Sourcetronic ST9201 Series User manual

◇2

Content

Chapter 1 Setup ...........................................................................4

1.1 Unpacking.....................................................................................4

1.2 Precautions for Installation..............................................................4

1.3 Precautions for Moving ...................................................................6

1.4Checking power source and fuse ......................................................6

1.5 Connecting the AC Power Cord ........................................................7

1.6 Grounding.....................................................................................7

1.7 Checking Operations ......................................................................8

1.8 Other specifications........................................................................9

Chapter 2 Precautions on Handling............................................10

2.1 Prohibited Operations ................................................................... 10

2.2 Action When in Emergency............................................................ 11

2.3 Precautions on Testing.................................................................. 11

2.4 Beware of Residual High Voltages .................................................. 12

2.5 Dangerous States of Failed Tester .................................................. 12

2.6 Ensuring Long-Term Use without Failures ........................................ 13

2.7 Daily Checking ............................................................................ 13

Chapter 3 Part names and Functions .........................................15

3.1 Front Panel ................................................................................. 15

3.2 Instruction of rear panel ............................................................... 17

3.3 Description ................................................................................. 18

Chapter 4 Basic operation..........................................................25

4.1 Interface structure overview ......................................................... 25

4.2 Instruction of interface function ..................................................... 26

4.2.1 SETUP........................................................................................................................................... 27

4.2.2 TEST (Take AC for example)........................................................................................................ 28

4.2.3 SYSTEM........................................................................................................................................ 28

4.2.4 MEMORY....................................................................................................................................... 31

4.3 Test item interface and parameter setup ......................................... 35

4.3.1 AC withstanding voltage test parameter setup:......................................................................... 35

4.3.2 DC withstanding voltage test parameter setup:......................................................................... 35

4.3.3 Insulation resistance test parameter setup:............................................................................... 36

4.3.4 Open and short detection test parameter setup: ....................................................................... 37

4.3.5 MF multichannel assist control setup (only used in multichannel test instruments).............. 38

◇3

4.4 Test function theory and instruction ............................................... 40

4.4.1 Start up test.................................................................................................................................. 41

4.4.2 Low terminal connection test...................................................................................................... 41

4.4.3 Voltage rise................................................................................................................................... 41

4.4.4 DC charging current detection.................................................................................................... 42

4.4.5 High-voltage test.......................................................................................................................... 42

4.4.6 Voltage fall.................................................................................................................................... 42

4.4.7 Electric wall function.................................................................................................................... 42

4.4.8 Current over limit and arc detection (ARC) function.................................................................. 43

4.4.9 Fail judgment................................................................................................................................ 44

4.4.10 Dealing with test results .............................................................................................................. 44

4.4.11 STOP............................................................................................................................................. 45

4.4.12 OFFSET......................................................................................................................................... 45

4.5 Structure and Use of Interface Circuit............................................. 45

4.5.1 PLC and HANDLER interfaces..................................................................................................... 45

Chapter 5 ST9201 RS232 Commands .........................................49

5.1 Commands for System settings ..................................................... 49

5.2 Commands for AC settings ............................................................ 60

5.3 Commands for DC settings............................................................ 67

5.4 Commands for IR Settings ............................................................ 75

5.5 Commands for OS Settings ........................................................... 80

5.6 Other Commands......................................................................... 82

Chapter 6 ST9201 series specification .......................................88

◇4

Chapter 1 Setup

This chapter describes the procedures from unpacking to installation

to operation checking.

1.1 Unpacking

Upon receiving the product, confirm that the necessary accessories are

included and have not been damaged in transit. Should any damage or

shortage be found, please contact your Sourcetronic distributor/agent.

Items

Quantity

ST9201/S / B/C

1

ST90003R withstanding-voltage test leadwires

1

ST90003B withstanding-voltage ground leadwires

1

3A (220V, 240V) / 5A (100V, 120V) Fuse (ST9201/S)

2

2A (220V, 240V) / 3A (100V, 120V) Fuse (ST9201B/C)

2

ST90004 withstanding-voltage test stick

1

ST26034 RS232C cable

1

AC Power cord

1

Operation Manual CD

1

Test Report

1

Optional accessories ordered by customer

1

1.2 Precautions for Installation

Be sure to observe the following precautions when installing the tester.

Do not use the tester in a flammable atmosphere.

To prevent explosion or fire, do not use the tester near alcohol, thinner, or

other combustible materials, or in an atmosphere containing such vapors.

