Sonation DBO-TF-FIS User manual

Sonation

lab solutions.

lab solutions.

Sonation

DOUBLE BARREL OVEN DBO-TF-FIS

Operators Manual

Analycs

Seite 2

CE-Konformitätserklärung

CE Declaration of Conformity

CE Déclaration de Conformité

CE Dichiarazione di Conformità

Der Hersteller /The manufacturer / Le fabricant / Il fabbricante

Sonation GmbH

Alte Schulstr. 39 –88400 Biberach - Deutschland

erklärt hiermit, dass die Produkte

herewith declares that the products

déclare par la présente que le produits

dichiara che il prodotti

DBO-TF-FIS

den Anforderungen der folgenden EG-Richtlinien entspricht.

meets the provisions of following EC-Directives.

remplit les exigences des Directives CE suivantes.

soddisfa tutte le disposizioni dalle Direttive CE.

Richtlinie

Directive

Directive

Direttiva

gültig bis

valid until

valable jusqu’à

con validità fino al

gültig ab

valid after

valable à partir de

applicabile dal

2006/95/EG, EC, CE

19.04.2016

2014/35/EU

20.04.2016

2004/108/EG, EC, CE

19.04.2016

2014/30/EU

20.04.2016

2011/65/EU

03.01.2013

Angewandte Normen:

Applied standards:

Normes appliquées:

Norme applicate :

EN 61326-1:2013 - Basic requirements

EN 61010-1 :2010 + Cor. :2011

Diese Erklärung gilt für die oben genannten Produkte ab dem Unterzeichnungsdatum.

This declaration is valid for the above mentioned products after the signature date below.

La présente déclaration est valable à partir de la date de signature.

Questa dichiarazione vale per il suddetto prodotti dalla data di firma.

______________________ __________________________

Ort / place / lieu / luogo Unterschrift / signature / signature / firma

Datum /date / date / data

Name / name / nom / nome:

(Geschäftsführer / management / directeur / delegato)

Biberach 04. Dec. 2020

Christof Völkle

Seite 3

Contents

1 Safety 4

1.1 Importantsafetyinstrucons .................................................................................................................................... 4

1.2 Intended use.............................................................................................................................................................. 4

1.3 Non-intended use...................................................................................................................................................... 4

1.4 Examples of foreseeable misuse ............................................................................................................................... 4

1.5 Who may use and operate the column oven ............................................................................................................ 5

1.6 Safety signs and symbols........................................................................................................................................... 5

Safety symbols on the device and in the user manual........................................................................................... 5

Symbols on the nameplate .................................................................................................................................... 5

2 Productdescripon 6

2.1 Overview ................................................................................................................................................................... 6

Column Oven (upper and lower part) ................................................................................................................... 6

Regulator................................................................................................................................................................ 6

HV-Switch............................................................................................................................................................... 6

2.2 Scope of delivery ....................................................................................................................................................... 7

Double Barrel Oven DBO-TF-FIS............................................................................................................................. 7

2.3 Available accessories................................................................................................................................................. 7

MounngKitforThermoFisherFlexIonSourceES071......................................................................................... 7

MounngKitforThermoFisherFlexIonSourceES072......................................................................................... 7

Micro-Tee with HV-connector ................................................................................................................................ 7

HV-cable with 2mm connector............................................................................................................................... 7

2.4 Hardware................................................................................................................................................................... 8

InstallaonoftheES071mounngkit................................................................................................................... 8

InstallaonoftheES072mounngkit................................................................................................................... 8

InstallaonoftheHV-switch .................................................................................................................................. 9

Aachingtheoventothesource........................................................................................................................... 9

Connecngthecables............................................................................................................................................ 9

2.5 Soware .................................................................................................................................................................. 10

Installing CO-Control ............................................................................................................................................ 10

3 Usage 10

3.1 ColumnloadingandapplyingtheHVvialiquidjuncon......................................................................................... 10

3.2 Using CO-Control ..................................................................................................................................................... 11

4 Maintenance and Care 12

Maintenance ........................................................................................................................................................ 12

Cleaning ............................................................................................................................................................... 12

5 Final Disposal 12

6 Technicaldata 12

7 FAQ-FrequentlyAskedQuesons 13

Page 4

Column Oven DBO-TF-FIS User manual

1 Safety

1.1 Importantsafetyinstrucons

Pleasereadtheseoperanginstruconscarefullybeforeusingtheproduct.ItcontainsimportantnotesonInstalla-

onandusage.

