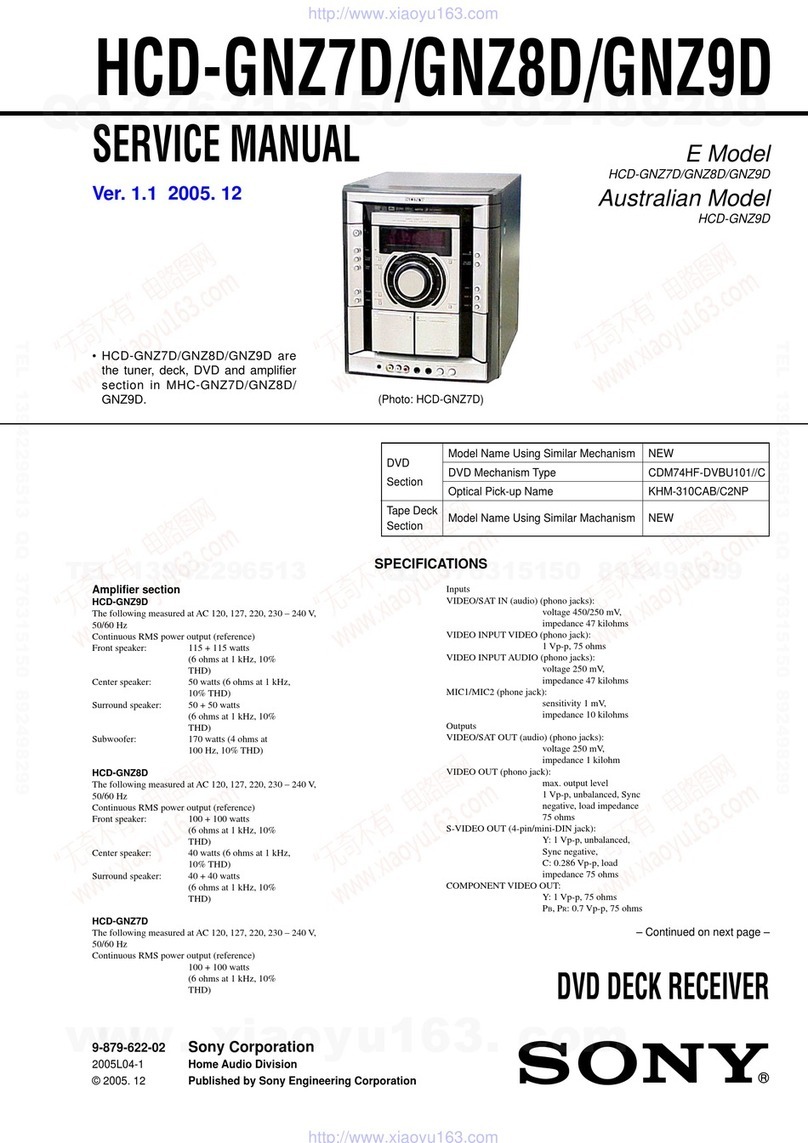

HCD-GNX600

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL

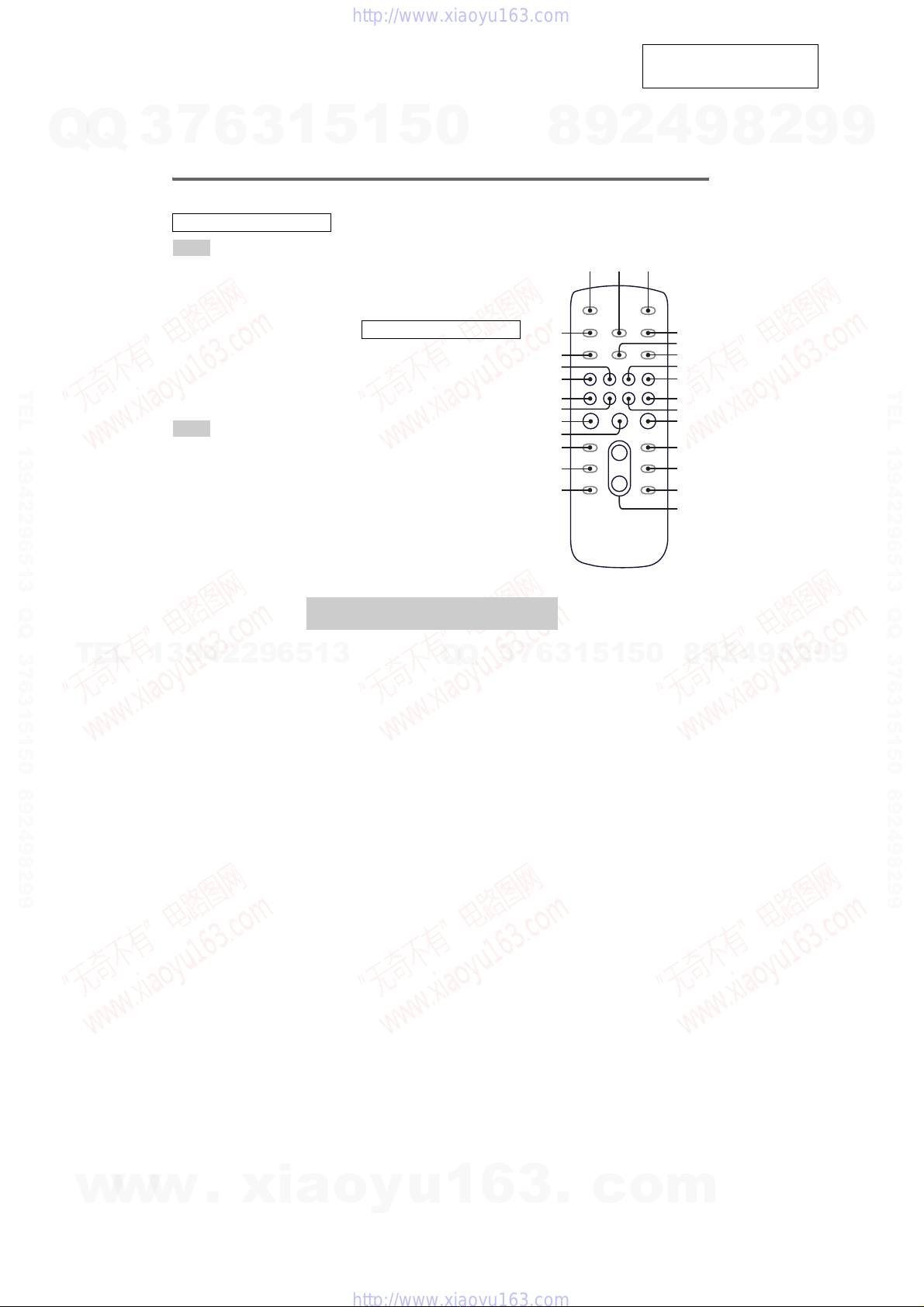

Locating the Controls ...................................................... 5

Setting the Clock ............................................................. 6