Avoid locations where the tester is exposed to high

temperatures or direct sunlight.

Do not locate the tester near a heater or in areas subject to drastic

temperature changes.

Operating temperature range: 5 °C to +35 °C

Storage temperature range: -20 °C to +60 °C

Avoid humid environments.

Do not locate the tester in a high-humidity environment—near a boiler,

humidifier, or water supply.

◇5

Operating humidity range: 20% to 80% RH (no dew condensation permitted)

Storage humidity range: 90% RH or less (no dew condensation permitted)

Condensation may occur even within the operating humidity range. In that

case, do not start using the tester until the location is completely dry.

Do not place the tester in a corrosive atmosphere.

Do not install the tester in a corrosive atmosphere or one containing sulfuric

acid mist or the like. This may cause corrosion of various conductors and

imperfect contact with connectors, leading to malfunction and failure, or in

the worst case, a fire.

Do not locate the tester in a dusty environment.

Dirt and dust in the tester may cause electrical shock or fire.

Do not use the tester where ventilation is poor.

This tester features a forced-air cooling system. Provide sufficient space for

the air inlet on the lateral side and the air outlet on the rear side to allow air

to flow.

Do not place the tester on a tilted surface or in a location

subject to vibrations.

If placed on a non-level surface or in a location subject to vibration, the tester

may fall, resulting in damage and injury.

Do not use the tester in locations affected by strong

magnetic or electric fields.

Operation in a location subject to magnetic or electric fields may cause the

tester to malfunction, resulting in electrical shock or fire.

Do not use the tester in locations near a sensitive

measuring instrument or receiver.

Operation in a location subject, may cause such equipment may be affected

by noise generated by the tester.

At a test voltage exceeding 3 kV, corona discharge may be generated to

produce substantial amounts of RF broadband emissions between grips on the

test leadwire. To minimize this effect, secure a sufficient distance between

alligator clips. In addition, keep the alligator clips and test leadwire away from

the surfaces of conductors (particularly sharp metal ends).

◇6

1.3 Precautions for Moving

When moving the tester to the installation site or otherwise transporting it,

take the following precautions:

Before moving the tester, turn off the power switch.

Transporting the tester with its POWER switch on can lead to electric shock

and damage.

When moving the tester, Disconnect all wires from it.

Moving the tester without disconnecting the cables may result in breakage

of the wire or injury due to the tester tipping over.

1.4 Checking power source and fuse

Toggle power line voltage

!

WARNING: This instrument is designed to operate from the overvoltage

category II. Do not operate it from the overvoltage category III or IV.

Before turning on the power, make sure of the fuse and the source voltage

agree with the LINE-VOLTAGE RANGE switch on the rear panel.

Nominal voltage range (allowable voltage range):

100V: AC (90V to110V AC)

120V: AC (108V to 132V AC)

220V: AC (198V to 242V AC)

240V: AC (216V to 260V AC)

Allowable frequency range: 47 Hz to 63 Hz

!

WARNING To prevent malfunctions, be sure to operate within the line-

voltage range.

Checking or replacing fuse

!

WARNING To prevent electric shock, before checking or replacing the

fuse, be sure to turn off the POWER switch and unplug the AC power cord.

Make sure that the fuse used conforms to the instrument specifications,

including shape, rating, and characteristics. Using a fuse with different

rating or short-circuiting, the fuse holder will damage the instrument.

1. Turn off the POWER switch, and unplug the AC power cord.

◇7

2. On the rear panel, remove the fuse holder, by pushing it inward and

unscrewing it counterclockwise using a screwdriver.

3. In accordance with the fuse rating specified below, check the fuse type and

replace the fuse.

4. Following the above steps in the reverse order, reinstall the fuse holder.

Voltage range

Frequency

Fuse type

Power

100V, 120V

47-63Hz

5A(ST9201/S)

500VA

3A(ST9201B/C)

350VA

220V, 240V

3A(ST9201/S)

500VA

2A(ST9201B/C)

350VA

1.5 Connecting the AC Power Cord

The power cord that is provided varies depending on the destination for the

product at the factory-shipment.

Do not use the AC power cord provided with the product as an AC

power cord for other instruments.

Connection procedure:

1. Confirm that the supply voltage is within the line voltage range of the tester.

2. Confirm that the line power are correctly selcected.

3. Confirm that the POWER switch on the tester is off.

4. Connect the AC power cord to the AC LINE connector on the rear panel.

5. Use the provided power code or power code that is selected by qualified

personnel.

