EG&G ORTEC 452 User manual

100MIDLAND

ROAD

OAK

RIDGE,

TENN.

37830

PHONE

(615)

482-4411

TWX

810-5

7

2-1078

INSTRUCTION

MANUAL

452

SPECTROSCOPY

AMPLIFIER

n

ci:ai\/iF='ArNiY

r-

ORTEC

452

SPECTROSCOPY

AMPLIFIER

Manual

Change

Sheet

May

19,1971

In

the

schematic,

452-0101-81,

please

make

the

following

changes:

Change

the

value

of

C12

from

430

to

470.

Change

the

value

of

C104

from

100

to

68.

Change

the

value

of

C105

from

68

to

39.

Change

the

value

of

C109

from

68

to

1000.

Add

a

capacitor,

C112,

15

from

pin

4

to

pin

3

of

Amp

2

(pin

3

is

not

shown

in

the

schematic

since

it

was

not

previously

used).

On

D20,

add

the

designation

1N5241,

and

delete

Q43.

In

Section

2

of

the

manual,

Specifications,

change

the

power

requirements

to

read:

+24

V,

120

mA;

+12

V,

45

mA;

-24

V,

130

mA;

-12

V,

30

mA.

INSTRUCTION

MANUAL

452

SPECTROSCOPY

AMPLIFIER

Serial

No.

Purchaser

Date

Issued

100

MIDLAND

RDAD

DAK

RIDGE,

TENN.

3783G

PHDNE

(615)

482-4411

TWX

B10-572-1D78

n

EGs.t3

cors/iF^Arsj-v

I

ORTEC

Incorporated

1970

Printed

In

U.

S.

A.

012571

TABLE

OF

CONTENTS

Page

WARRANTY

PHOTOGRAPHS

1.

DESCRIPTION

1

1.1

General

Description

1

1.2

Pole-Zero

Cancellation

1

1.3

Active

Filter

3

2.

SPECIFICATIONS

5

3.

INSTALLATION

7

3.1

General

3.2

Connection

to

Preamplifier

3.3

Connection

of

Test

Pulse

Generator

3.4

Connection

to

Power

3.5

Shaping

Considerations

3.6

Use

of

Delayed

Output

8

3.7

Output

Connections

and

Terminating

Considerations

8

3.8

Shorting

or

Overloading

the

Amplifier

Outputs

8

4.

OPERATING

INSTRUCTIONS

9

4.1

Initial

Testing

and

Observation

of

Pulse

Waveforms

9

4.2

Front-Panel

Controls

9

4.3

Front-Panel

Connectors

(All

Type

BNC)

9

4.4

Rear-Panel

Connectors

9

4.5

General

Considerations

for

Operation

with

Semiconductor

Detectors

10

4.6

Operation

in

Spectroscopy

Systems

12

4.7

Other

Experiments

13

4.8

Baseline

Restorer

(BLR)

14

4.9

Methods

of

Connection

to

Various

Analyzers

15

5.

CIRCUIT

DESCRIPTION

17

6.

MAINTENANCE

19

6.1

Test

Equipment

Required

19

6.2

Pulser

Modifications

for

Overload

Tests

19

6.3

Pulser

Test

19

6.4

Suggestions

for

Troubleshooting

21

6.5

Tabulated

Test

Point

Voltages

on

Etched

Board

22

SCHEMATIC

AND

BLOCK

DIAGRAM

452-0201-B1

ORTEC

452

Block

Diagram

452-0101-S1

ORTEC

452

Schematic

LIST

OF

FIGURES

Page

g.

1.1.

Clipping

in

an

Amplifier

Without

Pol6-Zero

Cancellation.

2

g.

1.2.

Differentiation

(Clipping)

in

a

Pole-Zero-Cancelled

Amplifier.

2

g.

1.3.

Pulse

Shapes

for

Good

Signal-to-Noise

Ratios.

3

g.

4.1

Typical

Effects

of

Shaping

Time

Selection

on

Output

Waveforms,

9

g.

4.2.

System

for

Measuring

Amplifier

and

Detector

Noise

Resolution.

10

g.

4.3.

Resolution

Effects

of

Capacitance.

10

g.

4.4.

Noise

as

a

Function

of

Bias

Voltage.

11

g.

4.5.

System

for

Measuring

Resolution

with

a

Pulse

Height

Analyzer.

11

g.

4.6.

System

for

Detector

Current

and

Voltage

Measurements.

11

g.

4.7.

Silicon

Detector

Back

Current

vs

Bias

Voltage.

12

g.

4.8.

System

for

High-Resolution

Alpha-Particle

Spectroscopy.

12

g.

4.9.

System

for

High-Resolution

Gamma

Spectroscopy.

12

g.

4.10.

Scintillation

Counter

Gamma

Spectroscopy

System.

13

g.

4.11.

High-Resolution

X-Ray

Energy

Analysis

System.

13

g.

4.12.

Gamma-Gamma

Coincidence

Experiment.

13

g.

4.13.

Gamma-Ray

Charged-Particle

Coincidence

Experiment

13

g.

4.14.

Gamma-Ray

Pair

Spectrometer.

14

g.

4.15.

General

System

Arrangement

for

Gating

Control.

14

g.

4.16.

Effects

of

Baseline

Restorer

on

Resolution.

14

g.

4.17.

Analyzer

Connection

with

No

Trigger

Required.

15

g.

4.18.

Analyzer

Connection

When

Trigger

Is

Required.

15

g.

6.1.

Pulse

Generator

Modifications.

19

g.

6.2.

Pole-Zero

Cancellation

of

a

Pulser

Output.

19

g.

6.3.

Circuit

Used

to

Measure

Nonlinearity.

20

g.

6.4.

Circuit

Used

to

Measure

Crossover

Walk

of

the

Amplifier

and

Single

Channel

Analyzer.

20

g.

6.5.

Circuit

Used

to

Measure

Crossover

Walk

of

the

Amplifier

Only.

21

g.

6.6.

Circuit

Used

to

Measure

Resolution

Spread

and

Amplitude

Changes

at

Various

Count

Rates.

21

STANDARD

WARRANTY

FOR

ORTEC

INSTRUMENTS

ORTEC

warrants

its

instruments

other

than

preampl

ifier

FET

input

transistors,

vacuum

tubes,

fuses,

and

batteries

to

be

free

from

defects

in

workmanship

and

materials

for

a

period

of

twelve

months

from

date

of

shipment

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replace

ment,

at

ORTEC

option,

wil

l

be

made

on

in-warranty

instruments,

without

charge,

at

the

ORTEC

factory.