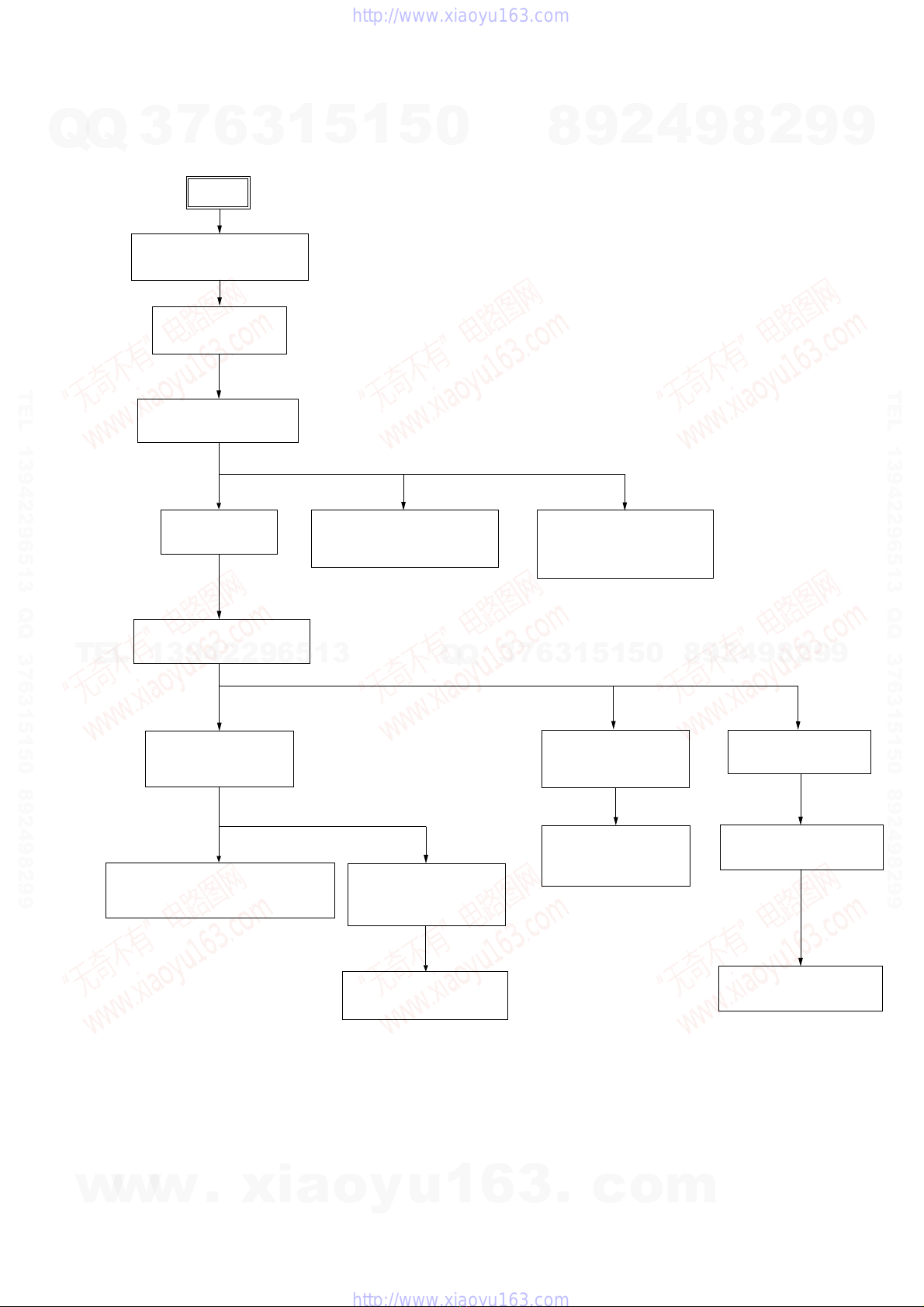

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

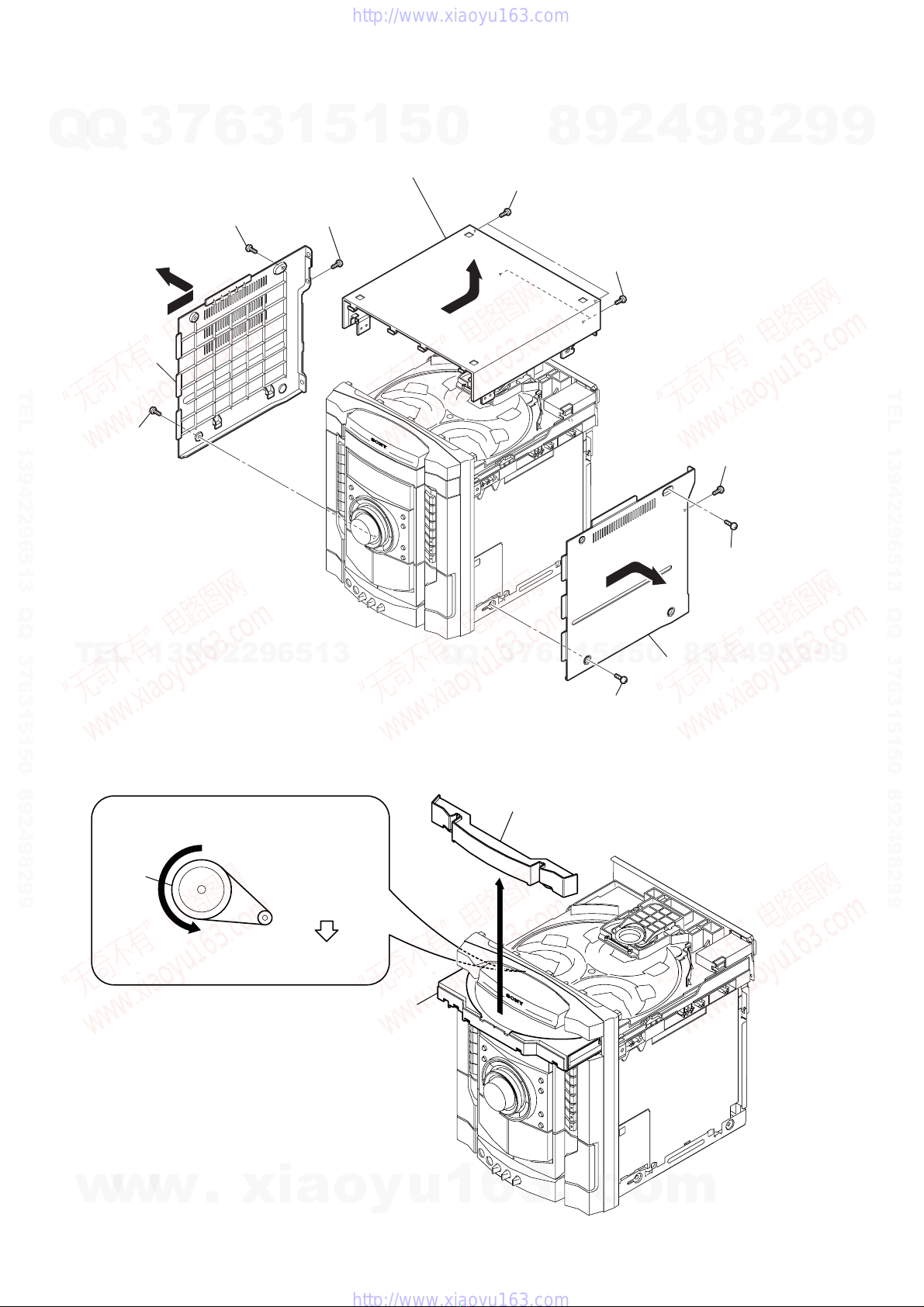

3-2. Side Case, Top Case ........................................................ 8

3-3. Loading Panel.................................................................. 8