6. Plug in the AC power cord.

1.6 Grounding

!

WARNING Be sure to connect the tester to an electrical ground (safety

ground). If the output to a conveyer or peripheral device that is connected to

an earth ground or a nearby commercial power line is short-circuited without

grounding, the tester chassis is charged to an excessively high voltage,

resulting in extreme danger.

This tester is designed as a Class I equipment (equipment protected against

electric shock with protective grounding in addition to basic insulation).

Therefore, electric shock may occur without proper grounding.

To ensure safety, be sure to ground the tester.

◇8

Choose either of the following two available methods of doing so:

1. Connect the AC power cord to a three-contact grounded

electrical outlet.

2. Connect the protective conductor terminal on the rear panel to

the earth ground. Have specialized engineers select,

manufacture, and install cables.To ensure secure connection,

use proper tools.

1.7 Checking Operations

!

WARNING Use only the interlock jumper to quickly cancel the protection

status.

When using this tester, use the interlock function as much as possible to

ensure a safe operating environment. To use jigs in withstanding voltage or

insulation resistance testing, provide a cover or other means for the DUT to

prevent electric shock by cutting off the output when the cover is opened. It

is also recommended that an enclosure be provided around the operating

area and that output be cut off every time the door is opened.

Before turning on the power, confirm that the allowable voltage range

indicated on the power supply is the same as that indicated on the rear

panel of the tester.

When the power is turned on, the tester lights all LEDs on the front panel

and self-diagnosis is started.

Before starting up the tester, confirm that all LEDs are on to ensure safety.

It is particularly dangerous to start a test when the DANGER lamp is broken.

Note that, in self-diagnosis, even when the DANGER lamp is lighting, no

output or voltage is being generated.

!

CAUTION After turning off the POWER switch, wait several seconds

before turning it back on. Turning the POWER switch on/off repeatedly with

insufficient intervals may damage the tester.

Earth

Ground

Ground

ground

◇9

Checking procedure:

1. Confirm that the supply voltage is the same as that indicated on the rear

panel.

2. Confirm that the power socket or the shell of the instrument has reliable

grounding.

3. Confirm that the AC power cord is properly connected to the AC LINE

connector on the rear panel.

4. Plug in the AC power cord.

5. Turn on the POWER switch. Confirm that all LEDs on the front panel are

lit and the opening screen is displayed.

6. Following the opening screen, display the ACW screen and confirm that

the tester is kept in the READY status

7. Turn off the POWER switch.

1.8 Other specifications

1. Power: ≤500VA (ST9201/S)

≤350VA (ST9201B/C)

2.Dimensions: 340mm*120mm*450mm

3.Weight: 15kg(ST9201/S)

13kg (ST9201B/C)

◇10

Chapter 2 Precautions on Handling

This chapter describes the precautions to be followed in the handling of this

tester.

When using the tester, take utmost care to ensure safety.

!

WARNING The tester derivers a 5 kV test voltage which can cause human

injury or death. When operating the tester, be extremely careful and observe the

cautions, warnings, and other instructions given in this chapter.

2.1 Prohibited Operations

Do not turn on/off the power repeatedly

After turning OFF the power switch, be sure to allow several seconds or more before

turning it ON again. Do not repeat turning ON/OFF the power switch rapidly. If you

do this, the protectors of the tester may not be able to render their protective

functions properly. Do not turn OFF the power switch when the tester is delivering

its test voltage–you may do this only in case of emergency.

Do not short the output to the earth ground

Pay attention so that the high test voltage line is not shorted to a nearby AC line

or nearby devices (such as conveyors) which are connected to an earth ground. If

it is shorted, the tester chassis can be charged up to a hazardous high voltage. Be

sure to connect the protective grounding terminal of the tester to an earth line. If

this has been securely done, even when the HIGH VOLTAGE terminal is shorted to

the LOW terminal, the tester will not be damaged and its chassis will not be charged

up to the high voltage.

Be sure to use a dedicated tool when grounding the protective grounding terminal.

!

CAUTION The term "AC line" here means the line on which the tester is

operating. That is the line to whose outlet the AC power cable of the tester is

connected. It may be of a commercial AC power line or of a private-generator AC

power line.

Do not apply an External Voltage

Do not apply a voltage from any external device to the output terminals of the

tester.

The voltmeter on the front panel cannot be used as stand-alone voltmeter.

