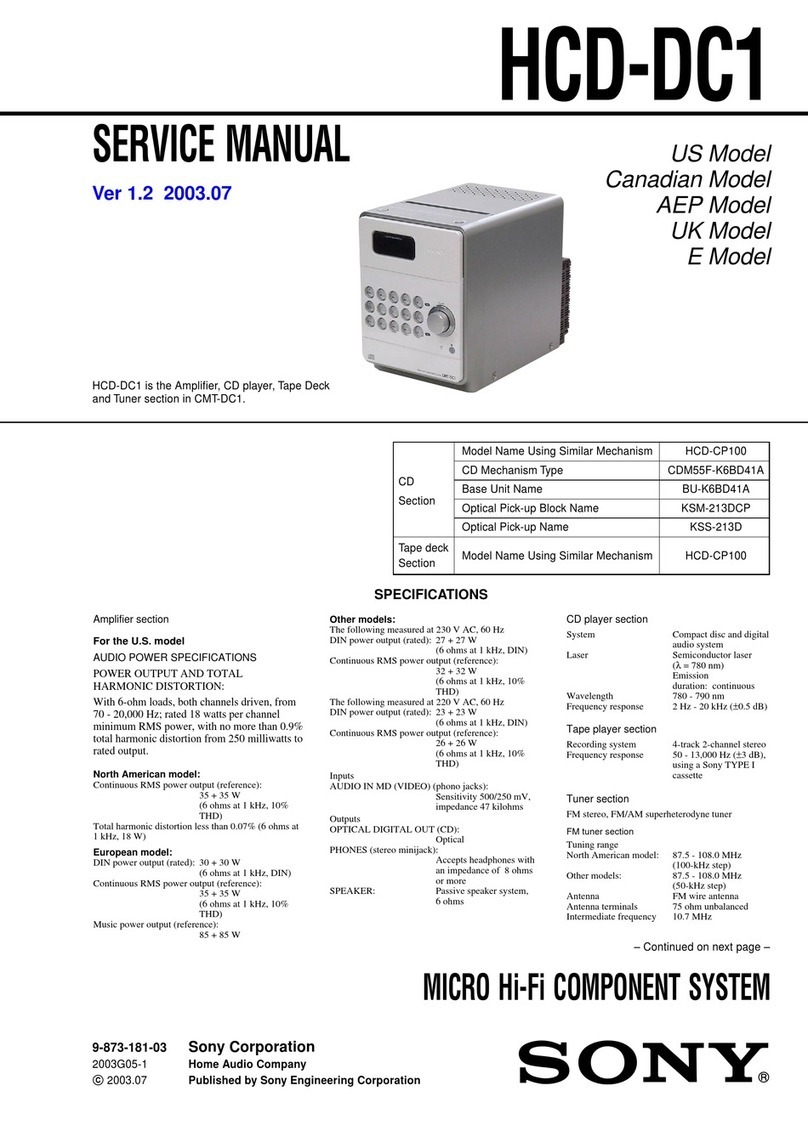

– 4 –

SECTION 1

SERVICING NOTES

NOTES ON HANDLINGTHE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pick-up

block. Therefore, when checking the laser diode emission, observe

more than 30 cm away from the objective lens.