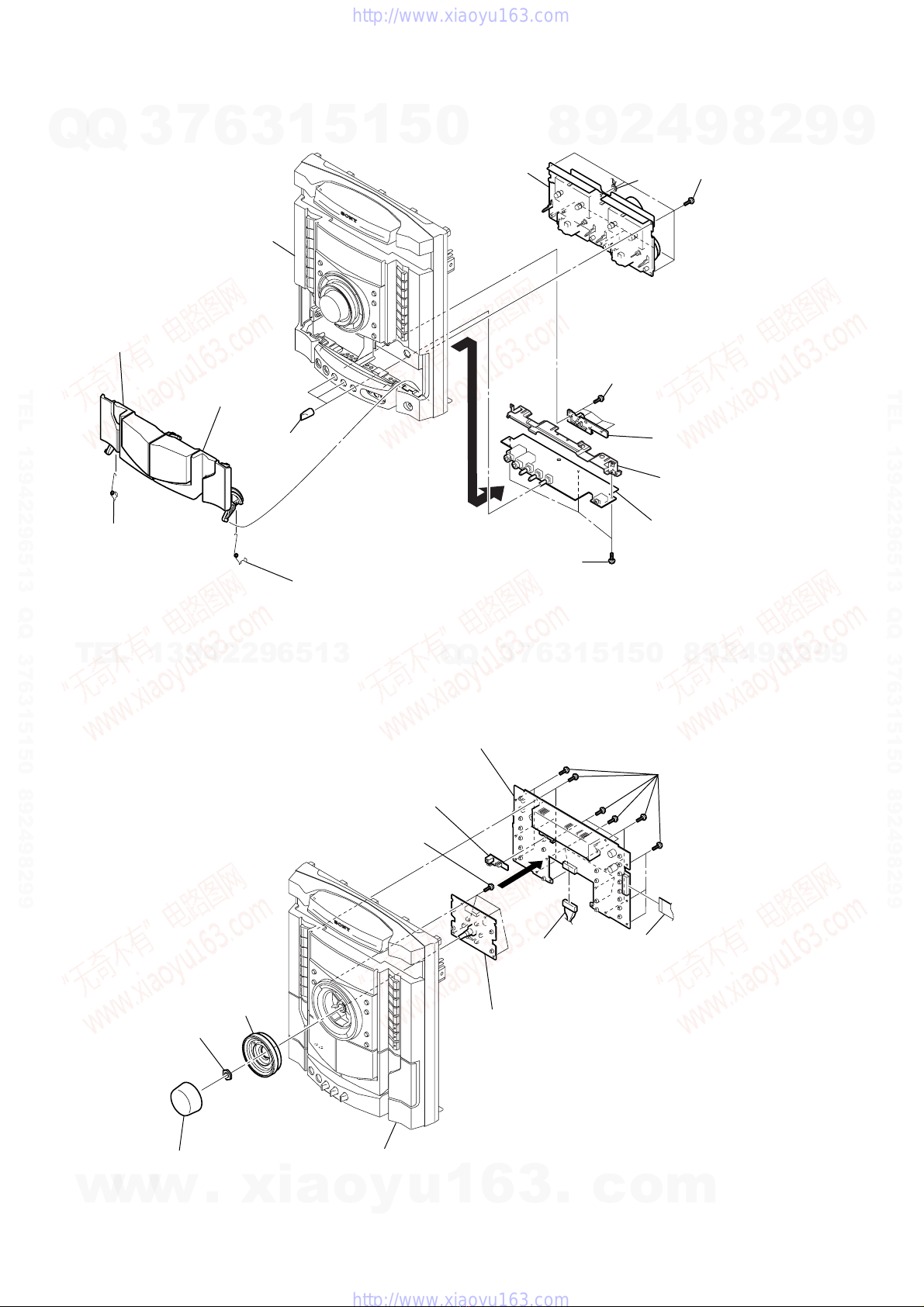

3-4. Front Panel Assy.............................................................. 9

3-5. Tuner Pack ....................................................................... 9

3-6. Tape Mechanism Deck, MIC Board ................................ 10

3-7. PANEL Board, IR Board, VOL Board ............................ 10

3-8. CD Mechanism Deck ...................................................... 11

3-9. Back Panel, DC FAN (M891) ......................................... 11

3-10. MAIN Board, ADC Board............................................... 12

3-11. POWER Board, SPEAKER Board.................................. 12

3-12. SMASTER Board............................................................ 13

3-13. DRIVER Board, SW Board............................................. 13

3-14. CD Board, Optical Pick-up ............................................. 14

3-15. SENSOR Board ............................................................... 14

3-16. MOTOR (TB) Board ....................................................... 15

3-17. MOTOR (LD) Board....................................................... 15

4. TEST MODE.............................................................. 16

5. MECHANICAL ADJUSTMENTS ....................... 20

6. ELECTRICAL ADJUSTMENTS

Deck section .................................................................... 20

CD Section ...................................................................... 21

7. DIAGRAMS.................................................................... 24

7-1. Block Diagram – CD Section – ...................................... 26

7-2. Block Diagram – Tape/Tuner Section – ......................... 27

7-3. Block Diagram – Main Section – ................................... 28