Shipping

expense

wil

l

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors

made

by

their

manufacturers

wil

l

be

extended

to

our

custdmers

only

to

the

extent

of

the

manufacturers'

liabil

ity

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibil

ity

for

modification

of

previously

manufactured

units.

Since

installation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

l

iabil

ities

associated

with

methods

of

installation

or

with

instal

lation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

instrument

must

pass

a

stringent

set

of

qual

ity

control

tests

designed

to

expose

any

flaws

in

materials

or

work

manship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

ORTEC

must

be

informed

in

writing

of

the

nature

of

the

fault

of

the

instrument

being

returned

and

of

the

model

and

serial

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

Our

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

qual

ity

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

wil

l

withstand

normal

transit

handl

ing

and

must

be

shipped

prepaid

via

Air

Freight

or

United

Parcel

Service

to

the

nearest

ORTEC

repair

center.lnstru-

ments

damaged

in

transit

due

to

inadequate

packing

wil

l

be

repaired

at

the

sender's

expense,

and

it

wil

l

be

the

sender's

responsibil

ity

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

wil

l

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

del

ivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normal

ly

l

iable

for

damage

in

shipment.

Packing

materials,

waybil

ls,

and

other

such

documentation

should

be

preserved

in

order

to

establ

ish

claims.

After

such

notification

to

the

carrier,

please

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

dam

age

claims

and

in

providing

replacement

equipment

if

necessary.

■

MODEL

452

SPECTROSCOPY

AMPLIFIER

COARSE

GAIN

100

SHAPING

TIME

1.0

2.0

0.25

At

FINE

GAIN

0.5-1.5

POS

ii

nl

NEG

PZ

ADJ

INPUT

BIPOLAR

UNIPOLAR

OUTPUT

RANGE

-lOV

-t-iov

L

-6V

HI

LO

OUT

BLR

I

DELAY

IN

I

OUT

UNIPOLAR

<•

V

;

OUTPUTS

ilPOLAN

I

UNIl'OLAH

£

l)S

u

OUTPUT'.;

PilEIb'

POWEW

ORTEC

452

SPECTROSCOPY

AMPLIFIER

1.

DESCRIPTION

1.1

GENERAL

DESCRIPTION

The

ORTEC

452

Spectroscopy

Amplifier

is

a

double-width

NIM

module

with

a

versatile

combination

of

switch-

selectable

pulse

shaping

and

output

characteristics.

It

features

extremely

low

noise,

wide

gain

range,

and

excellent

overload

response

for

universal

appl

ication

in

high-resolu

tion

spectroscopy.

It

accepts

input

pulses

of

either

polarity

which

originate

in

germanium

or

sil

icon

semiconductor

detectors,

in

scintil

lation

detectors

with

either

fast

or

slow

scintillators,

in

proportional

counters,

in

pulsed

ionization

chambers,

in

electron

multipliers,

etc.

The

452

has

a

dc

input

impedance

of

approximately

lOOOfi

and

accepts

either

positive

or

negative

input

pulses

with

rise

times

<650

ns

and

fall

times

>25

/is.

Six

integrate

and

differentiate

time

constants

are

switch-selectable

to

provide

optimum

shape

for

resolution

and

count

rate.

The

first

differentiation

network

has

variable

pole-zero

cancella

tion

that

can

be

adjusted

to

match

preampl

ifiers

with

>25

IIS

decay

time.

The

pole-zero

cancellation

drastical

ly

reduces

the

undershoot

after

the

first

cl

ip

and

greatly

im

proves

overload

characteristics.

In

addition,

the

amplifier

contains

an

active

filter-shaping

network

that

optimizes

the

signal-to-noise

ratio

and

minimizes

the

overall

resolving

time.

Both

unipolar

and

bipolar

outputs

are

provided

simultaneously

on

the

front

and

rear

panels.

The

unipolar

output

should

be

used

for

spectroscopy

when

dc

coupl

ing

can

be

maintained

from

the

452

Ampl

ifier

to

the

analyzer.

A

BLR

(Base

Line

Restoration)

circuit

is

included

in

the

452

for

improved

performance

at

high

count

rates.

A

switch

on

the

front

panel

permits

this

circuit

to

be

switched

out,

set

for

low

count

rates,

or

set

for

high

count

rates.

When

using

the

direct-coupled

input

of

the

various

analyzers,

a

variety

of

voltage

requirements

exist.

To

meet

these

requirements

the

452

unipolar

output

can

be

selected

for

ful

l-scale

voltage

of

-3

V,

±6

V,

or

±10

V.

The

unipolar

output

dc

level

can

be

adjusted

from

-1

V

to

+

1

V.

This

output

permits

the

use

of

the

direct-coupled

input

of

analyzers

with

a

minimum

amount

of

interface

problems.

The

452

bipolar

output

may

be

preferable

for

spectroscopy

when

operating

into

an

ac-coupled

system

at

high

counting

rates.

The

452

can

be

used

for

crossover

timing

when

used

in

conjunction

with

an

ORTEC

407

Crossover

Pickoff

or

a

420A

or

455

Timing

Single

Channel

Analyzer.

The

ORTEC

Timing

Single

Channel

Analyzers

feature

a

minimum

of

walk

as

a

function

of

pulse

ampl

itude

and

incorporate

a

variable

delay

time

on

the

output

pulse

to

enable

the

cross

over

pickoff

output

to

be

placed

in

time

coincidence

with

other

outputs.

A

switch-selectable

2-jus

delay

is

provided

on

the

unipolar

output

to

aid

in

obtaining

the

proper

spacing

of

the

l

inear

pulse

in

a

coincidence-gated

system.

The

452

has

complete

provisions,

including

power,

for

operating

any

ORTEC

solid-state

preampl

ifier

such

as

the

109A,

113,

118A,

120, 124,

and

125.

Preamplifier

pulses

should

have

a

rise

time

of

0.25/ts

or

less

to

properly

match

the

amplifier

filter

network

and

a

decay

time

>25

iis

for

proper

pole-zero

cancellation.

The

452

input

impedance

is

1000^2.

When

long

preampl

ifier

cables

are

used,

the

cables

can

be

terminated

in

series

at

the

preamplifier

end

or

in

shunt

at

the

ampl

ifier

end

with

the

proper

resistors.

The

output

impedance

of

the

452

is

about

O.lfi

at

the

front-

panel

connectors

and

93T2

at

the

rear-panel

connectors.

The

front-panel

outputs

can

be

connected

to

other

equipment

by

single

cable

going

to

all

equipment

and

shunt

terminated

at

the

far

end.

If

series

termination

is

desired,

the

rear-

panel

connectors

can

be

used

in

connecting

the

452

to

other

modules

(see

Section

3).

