Sound Skulptor MP 512 User manual

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

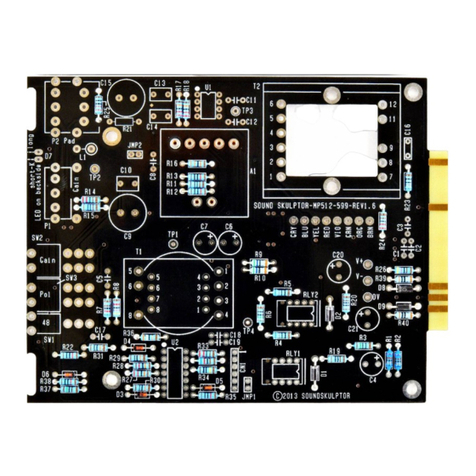

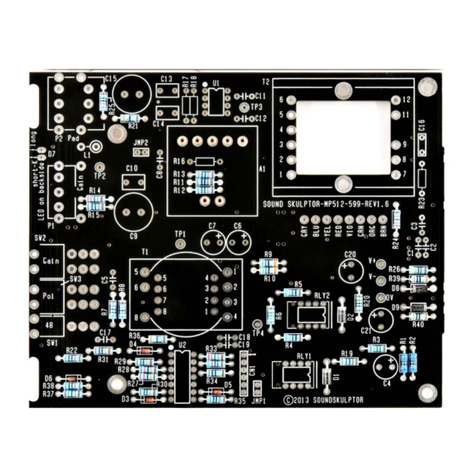

M 5.12 Assembly guide

Safety warning

The kits are main powered and use potentially lethal voltages. Under no circumstance should someone undertake the

realisation of a kit unless he has full knowledge about safely handling main powered devices.

lease read the “DIY guide” before beginning.

rint or open the following documents :

•M 512 Schematics

•M 512 Components layout

•M 512 arts list

•M 512 Test guide

Follow this guide from item number 1 till the end, in this order. The assembly order is based on components height, from

low to high profile, in order to ease the soldering process : The component you are soldering is always taller than the

previously assembled ones and it is pressing nicely against the work area foam.