7-4. Block Diagram – AMP Section – ................................... 29

7-5. Block Diagram – Display/Power Section –.................... 30

7-6. Printed Wiring Board – CD Board – .............................. 31

7-7. Schematic Diagram – CD Board – ................................. 32

7-8. Printed Wiring Boards – CD Mechanism Sectiom –...... 33

7-9. Schematic Diagram – CD Mechanism Section – ........... 34

7-10. Printed Wiring Board – MAIN Board – ......................... 35

7-11. Schematic Diagram – MAIN Board (1/3) – ................... 36

7-12. Schematic Diagram – MAIN Board (2/3) – ................... 37

7-13. Schematic Diagram – MAIN Board (3/3) – ................... 38

7-14. Printed Wiring Board – PANEL Section – ..................... 39

7-15. Schematic Diagram – PANEL Section – ......................... 40

7-16. Printed Wiring Boards

– MIC,VOL and SPEAKER Boards – ............................ 41

7-17. Schematic Diagram

– MIC,VOL and SPEAKER Boards – ............................ 42

7-18. Printed Wiring Board – ADC Board –............................ 43

7-19. Schematic Diagram – ADC Board – .............................. 44

7-20. Printed Wiring Board – SMASTER Board (Side A)– ... 45

7-21. Printed Wiring Board – SMASTER Board (Side B)– .... 46

7-22. Schematic Diagram – SMASTER Board (1/2)– ............ 47

7-23. Schematic Diagram – SMASTER Board (2/2)– ............ 48

7-24. Printed Wiring Boards – Power Board – ........................ 49

7-25. Schematic Diagram – Power Board – ............................ 50

7-26. IC Pin Function Description............................................ 54

8. EXPLODED VIEWS

8-1. Case (Top), Back Panel Section ...................................... 61

8-2. Front Panel Section ......................................................... 62