Gain

changing

is

accomplished

by

varying

feedback

net

works.

These

networks

are

varied

in

such

a

manner

that

the

band

width

of

the

feedback

amplifier

stages

remains

essentially

constant

regardless

of

gain,

and

therefore

rise-

time

changes

with

gain

switching

(which

cause

crossover

walk)

are

limited

to

small

variations.

1.2

POLE-ZERO

CANCELLATION

Pole-zero

cancellation

is

a

method

for

eliminating

pulse

undershoot

after

the

first

differentiating

network.

The

technique

employed

is

described

by

referring

to

the

wave

forms

and

equations

shown

in

Figs.

1.1

and

1.2.

In

an

ampl

ifier

not

using

pole-zero

cancel

lation,

the

exponential

tail

on

the

preamplifier

output

signal

(usually

50

to

500/us)

causes

an

undershoot

whose

peak

ampl

itude

is

roughly

undershoot

amplitude

differentiation

time

differentiated

pulse

ampl

itude

preamplifier

pulse

decay

time

For

a

l-^ts

differentiation

time

and

a

50-/us

preamplifier

pulse

decay

time,

the

maximum

undershoot

is

2%

and

decays

with

a

50-/us

time

constant.

Under

overload

con

ditions

this

undershoot

is

often

sufficiently

large

to

saturate

the

ampl

ifier

during

a

considerable

portion

of

the

undershoot,

causing

excessive

dead

time.

This

effect

can

be

reduced

by

increasing

the

preampl

ifier

pulse

decay

time

(which

generally

reduces

the

counting

rate

capabil

ities

of

the

preamplifier)

or

compensating

for

the

undershoot

by

using

pole-zero

cancel

lation.

Pole-zero

cancel

lation

is

accompl

ished

by

the

network

shown

in

Fig.

1.2.

The

pole

[1/s

+

(I/To)]

due

to

the

preampl

ifier

pulse

decay

time

is

cancel

led

by

the

zero

[s

+

(/C/R2C1

)]

of

the

network.

In

effect,

the

dc

path

across

the

differentiation

capacitor

adds

an

attenuated

replica

of

the

preamplifier

pulse

to

just

cancel

the

negative

undershoot

of

the

cl

ipping

network.

eo

(t)

eo(t)=E„ax^

°

Undershoot

First

C'-PP®"

Charge

loop

^lippj^g

_

pulse

°P*P"< network

^

undershoot

Equations:

-t

Emax

X

G(t)

=

(t)

1

s

T-

X

—

=£^1

(s);

Laplace

Transform

rnox

j j

s

+

—

s

+

T

o

RiCi

To

-

h

Fig.

1.1.

Clipping

in

an

Amplifier

Without

Pole-Zero

Cancellation.

-t

max

Tt

To

,

, ,

—

„

_

To

e

—Tie

=

ei

where

Ti

=

Ri

Ci

o<K<1

®o

I

f/

^max

®

ei

(t)

No

Undershoot

Pole-zero

_.

,

cancelled

_

Clipped

pulse

Charge

loop

x

-

„i,hout

network

undershoot

1

K

Pole

zero

cancel

by

letting

s

+

—

=

s

+

-

T

o

R2C1

or:

1

s

-I-

R2C1

-max

1

Ri

+R2

s

+

—

s

+

To

R,R2C,

=

E^

(s);

Laplace

Transform

Tmax

^max

Ri

+

R2

1

s

+

^^^

s

+

R

£.

(s);

where

Rp

=

1R2

C|

RpCi

-t

^

RnCl

/

I

Tmax

®

~

(t)

Fig.

1.2.

Differentiation

(Clipping)

in

a

Pole-Zero-Cancelled

Amplifier.

Total

preamplifier-amplifier

pole-zero

cancel

lation

requires

that

the

preampl

ifier

output

pulse

decay

time

be

a

single

exponential

decay

and

matched

to

the

pole-zero-cancel

la-

tion

network.

The

variable

pole-zero-cancel

lation

network

allows

accurate

cancel

lation

for

all

preampl

ifiers

having

25

/is

or

greater

decay

times.

The

network

is

factory

ad

justed

to

50

/is,

which

is

compatible

with

al

l

ORTEC

FET

preamplifiers.

Improper

matching

of

the

pole-zero-cancella

tion

network

wil

l

degrade

the

overload

performance

and

cause

excessive

pileup

distortion

at

medium

counting

rates.

Improper

matching

causes

either

an

undercompensation

(undershoot

is

not

el

iminated)

or

an

overcompensation

(output

after

the

main

pulse

does

not

return

to

the

baseline

and

decays

to

the

baseline

with

the

preamplifier

time

constant).

The

pole-zero

adjust

is

accessible

from

the

front

panel

of

the

452

and

can

easily

be

adjusted

by

observing

with

an

oscilloscope

the

basel

ine

with

a

monoenergetic

source

or

pulser

having

the

same

decay

time

as

the

preamp

l

ifier

under

overload

conditions.

The

adjustment

should

be

made

so

that

the

pulse

returns

to

the

baseline

in

the

minimum

time

with

no

undershoot.

1.3

ACTIVE

FILTER

When

only

FET

gate

current

and

drain

thermal

noise

are

considered,

the

best

signal-to-noise

ratio

(Fig.

1.3)

occurs

when

the

two

noise

contributions

are

equal

for

a

given

pulse

shape.

The

Gaussian

pulse

shape

of

this

amplifier

requires

a

single

RC

differentiate

and

n

equal-RC

integrates,

where

n

approaches

infinity.

The

Laplace

transform

of

this

transfer

function

is

G(s)

=

1

[s-t(1/RC)

[s-(-(1/RC)]n

where

the

first

factor

is

the

single

differentiate

and

the

second

factor

is

the

n

integrates.

The

452

Active

filter

approximates

this

transfer

function.

CUSP

t>0

GAUSSIAN

1

s-r(1/RC)

[s+(1/RC)]"

GAUSSIAN

APPROXIMATION

FOR

n

=

2

1

s

+

(1/RC)

[s

+

(l/RC)]'

ACTIVE

FILTER

s

+

(1/RC)

_1+j

/=

VTT

200363

Fig.

1.3.

Pulse

Shapes

for

Good

Signal-to-Nolse

Ratios.

2.

SPECIFICATIONS*

PERFORMANCE

GAIN

RANGE

9-position

Coarse

selection

from

X5to

X2000

and

10-turn

potentiometer

for

Fine

adjustment

from

X0.5

to

XI

.5;

total

gain

is

the

product

of

Coarse

and

Fine

Gain

settings;

Coarse

Gain

factors

are

obtained

by

feedback

techniques.