Theusermanualispartoftheproduct.Keepitinasafeplace.Iftheproductissold,rentedorpassedoninanyother

way,theusermanualmustbeincluded.

Heedallwarnings.Thesepointoutdangersandgiverecommendaonsforaccidentprevenon.

Onlyinstalltheunitinlocaonsexpresslyrecommendedbythemanufacturer.

Ifcondensaonformsaerunpacking,allowatleast2hoursfortheunittoacclimaze.

Thisdevicemayonlybeoperatedatsocketswithprotecveearth.

Makesurethatyoucannottripoverthemainscableandthatthecableisnotdisconnected,ispinched,tornoor

squeezed.

Only use accessories expressly recommended by the manufacturer.

Leaveallmaintenanceworktoanexperiencedservicetechnician.Servicingorrepairsarerequiredifthereisvisible

damage,ifthepowercordorplugisdamaged,ifliquidhasbeenspilledinsidetheapparatus,iftheapparatushas

beenexposedtorain,ifitdoesnotperformasexpected,orifithasfallen.

Onlyuseconneconcablesorextensioncablesthatareapprovedforthemaximumpermissibletotalcurrentor

power.

Operaonofthedeviceinamannernotintendedbythemanufacturermayaecttheproteconprovidedbythe

device.

1.2 Intended use

Theovenisexclusivelydesignedfortheheangandtemperingofseparaoncolumnsinnano-ESIapplicaons.

TheovenisaproductaccordingtotheMachineryDirecve2006/42/EC(completemachine).

The oven must be installed as described in this manual.

Thefanmustbeabletoturnfreeandmaynotbeblocked.

Do not use any adhesive tape or other non-heat-resistant materials inside the oven.

Theovenisconstructedastechnicalworkequipmentandnotintendedforprivateuse.

The device may only be used in clean and dry rooms.

Thelimitvaluesfortemperatureandhumidityduringtransport,storageandoperaonspeciedunder6„Technical

data“ on page 12 must not be exceeded or undercut.

Theovenmustnotbeusedinpotenallyexplosiveatmospheres,especiallyinareasenrichedwithoxygen,combus-

bleanesthecs(classAP)orcombusbleanesthecswithoxidizingagents(classAPG).

Theovenmustbekeptawayfromeasilyinammableandcombusbleliquids.

Ifaliquidshouldpenetratetheelectricalpartoftheovenorregulatoritistobesetimmediatelyoutofoperaonand

mustbecheckedbyaspecialist.

Usetheovenonlywithinthespecicaonsspeciedinthismanual.

Thevalidaccidentguardingregulaonsaccordingtoeachcountrymustbeconsidered.

The device may only be repaired by a specialist.

1.3 Non-intended use

A non-intended use is given when the equipment is treated in any way that is contrary to any of the points from the

chapter1.2„Intendeduse“onpage4.

Iftheovenisnotusedasintended,handledimproperlyandused,assembledorhandledbyuntrainedpersonnel,

hazardsmayariseforpersonnelfromtheoven.

1.4 Examples of foreseeable misuse

Use in environments with high humidity > dew point.

UseinroomswithexplosiveatmospheresaccordingtoATEXdirecve.

User manual Column Oven DBO-TF-FIS

Page 5

Use with damaged supply lines.

Outdoor use.

1.5 Whomayuseandoperatethecolumnoven

Physicallyandmentallyhealthypersonswhohavefullyreadandunderstoodtheinstruconsforusemayuseand

operatethecolumnovenaslongastheyarenotaectedbymedicaonordrugs.

1.6Safety signs and symbols

Safetysymbolsonthedeviceandintheusermanual

The“generalmandatorysign”indicatesthatyoushouldbehaveaenvely.Markedinformaoninthis

usermanualisintendedtodrawyourparcularaenon.Youwillreceiveimportantinformaonon

funcons,sengsandprocedures.Failuretodosomayresultinmalfunconoftheequipmentorits

surroundings.