They may be damaged if their output terminals are subject to an external voltage.

◇11

2.2 Action When in Emergency

In case of an emergency (such as electric shock hazard or burning of DUT), take

the following actions. You may do either (1) or (2) first. But be sure to do both.

1. Turn OFF the power switch of the tester.

2. Disconnect the AC power cord of the tester from the AC line receptacle.

2.3 Precautions on Testing

Wearing Insulation Gloves

When handling the tester, be sure to wear electrical insulation gloves in order to

protect yourself against high voltages.

Precautions for Pausing Tests

When changing test conditions, press the STOP switch once to take precautions. If

you are not going to resume the test soon or if you are leaving the Test area, be

sure to turn OFF the POWER switch.

Items Charged Up to Dangerous High Voltages

When in test, the DUT, test leadwires, probes, and output terminals and their

vicinities can be charged up to dangerous high voltages. Never touch them when

in test.

!

WARNING The vinyl sheaths of the alligator clips of the test leadwires which

are supplied accompanying the tester have no sufficient insulation for the high

test voltages. Never touch them when in test.

Matters to be Sure of After Turning-OFF Power

If you have to touch the DUT, test leadwires, probes, and/or output terminals and

their vicinities for re-connections or other reasons, be sure of the following two

matters.

1. The analog voltmeter indicates “zero.”

2. The DANGER lamp has gone out.

Warnings for Remote Control

Be extremely careful when operating the tester in the remote control mode in which

the dangerous high test voltage is ON/OFF-controlled remotely. Provide protective

means as follows:

1. Provide means to assure that the test setup does not become the test voltage is

being delivered by inadvertent operation.

2. Provide means to assure that none can touch the DUT, test leadwires, probes,

output terminals and their vicinities when the test voltage is being delivered.

◇12

2.4 Beware of Residual High Voltages

!

WARNING In DC withstanding voltage testing and insulation resistance testing,

the test lead wire, test probe, and DUT are charged to a high voltage. The tester is

equipped with a discharge circuit, but some time is nonetheless required to

discharge them after the output is cut off. There is a danger of electric shock during

discharge. To avoid electric shock, take the utmost care to ensure that the DUT,

test lead wire, probe, and highly charged parts around the output terminal are not

touched. If it is necessary to touch them, be sure to confirm both (1) and (2):

(1) The analog voltmeter indicates “zero.”

(2) The DANGER lamp has gone out.

As soon as the output is cut off, the tester’s discharge circuit starts forced

discharging. Do not disconnect the DUT during a test or prior to completion of

discharging.

Discharge time

The length of the discharge time varies according to the properties of the DUT.

Discharge is conducted at a resistance of approximately 2kΩin DC withstanding

voltage testing, and at 10kΩin insulation resistance testing.

When no DUT is connected, the tester itself requires the following lengths of time

to reduce the internal capacitor voltage to 30V.

If the DUT is disconnected during a test or before the completion of discharging,

assuming that the DUT has a capacity of 0.01µF and a parallel resistance of 100MΩ,

approximately 5.3 seconds at 5kV and approximately 3.5 seconds at 1kV are

required for the DUT to discharge to 30V.

When the approximate time constant of the DUT is known, the time required for

discharging to 30V after the output is cut off is calculated as the time constant

times the value given above.

2.5 Dangerous States of Failed Tester

Typical possible dangerous states of the tester are as shown below and in which

cases the most dangerous situation that “the high test voltage remains

delivered and won't be turned off!” may occur. When this situation has occurred,

immediately turn OFF the power switch and disconnect the AC power cable from

the AC line receptacle.

•The DANGER lamp does not go out despite you have pressed the STOP

switch.

•The DANGER lamp does not light up despite the pointer of the analog

voltmeter is deflected indicating that the output voltage is being delivered.

◇13

Also when the tester is in other malfunctioning states than the above, there is a

possibility that the output voltage is delivered irrespective of your proper operating

procedure. Never use the tester when it has failed.

!

WARNING Keep the tester away from other people until you call our service

engineer for help.

Immediately call your Sourcetronic agent. It is hazardous for an unqualified person

to attempt to troubleshoot any tester problem.

2.6 Ensuring Long-Term Use without Failures

The withstanding voltage-generating block of the tester is designed to release half

the rated amount of heat, in consideration of the size, weight, cost, and other

factors of the tester. The tester must therefore be used within the ranges

specified below. If you deviate from these ranges, the output block may be

heated to excess, activating the internal protection circuit. Should this happen,

wait until the temperature returns to the normal level.