SFIAPING

FILTER

Front-panel

switches

perm

it

selection

of

integration

and

differentiation

time

constants

(r

=

0.25,

0.5,

1,

2,

3,

or

6

/us);

time

to

Unipolar

peak

=

2t;

time

to

Bipolar

crossover

=

2.8r.

INTEGRAL

NONLINEARITY

<0.05%.

NOISE

<4/uV

(Unipolar)

or<7/uV

(Bipolar),

referred

to

the

input,

with

3-/lis

shaping

and

Coarse

Gain

>100.

TEMPERATURE

STABILITY

GAIN

0.005%/°C,0to50°C.

DC

LEVEL

<0.1

mV/°C,0to

50°C.

CROSSOVER

WALK

<-t2

ns

for

100:1

dynamic

range.

COUNT

RATE

STABILITY

A

pulser

peak

at

85%

of

analyzer

range

shifts

less

than

0.2%

in

the

presence

of

0

to

5

X

lO"

random

counts/sec

from

a

'^''Cs

source

with

its

peak

stored

at

75%

of

analyzer

range,

using

1-/us

filter

time

constants.

OVERLOAD

RECOVERY

Recovers

to

within

2%

of

rated

output

from

1000X

overload

in

2.5

non-overloaded

Bipolar

pulse

widths,

using

maximum

gain

and

>0.5-/us

shaping

time

constants.

CONTROLS

FINE

GAIN

10-turn

precision

potentiometer

for

continu

ously

variable

direct

reading

gain

factor

of

X0.5

to

XI.5.

COARSE

GAIN

9-position

switch,

selects

feedback

re

sistors

for

gain

factors

of

X5,

10,

20,

50,

100,

200,

500,

1

K,

and

2K.

INPUT

POLARITY

Sl

ide

switch,

sets

input

circuit

for

either

Pos

or

Neg

input

polarity.

UNIPOLAR

OUTPUT

5-position

switch,

selects

either

Pos

or

Neg

Unipolar

output

and

amplitude.

PZ

ADJ

Potentiometer

to

adjust

Pole-Zero

cancellation

for

decay

times

from

25

/us

to

oo.

DC

ADJ

Potentiometer

to

adjust

the

DC

level

for

Unipolar

outputs;

range

±1.0

V.

DELAY

Sl

ide

switch,

selects

either

2-;us

delayed

(In)

or

prompt

(Out)

output

for

the

Unipolar

signals.

BLR

3-position

slide

switch,

selects

baseline

restorer

function;

Fli

for

duty

cycles

>15%,

Lo

for

duty

cycles

<15%,

or

Out.

SFIAPING

6-position

switch,

selects

time

constants

of

0.25,

0.5,

1,

2,

3,

or

6

/us.

INPUT

Switch-selectable

active

baseline

restorer

rate;

positive

or

negative

output

from

a

preamplifier;

max

linear

input

5.5

V;

max

input

20

V.

RISE

TIME

10

to

650

ns.

DECAY

TIME

25

to

2000/us.

IMPEDANCE

~1000fi;

dc-coupled.

OUTPUTS

UNIPOLAR

Prompt

or

delayed

with

full-scale

linear

range

of

-3,

±6,

or

±10

V

as

selected;

±12

V

max;

active-

filter-shaped;

dc-restored,

with

switch-selectable

active

baseline

restorer

rate,

and

baseline

level

adjustable

to

±1.0

V;

impedance

<0.112

front

panel

and

9312

rear

panel;

short-circuit

protected

BIPOLAR

Prompt

output

with

positive

lobe

leading,

with

linear

range

0

to

±10

V

independent

of

Unipolar

range

and

polarity;

±12

V

max;

active

filter-shaped;

impedance

<0.112

front

panel

and

9312

rear

panel;

short-circuit

protected.

CONNECTORS

INPUT

BNC

(UG-1094/U),

front

panel.

UNIPOLAR

OUTPUT

BNC

(UG-1094/U),

front

panel

for

Zq

<0.112;

rear

panel

for

Zq

=

9312.

BIPOLAR

OUTPUT

BNC

(UG-1094/U),

front

panel

for

Zo

<0.112;

rear

panel

for

Zq

=

9312.

PREAMP

Standard

ORTEC

power

connector

for

mating

preamplifier;

Amphenol

type

17-10090,

rear

panel.

ORDERING

INFORMATION

POWER

REQUIRED

+24

V,

90

mA;

+12

V,

25

mA;

-24

V,

100

mA;

-12

V,

15

mA.

WEIGHT

(Shipping)

6

lb

9

oz

(-2.95

kg).

WEIGHT

(Net)

3

lb

13

oz

(~1.80

kg).

DIMENSIONS

Standard

double-width

module

(2.70

by

8.714

in.)

per

TID-20893

(Rev.).

"Checked

in

accordance

with

methods

outlined

in

IEEE

Standards

No.

301,

LISAS

N42.2,

IEEE

Transactions,

Vol

NS-16(6)

(December

1969).

3.

INSTALLATION

3.1

GENERAL

The

452

used

in

conjunction

with

a

401A/402A

Bin

and

Power

Supply

is

intended

for

rack

mounting;

therefore

any

vacuum

tube

equipment

operating

in

the

same

rack

with

the

452

must

be

sufficiently

cooled

by

circulating

air

to

prevent

local

ized

heating

of

the

all-semiconductor

circuitry

used

throughout

the

452.

The

temperature

of

equipment

mounted

in

racks

can

easily

exceed

120°F

(50°C)

unless

precautions

are

taken.

3.2

CONNECTION

TO

PREAMPLIFIER

The

preampl

ifier

output

signal

is

connected

to

the

452

through

the

BNC

connector

on

the

front

or

rear

panel

labeled

Input.

The

input

impedance

is

1000T2

and

is

de

coupled

to

ground;

therefore

the

output

of

the

preampl

ifier

must

be

either

ac-coupled

or

have

approximately

zero

dc

voltage

under

no-signal

conditions.

The

452

incorporates

pole-zero

cancellation

in

order

to

enhance

the

overload

characteristics

of

the

amplifier.

This

technique

requires

matching

the

network

to

the

preampl

ifier

decay

time

constant

in

order

to

achieve

perfect

compen

sation.

The

network

is

variable

and

factory

adjusted

to

50

jus

to

approximately

match

all

ORTEC

FET

preamp

l

ifiers.

If

other

preamplifiers

or

more

careful

matching

is

desired,

the

adjustment

is

accessible

from

the

front

panel

.