The“generalwarningsign”indicatesdangerpointsorpossibledangeroussituaons.Markedinfor-

maoninthisusermanualappliestoyourspecialaenon.Youwillreceiveimportantinformaon

onsafety-relevantmaers.Failuretodosomayresultinpersonalinjury,malfunconofthedevice

ortheenvironment.

Thewarningsign“Hotsurface”indicatesapotenallyhotsurface.Non-observancemaycauseburns.

Itisessenalthatyouobservethesafetyinstruconsintheoperanginstrucons.

Thewarningsign“Warningofelectricalvoltage”indicatespotenalhazardsduetoelectricalvolt-

age.Theposionsonthedevicemarkedwiththissymbolandtheinformaonintheseoperang

instruconsareintendedtodrawyourparcularaenon.Youwillreceiveimportantinformaon

onsafety-relevantmaers.Failuretodosomayresultinpersonalinjury,malfunconofthedevice

orthesurroundingarea.

Symbolsonthenameplate

ConformitytolowvoltageandEMCdirecves

Donotdisposeofinhouseholdwaste

Indoor use only

Appliance class I

Page 6

Column Oven DBO-TF-FIS User manual

2 Productdescripon

2.1 Overview

ThedoublebarrelovenDBO-TF-FISallowstheparallelusageoftwoindependantanalycalcolumns.Asloading,equil-

ibraonandwashingstepscanbealternated,theulizaonandthroughputofthemassspectrometercanbesigni-

cantly increased.

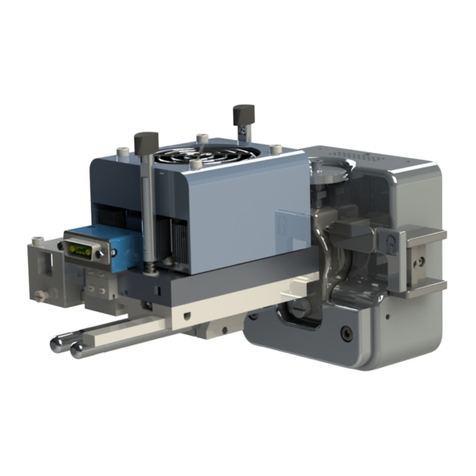

ColumnOven(upperandlowerpart)

❶❶Lockingbars ❷❷Receptacle for oven control cable ❸❸Cross/T-holdersonslidingrails

❹❹Column clamp handles ❺❺Mounngbar ❻❻Lateral sliding rail

Regulator

❶❶“Oven control” connector ❷❷High voltage switch input ❸❸High voltage switch output

❹❹“RS232/Contactclosure”connector ❺❺Power in connector

HV-Switch

❶❶High voltage input from Flex Ion source

❷❷High voltage output to column 1

❸❸High voltage output to column 2

❹❹Mounngplatewithscrewsandsleves

❺❺Controlinput(boomside,notvisibleonillustraon)

❶❶

❷❷

❸❸

❹❹

❺❺

❻❻

Fig. 1: Column oven (top and boom part)

❶❶

❷❷❸❸

❹❹

❺❺

Fig. 2: Regulator - front and back view

❶❶

❷❷

❸❸

❹❹

❺❺

Fig. 3: HV-Switch with screws and sleves

User manual Column Oven DBO-TF-FIS

Page 7

2.2 Scopeofdelivery

DoubleBarrelOvenDBO-TF-FIS

1xColumnoven(topandboompartwith4columnpins)

1 x Regulator

1xHV-switchwith2xM4x40mounngscrewsand2x24mmplascsleeves

1 x HV-cable: Source to HV-switch

1 x Oven control cable: Regulator to oven

1 x HV control cable: Regulator to HV-switch

1 x Data cable for RS232 and contact closure

1 x USB to serial adapter

1x24Vpowersupplywithwiderangeinputandpowercable(withEU,CH,UKorUSplug)

2xCrossholderwithcrossholderlid,2xM4x6screwand1xnylonthumbscrewM4x16each

1xCountersunkheadscrewM5x20withM5lockingnutformounngtheoventothesource

1xUSBashdrivewithsoware

1 x This manual

2.3 Availableaccessories

MounngKitforThermoFisherFlexIonSourceES071

AllowstheoventobemountedonaThermoFisherFlexIonSourceES071.Consistsof:

1 x Acrylic shield

1xModieduppercameraholder

1xDistanceblockforlecameraholder

2xScrewM5x20Allenhead

Ordercode:PRSO-V2-KES71

MounngKitforThermoFisherFlexIonSourceES072

AllowstheoventobemountedonaThermoFisherFlexIonSourceES072.Consistsof:

1 x Acrylic shield

1 x Upper camera holder

1xLecameraholder

1 x Oven holder

1 x Acrylic shield holder

Ordercode:PRSO-V2-KES72

Micro-TeewithHV-connector

MicroT-piecewith3x360µmconnectorsand2mmHVconnectorforsprayvoltagefeed(liquidjuncon).

Order code: PRSO-V2-MT

HV-cablewith2mmconnector

ConneconcablebetweentheHVoutputoftheFlexIonSourcerespecvelytheHVoutputoftheHV

switch and a 2mm plug.

Order code: PRSO-HV-LE-HI

Page 8

Column Oven DBO-TF-FIS User manual

Installaon

2.4 Hardware

Beforeinstallingtheovenmakesurethehighvoltage(sprayvoltage)hasbeenturnedo.

TheovencanbeusedwiththeES071andtheES072versionoftheThermoFisherFlexIonSource.Tobeabletousethe

ovenattherespecvesource,thecorrespondingmounngkitisrequired(see„2.3Availableaccessories“).

InstallaonoftheES071mounngkit

Firsttheoriginalacrylicsafetyshieldhastoberemoved.Aer

removing the two screws on the shield clamp it can be dis-

mounted.

Also the two camera holders have to be dismounted by remov-

ing the corresponding screws. The upper camera holder has

tobereplacedbytheoneintheconversionkit.Pleaseusethe

originalscrewstoxthemodiedcameraholder.

Thedistanceblockhastobemountedbetweenthelecamera

holderandthesource.Toxthelecameraholderpleaseuse

theprovidedM5x20screwsastheoriginalscrewsaretooshort.

Now mount the provided safety shield instead of the original

one. Please see Fig. 4 for reference.

InstallaonoftheES072mounngkit

Removetheshieldclamp,theupperandlecameraholder,theacrylicshield,theXYZ-manipulatorandtheaached

mounngbarbylooseningthescrewsmarkedinFig.5.

Slidethemodiedacrylicshieldfromtheconversionkitontothesource.Youmighthavetobenditcarefullytomake

itslipovertheange.

InstalltheovenholderontotheXYZ-manipulator.

ReinstalltheXYZ-manipulatorontothesourcebypungtheshieldholderbetweenthemanipulatorandthemanipu-

lator holder using the original screws.

Installthemodiedleanduppercameraholdersbyreusingtheoriginalscrews.

Fig. 4: Installaon of the ES071 mounng kit

Lecamera holder

Acrylic shield

Mounng bar

XYZ-Manipulator

Shield clamp

Upper camera holder

Modied le

camera holder Modied acrylic shield

Shield holder

Oven holder

Modied upper

camera holder

Fig. 5: Installaon of the ES072 mounng kit

Fig. 6: Mounng the HV-switch to the source Fig. 7: Aaching the oven to the source

User manual Column Oven DBO-TF-FIS

Page 9

Installaon

2.4 Hardware

Beforeinstallingtheovenmakesurethehighvoltage(sprayvoltage)hasbeenturnedo.

TheovencanbeusedwiththeES071andtheES072versionoftheThermoFisherFlexIonSource.Tobeabletousethe

ovenattherespecvesource,thecorrespondingmounngkitisrequired(see„2.3Availableaccessories“).

InstallaonoftheES071mounngkit

Firsttheoriginalacrylicsafetyshieldhastoberemoved.Aer

removing the two screws on the shield clamp it can be dis-

mounted.

Also the two camera holders have to be dismounted by remov-

ing the corresponding screws. The upper camera holder has

tobereplacedbytheoneintheconversionkit.Pleaseusethe

originalscrewstoxthemodiedcameraholder.

Thedistanceblockhastobemountedbetweenthelecamera

holderandthesource.Toxthelecameraholderpleaseuse

theprovidedM5x20screwsastheoriginalscrewsaretooshort.