M 5.12 Assembly guide

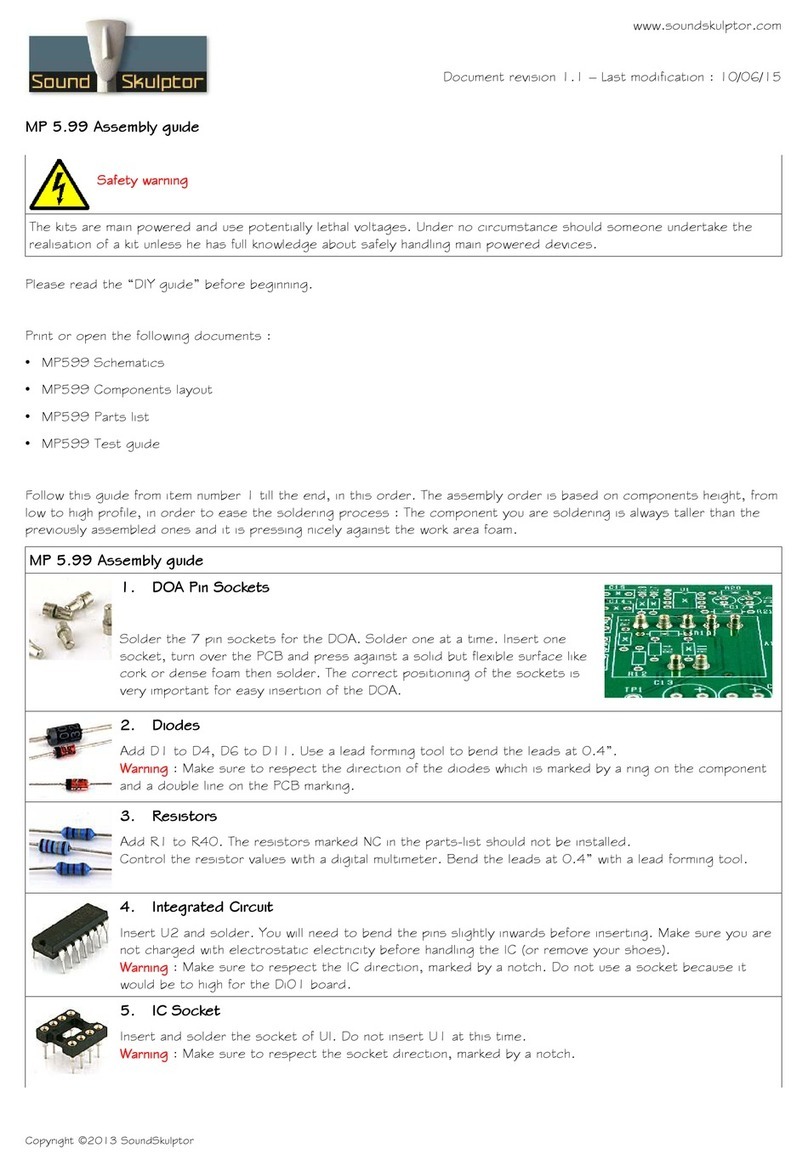

1. DOA in Sockets

Solder the 7 pin sockets for the DOA. Solder one at a time. Insert one

socket, turn over the CB and press against a solid but flexible surface like

cork or dense foam then solder. The correct positioning of the sockets is

very important for easy insertion of the DOA.

2. Diodes

Add D1 to D4, D6 to D11. Use a lead forming tool to bend the leads at 0.4”.

Warning : Make sure to respect the direction of the diodes which is marked by a ring on the component

and a double line on the CB marking.

3. Resistors

Add R1 to R40. The resistors marked NC in the parts-list should not be installed.

Control the resistor values with a digital multimeter. Bend the leads at 0.4” with a lead forming tool.

4. Integrated Circuit

Insert U2 and solder. You will need to bend the pins slightly inwards before inserting. Make sure you are

not charged with electrostatic electricity before handling the IC (or remove your shoes).

Warning : Make sure to respect the IC direction, marked by a notch. Do not use a socket because it

would be to high for the Di01 board.

5. Inductor

Add L1. Bend at 0.8”.

Copyright ©2013 SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

M 5.12 Assembly guide

6. Led

Bend the leads of D5 right angle at 6mm from the body taking care of the

anode position (the longest lead).Insert from the CB bottom and solder with

the LED body lined up with the CB

surface.

Warning : it is easy to bend the leads in

the wrong direction !

7. Test pins

Solder the 6 test pins T 1 to T 3, V+, V- and GND.

8. Jumper header

Solder the jumper header JM 3. Solder one pin first, check verticality, then solder the other pins.

9. Connector

Solder the connector socket CN1. Solder one pin first, check verticality, then solder the other pins.

10. Ceramic capacitors

Add C5.

Warning : Some capacitors have provision for 2 sizes. Small size capacitors must be inserted in the

correct holes as shown in the picture.

11. Film capacitors

Add C1, C2, C10, C11, C20.

Warning : Some capacitors have provision for 2 sizes. Small size capacitors

must be inserted in the correct holes as shown in the picture.

Copyright ©2013 SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

M 5.12 Assembly guide

12. Relay

Add RLY1 and RLY2.

13. Small electrolytic capacitors

Add C3, C4, C12, C13, C21, C22, C23.

Solder one lead first, adjust verticality then solder the second lead.

Warning : The +lead must go into the +hole. Do not reverse (they may explode !)

14. Switches

Add SW1, SW2 and SW3. The position of the switches is critical for a good front-plate matching. They

must sit flat on the CB. ress firmly the switch on the CB and solder one of the front pins (housing).

Check verticality and horizontality. Then solder the other pins.

Copyright ©2013 SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

M 5.12 Assembly guide

15. otentiometers 1 & 3

lace the bracket on the potentiometer bush. Do not insert the nut yet. Insert potentiometer and

bracket into the CB holes. Solder the 2 central potentiometer pins, taking care that it sits perfectly flat

on the CB.

Warning : The bracket sometimes prevents a correct positioning of the pot. In that case, angle slightly

the bracket so that it does not come in the way. Il will take its correct position after the pot is soldered.

Once the position is correct, solder the other 4 potentiometer pins.

Now attach the washer and nut to the potentiometer bush and tighten gently.

Last, solder the 4 bracket pins.

16. Input transformer

It is necessary to leave a small gap between the transformer and the CB surface in order to avoid any

electrical contact between the metal case and pads. Fit a piece of double sided adhesive tape under the

transformer, between the pins. It is not necessary to remove the second protective layer from the tape

as it is only used as a spacer.

in 1 on the transformer is identified by a red dot. Insert the transformer, pin 1 into hole number 1.