Output requirements for withstanding voltage testing

Ambient

temperature

Upper current

Pause Time

Output time

T≤40°C

AC

>20mA

(ST9201/S)

>12mA

(ST9201B/C)

At least as long as

the output time

Maximum of 1

minute

<10mA

(ST9201/S)

<6mA

(ST9201B/C)

Not necessary

Continuous

output

possible

DC

>6mA(ST9201/S)

>3m (ST9201B/C)

At least as long as

the output time

Maximum of 1

minute

<5mA (ST9201/B)

<2mA(ST9201B/C)

At least as long as

the judgment wait

time (WAIT TIME)

Continuous

output

possible

(Output time = voltage rise time + test time + voltage fall time)

2.7 Daily Checking

To avoid accidents, confirm at least the following before starting operation:

1. The input source complies with the standard and the tester power configuration

is correct.

2. The tester is connected to an earth ground.

◇14

3. The coating of the high-voltage test lead wire is free from cracks, fissures, and

breakage.

4. The low-voltage test lead wire is not broken.

5. The tester generates FAIL signal when the ends of the low-voltage test lead wire

and high-voltage test lead wire are short-circuited.

◇15

Chapter 3 Part names and

Functions

This chapter describes the names and functions of components such as switches,

displays, and connectors on the front and rear panels.