Now mount the provided safety shield instead of the original

one. Please see Fig. 4 for reference.

InstallaonoftheES072mounngkit

Removetheshieldclamp,theupperandlecameraholder,theacrylicshield,theXYZ-manipulatorandtheaached

mounngbarbylooseningthescrewsmarkedinFig.5.

Slidethemodiedacrylicshieldfromtheconversionkitontothesource.Youmighthavetobenditcarefullytomake

itslipovertheange.

InstalltheovenholderontotheXYZ-manipulator.

ReinstalltheXYZ-manipulatorontothesourcebypungtheshieldholderbetweenthemanipulatorandthemanipu-

lator holder using the original screws.

Installthemodiedleanduppercameraholdersbyreusingtheoriginalscrews.

Fig. 4: Installaon of the ES071 mounng kit

Lecamera holder

Acrylic shield

Mounng bar

XYZ-Manipulator

Shield clamp

Upper camera holder

Modied le

camera holder Modied acrylic shield

Shield holder

Oven holder

Modied upper

camera holder

Fig. 5: Installaon of the ES072 mounng kit

Fig. 6: Mounng the HV-switch to the source Fig. 7: Aaching the oven to the source

InstallaonoftheHV-switch

TheHVswitchhastobeaachedtothesourceasshownonFig.6.Todoso,rstremovetheoriginalscrewsfromthe

boomofthesource,theninserttheslevesandmounttheHV-switchwiththeprovidedscrews.

Aachingtheoventothesource

PlacethemounngbaroftheovenontotheXYZ-manipulatorandxitwiththeprovidedscrewandnutasshownon

Fig.7.IftheXYZ-manipulatorwon’tstayinplace,thisisduetotheweightoftheoven.Thefriconofthemanipulator

canberegulatedwithadjusngscrews.Sojustincreasethefriconunltheovenstaysinposion.

Connecngthecables

Connect the regulator with the provided data cable to an available com-port on your instrument PC. If there is no

com-portavailable,pleaseusetheprovidedUSBtoserialadapter.

The remaining two open leads of this cable can be connected to the “contact closure out” of your instrument to

switchbetweentwopresettemperatures.Thisisonlyneededifyouwanttoswitchautomacallybetweentwopre-

settemperatures.Switchingcanalsobedonewiththeprovidedovencontrolsoware.

Connect the oven to the controller with the provided oven control cable.

Connect the HV cable from the HV output of your Flex Ion Source to “HV IN” on the HV switch.

MS

Regulator

Power supply

24V/200W

HPLC

PC

HV-switch

Flex Ion

Source

Oven

HV-OUT1

HV-IN

HV-OUT2

To column 1

To column 2

Fig. 8: Wiring scheme

Page10

Column Oven DBO-TF-FIS User manual

Connectthetwohighvoltagecables(2xSonaonP/NPRSO-HV-LE-HI)tothe“COL1OUT”and“COL2OUT”oftheHV

switch. The other ends are connected later to the columns using the micro T-pieces with HV connector. If you use the

Thermoliquidjunconkit(P/NES269)theHVcablesarealreadyinstalledtothealsoincludedcrosspieces.Inthis

caseconnectthemlaterasdiscribedin3.1„ColumnloadingandapplyingtheHVvialiquidjuncon“onpage10.

Connectthecontactclosurecable(ThermoP/N6000.1004)betweentheHPLCandthe“CCHV”inputontheregula-

tor.PleaseseeThermoFishertechnote73671fordetailedinformaon.

Connect the 24-Volt power supply to the power connector on the regulator. Thewidesideoftheplugfacesthetop

ofthecontrolmodule,donotforceitintwisted. The power supply will be connected to a wall outlet later.

2.5 Soware

Installing CO-Control

Toinstalltheovencontrolsoware,executesetup.exeinthedirectoryCOControlontheprovidedUSBashdrive.Fol-

lowthestepsofthesetupwizard.ThesowareneedsaninstalledMicroso.NET.Ifthesowarewon‘tstartandthrows

anerrormessageshowing.NETismissing,installitfromtheprovidedUSBashdrive.