Start soldering 2 opposite pins, check the position, adjust if necessary then solder the other pins.

Warning : Double check the pin 1 position because this transformer can be mounted backwards!

17. Output transformer

The transformer is mounted using two 25mm M3 screws inserted

from the back of the board. Two metal washers are fitted on each

screw to prevent the transformer touching the CB. One more

washer is used before the nut to protect the lams.

Shorten the leads to the necessary length, around 6 cm. Strip on

5mm and tin them. Insert in the pad hole and bend the tinned tip flat

on the pad before soldering. Cut flush.

Warning: There is an error in the CB writings. It is necessary to swap the green and grey wires to keep

the phase correct. The green wire goes into the GRY hole and the grey wire goes into the GRN hole.

18. Large electrolytics

Add C8, C9 and C19.

These capacitors are bipolar so they can be inserted in any direction.

19. Jumpers

Insert 2 jumpers on JM 3.

These jumpers set the output transformer ratio to 1:2. One single jumper placed on the center 2 pins

would set it to 1:1.

Copyright ©2013 SoundSkulptor

Nut

Transformer

CB

1 Washer

2 Washers

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

M 5.12 Assembly guide

20. Visual check

At this point, brush the solder side with a hard tooth brush to remove any remaining solder bits.

Make a full visual check. Any missing component on the board ? Any remaining component in the box ?

When everything looks correct, proceed with the frame assembly.

21. Frame assembly

Attach the side panel to the front plate with two M3x8 black

countersunk screws.

Warning : Do not confuse the M3x8mm countersunk black

screws with the #4-40 3/8" black screw that are used to

attach the module in the lunchbox.

22. CB mounting

ut the CB in place, switches and pots going through the front panel. Watch out the LED position.

Attach the CB with 4 M3x6mm screws and 4 shake-proof washers.

Copyright ©2013 SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

M 5.12 Assembly guide

23. Knobs

Attach the 2 knobs.

24. Test

Your M 5.12 is now ready for test. lease follow instructions in the “M 512 Test” document.

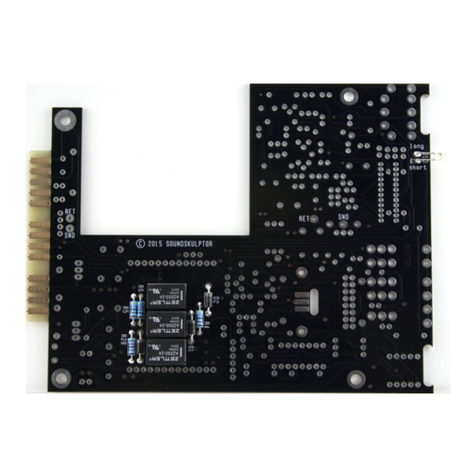

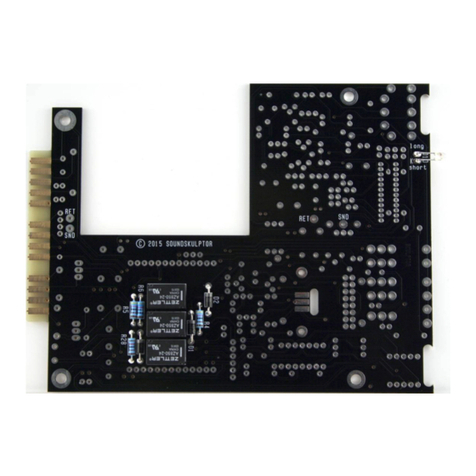

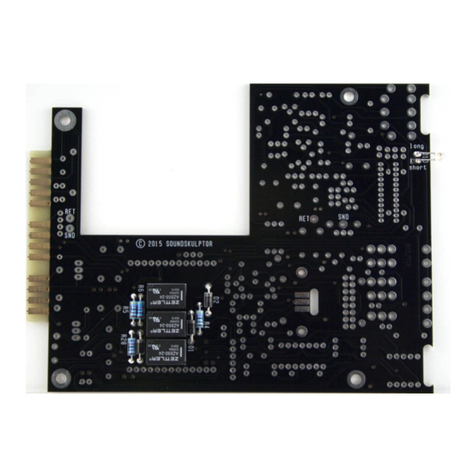

Di01 Assembly guide

rint or open the following documents :