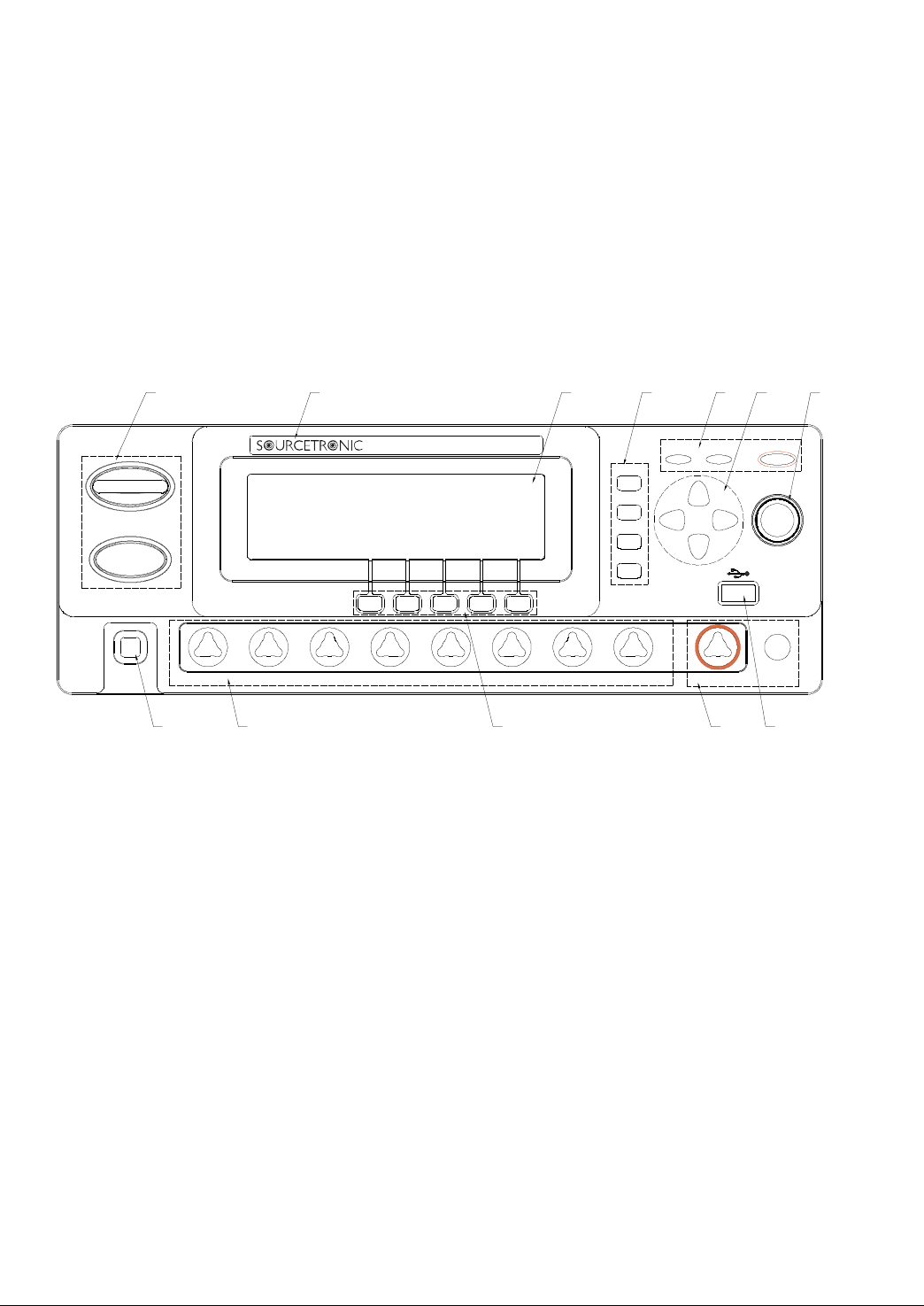

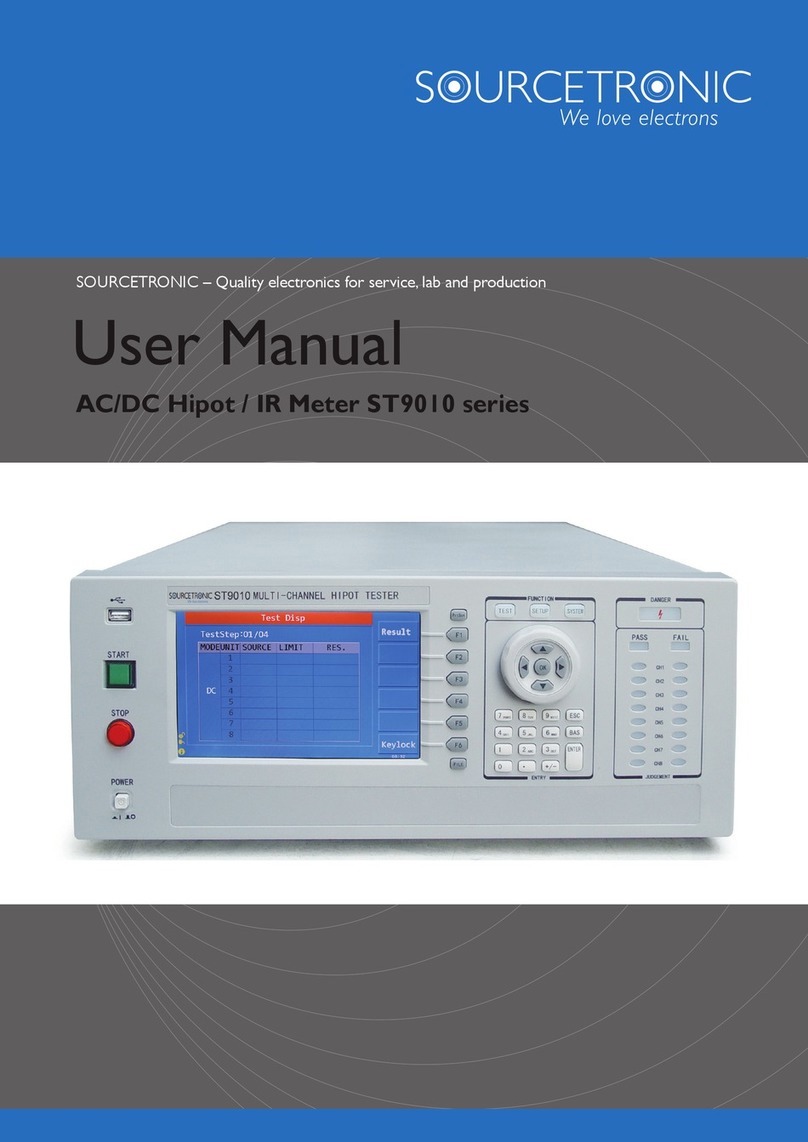

3.1 Front Panel

Figure 3-1

1. START and STOP

START : Start up the instrument, once test starts, “TEST” will be displayed at the

top right corner of the screen, DANGER indicator lights.

STOP : Stop key, used to cancel the test, or PASS,FAIL status.

2. Brand and model

3. LCD screen

240×64 dot matrix LCD screen, display setting and test interface .etc.

4. FUNCTION

Select mode, system, interface..

● TEST

Press the key, and the corresponding key lights, the instrument is ready to test.