3 Usage

3.1 ColumnloadingandapplyingtheHVvialiquidjuncon

Makesurethatthehighvoltage(sprayvoltage)isswitchedoduringtheinstallaonofthecolumns

andduringanysubsequentpluggingorunpluggingofhighvoltagecables.

Makesurethatyouhaveinstalledthecrossholderlidsbeforeswitchingonthehighvoltage.

Donotuseanyadhesivetapeorothertemperaturesensivematerialsinsidetheoven.

Thepoftheemierisverysensive.Becarefulnottohitanythingwheninserngthecolumns.

Duringoperaonthesurfaceoftheovencangetveryhot!

Opentheovenbyturningthelockingbarsatthefront

andbackoftheoven.Thetoppartcannowberemoved.

Remove the cross holders from the sliding rails by loos-

ening the thumb screws.

Removethescrewsontopofthecrossholdersandtake

othecovers.Usea2.5mmAllenscrewdriver.

Connect the columns to the T-pieces with the high

voltageconnectors(SonaonP/NPRSO-V2-MT)ortothe

crosspiecesincludedintheThermoliquidjunconkit

(P/NES269).Useaconnectornexttothehighvoltage

plug and not the one opposite.

Insert the T- or cross pieces into the provided cross hold-

ers and remount the lids.

Connect the high voltage cables coming from “COL1

OUT”and“COL2OUT”fromtheHVswitchtotheT-pieces.IfyouusetheThermoliquidjunconkit(P/NES269)

connect the plugs of the high voltage cables connected to the cross pieces to “COL1 OUT” and “COL2 OUT” at the HV

switch.

Fig. 9: Column loading

User manual Column Oven DBO-TF-FIS

Page 11

Slidethecrossholdersontotheslidingrailswiththecolumnsfacingtheinletsoftheoven.Inmostcasesitworks

besttousethelateralandoneofthefrontalrails.Whenusingthetwofrontalmounngrails,makesurethatthe

high-voltageconnectorspointoutwards,otherwisethereisnotenoughspacetoconnectthehigh-voltagecables.

Now place the columns inside the oven. Longer columns can be wound around the column pins as needed. Therefor

thecolumnpinscanbeplacedinanyofthedesignatedposions.

Theendofeachcolumnisledoutatoneoutleteachandheldinposionbytheclampingmechanism.Placethe

columnsinawaythatthepsareabout5mmapart.

Now reinstall the top part of the oven and plug in the power cord from the power supply to a wall outlet.

The oven is now ready to use.

3.2 Using CO-Control

Aerstarngthesowareitcomesupwiththemainview(Fig.10).

Onthe“COMPorts”tabchoosetheportthecontrollerisconnectedtoandclick„connect“.Nowyoushouldseethe

currenttemperatureoftheoveninthedisplayintheupperright.Ifnotemperatureisdisplayed,pleaseensurethatthe

toppartoftheovensitsproperontheboompart.Iftheovenisnotproperlyclosed,thetemperaturereadoutwill

show -999°C.

Inthemainviewyoucanadjustthetwotemperaturesetpoints„Temp.normal“and„Temp.high“.Byclicking„Switch

regulatoron“theregulatorstartstoheatorcooltheoventooneofthesesetpoints,dependingonthestateofthe

contactclosureinput.Tovisualizethetemperatureprole,agraphwindowcanbedisplayed.Toshowitup,chose

„Opons>ShowGraph“fromthemainmenu.Inthesengswindowunder„Opons>Sengs“thegraphwindowcan

beshownautomacallyonstartup.

Itispossibletounlockanextendedtemperaturerange.Ifyourapplicaonrequireshigherorlowertemperatures,

pleaseaskSonaonforanoponcode.ButalsokeepinmindthatahighertemperaturerangeisstressforthePel-

er-modulesandcanleadtoashorterlifeme.

Fig. 10: Oven control soware co-control

Page 12

Column Oven DBO-TF-FIS User manual

4 Maintenance and Care

Maintenance

Theproductisbasicallymaintenance-freebutnotwear-free.Ifawear-relateddefectshouldoccur,pleasecontactyour

dealerorSonaondirectlytoclarifythefurthersteps.

Cleaning

Useaso,dampclothtocleanthesurfaces.Aggressivesolvents,basesoracidsmustnotbeusedforcleaning.