•Di01 Schematics

•Di01 Components layout

•Di01 arts list

Copyright ©2013 SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

Di01 Assembly guide

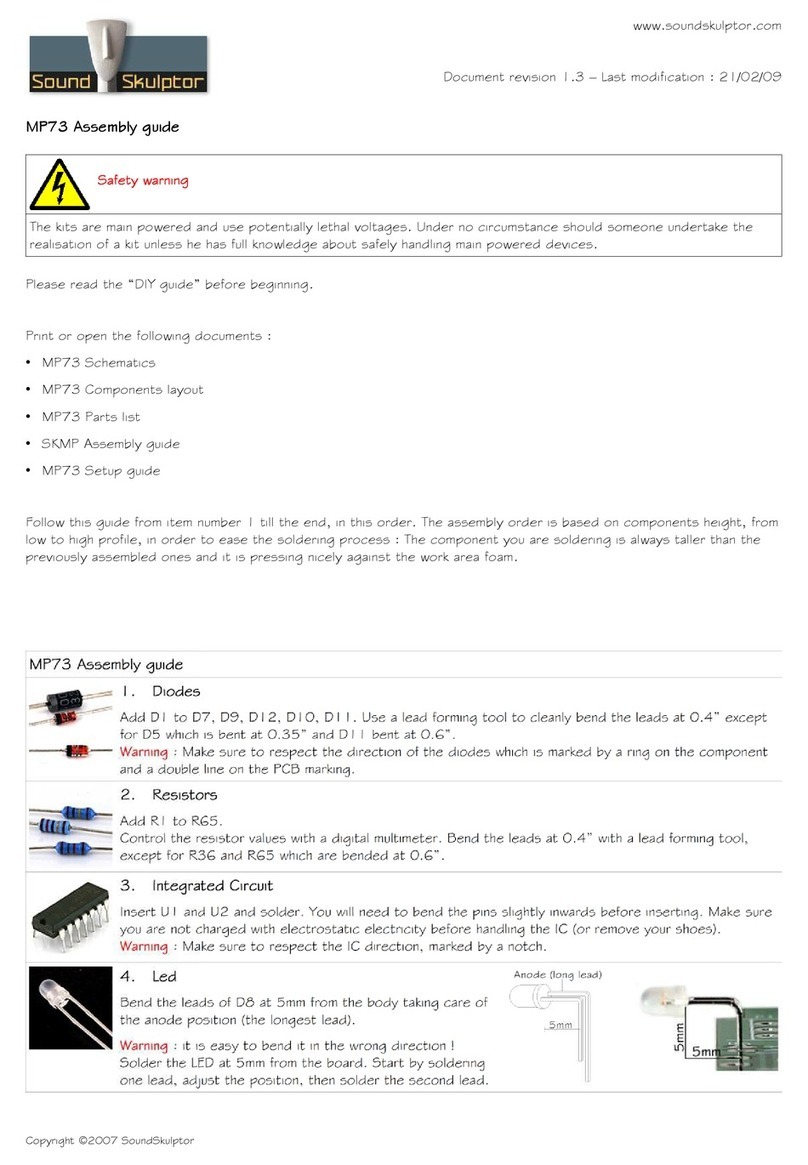

1. Diodes

Add D1, D2 and D3. Use a lead forming tool to bend the leads at 0.4”.

Warning : Make sure to respect the direction of the diodes which is marked by a ring on the component

and a double line on the CB marking.

2. Resistors

Add R1 to R11.

Control the resistor values with a digital multimeter. Bend the leads at 0.4” with a lead forming tool.

3. Film capacitor

Add C1.

4. Transistors

Add Q1 and Q2.

Warning : Watch out the transistor direction.

5. Electrolytic capacitors

Add C2, C3, C4.

Solder one lead first, adjust verticality then solder the second lead.

Warning : The +lead must go into the +hole. Do not reverse (they may explode !)

6. Jack connector

Add CN1. The position of the socket is important for a good front-plate matching. It must sit flat

on the CB. ress firmly the socket on the CB and solder one of the pins. Check position then solder

the other pins.

7. Connector

Solder the connector CN2. Solder one pin first, check verticality, then solder the other pins.

Warning : the connector pins must be exactly perpendicular to the CB to allow proper insertion in the

preamp board.