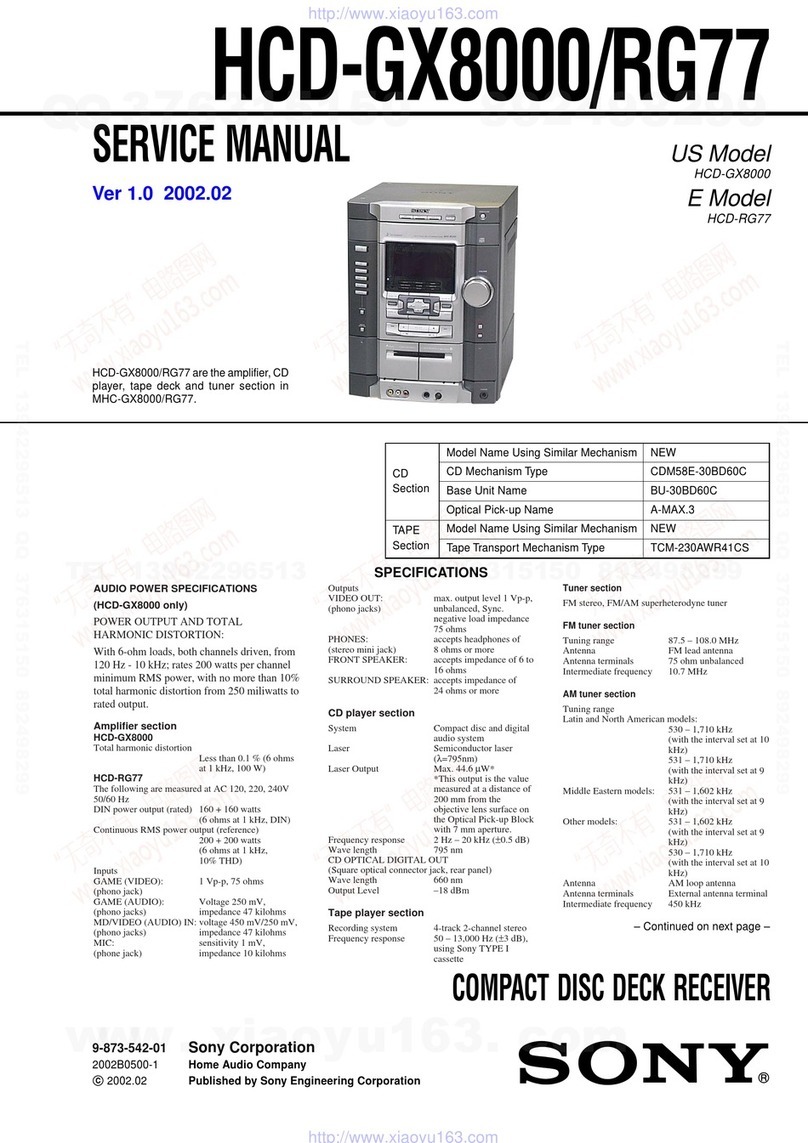

Cautions when replacing IC121 and

IC171 on the BD board

A change has been made from CXD2535BR due to a modification of

IC121 on the BD board in this unit.

Accompanying this modification, a portion of the nonü]volatile

memory of IC171 (XC24CO1S) has been changed.

Conversely, when IC121 has been replaced, use CXD2535BR and

rewrite the contents of IC171.

Contents of non-volatile memories CXD2535BR

Address CXD2535BR

15 93

2D 1A

2E 1A

Rewrite Procedure for Non-volatile Memory

(1) With the power switched off and the power plug plugged into a

socket.press the BASS/TREBLEbutton. CLOCK button,andMD

button more than one at a time in order.

(2)Rotate the JOG dial knob and display the “EEP MODE”.

When you press theYES key, the display changes to show

“EEP**@@”.

(Here, **indicates the address, and @@ indicates the data.)

(3)Rotate the JOG dial knob and display the “EEP 15 @@”.

(4)When you press the CD SYNCHRO button, “EEP 15 @@>@@”

is displayed so then turn the JOG dial knob to show ügEEP 15

@@>93”

(5)Press the YES key and “COMPLETE” will appear for a moment

and data shown as “EEP 15 93” is being rewritten.

(6)Rewrite address 2D and address 2E, into 1A using steps (3) to (5)

above.

(7)When all changes are complete, press the NO key and display

“EEP MODE”.

(8)Press the REPEAT button. If no disc is loaded, the time is dis-

played, so unplug the power plug. If a disc is loaded, the disc is

ejected, then the time is displayed. Unplug the power plug from

the socket to end EEP rewrite mode. (See “How to end test mode”

below.)

Note: Changes in the contents of non-volatile memory are not re-

flected until the power is switched off, then on.

HOW TO END TEST MODE

Method :

l Press the REPEAT button.

2 If no disc is loaded, the time is displayed. If a disc is loaded, the

disc is ejected, then the time is displayed .

3 Unplug the power plug from the socket.

ENTERINGTEST MODE

When you press the DISP button, pbutton, and EDIT

button at the

same tilne, the system goes into key, fluorescent tube, jogr and LED

check mode.

rFluorescent tube check

All the lights light up. Then, each time you press the

ENTER

but-

ton, the display mode changes as shown below.

nAll lit npartially lit l npartially lit 2

rLED check

When you turn the jog dial, the LEDS change froln all lit to indi-

vidually lit.

rKey check

The EDIT/NO button puts the system into key/jog check mode .

When you press a button, the number is counted up.

However, pressing a button again that you already pressed does

not count up the number.

Turning the jog dial to the right increases the jog count display,

turning the jog dial to the left decreases the jog count.

When you have pressed all the buttons and “KEY= 0K” is dis-

played, pressing any button ends test Inode.