5 Final Disposal

Disposetheproductinaccordancewithlocalandnaonalsafetyandenvironmentalregulaons.

Theproductcontainselectroniccomponents,cables,metals,plascs,etc.andhastobedisposedinaccordancewith

applicableenvironmentalregulaonsoftherespecvecountry.ThedisposaloftheproductinGermanyissubjecttothe

Elektro-G(RoHS)andintheEuropeanareaoftheEUDirecve2002/95/ECortherespecvenaonallegislaon.

Theproductcanalsobereturnedtothesellerfordisposal.Inthiscasethecostoftransport,includingthepackaging

costsshallbebornebythebuyer.Pleasenofythesellerofthereturnwithin14daysbeforetheexpectedarrival.

6 Technicaldata

Temperature control range

Standard range:

Extended range:

15°C-60°C(59°F-140°F)

15°C-80°C(59°F-176°F)

Temperature control rate

Heang:

Cooling:

30°Cto50°C:Lessthan90s

50°Cto30°C:Lessthan180s

Control accuracy ±0,1°C

Usable column lengts From130mm

Usable column diameter Up to 2mm

Oven weight 0,9kg

Permissibleambientcondions

Transport

Storage

Operaon

Temperature Humidity

-20-60°C/-4-140°F 5-90%(non-condensing)

10-40°C/50-104°F 10-80%(non-condensing)

10-30°C/50-86°F 20-80%(non-condensing)

Power cable

EU

CH

UK

US

CEE7/4plug(Schukoplug)toIEC60320C13,length:1,8m

T12plug(accordingtoSEV1011:2009)toIEC60320C13,length:1,8m

TypeGplug(BS1363)toIEC60320C13,length:1,8m

NEMA-5plugtoIEC60320C13,length:1,8m

Supply voltage 100-240VAC/50-60Hz

Max power input 200W

Appliance class Class I (earth conductor)

User manual Column Oven DBO-TF-FIS

Page 13

7 FAQ-FrequentlyAskedQuesons

MyPCdoesnothaveanyCOMports/noavailableCOMports.CanIruntheovenanyhow?

Yes.PleaseusetheprovidedUSBtoserialconvertertoinstallavirtualcom-port.

I‘vesuccessfullyconnectedtotheovenbutcansllseenotemperature.Whatiswrong?

Pleaseensurethatyourovenisclosedproperly.Whentheovenisopenorevennotproperlyclosed,thetemperature

sensor cannot be read.

Isitpossibletosetuphighertemperaturesthan60°Corlowertemperaturesthan15°C?

Yes,itispossible.PleaseaskSonaonforanoponcode,butrememberthatthelifemeofthePeler-elementswillbe

loweredbecauseoftheaddionalthermalstress.

Thetemperatureoftheovenuctuates/oscillatessomedegreesaroundthesetpoint.What’swrong?

Themostcommoncauseisthattheupperpartoftheovensitsnotproperlyonthelowerpart,sothethermalconnec-

onisbad.Pleasecheckifthecolumnorotherthingsaretrappedbetweentheupperandlowerpart.

Seite 14

Säulenofen DBO-TF-FIS Originalbetriebsanleitung

Thispageisintenonallyleblank

Originalbetriebsanleitung Säulenofen DBO-TF-FIS

Seite 15

Thispageisintenonallyleblank

Sonation

lab solutions.

lab solutions.

Sonation Tel.:+49(0)735130038-39

E-Mail:mail@sonaon.com

www.sonaon.com

SonaonGmbH

Alte Schulstraße 39

D-88400Biberach

IMPROVEYOURSCIENCE

www.sonaon.com Rev.300029_000_00

07.Dec.2020

Table of contents

Other Sonation Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

RS PRO

RS PRO RS-983 instruction manual

Agilent Technologies

Agilent Technologies 7673 operating manual

BANDELIN

BANDELIN SONOREX TECHNIK W 65 Instructions for use

Thermo Scientific

Thermo Scientific Applied Biosystems VeritiPro quick reference

Sheldon

Sheldon VWR International 2015 Installation and operation manual

Agilent Technologies

Agilent Technologies 1200 Infinity Series user guide