8. Visual check

Brush the solder side with a hard tooth brush to remove any remaining solder bits. Make a full visual

check. Any missing component on the board ? Any remaining component in the box ?

The Di01 is ready for testing !

Copyright ©2013 SoundSkulptor

www.soundskulptor.com

Document revision 1.1 – Last modification : 15/07/20

Di01 Assembly guide

9. Board installation

lace one 1.2mm plastic spacer on the jack sockets and insert into the front panel while fitting the CN2

connector pins into the socket on the preamp CB. Screw in the front nut through the bevelled front

spacer with an M12 socket spanner.

Copyright ©2013 SoundSkulptor

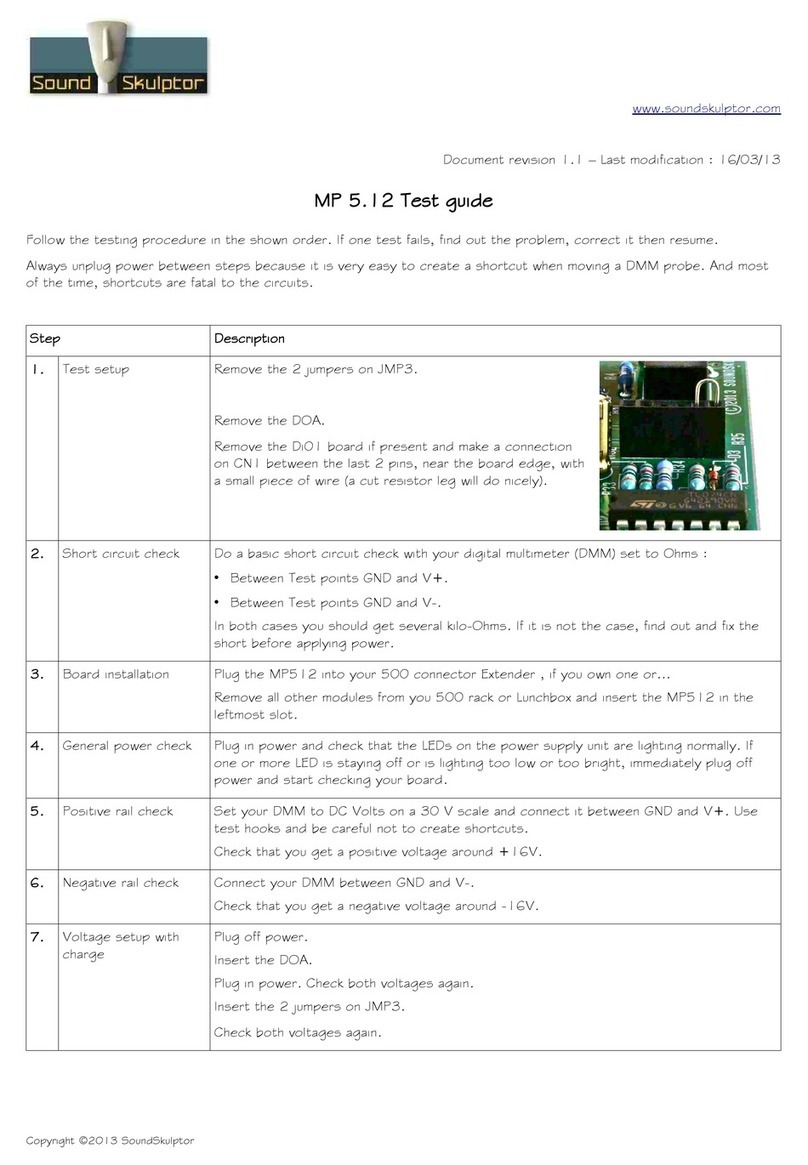

Other manuals for MP 512

2

Table of contents

Other Sound Skulptor Amplifier manuals

Sound Skulptor

Sound Skulptor MP73 User manual

Sound Skulptor

Sound Skulptor MP 599 User manual

Sound Skulptor

Sound Skulptor MP73 User manual

Sound Skulptor

Sound Skulptor MP 599 User manual

Sound Skulptor

Sound Skulptor MP573 User manual

Sound Skulptor

Sound Skulptor MP 512 User manual

Sound Skulptor

Sound Skulptor SK25 User manual

Sound Skulptor

Sound Skulptor MP 566 User manual

Sound Skulptor

Sound Skulptor MP573 User manual

Sound Skulptor

Sound Skulptor MP 512 User manual