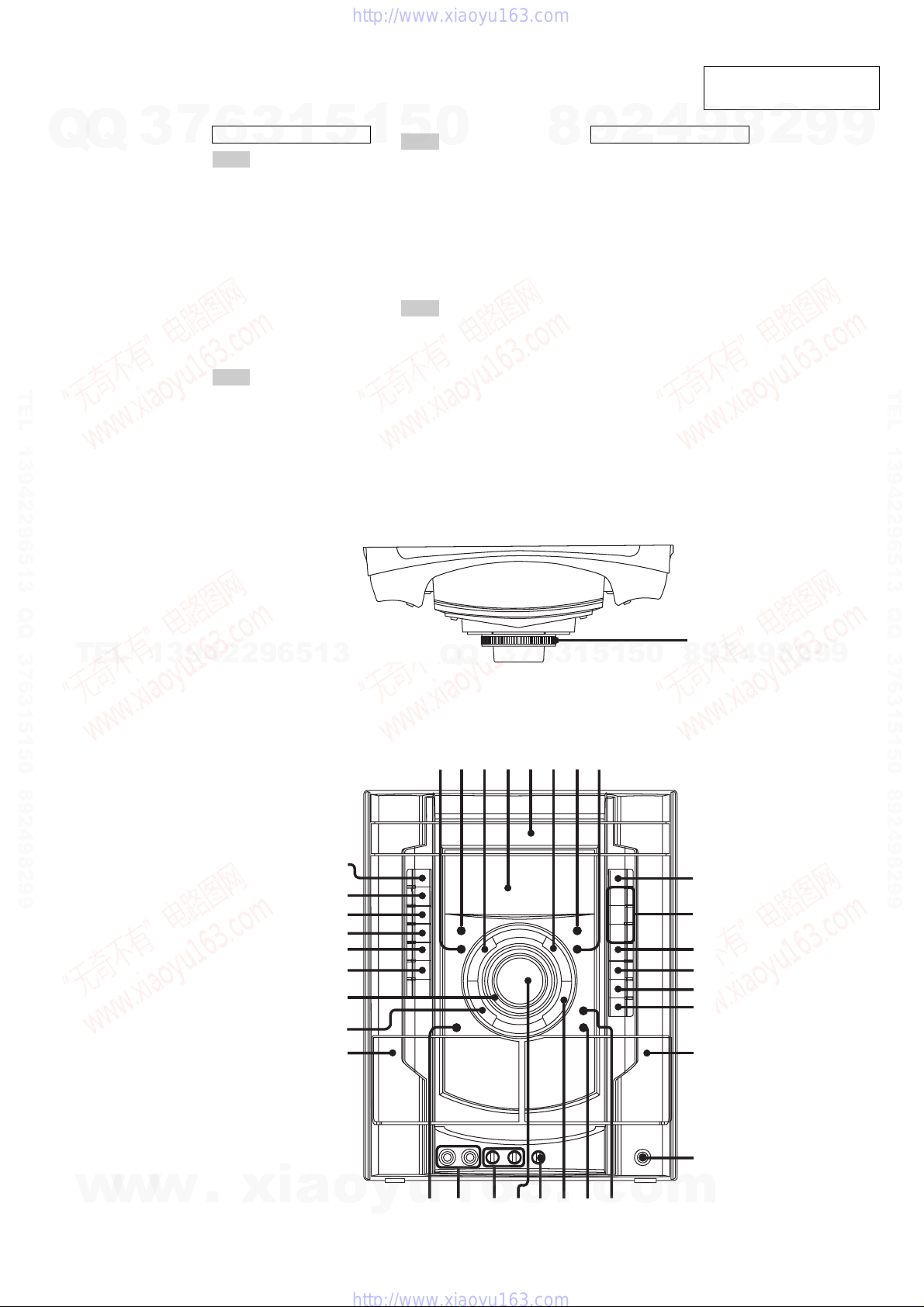

8-3. Chassis Section................................................................ 63

8-4. CD Mechanism Deck Section-1 ...................................... 64

8-5. CD Mechanism Deck Section-2 ..................................... 65

9. ELECTRICAL PARTS LIST................................ 66

w

w

w

.

x

i

a

o

y

u

1

6

3

.

c

o

m

Q

Q

3

7

6

3

1

5

1

5

0

9

9

2

8

9

4

2

9

8

T

E

L

1

3

9

4

2

2

9

6

5

1

3

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299

http://www.xiaoyu163.com

http://www.xiaoyu163.com