Adjustment

is

easily

accompl

ished

by

using

a

monoenergetic

source

and

observing

the

ampl

ifier

baseline

with

an

oscilloscope

after

each

pulse

under

overload

conditions.

Adjustment

should

be

made

so

that

the

pulse

returns

to

the

basel

ine

in

a

minimum

of

time

with

no

undershoot.

Preampl

ifier

power

of

-i-24

V,

+M

V,

-12

V,

and

-24

V

is

available

on

the

preampl

ifier

power

connector.

When

using

the

452

with

a

remotely

located

preampl

ifier

(i.e.,

preamplifier-to-amplifier

connection

through

25

ft

or

more

of

coaxial

cable),

care

must

be

taken

to

ensure

that

the

characteristic

impedance

of

the

transmission

line

from

the

preampl

ifier

output

to

the

452

input

is

matched.

Since

the

input

impedance

of

the

452

is

1000J2,

sending

end

termination

will

normal

ly

be

preferfed;

i.e.,

the

transmission

l

ine

should

be

series

terminated

at

the

output

of

the

preamplifier.

Al

l

ORTEC

preampl

ifiers

contain

series

ter

minations

that

are

either

93^2

or

variable;

coaxial

cable

type

RG-62/U

or

RG-71/U

is

recommended.

3.3

CONNECTION

OF

TEST

PULSE

GENERATOR

Connection

of

Pulse

Generator

to

the

452

Through

a

Preamplifier.

The

satisfactory

connection

of

a

test

pulse

generator

such

as

the

ORTEC

419

or

equivalent

depends

primarily

on

two

considerations:

the

preampl

ifier

must

be

properly

connected

to

the

452

as

discussed

in

Section

3.2,

and

the

proper

input

signal

simulation

must

be

applied

to

the

preampl

ifier.

To

ensure

proper

input

signal

simulation,

refer

to

the

instruction

manual

for

the

particular

preamp

l

ifier

being

used.

Direct

Connection

of

Pulse

Generator

to

the

452.

Since

the

input

of

the

452

has

1000^2

input

impedance,

the

test

pulse

generator

will

normally

have

to

be

terminated

at

the

ampl

ifier

input

with

an

additional

shunt

resistor.

In

addition,

if

the

test

pulse

generator

has

a

dc

offset

greater

than

1

V,

a

large

series

isolating

capacitor

is

also

required

since

the

input

of

the

452

is

dc-coupled.

The

ORTEC

Test

Pulse

Generators

are

designed

for

direct

connection.

When

any

of

these

units

are

used,

they

should

be

terminated

with

a

100r2

terminator

at

the

ampl

ifier

input

or

used

with

at

least

one

of

the

output

attenuators

set

at

IN.

(The

small

error

due

to

the

finite

input

impedance

of

the

ampl

ifier

can

normally

be

neglected.)

Special

Test

Pulse

Generator

Considerations

for

Pole-Zero

Cancellation.

The

pole-zero-cancel

lation

network

in

the

452

is

factory

adjusted

for

a

bO-iis

decay

time

to

match

ORTEC

FET

preampl

ifiers.

When

a

tail

pulser

is

connected

directly

to

the

ampl

ifier

input,

the

PZ

ADJ

should

be

adjusted

if

overload

tests

are

to

be

made

(other

tests

are

not

affected).

See

Section

6.2

for

the

details.

If

a

preampl

ifier

is

used

and

a

tail

pulser

connected

to

the

preampl

ifier

test

pulse

input,

similar

precautions

are

necessary.

In

this

case,

the

effect

of

the

pulser

decay

must

be

removed,

i.e.,

a

step

input

should

be

simulated.

Details

for

this

modification

are

also

given

in

Section

6.2.

3.4

CONNECTION

TO

POWER

The

452

contains

no

internal

power

supply

and

therefore

must

obtain

power

from

a

Nuclear

Standard

Bin

and

Power

Supply

such

as

the

ORTEC

401A/402A.

It

is

recommended

that

the

Bin

power

supply

be

turned

off

when

modules

are

inserted

or

removed.

The

ORTEC

NIM

modules

are

designed

so

that

it

is

not

possible

to

overload

the

Bin

power

supply

with

a

ful

l

complement

of

modules

in

the

Bin.

Since,

how

ever,

this

may

not

be

true

when

the

Bin

contains

modules

other

than

those

of

ORTEC

design,

the

power

supply

voltages

should

be

checked

after

the

modules

are

inserted.

The

401A/402A

has

test

points

on

the

Power

Supply

control

panel

to

monitor

the

dc

voltages.

3.5

SHAPING

CONSIDERATIONS

The

shaping

time

constant

on

the

452

Ampl

ifier

is

switch-

selectable

in

steps

of

0.25,

0.5,

1,

2,

3, and

6

^ts.The

choice

of

the

proper

shaping

time

is

generally

a

compromise

be

tween

operating

at

high

counting

rates

and

operating

with

the

best

signal-to-noise

ratio.

For

scintillation

counters

the

energy

resolution

largely

depends

on

the

scintillator

and

photomultipl

ier,

and

therefore

a

shaping

time

constant

of

about

four

times

the

decay

time

constant

of

the

scintil

lator

is

a

reasonable

choice

(for

Nal

,

a

l-jus

shaping

time

constant

is

about

optimum).

For

gas

proportional

counters

the

collection

time

constant

is

normal

ly

in

the

0.5-

to

5-/is

range

and

the

2-/ts

or

greater

resolving

time

will

general

ly

give

optimum

resolution.

For

surface

barrier

semiconductor

detectors

a

1-

or

2-iis

resolving

time

will

generally

provide

optimum

resolution.

Shaping

time

for

Ge(Li)

detectors

wil

l

vary

from

1

to

6

jus,

depending

upon

the

size,

configuration,

and

collection

time

of

the

specific

detector

and

preamplifier.

When

a

charge-sensitive

preampl

ifier

is

used,

the

optimum

shaping

time

constant

to

minimize

the

noise

of

a

system

can

be

determined

by

measuring

the

output

noise

of

the

system

and

dividing

it

by

the

gain

of

the

system.

Since

the

452

has

almost

constant

gain

for

all

shaping

modes,

the

optimum

shaping

can

be

determined

by

measuring

the

output

noise

of

the

452

with

a

voltmeter

as

each

of

the

shaping

modes

is

selected.

The

452

provides

both

the

unipolar

and

bipolar

outputs.

The

unipolar

output

pulse

should

be

used

in

applications

where

the

best

signal-to-noise

ratio

(resolution)

is

desired,

such

as

high-resolution

spectroscopy

using

semiconductor

detectors.