● SETUP

Press the key, and the corresponding key lights, the instrument enters

parameter setting;

POWER

TEST

SETUP

SYSTEM

MEMORY

CH1 CH2 CH3 CH4 CH5 CH7CH6 CH8 OUTPUT RTN/LOW

PASS FAIL

ENTRY

AC/DC/IR/SC DANGER

ST9201S HIPOT TESTER

START

STOP

41 2 3 5 6 7

12 11 10 9 8

◇16

● SYSTEM

Press the key, and the corresponding key lights, display SYSTEM1 setting

interface;

It can be switched to SYSTEM2, SYSTEM3 and INTERFACE.

● MEMORY

Press the key in the SETUP page, and the corresponding key lights, the SAVE

window is used to save the currently edited test programm; while the LOAD

window is used to retrieve saved data, you can set the selected data as the default

scheme.

5. Indicator

● DANGER

In the process of testing, it lights in output voltage.

● PASS

Indicate a test result, it lights in PASS;

When the time function is off (TIME OFF), no PASS judge.

● FAIL

Indicate a test result, it lights in FAIL.

6. Direction key

Move direction key to the required setting test condition.

Press SHIFT and to change LCD display contrast.

7. Code switch

When in SETUP status, set the test condition on LCD.

8. USB interface

Externally connect to USB storage

9. Output voltage HIGH and RTN/LOW terminal

High and low voltage/return terminal in test voltage output.

!

Warning: In the process of testing, don’t touch the high terminal!

Caution: If external voltage is used in test terminal, it will cause damage to

internal circuit.

10. Shortcut key (F1-F5)

Corresponding with the function operation or shortcut key on LCD.

11. 8-channel sweep interface (only for ST9201S/SX)

Internal 8-channel sweep output interface.

12. POWER

◇17

3.2 Instruction of rear panel

WARNING:FOR CONTINUED PROTECTION AGAINST FIRE

HAZARD,REPLACE ONLY WITH THE SAME TYPE AND RATING OF FUSE

AS SPECIFIED FOR THE LINE VOLTAGE BEING UTILIZED.

CAUTION:NO OPERATOR SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALITIFIED PERSONNEL.

90V-110V~

108V-132V~

198V-242V~

216V-250V~

5AT

250V

2.5AT

250V

HIGH VOLTAGE

MAX:5kV AC 30mA/6kV DC 10mA

HV OUTPUT RTN/

LOW

100V/120V/220V/240V~

50/60Hz 500W MAX

GPIB

CONT.

CHECK

OPTION

1Ω CAL

VOLTAGE SELECTOR

POLLUTION DEGREE 2

INSTALLATION CATEGORY Ⅱ

贴标签

!

!

OUTPUT

FAIL

START

RESET

COM

INTER

LOCK

UNDER

TEST

PASS

15

9

UNDER RESET

TEST START

PASS FAIL

6

SCANNER

RS-232C

1 2 3 4 5 6 7 8

91011121314

Figure 3-2

1. Fan

Power amplifier circuit radiator.

2. Line voltage range

Switch of input voltage range.

3. PLC controller interface

Used to connect programming controller, where:

INTERLOCK: input the connecting locked signal, if off, starting output is not

allowed.

TEST: Output synchronized-signal control when high voltage output is

started.

START: Input the starting signal for outputting high voltage, corresponding

to the START button on the front panel.

RESET: Input the reset signal for stopping output of high voltage,

corresponding to the STOP button on the front panel.

PASS: Indicate the test result, corresponding to PASS indication on the

front panel.

FAIL: Indicate the test result, corresponding to FAIL indication on the

front panel.

4. OUTPUT

TEST output control, output 24V level or potential-free relay switch signal; it is

suggested to use the switch signal to assure signal separation.

5. HANDLER interface

Use 9 core model D jack to output.

6. Ground break-over test interface

When open ground break-over test function, the terminal has to be connected to

◇18

the place where DUT is connected with low terminal.

7. SCAN interface

Be used to connect ST9121 multi-channel tester. SBOX control program is needed

to be customized.

8. Backup interface

1. IEEE488 (GPIB) parallel communication interface. (Option)

2. ST10203 control interface (Option): it includes all functions of HANDLER

interface. In addition, 24V/1A DC power supply is addeded to connect the small

power-driven circuit, such as indicator light.

9. Protective earth terminal

Be used to connect instrument to ground.

10. RS232C serial interface

Serial communication, realize the communication with computer.

11. Power jack

Be used to input AC power; please use the attached power line with fuse. Change

the fuse according to input power.

12. Ground break-over calibration

Ground break-over resistance is 1 ohm, use potentiometer to calibrate if there is

deviation.

13. Mark

This mark describes the instrument’s SN.

14. High voltage output interface (optional)

Stand-by high voltage output interface.

3.3 Description

ST9201 Provide 5kVAC/30mA withstanding voltage, 6kVDC/10mA withstanding

voltage and insulation resistance tester.

ST9201S Provide 5kVAC/30mA withstanding voltage, 6kVDC/10mA withstanding

voltage and insulation resistance with scanning test.

ST9201B Provide 5kVAC/20mA withstanding voltage, 6kVDC/5mA withstanding

voltage and insulation resistance test.

ST9201C Provide 5kVAC/20mA withstanding voltage test.

In high voltage modular, there is an AB power amplifier power which can assure

the programming of output voltage as well as the isolation of output voltage power

and line power. 40~600Hz high voltage transformer can rise voltage, and use high

voltage feedback loop to assure the accuracy of output voltage, then the actual

voltage adjustment rate is far smaller than that of transformer, which can be used

to the product whose VA is larger than the actual power.

In AC output, set the operation in 50 or 60Hz, not being limited by line voltage,

◇19

the voltage waveform isn’t affected by line voltage neither. The instrument also has

the real current test, and then the large current generated by distributed

capacitance can’t affect the judgment of real insulation.

For DC and insulation resistance test, ST9201/S/B testers use 600Hz AC to

form the DC voltage to power the test, which can assure the DC power ripple is

far less than the norm for withstanding voltage testers, thus to assure the stability

of 5000V, 10mA test.

Once connecting the load, ST9201 can not only perform independent AC

withstanding test, DC withstanding voltage test, and insulation resistance test, but

also multi–item test via the setting of test programs. When connecting with high

voltage scanner ST9121, perform multi-items and multi-products test via setting

the individual steps of the test program. Each scanner can adopt 8 channels. The

tester can be connected to two scanners, reaching up to 16 channels in total.

ST9201 series all allocate PLC interface, RS-232C, GPIB (optional), thus the

instrument can adapt to the auto test system of different required safety and

reliability.

Features:

4 test functions—AC withstanding voltage test, DC withstanding

voltage test, insulation resistance test and open & short detection.

ST9201/S/B(X) provides AC withstanding voltage test and insulation resistance

test. ST9201C(X) provides AC withstanding voltage test only.

Once connected with load, the tester can perform different tests continually.

AC withstanding voltage test 5kV/30mA (ST9201/S) or 5kV/20mA

(ST9201B/C)

In ST9201/S high voltage modular, there is an AB power amplifier circuit and a

150VA transformer, which can realize the Max. output of 5kV/30mA (1 min),

while ST9201B/C power amplifier circuit and a 100VA transformer can realize

the Max. output of 5kV/20mA (1 min).

ST9201/S has the highest limit current 30mA, Min. voltage 50V, so instrument

generates the test voltage corresponding with 50Hz/60Hz, independent power,

auto voltage adjusting rate is smaller than ±3%. It’s not necessary to adjust

output voltage after setting test voltage.

◇20

Figure 3-3 AC voltage load adjusting rate

DC withstanding voltage test 5kV/10mA(ST9201/S)

5kV/5mA(ST9201B/C)

ST9201 series can provide DC withstanding voltage test of wide voltage range

(Max. output voltage is 6kV). Instrument allocates a reliable, low ripple

DC/AC switch circuit, voltage load adjusting rate≤1%+10V. When the

voltage is between 50-500V, low load impedance may cause unstable output

voltage, set the hardware automatic voltage regulation function as OFF and

the voltage regulation factor is 10%.

Figure 3-4 DC voltage output range

This manual suits for next models

3

Table of contents

Other Sourcetronic Test Equipment manuals

Sourcetronic

Sourcetronic MD-5060 Series User manual

Sourcetronic

Sourcetronic ST2826 User manual

Sourcetronic

Sourcetronic ST2523 User manual

Sourcetronic

Sourcetronic ST9110/A User manual

Sourcetronic

Sourcetronic ST2883-5 User manual

Sourcetronic

Sourcetronic TM-25R User manual

Sourcetronic

Sourcetronic MD-5075 Series User manual

Sourcetronic

Sourcetronic ST2883 Series User manual

Sourcetronic

Sourcetronic ST9010 Series User manual