Use

of

the

unipolar

output

with

baseline

restoration

wil

l

also

give

excellent

resolution

at

high

count

ing

rates.

The

bipolar

output

should

be

used

in

high

count

rate

systems

when

the

analyzer

system

is

ac-coupled

and

noise,

or

resolution,

is

a

secondary

consideration.

3.6

USE

OF

DELAYED

OUTPUT

The

prompt

output

is

used

for

normal

spectroscopy

applications.

The

delayed

output

(equal

in

ampl

itude

to

the

prompt

output,

but

delayed

by

2

us)

is

used

in

coinci

dence

experiments

where

the

output

may

be

delayed

to

compensate

for

time

delays

in

obtaining

the

coincidence

information.

The

considerations

regarding

the

proper

choice

of

shaping

for

the

delayed

output

are

discussed

in

Section

3.5.

3.7

OUTPUT

CONNECTIONS

AND

TERMINATING

CONSIDERATIONS

Since

the

452

unipolar

output

is

normally

used

for

spectroscopy,

it

is

designed

with

a

great

amount

of

flexi

bility

in

order

to

interface

this

output

with

an

analyzer.

A

BLR

circuit

is

included

in

this

output

for

improved

per

formance

at

high

count

rate.

A

switch

permits

this

circuit

to

be

switched

out,

set

for

low

count

rates,

or

set

for

high

count

rates.

When

using

the

direct-coupled

input

of

the

various

analyzers,

a

variety

of

voltage

requirements

exist.

To

meet

these

requirements

the

452

unipolar

output

can

be

selected

for

full

range

voltages

of

-3

V,

±6

V,

or

±10

V.

The

unipolar

output

dc

level

can

be

adjusted

from

-1

V

to

+1

V

to

set

the

zero

intercept

on

the

analyzer

when

the

direct-coupled

input

is

used.

The

bipolar

output,

with

a

0-

to

10-V

range

regardless

of

the

unipolar

range

setting,

can

be

used

for

crossover

timing

or

may

be

preferable

for

spectroscopy

when

operating

into

ac-coupled

systems

at

high

counting

rates.

Typical

system

block

diagrams

for

a

variety

of

experiments

are

described

in

Section

4.

There

are

three

general

methods

of

termination

that

are

used.

The

simplest

of

these

is

shunt

termination

at

the

receiving

end

of

the

cable.

A

second

method

is

series

termination

at

the

sending

end.

The

third

is

a

combination

of

series

and

shunt

termination,

where

the

cable

impedance

is

matched

both

in

series

at

the

sending

end

and

in

shunt

at

the

receiving

end.

The

most

effective

method

is

the

combination,

but

termination

by

this

method

reduces

the

amount

of

signal

strength

at

the

receiving

end

to

50%

of

that

which

is

available

in

the

sending

instrument.

To

use

shunt

termination

at

the

receiving

end

of

the

cable,

connect

the

output

of

the

sending

device

through

93^2

cable

to

the

input

of

the

receiving

instrument.

Then

use

a

BNC

tee

connector

to

accept

both

the

interconnecting

cable

and

a

100S2

resistive

terminator

at

the

input

connector

of

the

receiving

instrument.

Since

the

input

impedance

of

the

receiving

instrument

is

normal

ly

lOOOfi

or

more,

the

effective

instrument

input

impedance

with

the

100J2

terminator

will

be

of

the

order

of

93J2,

and

this

correctly

matches

the

cable

impedance.

For

series

termination,

use

the

93r2

output

of

the

sending

instrument

for

the

cable

connection.

Use

93f2

cable

to

interconnect

this

into

the

input

of

the

receiving

instrument.

The

1000J2

(or

more)

normal

input

impedance

at

the

in

put

connector

represents

an

essentially

open

circuit,

and

the

series

impedance

in

the

sending

instrument

now

provides

the

proper

termination

for

the

cable.

For

the

combination

of

series

and

shunt

termination,

use

the

930

output

in

the

sending

instrument

for

the

cable

connection

and

use

93J2

cable.

At

the

input

for

the

receiv

ing

instrument,

use

a

BNC

tee

to

accept

both

the

inter

connecting

cable

and

a

100J2

resistive

terminator.

Note

that

the

signal

span

at

the

receiving

end

of

this

type

of

receiving

circuit

will

always

be

reduced

to

50%

of

the

signal

span

furnished

by

the

sending

instrument.

For

your

convenience,

ORTEC

stocks

the

proper

ter

minators

and

BNC

tees,

or

you

can

obtain

them

from

a

variety

of

commercial

sources.

3.8

SHORTING

OR

OVERLOADING

THE

AMPLIFIER

OUTPUTS

All

outputs

of

the

452

are

dc-coupled

with

an

output

impedance

of

about

0.1J2.

If

the

output

is

shorted

with

a

direct

short

circuit

or

the

amplifier

counting

rate

exceeds

35%

duty

cycle,

the

output

stage

wil

l l

imit

the

peak

current

of

the

output

so

that

the

ampl

ifier

will

not

be

harmed.

4.

OPERATING

INSTRUCTIONS

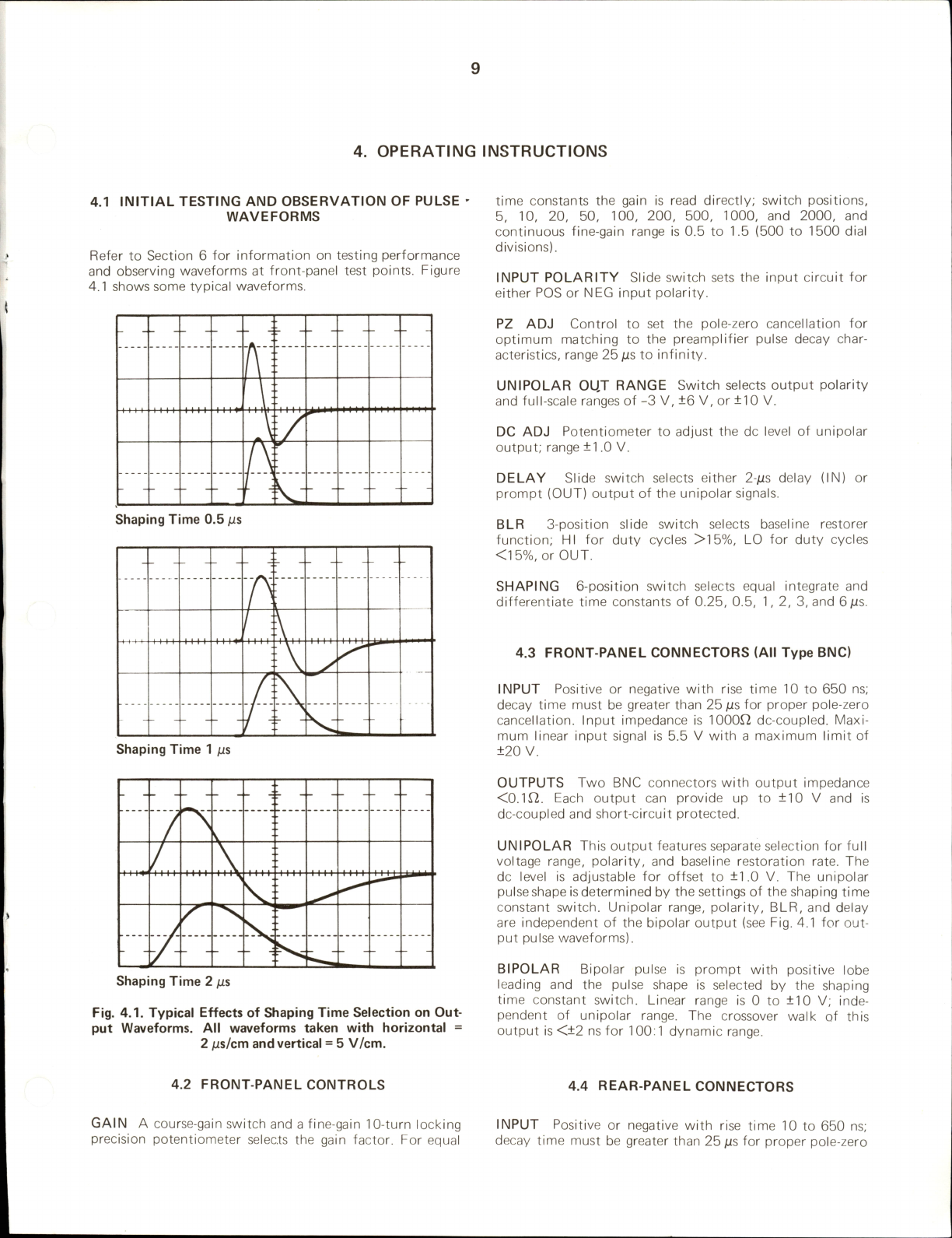

4.1

INITIAL

TESTING

AND

OBSERVATION

OF

PULSE

WAVEFORMS

Refer

to

Section

6

for

information

on

testing

performance

and

observing

waveforms

at

front-panel

test

points.

Figure

4.1

shows

some

typical

waveforms.

-

-

-

-

A

-

-

-

-

Shaping

Time

0.5

/is

Shaping

Time

1

/is

time

constants

the

gain

is

read

directly;

switch

positions,

5,

10,

20,

50,

100,

200,

500,

1000,

and

2000,

and

continuous

fine-gain

range

is

0.5

to

1.5

(500

to

1500

dial

divisions).

INPUT

POLARITY

Sl

ide

switch

sets

the

input

circuit

for

either

PCS

or

NEC

input

polarity.

PZ

ADJ

Control

to

set

the

pole-zero

cancellation

for

optimum

matching

to

the

preampl

ifier

pulse

decay

char

acteristics,

range

25

fis

to

infinity.

UNIPOLAR

OUT

RANGE

Switch

selects

output

polarity

and

ful

l-scale

ranges

of

-3

V,

±6

V,

or

±10

V.

DC

ADJ

Potentiometer

to

adjust

the

dc

level

of

unipolar

output;

range

±1.0

V.

DELAY

Sl

ide

switch

selects

either

2-/JS

delay

(IN)

or

prompt

(OUT)

output

of

the

unipolar

signals.

BLR

3-position

sl

ide

switch

selects

basel

ine

restorer

function;

HI

for

duty

cycles

>15%,

LO

for

duty

cycles

<15%,

or

OUT.

SHAPING

6-position

switch

selects

equal

integrate

and

differentiate

time

constants

of

0.25,

0.5,

1,

2,

3,

and

G/ts.

4.3

FRONT-PANEL

CONNECTORS

(All

Type

BNC)

INPUT

Positive

or

negative

with

rise

time

10

to

650

ns;

decay

time

must

be

greater

than

25/is

for

proper

pole-zero

cancel

lation.

Input

impedance

is

lOOOfi

dc-coupled.

Maxi

mum

l

inear

input

signal

is

5.5

V

with

a

maximum

l

imit

of

±20

V.

-

-

-

-

/

\

L

Shaping

Time

2

/is

Fig.

4.1.

Typical

Effects

of

Shaping

Time

Selection

on

Out

put

Waveforms.

All

waveforms

taken

with

horizontal

=

2

/is/cm

and

vertical

=

5

V/cm.

OUTPUTS

Two

BNC

connectors

with

output

impedance

<0.1^2.

Each

output

can

provide

up

to

±10

V

and

is

dc-coupled

and

short-circuit

protected.

UNIPOLAR

This

output

features

separate

selection

for

full

voltage

range,

polarity,

and

basel

ine

restoration

rate.

The

dc

level

is

adjustable

for

offset

to

±1.0

V.

The

unipolar

pulse

shape

is

determined

by

the

settings

of

the

shaping

time

constant

switch.

Unipolar

range,

polarity,

BLR,

and

delay

are

independent

of

the

bipolar

output

(see

Fig.

4.1

for

out

put

pulse

waveforms).

BIPOLAR

Bipolar

pulse

is

prompt

with

positive

lobe

leading

and

the

pulse

shape

is

selected

by

the

shaping

time

constant

switch.

Linear

range

is

0

to

±10

V;

inde

pendent

of

unipolar

range.

The

crossover

walk

of

this

output

is

<±2

ns

for

100:1

dynamic

range.

4.2

FRONT-PANEL

CONTROLS

4.4

REAR-PANEL

CONNECTORS

GAIN

A

course-gain

switch

and

a

fine-gain

10-turn

locking

precision

potentiometer

selects

the

gain

factor.

For

equal

INPUT

Positive

or

negative

with

rise

time

10

to

650

ns;

decay

time

must

be

greater

than

25/is

for

proper

pole-zero

10

cancel

lation.

Input

Impedance

is

lOOOfi

dc-coupled.

Maxi

mum

l

inear

input

signal

is

5.5

V

with

a

maximum

l

imit

of

+20

V.

OUTPUTS

The

unipolar

and

bipolar

pulses

are

brought

to,

the

rear

panel

on

BNC

connectors.

The

specifications

of

these

outputs

are

the

same

as

those

for

the

front-panel

connectors

except

that

the

output

impedance

is

93J2

at

these

connectors.

PREAMP

POWER

Standard

power

connector

for

mating

with

ORTEC

preamplifiers;

±24

V

and

±12

V.

4.5

GENERAL

CONSIDERATIONS

FOR

OPERATION

WITH

SEMICONDUCTOR

DETECTORS

Calibration

of

Test

Pulsar.

The

ORTEC

419

Pulser,

or

equivalent,

is

easily

cal

ibrated

so

that

the

maximum

pulse

height

dial

reading

(1000

divisions)

is

equivalent

to

10

MeV

loss

in

a

silicon

radiation

detector.

The

procedure

is

as

follows:

1.

Connect

the

detector

to

be

used

to

the

spectrometer

system,

i.e.,

preampl

ifier,

main

amplifier,

and

biased

anrrplifier.

2.

Allow

particles

from

a

source

of

known

energy

(alpha

particles,

for

example)

to

fal

l

on

the

detector.

3.

Adjust

the

ampl

ifier

gain

and

the

bias

level

of

the

biased

amplifier

to

give

a

suitable

output

pulse.

4.

Set

the

pulser

PULSE

HEIGHT

potentiometer

at

the

energy

of

the

alpha

particles

striking

the

detector

(e.g.,

for

a

5.47-Me\/

alpha

particle,

set

the

dial

on

547

divisions).

5.

Turn

on

the

Pulser,

and

use

the

NORMALIZE

po

tentiometer

and

attenuators

to

set

the

output

due

to

the

pulser

for

the

same

pulse

height

as

the

pulse

obtained

in

step

3.

Lock

the

NORMALIZE

dial

and

do

not

move

again

until

recal

ibration

is

necessary.

The

pulser

is

now

cal

ibrated;

the

PULSE

HEIGHT

dial

reads

in

MeV

if

the

number

of

dial

divisions

is

divided

by

100.

Amplifier

Noise

and

Resolution

Measurements.

As

shown

in

Fig.

4.2.,

the

preampl

ifier,

amplifier,

pulse

generator,

oscil

loscope,

and

a

wide-band

rms

voltmeter

such

as

the

Hewlett-Packard

400D

are

required

for

this

measurement.

Connect

a

suitable

capacitor

to

the

input

to

simulate

the

detector

capacitance

desired.

To

obtain-the

resolution

spread

due

to

ampl

ifier

noise:

/I.

Measure

the

rms

noise

voltage

(Erms)

at

the

amplifier

output.

2.

Turn

on

the

ORTEC

419

Precision

Pulse

Generator

and

adjust

the

pulser

output

to

any

convenient

readable

voltage,

Eq,

as

determined

by

the

oscilloscope.

The

full

width

at

half

maximum

spread

due

to

amplifier

noise

is

then

(FWHM)

resolution

where

E^iai

is

the

pulser

dial

reading

in

MeV,

and

2.66

is

the

factor

for

rms

to

FWHM

(2.34)

and

noise

to

rms

meter

correction

(1.13)

for

average-indicating

voltmeters

such

as

the

Hewlett-Packard

400D.

A

true

rms

voltmeter

does

not

require

the

latter

correction

factor.

Detector

Capacitor

Oscilloscope

ORTEC

Preamp

ORTEC

Amplifier

ORTEC

Pulse

Generator

Voltmeter

Fig.

4.2.

System

for

Measuring

Amplifier

and

Detector

Noise

Resolution.

The

resolution

spread

will

depend

upon

the

total

input

capacitance,

since

the

capacitance

degrades

the

signal-to-

noise

ratio

much

faster

than

the

noise.

A

typical

resolution

spread

versus

external

input

capacitance

for

the

ORTEC

120

Preampl

ifier

and

the

452

Ampl

ifier

is

shown

in

Fig.

4.3.

I

I I I

u

\

miTEC

120-2

Direct

Coupled

Shaping

T

=

2iis

14521

Direct

Coupled

Shaping

T

=

2

jjs

1452]

5

10

50

100

EXTERNAL

INPUT

CAPACITANCE

|pF)

500

1000

N(FWHM)

=

2.66

Erms

Edial

Fig.

4.3.

Resolution

Effects

of

Capacitance.

11

Detector

Noise

Resolution

Measurements.

The

same

measurement

just

described

can

be

made

with

a

biased

detector

instead

of

the

external

capacitor

used

to

simulate

the

detector

capacitance.

The

resolution

spread

wil

l

be

larger

because

the

detector

contributes

both

noise

and

capacitance

to

the

input.

The

detector

noise

resolution

spread

can

be

isolated

from

the

ampl

ifier

noise

spread

if

the

detector

capacity

is

known,

since

(Ndet)^

+

(N3rnp)

~

C^total'

'

where

Ntotal

'S

the

total

resolution

spread

and

Ngmp

is

the

amplifier

resolution

spread

with

the

detector

replaced

by

its

equivalent

capacitance.

The

detector

noise

tends

to

increase

with

bias

voltage,

but

the

detector

capacitance

decreases,

thus

reducing

the

resolution

spread.

The

overall

resolution

spread

wil

l

depend

upon

which

effect

is

dominant.

Figure

4.4

shows

curves

of

typical

total

noise

resolution

spread

versus

bias

voltage,

using

the

data

from

several

ORTEC

sil

icon

surface-barrier

semiconductor

radiation

detectors.

_

.6

111

V)

O

z

(/]

s

oc

A

-

ORTEC

B/

B

-

ORTEC

Bfi

L030-007-300

025-050-100

-025-100-100

L-030-200-100

-045-450-100

C

-ORTEC

B/

E

-ORTEC

Bfi

E

■

D

■

25

50

75

100

BIAS

VOLTAGE

125

Fig.

4.4.

Noise

as

a

Function

of

Bias

Voltage.

Amplifier

Noise

and

Resolution

Measurements

Using

a

Pulse

Height

Analyzer.

Probably

the

most

convenient

method

of

making

resolution

measurements

is

with

a

pulse

height

analyzer

as

shown

by

the

setup

il

lustrated

in

Fig.

4.5.

The

ampl

ifier

noise

resolution

spread

can

be

measured

directly

with

a

pulse

height

analyzer

and

the

mercury

pulser

as

fol

lows:

1.

Select

the

energy

of

interest

with

an

ORTEC

419

Pulse

Generator,

and

set

the

Ampl

ifier

and

Biased

Ampl

ifier

GAIN

and

BIAS

LEVEL

controls

so

that

the

energy

is

in

a

convenient

channel

of

the

analyzer.

2.

Cal

ibrate

the

analyzer

in

keV

per